Heater calculation: how to calculate the power of a device for heating air for heating

Heaters have high performance, so with their help you can heat even very large rooms in a fairly short time. Many models of these devices operating on the basis of different coolants go on sale.

To choose the best option, you need to calculate the heater, which can be done either manually or using an online calculator. We will help you figure out the issue of calculations - in this article we will give an example of the calculations that will be needed when choosing a suitable device for heating air.

We will also consider the design features of various types of air heaters, the advantages and disadvantages of a heating system using such devices.

The content of the article:

Pros and cons of heating with a heater

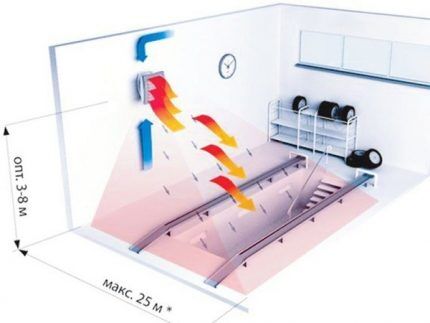

A home heating system, based on supplying air heated to a set temperature directly into the house, is of particular interest to homeowners.

This heating system design consists of the following important components:

- a heater acting as a heat generator that heats the air;

- channels (air ducts) through which heated air masses enter the house;

- a fan that directs well-heated air throughout the entire room.

There are many advantages to this type of system.These include high efficiency, the absence of auxiliary elements for heat exchange in the form of radiators, pipes, and the ability to combine it with a climate system, and low inertia, as a result of which large volumes are heated very quickly.

For many homeowners, the disadvantage is that installation of the system is only possible simultaneously with the construction of the house itself and then further modernization is impossible.

The downside is such a nuance as the mandatory presence of backup power and the need for regular maintenance.

On our website there are more detailed materials on the installation of air heating in a house and cottage. We recommend that you familiarize yourself with them:

- Do-it-yourself air heating: everything about air heating systems

- How to arrange air heating for a country house: rules and construction plans

- Calculation of air heating: basic principles + calculation example

Classification of air heaters

Air heaters are included in the design of a heating system to heat air. There are the following groups of these devices according to the type of coolant used: water, electric, steam, fire.

It makes sense to use electrical appliances for rooms with an area of no more than 100 m². For buildings with large areas, a more rational choice would be water heaters, which operate only in the presence of a heat source.

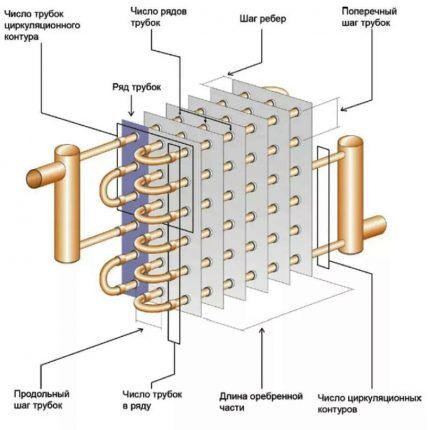

The most popular are steam and water heaters. Both the first and second surfaces in shape are divided into 2 subtypes: ribbed and smooth-tube. According to the geometry of the fins, finned heaters can be plate-type or spiral-wound.

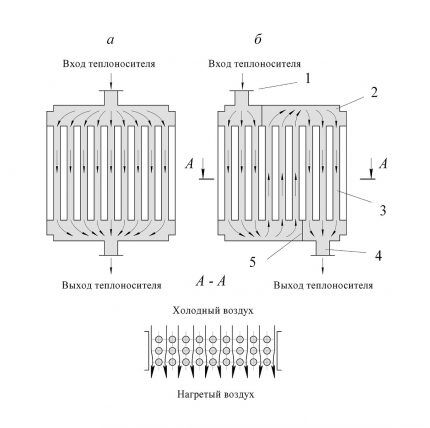

By design, these devices can be single-pass, when the coolant in them moves through tubes, adhering to a constant direction, and multi-pass, in the covers of which there are partitions, as a result of which the direction of movement of the coolant is constantly changing.

