Refrigerator compressor: review of common breakdowns + step-by-step instructions for replacement

Refrigerators differ from other large household appliances in their durability, while still functioning on a daily basis.However, they are also prone to breakdowns.

With frequent power surges, the compressor for the refrigerator is the first to fail. It is this mechanism that is considered the most important element of the system, driving freon through the pipes, which ensures cooling.

In this article, we will look at the existing types of compressor and analyze the causes of typical breakdowns. We will also provide detailed instructions on how to replace it yourself.

The content of the article:

Existing types of compressors

Breakdown of the most important element of the refrigerator most often occurs as a result of voltage surges. If you regularly experience problems with power supply, we recommend that you take a closer look at voltage stabilizers.

A broken compressor promises significant expenses not only for the purchase of a new device, but also for the work of a repairman.

However, you can go the other way and make the replacement yourself. Whatever option is chosen, you will first need to select the right type of compressor.

Manifold air blower

When receiving information from sources about innovative models of refrigerators, you can come across such a thing as a “regular” compressor. However, not everyone knows its meaning.

This term refers to a commutator mechanism with a vertically mounted electric motor shaft. It is mounted on a spring mechanism and closed with a sealed box, thereby ensuring a high degree of sound insulation of the system.

Older models used a horizontal layout, which made the unit noisier - vibration was reflected throughout the entire body.

It uses a standard operating principle and technology developed many decades ago - the blower operates until the set temperature is reached in the refrigeration unit, and then turns off.

Review models are mainly equipped with budget versions of refrigerators, and this is their only advantage over other representatives of the species.

Inverter compressor type

The modernized units are equipped with an inverter type of supercharger. A conventional compressor reaches the peak of its capabilities when switched off, and there are a lot of such repetitions per day, and accordingly, it is subject to rapid wear and reduced service life.

Whereas inverter devices operate even with sufficient air injection in the chambers, periodically reducing the number of revolutions. The wear resistance of the component elements is significantly lower, and, accordingly, the period of uninterrupted use is longer.

The leading position in the development of inverter devices is occupied by Samsung, which was the first to massively equip refrigerators with non-switching mechanisms. Manufacturers provide a ten-year guarantee on their work.

To learn more about the features of refrigerators with an inverter compressor, their advantages and disadvantages, please go to this link.

Linear view of the device

Innovative developments in imported technology have involved a new type of supercharger - linear. The operating principle is similar to previous versions of the devices, but this type is much quieter and more economical.

Unlike conventional mechanisms, they do not have a crankshaft. Through the action of electromagnetic forces, reciprocating movements of the rotor are ensured.

Linear blowers are technically similar to the two previous analogues, but have a number of significant advantages:

- less weight;

- high degree of reliability during operation;

- lack of friction in the compression plane;

- application at low temperatures.

The main ideologist who began actively introducing linear superchargers is the LG company. Most often they are used in refrigerators with a system No Frosthaving individual temperature controllers in different blocks.

Rotary blower with plates

Rotary (rotary) horizontally or vertically positioned blowers are equipped with one or two rotors and are analogues of a twin-screw juicer, but the screw-type spirals are unequal.

Depending on the principle of operation, they are divided into two main classes: with a rolling and rotating shaft.

In the first case, the unit is represented by an engine shaft with a mounted cylindrical piston, located eccentrically relative to the center, that is, offset.

The rotation cycles are carried out inside the cylinder body. The gap between the housing and the rotor changes its size during rotation.

At the minimum hole there is a discharge pipe, and at the maximum hole there is a suction pipe. A plate, in turn, is attached to the revolving piston by means of a spring, which blocks the space between the two nozzles.

In the second version, the operating principle is similar with one difference - the plates are stationary and placed on the rotor. During operation, the piston rotates relative to the cylinder, and the plates rotate with it.

