How to make an induction heater with your own hands from a welding inverter

Induction heating boilers are devices that are characterized by very high efficiency. They can significantly reduce energy costs compared to traditional devices equipped with heating elements.

Industrial production models are not cheap. However, any home craftsman who owns a simple set of tools can make an induction heater with his own hands. To help him, we offer a detailed description of the principle of operation and assembly of an effective heater.

The content of the article:

Working principle of induction heater

Induction heating is impossible without the use of three main elements:

- inductor;

- generator;

- heating element.

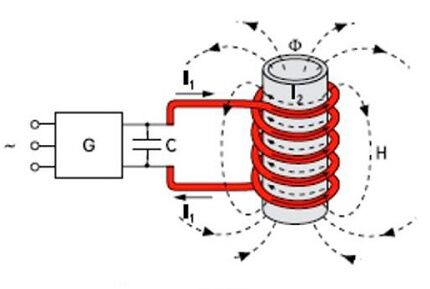

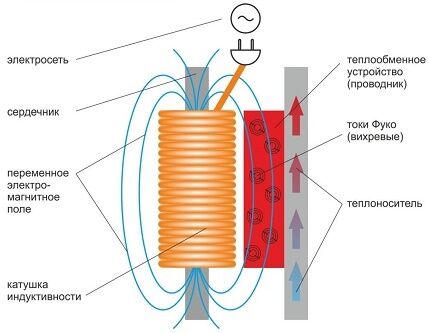

An inductor is a coil, usually made of copper wire, that generates a magnetic field. An alternator is used to produce a high-frequency current from the standard 50 Hz household electrical current.

A metal object capable of absorbing thermal energy under the influence of a magnetic field is used as a heating element. If you connect these elements correctly, you can get a high-performance device that is perfect for heating coolant liquid and home heating.

Using a generator, an electric current with the necessary characteristics is supplied to the inductor, i.e. onto a copper coil. When passing through it, a stream of charged particles forms a magnetic field.

The peculiarity of the field is that it has the ability to change the direction of electromagnetic waves at high frequencies.If any metal object is placed in this field, it will begin to heat up without direct contact with the inductor under the influence of the created eddy currents.

The absence of contact makes it possible to make energy losses during the transition from one type to another negligible, which explains the increased efficiency of induction boilers.

To heat water for the heating circuit, it is enough to ensure its contact with a metal heater. Often a metal pipe is used as a heating element, through which a stream of water is simply passed. The water simultaneously cools the heater, which significantly increases its service life.

Advantages and disadvantages of the device

There are a lot of “advantages” of a vortex induction heater. This is a simple circuit for self-production, increased reliability, high efficiency, relatively low energy costs, long service life, low probability of breakdowns, etc.

The productivity of the device can be significant; units of this type are successfully used in the metallurgical industry. In terms of heating rate of the coolant, devices of this type confidently compete with traditional electric boilers; the water temperature in the system quickly reaches the required level.

During operation of the induction boiler, the heater vibrates slightly. This vibration shakes off limescale and other possible contaminants from the walls of the metal pipe, so such a device rarely needs to be cleaned. Of course, the heating system should be protected from these contaminants using a mechanical filter.

Constant contact with water minimizes the likelihood of the heater burning out, which is a fairly common problem for traditional boilers with heating elements. Despite the vibration, the boiler operates extremely quietly; additional sound insulation at the installation site is not required.

Another good thing about induction boilers is that they almost never leak, unless the system is installed correctly. This is a very valuable quality for electric heating, as it eliminates or significantly reduces the likelihood of dangerous situations occurring.

The absence of leaks is due to the non-contact method of transferring thermal energy to the heater. Using the technology described above, the coolant can be heated almost to a vapor state.

This provides sufficient thermal convection to encourage efficient movement of coolant through the pipes. In most cases, the heating system will not have to be equipped with a circulation pump, although it all depends on the features and design of the specific heating system.

Sometimes circulation pump necessary. Installing the device is relatively easy. Although this will require some skills in installing electrical appliances and heating pipes.But this convenient and reliable device has a number of disadvantages that should also be taken into account.

For example, a boiler heats not only the coolant, but also the entire working space surrounding it. It is necessary to allocate a separate room for such a unit and remove all foreign objects from it. For a person, staying in close proximity to a working boiler for a long time can also be unsafe.

The device requires electricity to operate. In areas where there is no free access to this benefit of civilization, an induction boiler will be useless. And even where there are frequent power outages, it will demonstrate low efficiency. If the device is handled carelessly, an explosion may occur.