There are 4 models of water and steam heaters available for sale, differing in heating surface area:

- CM - the smallest with one row of pipes;

- M — small with two rows of pipes;

- WITH — medium with pipes in 3 rows;

- B - large, with 4 rows of pipes.

During operation, water heaters can withstand large temperature fluctuations - 70-110⁰.For a heater of this type to work well, the water circulating in the system must be heated to a maximum of 180⁰. In the warm season, the heater can act as a fan.

Design of different types of air heaters

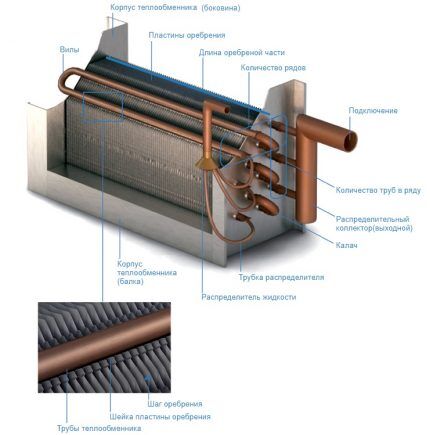

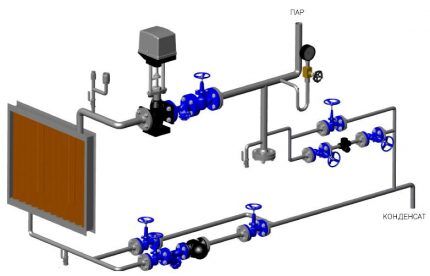

A heating water heater consists of a housing made of metal, a heat exchanger placed in it in the form of a series of tubes and a fan. At the end of the unit there are inlet pipes through which it is connected to a boiler or centralized heating system.

As a rule, the fan is located at the back of the device. Its task is to drive air through the heat exchanger.

After heating, the air flows back into the room through the grille located on the front part of the heater.

Most often, the housing is made in the shape of a rectangle, but there are models designed for round ventilation ducts. Two- or 3-way valves are installed on the supply line to regulate the power of the unit.

Air heaters also differ in the method of installation - they can be ceiling or wall mounted. Models of the first type are placed behind a false ceiling, only the grille looks beyond it. Wall mounted units are more popular.

Type #1 - smooth-tube heaters

The smooth-tube design consists of heating elements in the form of thin hollow tubes with a diameter of 20 to 32 mm, located at a distance of 0.5 cm relative to each other. Coolant circulates through them. The air, washing the heated surfaces of the tubes, is heated due to convective heat exchange.

The tubes in the air heater are arranged in a checkerboard or corridor pattern. Their ends are welded into the collectors - upper and lower. The coolant enters the distribution box through the inlet pipe, then, after passing through the tubes and heating them, it exits through the outlet pipe in the form of condensate or chilled water.

More stable heat transfer is provided by devices with a staggered arrangement of tubes, but the resistance to air flows is higher here. It is necessary to calculate the power of the unit in order to know the real capabilities of the device.

There are certain requirements for the air - there should be no fibers, suspended particles, or sticky substances. Permissible dust content is less than 0.5 mg/mᶾ. Inlet temperature is at least 20⁰.

The thermal characteristics of smooth-tube heaters are not very high.Their use is advisable when significant air flow and heating to a high temperature are not required.

Type #2 - finned air heaters

The pipes of finned devices have a ribbed surface, therefore, the heat transfer from them is greater. With fewer pipes, their thermal characteristics are higher than those of smooth-tube air heaters.

Plate heaters include tubes with plates mounted on them - rectangular or round.

The first type of plates is mounted on a group of pipes. The coolant passes into the distribution box of the device through a fitting, warms up the air passing at a significant speed through channels of small diameter, and then exits the assembly box through the fitting.

Heaters of this type are compact, easy to maintain and install.

Single-pass plate devices are designated: KFB, KFS, KVB, STD3009V, KZPP, K4PP, and multi-pass plate devices are designated as KVB, K4VP, KZVP, KVS, KMS, STDZOYUG, KMB. The middle model is designated KFS, and the large one is designated KFB.