General operation algorithm of the refrigerator

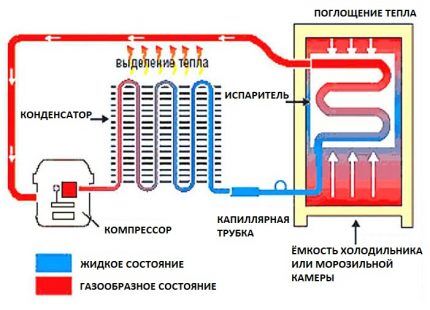

The operation of all refrigerators is based on the influence of freon, which acts as a refrigerant.Moving along a closed circuit, the substance changes its temperature parameters.

Under pressure, the refrigerant is brought to a boil, which is from -30 °C to -150 °C. As it evaporates, it captures the warm atmosphere located on the walls of the evaporator. As a result, the temperature in the refrigeration unit drops to a predetermined level.

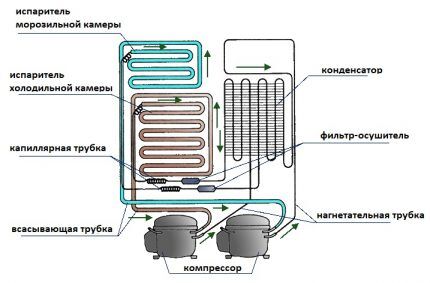

In addition to the main pumping device that creates pressure in the refrigerator, there are auxiliary elements that perform the specified options:

- evaporator, collecting heat inside the refrigeration unit;

- capacitor, displacing the coolant outside;

- throttling device, regulating the flow of refrigerant through a capillary tube and a thermostatic valve.

All these processes are dynamic. It is also worth considering the algorithm of the motor operation and the principle of operation in case of its malfunction.

The compressor is responsible for the systemic regulation of pressure level differences. The evaporated refrigerant is drawn into it, which is compressed and pushed back into the heat exchanger.

At the same time, the temperature of freon increases due to which it turns into a liquid state. The compressor operates using an electric motor located in a sealed housing.

Additionally, it is worth noting that most refrigeration devices have different temperature readings inside the main unit. This is how manufacturers simplify the storage organization system for various categories of products.

Depending on the zone, the climate can be adjusted from dry to humid, and the temperature of the main compartment is from 0 to 5-6 °C, the freezer compartment - up to -30 °C.

We examined in more detail the structure and operating principle of the refrigerator in this publication.

Having dealt with the device, we move on to analyzing the main factors of compressor failure, after which it will be necessary to dismantle it.

The main causes of supercharger failure

All problems in the compression unit are conventionally divided into two main groups: with a working and non-working motor. The first option looks like this: when you turn it on, you hear a sound from the compressor, and the light on the refrigerator lights up. Accordingly, in another embodiment, the unit does not turn on at all.

Reason #1 - refrigerant leak or thermostat defect

Here the main reason may be a freon leak.

You can carry out an independent check in this way: touch the capacitor - its temperature will correspond to room temperature.

Another possible reason is failure thermostat. In this case, a signal about incorrect temperature conditions will simply not be received.

Reason #2 - problems with the winding

If the unit does not turn on, a possible reason may be an open circuit in the compressor windings.

This situation can occur both at the working and at the starting stage, or at both at once. When the refrigerator is plugged in, the blower does not work, and the temperature of its unit is room temperature.

Reason #3 - interturn short circuit

The device starts up, but for no more than a minute. And the body heats up excessively.

In this case, the winding turns are closed, their resistance is reduced, and an increased current flows through the relay unit. The relay turns off the supercharger and a click will be heard. After the starter has cooled, it turns on the compressor again and so on in a circle.

Reason #4 - engine jamming

When turned on, you can hear the operation of the electric motor, but there is no rotation, the compressor does not perform compression, and the winding resistance is at maximum.

Reason #5 - valve failure

Loss of cooling capacity is associated with defective valves.

As a result of such a breakdown, the unit operates without shutting down and does not create the required level of compression; accordingly, the units of the refrigeration device do not reach the required temperature.

Often in this case, an uncharacteristic ringing of metal parts may be heard during operation. This can be determined by determining the degree of air supply.

To make sure of the “diagnosis”, you will need to cut off the filling pipe using a pipe cutter. We perform similar actions with the capacitor filter.

