Three-way valve on a heating system: operation, selection rules, diagram and installation

To constantly maintain a comfortable thermal balance in the house, an element such as a three-way valve on the heating system is included in the heating circuit, which evenly distributes heat throughout all rooms.

Despite the importance of this unit, it does not have a complex design. Let's look at the design features and operating principles of a three-way valve. What rules should you follow when choosing a device and what nuances are present in its installation.

The content of the article:

Features of Three Way Valve

The water entering the radiator has a certain temperature, which is often not possible to influence. The three-way valve makes adjustments by changing not the temperature, but the amount of liquid.

This makes it possible, without changing the area of the radiator, to supply the rooms with the required amount of heat, but only within the limits of the system’s power.

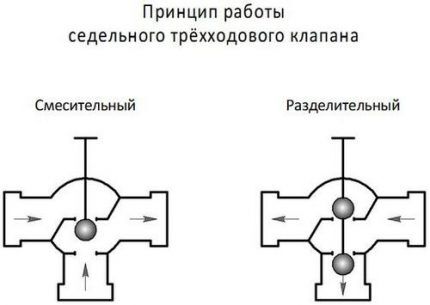

Separating and mixing devices

Visually, a three-way valve is similar to a tee, but performs completely different functions. Such a unit, equipped with a thermostat, belongs to the shut-off valves and is one of its main elements.

There are two types of these devices: separation and mixing.

The first ones are used when the coolant needs to be supplied simultaneously in several directions. In fact, the unit is a mixer that forms a stable flow at a set temperature. It is installed in a network through which heated air is supplied, and in water supply systems.

Products of the second type are used to combine flows and their thermoregulation. There are two openings for incoming flows having different temperatures, and one for their exit. They are used when installing heated floors to prevent overheating of the surface.

The three-way valve and temperature controller are sold separately. For autonomous heating systems, purchasing a design with a thermostat is still considered a more rational and effective solution.

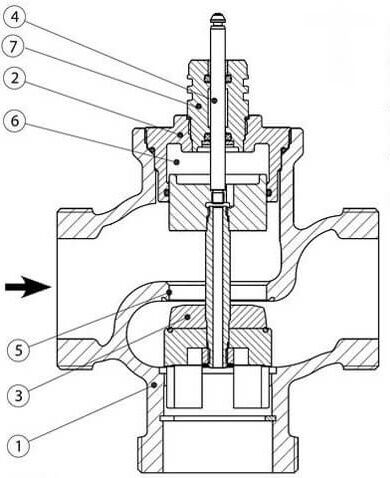

Design of three-way valves

According to their design, valves are divided into seat valves and rotary valves. The principle of operation of the former is based on the rhythmic movement of the rod vertically - the “rod-seat” adjustment scheme. This type belongs to mixing type valves. Often control is carried out by an electromechanical drive.

The key element of the rotary design is the rotating sector. During movement, the rod acts on the ball valve, and it partially or completely cuts off the coolant supply. This adjustment scheme is called “ball-socket”.

These devices have increased wear resistance. They are adapted to large temperature differences and are classified as shut-off valves. In private homes, where water is consumed in relatively small quantities, they can also function as faucets.

A special feature of the mixing valve is the presence of one outlet and two inlets. It is designed to control the temperature of the working fluid by combining high and low temperature flows. With proper installation, the product can also separate flows.

A three-way dividing valve is used when it is necessary to supply hot coolant in several directions.

All models are like this cranes differ from each other in several ways:

- shutter mechanics — it can be either tension or stuffing box;

- plug shape — there are L, T, S-shaped;

- shutter type - cylindrical, spherical, conical are found;

- connection to the circuit - using a coupling, flange, welding, etc.;

- management method - automatic, semi-automatic, manual.

The mixing device is equipped with a rod located in the center, and there is only one ball valve in it. It closes the inlet valve at the right moment.

In separating type devices, the stem is equipped with two valves mounted in the outlet pipes.

It functions according to a slightly different scheme. The operation of a three-way valve becomes clearer after a detailed analysis of its design.

The body of this type of product is cast. It is made of brass or bronze with a galvanic coating of chromium-nickel. It performs both protective and decorative functions. For connection to the pipeline there are threaded bends - only three pieces. The type of threaded connection depends on the selected model.

The optimal pressure parameters in the heating system for stable operation of the valve are 10 kg/cm².If this value is exceeded, problems may occur.

There are also restrictions on temperature indicators - 95º for boilers, 110º for solar panels. The permissible adjustment of the coolant temperature for different models is in the range of 20-60º. Productivity ranges from 1.6–2.5 m3/h.

How the device works

By installing a three-way mixing valve, it is possible to ensure that the outlet temperature of the liquid is within the established limits.

The operating principle for both a closed heating system and a hot water supply system is the same. The only difference is that in the first case, the coolant evenly transfers heat from the source to the radiators, and in the second, it transfers warm water to household appliances.

Until the temperature-sensitive element reaches a certain temperature, the coolant is supplied from the front pipe and flows freely into the right one. When the working element reaches a temperature higher than the set one, it expands.

This entails the valve moving vertically downward and, as a result, blocking the flow path of the heated coolant from below. Next, the left pipe opens to supply cold liquid.

Mixing cold liquid with hot liquid equalizes the temperature. The temperature-sensitive element returns to its previous shape, and the damper returns to its original position.

If a three-way valve is installed in a return circuit, then the process must occur in the opposite sequence. When the liquid cools, a path is directly opened for hot water from the boiler.

Drive mechanism of the device

The type of drive mechanism may also be different for valves. The drive can be hydraulic, electromechanical, pneumatic, or manual.