A corrugated steel tape 1 cm wide and 0.4 mm thick is wound onto the tubes of these heaters. The coolant for them can be either steam or water.

The first is equipped with three rows of tubes, and the second with four. The plates of the medium model have a thickness of 0.5 mm and dimensions of 11.7 x 13.6 cm. The plates of the large model of the same thickness and width are longer - 17.5 cm.

The plates are located at a distance of 0.5 cm from each other and have a zigzag arrangement, whereas in the middle-type models the plates are arranged according to the corridor principle.

Air heaters marked STD have 5 numbers (5, 7, 8, 9, 14). In STD4009V heaters the coolant is steam, and in STD3010G it is water. The installation of the former is carried out with a vertical orientation of the tubes, the latter - with a horizontal orientation.

Type #3 - bimetallic heaters with fins

In heating systems with heated air, models of bimetallic heaters KP3-SK, KP4-SK, KSk - 3 and 4 with a special type of fins - spiral-rolled - are often used. The coolant for heaters KP3-SK, KP4-SK is hot water with the highest pressure of 1.2 MPa and maximum temperature of 180⁰.

To operate the other two air heaters, steam is required with the same operating pressure as for the first ones, but with a slightly higher temperature - 190⁰. Manufacturers must carry out acceptance tests. The devices are also tested for leaks.

There are 2 lines of bimetallic air heaters - KSK3, KPZ, which have 3 rows of tubes, are medium-sized, and KSK4, KP4 with 4 rows of tubes are large models. The components of these devices are bimetallic heat exchange elements, side shields, tube grilles, and covers with partitions.

The heat exchange element consists of 2 tubes - an inner one with a diameter of 1.6 cm, made of steel and an aluminum outer one with fins mounted on it. The transverse spacing between the heat transfer tubes is 4.15 cm, and the longitudinal spacing is 3.6 cm.

Rules for calculations and selection of a suitable unit

When designing a heating system with one or a group of heaters, as well as when performing calculations, a number of rules must be followed. Let's look at them in more detail in the photo selection below.

Water heater calculation

To calculate the power of a water or steam heater, the following initial parameters are needed:

- System performance, or in other words, the amount of air distilled per hour. The unit of measurement for volume flow is mᶾ/h, mass kg/h. Symbol - L.

- Initial or outside temperature - tul.

- The final air temperature is tfin.

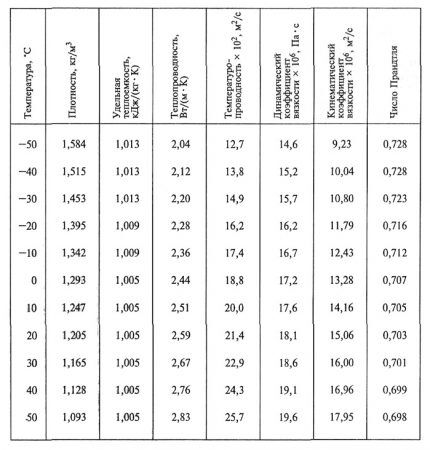

- Density and heat capacity of air at a certain temperature - data is taken from tables.

First, the cross-sectional area along the front of the air heating device is calculated.Having learned this value, the preliminary dimensions of the unit are obtained with a margin.

For calculation use the formula:

Af = Lρ / 3600 (ϑρ),

Where L — volumetric air flow or productivity in m³/h, ρ — air density outside measured in kg/m³ ϑρ – mass air velocity in the calculated section, measured in kg/(cm²).

Having received this parameter, for further calculations they take the typical size of the heater, the closest in size. If the final area value is large, several identical units are installed in parallel, the total area of which is equal to the resulting value.

To determine the required power for heating a specific volume of air, you need to find out the total consumption of heated air in kg per 1 hour using the formula:

G = L x p,

Where R - air density at average temperature. It is determined by summing the temperatures at the inlet and outlet of the unit, then dividing by 2. Density indicators are taken from the table.

Now you can calculate the heat consumption for heating the air, for which the following formula is used:

Q (W) = G x c x (t end - t start),

Where G — mass air flow in kg/hour. The specific heat capacity of air, measured in J/(kg x K), is also taken into account when calculating. It depends on the temperature of the incoming air, and its values are in the table above. The temperature at the inlet and outlet of the device is indicated t start. And t con. respectively.