Now we connect a pressure gauge manifold in their place, turn on the supercharger and check the level of air compression being formed - the norm is 30 atm.

Reason #6 - temperature sensor or start relay

It is also necessary to check for defects such elements as the temperature control sensor and start relay.

With such a failure, the compressor either does not turn on or turns on for 1-2 minutes. When checking the resistance of the windings, the nominal values will be recorded.

Step-by-step self-replacement process

If the causes of malfunctions are not determined, the supercharger itself must be repaired. First, you will need to remove it from the refrigeration unit and check its functionality.

Stage #1 - we dismantle the supercharger

The compressor is located at the back of the refrigerator in its lower part.

The following tools will be used during the dismantling process:

- pliers;

- spanners;

- positive and negative screwdrivers.

The supercharger is located between two pipes connected to the cooling system. You will need to bite them off using pliers.

The refrigerator is started for 5 minutes, during which the freon turns into condensate. Afterwards, a valve with a hose connected to the cylinder is connected to the filling line. In 30 seconds, with the valve open, all the refrigerant will be released.

Then remove the relay block. Visually, it can be compared to an ordinary black box with wires coming out of it.

First of all, the top and bottom of the launcher are marked - this will be useful during the reinstallation process. Having unscrewed the fasteners and removed it from the traverse, we also cut through the wiring leading to the plug.

We unscrew all the fasteners together with the viewing device.We clean all the tubes for soldering the new device.

Stage #2 - measure the resistance with an ohmmeter

In order to verify the functionality of the component, we will perform an external inspection, as well as testing and testing of its individual components. First of all, we inspect the condition of the motor. This can be done using a multimeter or ohmmeter.

As mentioned earlier, the power cable is first checked. If it is working, we will examine the supercharger itself. To do this, we will use a tester.

First of all, we remove the protective block and remove the contents, disconnecting it from the starting relay. Next, using the multimeter probes, we measure the wires in pairs.

We compare the results obtained with the table, which shows the optimal indicators for this particular compressor model.

The data for a working device in the standard version will be as follows: between the top and left-side contacts - 20 Ohms, top and right-side contacts - 15 Ohms, left and right-side contacts - 30 Ohms. Any deviations indicate breakdowns.

The resistance between the feed-through contacts and the housing is checked. The indication of a break (infinity sign) indicates the serviceability of the device. If the tester produces any indicators, most often it is zero, there are malfunctions.

Stage #3 - checking the current strength

After checking the resistance, you need to measure the current. To do this, connect the start relay and turn on the electric motor.Using the tester's pliers, we clamp one of the network contacts leading to the device.

The current must be identical to the motor power. For example, a 120 W motor corresponds to a current of 1.1-1.2 A.

Stage #4 - preparing tools and equipment

To replace a faulty refrigerator compressor, you need to prepare the following set of tools and materials:

- portable regeneration, filling and vacuum station;

- welding machine or burner with MAPP gas cylinder;

- compact pipe cutter;

- mites;

- Hansen coupling for a hermetically sealed connection between the compressor and the filling pipe;

- copper pipe 6 mm;

- filter-absorber for installation at the entrance to the capillary tube;

- alloys of copper with phosphorus (4-9%);

- soldering borax as a flux;

- freon bottle.

You should also focus on safety measures when working with repair equipment. First of all, you need to arrange an insulating area and disconnect the refrigeration unit from the power supply.

After each refill with freon, before soldering, the room is ventilated for a quarter of an hour. It is not allowed to turn on heating devices in the room where repairs are being made.

Stage #5 - installing a new compressor

First of all, you need to attach the new blower to the cross-arm of the refrigeration unit. Remove all plugs from the tubes coming from the compressor and check the atmospheric pressure in the device.

Depressurize it no earlier than 5 minutes before the soldering process. Then we connect the compressor pipes with the discharge, suction and filling lines; their length is 60 mm and their diameter is 6 mm.

Process soldering tubes is carried out according to the order: filling, removing excess refrigerant and discharge.

