Turbo deflector for ventilation: operating principle and comparison of types of rotary deflectors

Excessive humidity and odors create an unhealthy atmosphere and even cause diseases.The quality of ventilation in a home, office or workplace directly affects the level of comfort, do you agree with this?

That is why properly arranged ventilation is the most important condition when putting construction projects into operation. A turbo deflector for ventilation helps to establish high-quality air exchange. But which one to choose and install correctly so as not to call specialists?

We will try to answer all questions in detail - this material discusses the operating principle, existing types of turbo deflectors, and installation features. Attention is also paid to maintenance and repair issues.

For a better understanding of the information presented, visual photographs and diagrams of the design of rotary deflectors have been selected, and video recommendations for troubleshooting breakdowns have been provided. The information is structured and even an inexperienced home craftsman will find it easy to understand the intricacies of choosing, installing and repairing a rotary deflector.

The content of the article:

Operating principle and design

The operation of the turbo deflector is based on the following principles: using wind energy, the device creates a vacuum of air in the ventilation shaft, increases draft and draws polluted air from the room, ventilation duct, and under-roof space.

No matter how the direction and strength of the wind changes, the rotating head (impeller) always rotates in one direction and creates a partial vacuum in the ventilation shaft.

Which increases the intensity air movement in the pipe, eliminates the appearance reverse thrust and improves overall air exchange.

In addition, the device prevents precipitation from entering the ventilation duct.

The upper part, the turbine head, rotates due to the force of the wind, creating a vacuum inside the ventilation shaft.

The lower part is attached to the channel itself. For this purpose, holes for self-tapping screws are provided in its base.

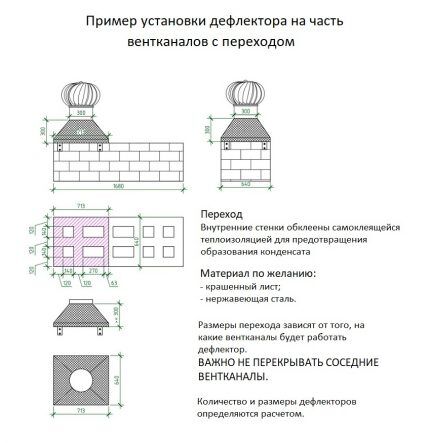

The rotary deflector can have round, square or flat square bases.

At the buyer's request, it is equipped with roofing passages designed for a slope angle from 15 to 35°.

Advantages and disadvantages of a turbo deflector

The following arguments can be made in favor of using a turbine:

- Fast air exchange. The rotating turbine head promotes rapid air exchange in the ventilation shaft, prevents the formation of reverse draft, and protects the roof space from the accumulation of condensate. The operating efficiency of the rotary device is much higher than that of a conventional deflector.

- Does not consume electrical energy, unlike electric fans, it works thanks to the power of the wind.This puts the turbo deflector among the most cost-effective devices.

- Average service life with regular maintenance and proper installation - about 100 thousand hours or 10 years, stainless steel models can last up to 15 years. This is three times longer than the operating time of the fans.

- Rain protection. Prevents snow, hail, and rain from entering the ventilation ducts. Can be used in regions with strong and frequent winds.

- Compact and lightweight design. Devices with a base diameter greater than 200 mm weigh significantly less than the TsAGI deflector. The largest model (680 mm) weighs only about 9 kg; in contrast, the TsAGI deflector with the same base diameter can weigh about 50 kg.

- Easy installation does not require special knowledge and skills.

There are undoubtedly many advantages of a turbo deflector for ventilation, but there are also disadvantages.

The following facts speak against its use:

- The device is quite expensive compared to conventional deflectors.

- Unfavorable atmospheric conditions such as lack of wind, high humidity and freezing temperatures can lead to a complete stop. It should be noted that moving turbines are subject to icing to a much lesser extent.

- The deflector cannot be used as the main means for removing contaminated air in rooms with increased ventilation requirements: in medical laboratories and in industries where work involves chemical and explosive substances.

The price of a rotary deflector is quite high compared to static devices; it depends on the material used for manufacturing - stainless steel, polymer-coated steel, galvanized steel.

But the efficiency of work pays off all costs.

Types of rotary deflectors

To improve the action apartment ventilation system or private house Many modifications of deflectors have been developed. Some are static, others are rotational.

The latter include turbines with a rotating impeller head, which operates thanks to the power of the wind.