Let’s say we need to select a heater with a capacity of 10,000 mᶾ/hour so that it heats the air to 20⁰ at an outside temperature of -30⁰. The coolant is water with a temperature at the entrance to the unit of 95⁰ and 50⁰ at the outlet.

Air mass flow: G = 10,000 mᶾ/h. x 1.318 kg/mᶾ = 13,180 kg/h.

Density value: ρ = (-30 + 20) = -10, when dividing this result in half, we got -5. From the table we selected the density corresponding to the average temperature.

Substituting the result obtained into the formula, the heat consumption is obtained: Q = 13,180 /3600 x 1013 x 20 – (-30) = 185,435 W. Here 1013 is the specific heat capacity selected from the table at a temperature of - 30⁰ in J/(kg x K). From 10 to 15% of the reserve is added to the calculated value of the heater power.

The reason is that the tabulated parameters often differ from the real ones downwards, and the thermal performance of the unit, due to clogging of the tubes, decreases over time. Exceeding the reserve value is undesirable.

With a significant increase in the heating surface, hypothermia and even defrosting in severe frosts can occur.

The power of steam heaters is calculated in the same way as water heaters. Only the formula for calculating the coolant differs:

G=Q/r,

Where r - specific heat that is released during steam condensation, measured in kJ/kg.

Electric heater calculation

Manufacturers in catalogs of electric air heaters often indicate the installed power and air flow, which greatly simplifies the choice.The main thing is that the parameters are not less than those indicated in the passport, otherwise it will quickly fail.

The heater design includes several special electric heating elements, the area of which is increased by pressing fins onto them.

The power of devices can be very large, sometimes hundreds of kilowatts. Up to 3.5 kW, the heater can be powered from a 220 V outlet, and at voltages above this it is necessary to connect it with a separate cable directly to the panel. If there is a need to use a heater with a power higher than 7 kW, a 380 V power supply will be required.

These devices are small in size and weight, they are completely autonomous, they do not necessarily require the presence of a centralized hot water supply or steam.

A significant disadvantage is that the low power is insufficient for using them over large areas. The second drawback is the high power consumption.

To find out how much current the heater consumes, you can use the formula:

I=P/U,

Where P — power, U - supply voltage.

With a single-phase connection of the heater, U is taken equal to 220 V. With a 3-phase connection - 660 V.

The temperature to which a heater of a certain power heats the air mass is determined by the formula:

T =2.98 x P/ L,

Where L — system performance. The optimal heater power values for a home are from 1 to 5 kW, and for offices - from 5 to 50 kW.

Conclusions and useful video on the topic

What air density to take when calculating is described in this video:

Video about how a heater works in a heating system:

When choosing a specific type of heater, you should proceed from considerations of feasibility and operational characteristics of the house.

For small areas, an electric heater would be a good purchase, but for heating a large house it is better to choose another option. In any case, you can’t do without a preliminary calculation..

Are you well versed in the issue of choosing and calculating a heater? Perhaps you would like to share useful recommendations for choosing an air heater or point out an error or inaccuracy in the calculations in the material discussed above? Leave your comment under this article - your opinion may be useful to people who are choosing the right heater for their home.

It all depends on the goals. I would recommend taking electric heaters for those rooms that are not intended for permanent residence, and they need to be heated for a short time, but quickly. By the way, it is important not only to make the correct calculations and choose the heater itself, but also to take into account the heat losses that occur due to improper construction or the use of cheap thermal insulation materials.

The choice of heating system type, Igor, is dictated by the energy infrastructure surrounding the facility. For example, having your own boiler house near a building turns electric heating into an unprofitable project.

The heating mode is dictated by permissible temperature fluctuations. For example, a wine cellar that requires minuscule temperature variations is usually “heated” with precision split systems. Your “short term, but quick” will cause the wine to spoil.

The article, Igor, describes an algorithm for selecting a heater based on several parameters of the supply air.Heat loss accounting is a “story” about heating system calculation.