Now we remove the plugs from the filter drier and install the latter on the heat exchanger, inserting the throttle pipe into it. We seal the seams of the two contour elements. At this stage, we put a Hansen coupling on the filling hose.

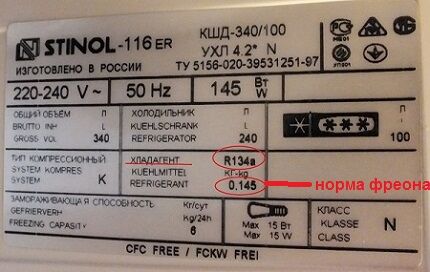

Stage #6 - add refrigerant to the system

To fill the refrigeration system with freon, connect a vacuum to the filling line with a coupling. For initial start-up, bring to a pressure of 65 Pa. By installing a protective relay on the compressor, the contacts are switched.

Connect the refrigerator to the power supply and fill it with refrigerant to 40% of the norm. This value is indicated in the table located on the back of the device.

The unit is turned on for 5 minutes and the connecting nodes are checked for leaks. Then it must be disconnected from the power supply again.

Perform evacuation a second time to a residual value of 10 Pa. The duration of the procedure is at least 20 minutes.

Turn on the unit and completely fill the circuit with freon. At the final stage, we preserve the tube using the clamping method. Remove the coupling and solder the pipe.

If you have never done such work, we recommend that you study the process yourself in more detail. refilling the refrigerator with freon.

Useful tips for soldering seams

Soldering two pipes made of copper, is carried out by an alloy of copper and phosphorus (4-9%). The docked elements are placed between the burner and the screen, heating it to cherry color.

Incandescent solder dipped into flux and melted by pressing the rod towards the heated joining area.

For soldering steel tubes or from its alloy with copper, solder containing silver is used. The soldering element is heated to red.

After the seam has hardened, it is wiped with a damp cloth to remove flux residues.

Conclusions and useful video on the topic

The tools and materials that will be required to replace the compressor, as well as all stages of work, are clearly presented in the video using the example of the Atlant refrigerator:

Basic rules for vacuuming and refilling the cooling system:

The compressor service life declared by the manufacturers is 10 years. However, its breakdowns are also inevitable.

If the supercharger malfunctions, you can replace the broken compressor yourself, having previously familiarized yourself with all the safety rules and the stages of the upcoming work. You will also need to stock up on the necessary equipment for these purposes..

Are you a professional refrigerator repairer and want to add to the above list of reasons for compressor failure? Or share useful repair tips with beginners? Write your comments and recommendations below under this article.

If you still have questions about troubleshooting yourself, ask our experts in the comments to this publication.

On our old Nord refrigerator, the compressor also failed and we also needed to fill it with freon, because it had been sitting in the garage for a long time without work. I had another refrigerator, so it became a donor for Norda. I didn’t touch the compressor myself, because I can’t pump freon myself. I called a friend, he is doing repairs. There you need special equipment, and I didn’t have any refrigerant.

The hardest part of installing the compressor yourself was finding the compressor! I personally installed a used one because... It was impossible to find a new compressor for an outdated model. Naturally, it turned out cheaper than buying a new refrigerator. But it took several days to find and install; we lived without a refrigerator for almost a week (in the summer!). I don’t trust my installation, so I still plan to buy a new refrigerator.

Hello. In our city it’s easier, try this option too. We already have an elderly refrigeration technician (ask on local forums, there will probably be one) who knows where to order inexpensive spare parts and will install them at an affordable cost. The refrigerator will be like new. This is from personal experience. Still cheaper than buying a new refrigerator.

Filling the refrigerator with refrigerant by non-specialists is prohibited by law.

Don't talk nonsense...

Hello. You are confusing the Labor Safety Rules for the operation of refrigeration units with the laws for individuals. persons: "9.1. Workers who have undergone training and have a certificate confirming their qualifications are allowed to service refrigeration units.“—these rules do not apply to ordinary people.

Why are your repair articles written in such ugly technical language?

For example, is the same device, say a starting relay, also called a “relay unit” and a “starter”?

And so throughout the text and with different devices?