Do-it-yourself air heat exchanger for a chimney: manufacturing examples and tips from experts

The productivity of a boiler, heating or sauna stove can be increased by installing a simple and at the same time effective device on the pipe - a heat exchanger. However, for its productive operation, you need to know the design features and manufacturing rules of the device. Do you agree?

We will tell you how to make a heat exchanger for a chimney with your own hands. We will list which modifications are suitable for self-installation and explain how the air model differs from the water model. Taking into account our recommendations, you can significantly increase the heat transfer of heating units.

The content of the article:

Operating principle of air heat exchanger

The main purpose of the heat exchanger is to transfer energy from the combustion products in the chimney to the coolant, which is water or air. Heat exchangers installed in chimneys (this applies to water modifications) are often called economizers.

These devices collect and transmit heat into the room, which simply goes into the atmosphere, so that the thermal energy generated by the furnace is used to the maximum. In addition to ordinary tap water, other liquids are sometimes used - oil or anti-freeze.

In this regard, all devices are divided into two large categories:

- air;

- liquid (water).

The choice of one type or another depends on several factors. The most important of them are the configuration and material of the chimney, as well as the characteristics of the device itself.

Let's look at how the aerial model works. The design of the device is simple: a durable case with a partitioned internal space. The role of partitions is played by plates or tubes, the main function of which is to slow down the movement of heated gases and direct heat in the right direction.

Some partitions (dampers) are not soldered, but made movable. By sliding the metal plates in/out, you can adjust the traction force, thereby reducing or increasing the performance of the heating device.

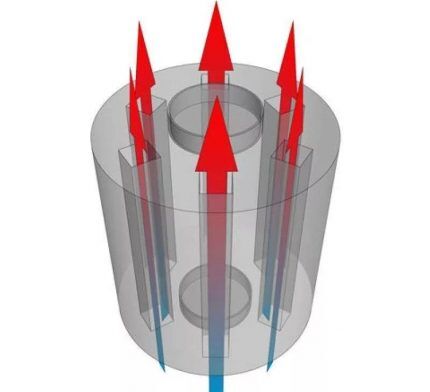

Air heat exchangers are called convectors, since their operation is based on the principle of convection. Cold air from the room enters the device, where its temperature rises due to the influence of hot flue gases. When heated, it moves further through another hole - back into the room or into the heating system.

Types of chimney devices

Among the air varieties, the traditional model for self-production is a tubular heat exchanger, although there are many other options.

Let's look at the main types that are relevant for installing long-burning stoves on the chimney: small-sized potbelly stoves, furnaces under development. The heat they convert from the energy of combustion products is called dry.

If we schematically imagine the internal part of the devices, it may have the following variations.

Horizontally or vertically located pipes welded to the firebox body. The vertical arrangement is more efficient, as air flows better through the channels.Manufacturing material – steel.

A pipe wrapped around the firebox. For good heat transfer, 2-3 turns are enough, but it is better to move them slightly apart to increase the heating area.

Partitions inside the housing. A kind of labyrinth is made up of metal plates installed vertically. The optimal thickness of parts is from 6 mm to 8 mm.

Pipes passing through the firebox.

With vertically located channels, air movement is more intense, therefore, the productivity of the device is increased. But in some cases, devices with horizontally located pipes or with partitions are appropriate. Each of the listed models is suitable for self-production if you have welding skills.

Which material is better?

When constructing a heat exchanger, metal parts are used - galvanized sheets, gas cylinders, pipes of various diameters, cast iron blanks, etc.Cast iron is not recommended because, compared to steel, it is brittle and heavy, which makes it difficult to install on a chimney.

The best option is austenitic steel. Stainless steel easily tolerates thermal changes, is resistant to mechanical damage, and can be independently processed and welded.

Galvanized steel is inferior to alloyed or austenitic steel, since it is not intended to be heated. High-temperature conditions lead to the release of zinc oxides, which are harmful to health, so if you plan to increase the temperature in the chimney to + 419.5 ºС, galvanizing should be abandoned. It is better to purchase expensive but safe material.

Options for making devices yourself

We offer several easy-to-make projects that, if desired, can be made from metal parts using welding and power tools.

Overview of a heat exchanger from a gas cylinder

If you install a homemade device on a potbelly stove, the heating efficiency in the room will increase by 30-40%. The smaller the garage or workshop, the higher the productivity of the device.

We suggest considering an option that is ideal for small stoves of the “potbelly stove” type, which are actively used for heating garages.

In general, a gas cylinder makes a fairly neat and efficient heat exchanger for a stove heating a small room. To further increase the heating efficiency without radically changing the design, fans can be installed on the pipes, and the number of pipes can be increased to 4-5.

Photo review of the Fehringer economizer

Factory models from popular manufacturers can serve as a sample for manufacturing. For example, the Feringer company, known for producing stoves, offers ready-made chimneys, which are essentially heat exchangers.

Let's consider models of simple design. All the parts they consist of can be made independently.

The main idea that can be taken from the advanced Fehringer models is the use of four pipes instead of one. If the stove is already installed in a garage or utility room, we remove part of the chimney and install a four-pipe economizer instead - and the temperature in the room immediately increases by several degrees.

Homemade air convector

The proposed model is made entirely of steel parts. This is a heat exchanger, which is approximately 1.5 times larger in size than a chimney.

It is a drum with tubes arranged perpendicularly chimney pipe. Stainless steel was chosen for good reason - it can easily withstand high temperatures, is easy to clean and does not burn through.

To work you will need:

- steel pipe with a diameter of 30 mm (for making 8 identical sections);

- pipe fragment 50 mm (for the central channel);

- metal sheet 2 mm thick (for making 2 round plates and a casing);

- 20 liter paint can (for the chimney adapter).

It is also necessary to prepare a tool for cutting and welding metal.

This is one of the best options for an air heat exchanger for a chimney stoves for garage or utility room. The design can be simplified by welding metal partitions instead of tubes, but the principle of operation will remain the same: heated air from the chimney will be an additional source of heat for the room.

Manufacturing process directly chimney for stove-stove This is the article we recommend. It is better to equip the chimney with a heat exchanger immediately during manufacturing.

Conclusions and useful video on the topic

Several video recommendations will help you better understand the structure and operating principle of a homemade heat exchanger.

Video #1. Tips for making a model from pipes:

Video #2. Aluminum sheet model:

Video #3. A simple option made from scrap materials:

As you can see, to increase the efficiency of a stove in a garage, utility room or bathhouse, you can not spend money on expensive devices, but make an effective device with your own hands. To work, you will need skills in working with metal and an approximate assembly diagram.

Do you know how to make an original version of a heat exchanger for installation on a chimney with your own hands? Did you have any questions while reading the information presented or do you have useful information for site visitors and us? Please write comments in the block below.