If you overheat the coolant, it will turn into steam. As a result, the pressure in the system will increase sharply, which the pipes simply cannot withstand and will burst. Therefore, for normal operation of the system, the device should be equipped with at least a pressure gauge, and even better - an emergency shutdown device, a thermostat, etc.

All this can significantly increase the cost of a homemade induction boiler. Although the device is considered virtually silent, this is not always the case. Some models may still produce some noise for various reasons. For a device made independently, the likelihood of such an outcome increases.

Homemade steps

Making such a device yourself is not that difficult. For this you will need:

- Make a heating element.

- Make an inductor coil from copper wire.

- Take a ready-made alternator.

- Connect the heater with the coil to the heating system.

- Connect the coil to the generator.

- Connect power to the system.

- Make a test run to check the operation of the unit.

In industrial models, a metal pipe with thick walls is used as a heater, but providing sufficient power to a homemade device to heat such an element is very difficult and does not make much sense. The induction coil is capable of heating any metal, so the heater can be modified.

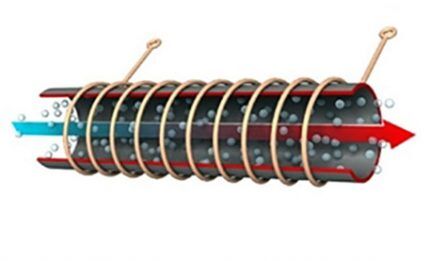

A piece of plastic pipe is used as a housing for an induction heater from a welding inverter. It should be slightly larger in diameter than the heating pipes. The length of the heater pipe can be approximately one meter, the internal diameter can vary between 50-80 mm.

To connect the heater to the system, adapters should be installed in the lower and upper parts of the housing. The lower part of the pipe must be covered with a grill, then a filler consisting of small metal particles is placed inside the body. You can get the filler, for example, from wire, rod, narrow metal pipe, etc.

The length of the segments can be varied arbitrarily. Most often, steel wire with a diameter of 6-8 mm is used for this, which is simply cut into small pieces. Some craftsmen recommend cutting it into long rods, about 90 cm, i.e. almost along the length of the heater.

The higher the magnetic resistance of the steel from which the wire is made, the better it will heat up. Depending on the size of these pieces, a protective mesh is selected, which is mounted at the bottom of the housing. The filler is poured or placed in the pipe to the very top. After this, the upper part is also covered with a mesh.

Thus, a homemade heater for an induction boiler looks like a thick plastic pipe stuffed with pieces of metal and closed on both sides with a mesh. The heater has adapters at the top and bottom for connection to the heating circuit. The polymer pipe for the heater must have fairly thick walls.

In addition, any plastic is not suitable for these purposes; the material must withstand the effects of fairly strong heat and at the same time not release any hazardous substances into the atmosphere or coolant. Now you need to make an induction grill. To do this, take copper wire and wind it directly onto the heater body.

The more turns of wire, the better. It is believed that the induction coil must have at least 90 turns. The inductor is wound onto the pipe very tightly; there should be no gap between the turns.

A 1-1.5 mm insulated copper wire is suitable for the winding.A thicker cable is not needed here, since it will complicate the winding work and it will be more difficult to position the turns closely.

The presence of gaps can lead to noise due to the vibration that accompanies the operation of such a unit. Over time, this situation can lead to the destruction of the insulation, which will cause an interturn short circuit.

In addition to the adapters, shut-off valves should be installed at the top and bottom. They are needed to provide the ability, if necessary, to shut off the water in the heating circuit.

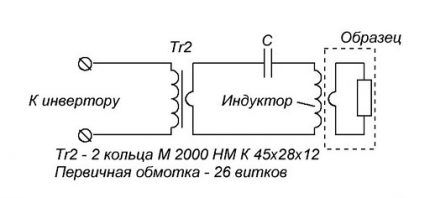

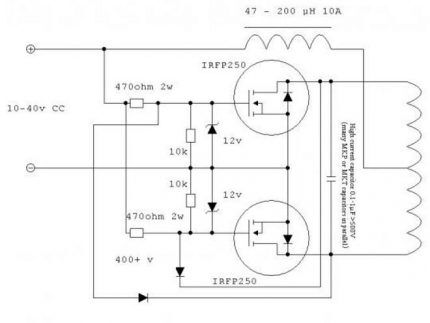

When installing the heater, remember that its lower end should be directed towards the return pipe, a pipe designed to collect the cooled coolant in two-pipe heating system. The easiest way to get an alternating field generator is to take an inverter from a welding machine.