Rotary turbines can be classified according to the following characteristics:

- material of manufacture — produce products from stainless steel, galvanized or painted metal;

- connecting ring diameter (nozzles) - it can range from 110 to 680 mm, the dimensions correspond to the typical sizes of sewer pipes.

Manufacturers produce models of turbo deflectors that are very similar in appearance to each other. But their characteristics may differ slightly.

Here is brief information about some of them:

- Turbovent. The company of the same name produces rotary ventilation turbines made of aluminum, the thickness of which is 0.5-1.0 mm. The base is made of galvanized steel 0.7-0.9 mm. The product can be painted in any color according to the generally accepted color standard - RAL.

- Turbomax. The manufacturer markets its product calling it a natural draft supercharger. For production, AISI 321 steel with a thickness of 0.5 mm is used. The product can be used for both ventilation and smoke ducts; it can withstand temperatures up to +250 °C.

These are high quality stainless steel products. Suitable for improving draft in ventilation systems and chimneys. Used at temperatures up to 500 °C.

There are also products from lesser-known brands and manufacturers on the market. When purchasing such products, you should be careful when requesting a quality certificate.

Application area of the device

The rotary turbine has proven itself well in rooms and facilities where increased air exchange is required.

It is used:

- In residential private and apartment buildings. It must be remembered that special requirements are imposed on the operation of ventilation shafts in multi-storey residential buildings. The device helps to cope with the problem of insufficient ventilation of rooms and attic space, and completely eliminates the phenomenon of reverse draft.

- On livestock farms and agricultural buildings - in stables, poultry houses, granaries, haylofts, etc. Helps remove gases and fumes that form during the keeping of animals, maintains optimal humidity.

- At processing plants. A non-volatile ventilation system allows you to save money on energy resources. The exception is facilities whose activities involve substances hazardous to human health.

- In public places — sports complexes, swimming pools, shopping centers and cinemas.

In addition to rooms, the turbine is used to ventilate the under-roof space.

How to calculate the need for devices?

For ventilation of small spaces (rooms, garages, basements) a turbine with a base diameter of 110-160 mm is used. Devices with sizes from 200 to 600 mm are suitable for rooms up to 40 m2 with up to four people permanently staying in them.

Large diameters, 400 to 680 mm, are used to ensure air exchange in large premises, apartment buildings, warehouses, and livestock farms.

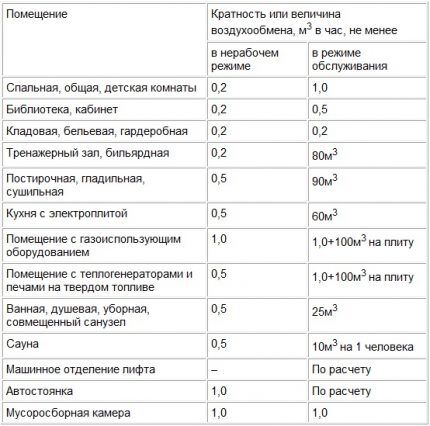

You can accurately calculate the number of deflectors required for installation using the formula:

Ventilated volume = air exchange rate per hour X volume of the room.

Number of ventilation deflectors = ventilated volume/deflector capacity.

For example: The room is 12 m wide, 20 m long and 3.5 m high. The average wind force is 3.5 m/s. The air exchange of the room should take place in 3 cycles per hour. Calculations are carried out as follows:

- Ventilated volume = (20x15x3.5) x 3 (number of air exchange cycles) = 3150 m3/hour$

- 3168/800 (deflector performance) = 3.94, that is, 4 pcs.

Based on the calculations, to ventilate the room it is necessary to install 4 deflectors of the corresponding model.

Installation turbo deflector on boiler chimneys, operating on gas or liquid fuel, is possible, provided that the outlet temperature does not exceed the maximum temperature declared by the manufacturer.

It can be from 100 to 500 °C. At higher temperatures than allowed, it is necessary to use special high-temperature nozzles.

You may also be interested in information about installing a deflector on a chimney yourself, reviewed here.

Turbine installation rules

Ventilation turbines can be installed directly on a pitched or straight roof, at the outlet of a chimney or ventilation shaft. The placement location depends on the application of the turbine.

For ventilation of the under-roof space a turbine with a base diameter of 315 mm is used. It can serve 50-80 m2 roofing - the exact area depends on the slope of the roofing - the smaller the angle, the greater the number of turbo deflectors that need to be installed.

For installation on a pitched structure, select the highest point on the slope. Upon improvement ventilation systems residential premises are installed at the exit of the ventilation shaft.