The contacts of the induction coil are connected to the poles of the inverter. As soon as power is supplied to the unit and it is turned on, the homemade induction boiler will begin to work.

To make such a device, even an inexpensive welding machine is suitable, for example, a Chinese-made model, which allows you to regulate the current strength, starting from a level of 10 A. A thermostat sensor should be installed near the adapter at the supply. The welding inverter is connected through this thermostat.

Rectifier diodes must be installed at the outputs. To do this, you will have to open the body of the welding machine and solder the conductors to the output, then connect them to the diodes.If you connect directly without diodes, then a current with a rectified voltage will flow to the winding, and the coil will work as an electromagnet, and not as an inductor.

Some modern welding machines have a touch sensor that starts work the moment the electrode touches the work surface. This point must be taken into account so that the sensor either triggers at the right moment or does not affect the operation of the homemade boiler.

If an inexperienced craftsman has problems with altering a welding machine, it is better for him to seek professional advice.

If everything is done correctly, the welding machine can be used in the future for its intended purpose. It will be necessary to unsolder the conductors with the diodes and reassemble them. When exposed to high frequency alternating current, the induction coil will create a magnetic field.

The metal inside the polymer housing will begin to heat up and transfer heat to the water, which circulates through the heating circuit. The device will only take a few minutes to warm up the coolant.

The location for the induction heater should be chosen correctly. The unit should be located 800 mm below the ceiling level, and should be separated from walls and furniture by at least 300 mm.

A few words about safety

Homemade induction boilers are usually not equipped with control and protection systems, which makes them unsafe.Therefore, before turning on the unit, you must make sure that the housing cavity is filled with coolant liquid.

If the polymer body of the heater is subjected to constant heating without being washed with coolant, it will simply melt, sometimes this leads not only to deformation of the heater, but also to its complete damage.

The loss of hot metal filler from the melted body can also be dangerous. In this case, you will have to almost completely dismantle the device and make a new heating element for it.

The connection to the power supply should be made via a separate cable from the panel. Of course, it is necessary to carefully cover all contacts with insulation. The inverter of the welding machine must also be grounded; this is an important point to ensure safety.

In this case, you will need a cable with a cross-section of at least four millimeters. Some experts recommend giving preference to a six-millimeter cable. To prevent overheating of a homemade induction heater due to a lack of water in the system, it is recommended to install an overpressure valve at the inlet of the heater.

A homemade device of this type, not equipped with special protective equipment, is a potentially dangerous object that requires constant monitoring. Therefore, it is worth spending a little more money but purchasing the necessary devices.

At the same time, it doesn’t hurt to estimate the costs; perhaps purchasing a ready-made induction boiler will not cost much more. Industrial devices are usually equipped with all the necessary protection.

Features and step-by-step manufacturing technology of another version of a homemade induction boiler for a heating system are given here.

Conclusions and useful video on the topic

Video #1. Overview of induction heating principles:

Video #2. An interesting option for making an induction heater:

To install an induction heater, you do not need to obtain permission from regulatory authorities; industrial models of such devices are quite safe, they are suitable for both a private home and an ordinary apartment. But owners of homemade units should not forget about safety precautions.

Please comment on the material we offer for review. Ask questions about interesting or unclear points. Perhaps you have your own experience in the construction or installation of an induction boiler? You can share and post unique photos in the comments block below.

Energosbyt will not be happy. Where inductive energy is used (electric motor, starter coil), reactive energy always arises, which neutralizes the active energy in the network. Induction devices must be used with a condenser compensating installation, selected according to the boiler power. Even though the home reagent meter does not register the electricity supply organization, harm will be caused.

Vladimir, these are the arguments of an absolute amateur.In all such devices, the 50Hz AC power is first rectified by diodes loaded on electrolytic capacitors, and only after that a voltage of about 310 volts from the DC source is converted by an inverter into high-frequency AC voltage, which works for heating.

Found someone to feel sorry for...

Let me explain Alexander’s comment for those in the tank: The reactor through the rectifier will not go back into the network.

However, strange as it may seem, Vladimir is right about something. Indeed, there are induction heaters directly from the industrial network 50Hz 220/380, low frequency. Such healthy coils of heating steel fools weighing a hundred kilos. Yes, they are, it is advisable to use them with capacitor compensation.

test

What is the harm from induction load?