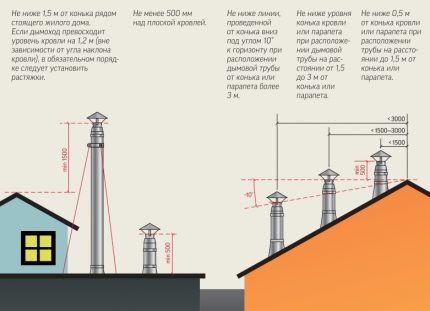

When installing a rotary turbine on a chimney pipe, the calculation of its height is carried out together with the device. That is, the turbo deflector, as part of the chimney, increases its length.

The rules for placing the chimney relative to the ridge remain the same as when installing a pipe without any nozzles:

- If the distance from the ridge to the pipe is less than or equal to 1.5 m, then the pipe is raised 0.5 m above the ridge.

- The height of the pipe, placed at a distance of 1.5 to 3 m, can be equal to the height of the ridge.

- When the distance is more than 3 m from the ridge, the top of the pipe should be no lower than the level of a conventional line drawn down 10° from the height of the ridge.

To reduce heat loss in winter through the ventilation system, the manufacturer allows the use of dampers (for residential premises) or adjustable air intake devices (for warehouse and production areas).

Maintenance and troubleshooting

Almost the only malfunction of the device is the lack of rotation of the impeller.

There may be several reasons for this:

- Insufficient wind force or no wind at all. You need to make sure there is enough wind for the device to work properly.

- The bearings are jammed. In this case, check whether there are any mechanical obstacles to their rotation. If necessary, lubricate or replace the bearing.

- The deflector has frozen. You need to check the device or wait for the temperature to rise.

- Mechanical damage. It is necessary to check whether a foreign object has entered the device.

The turbo deflector used for ventilation is a fairly simple device and does not require frequent maintenance.

To extend service time ventilation deflector It is enough to lubricate the bearings once a year (after winter).For processing, litol is used, a waterproof lubricant based on recycled petroleum products.

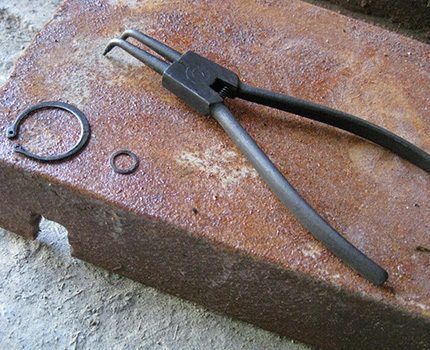

To lubricate or replace a failed bearing, disconnect the cap, open the retaining ring with a special tool - a puller - and lubricate or replace the bearing.

You may also find information about how to properly clean the ventilation shaft, discussed in our other article.

Conclusions and useful video on the topic

What is a rotary deflector for ventilation:

What to choose for ventilation - a turbo deflector or a TsAGI deflector:

How to repair a turbo deflector yourself:

The best solution to a problem is always simple. There is no longer a need to install electric fans to improve draft in ventilation ducts. The appearance of turbo deflectors on the market has deprived consumers of many problems.

Have you equipped your home ventilation ducts with turbo deflectors? Or perhaps you assembled the rotational deflector yourself and secured it with your own hands? Tell us how difficult the manufacturing process turned out to be and how the device performed in action.

Or did you notice any inaccuracies in the material presented above? Please write to us about this in the comments below the article.

I live in a private house in Krasnogorsk. I came across the fact that the hood in the kitchen does not work at all, although ventilation was initially installed during the construction of the house. Because of this, the kitchen was always humid and stuffy when cooking, and there was a smell of cooking food that emanated throughout the house.At first I thought that the builders had clogged the ventilation duct, I tried to clean it, but it turned out to be pointless, it was not clogged, the problem was precisely the lack of draft, the reasons are not clear... I decided to install a turbine deflector on the roof. Installed it myself. The turbine is attached directly to the ventilation pipe using ordinary self-tapping screws. The deflector almost always spins, even in light winds, and draws air out of the kitchen. I tried to bring a match and a sheet of paper to the ventilation: the difference “before” and “after” is very noticeable. The turbo deflector definitely works!

Recently, our company installed these expensive devices. Before this, especially in the summer, there was a malfunction in the operation of our ventilation, since the exhaust air stagnated in the room, it was completely unbearable to work. After installing them, I was surprised that there was actually more fresh air. Moreover, they are also beneficial because they do not require electricity to operate.

How do deflectors behave on chimneys, since the bearings are not protected from hot smoke and soot?