Electromechanical drives are divided into types, the most common of which is simple thermostatic. It functions as a result of the expansion of a liquid with a thermoactive element in its composition. As a result, pressure occurs on the rod. This is an easily removable design used in products installed in household systems.

The next option is a drive with a thermostatic head equipped with a temperature-sensitive element. The device is supplemented with a remote temperature sensor located directly in the pipeline. It is connected to the drive by a capillary tube.

This type of adjustment is considered the most accurate. If desired, the simple thermostatic drive can easily be replaced with a thermostatic head.

There is an electrically actuated three-way valve option. It is controlled by a controller equipped with temperature sensors and sending commands to the main mechanism. A simplified version of a drive with a controller is a servo drive.

It controls the valve directly. The simplest drive is manual. Here the adjustment is made by turning the plastic cap having a threaded connection. Its bottom is in contact with the end of the rod. The spool is moved by twisting or unscrewing.

The presence of an electric or servo drive allows you to program the temperature regime based on the time of day. The three-way valve does not initially come with a drive mechanism.It is purchased separately based on the characteristics of a particular heating network. The product can be used in any heating system.

Where are three-way valves used?

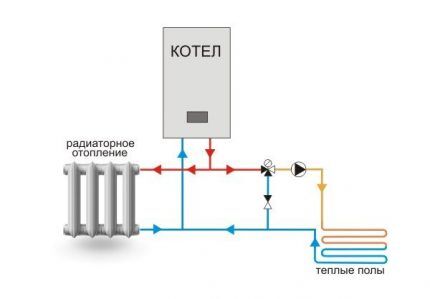

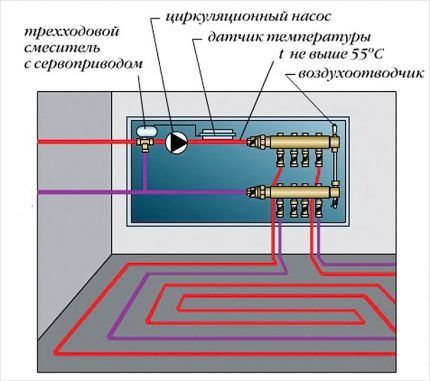

Valves of this type are found in different designs. They are included in the wiring diagram heated floors to ensure uniform heating of all its sections and avoid overheating of individual branches.

If there is a solid fuel boiler, condensation is often observed in its chamber. Installing a three-way tap will help combat it.

A three-way device works effectively in a heating system when there is a need to connect the DHW circuit and separate the heat flows.

The use of a valve in radiator piping allows you to do without bypass. Installing it on the return line creates the conditions for installing a short circuit.

Nuances of choosing a device

The following guidelines are general when selecting a suitable three-way valve:

- Reputable manufacturers are preferred. Often on the market you can find low-quality shut-off valves from unknown companies.

- Copper or brass products have greater wear resistance.

- Manual control is more reliable, but less functional.

The key point is the technical parameters of the system in which it is supposed to be installed. The following characteristics are taken into account: pressure level, the highest temperature of the coolant at the point of installation of the device, the permissible pressure drop, the volume of water passing through the valve.

Only a valve with the correct capacity will work well. To do this, you need to compare the performance of your plumbing system with the throughput coefficient of the device. It is mandatory indicated on each model.

For rooms of limited space, such as a bathroom, it is irrational to choose an expensive valve with a thermomixer.

Large areas with heated floors require a device with automatic temperature control. The guideline for selection should also be the conformity of the product GOST 12894-2005.

The cost can be very different, it all depends on the manufacturer.

In country houses with installed solid fuel boiler The heating circuit is not very complicated. A three-way valve of a simplified design is quite suitable here.

It operates autonomously and does not have a thermal head, sensor, or even a rod. The thermostatic element that controls its operation is set to a specific temperature and is located in the housing.

Manufacturers of three-way devices

There is a wide range of three-way valves on the market from both reputable and unknown manufacturers. The model can be selected after the general parameters of the product have been determined.

The first place in the sales ranking is occupied by valves from a Swedish company Esbe. This is a fairly well-known brand, so the three-way products are reliable and durable.

Three-way valves from a Korean manufacturer are known among consumers for their quality. Navien. They should be purchased if you have a boiler from the same company.

Greater adjustment accuracy is achieved by installing a device from a Danish company Danfoss. It works completely automatically.

The valves are of good quality and affordable cost Valtec, manufactured jointly by specialists from Italy and Russia.

The products of the company from the USA are effective in operation. Honeywell. These valves have a simple design and are easy to install.

Product installation features

During the installation of three-way valves, many nuances arise. The smooth functioning of the heating system depends on their accounting. The manufacturer includes instructions for each valve, compliance with which will help you avoid many troubles later.

General installation recommendations

The main thing is to initially install the valve in the correct position, following the tips indicated by the arrows on the body. Signs indicate the trajectory of the water flow.

The symbol A indicates direct travel, B - perpendicular or bypass direction, AB - combined input or output.

Based on the direction, there are two valve models:

- with a symmetrical or T-shaped design;

- with asymmetrical or L-shaped.

When installed along the first of them, liquid enters the valve through the end holes. It comes out through the central one after mixing.

In the second option, the warm flow enters from the end, and the cold flow enters from below. The exit after mixing the liquid of different temperatures occurs through the second end.

The second important point when installing a mixing valve is that its drive or thermostatic head must not be positioned downward. Before starting work, preparation is necessary: turn off the water before the installation point. Next, check the pipeline for the presence of residues in it that could cause failure of the valve gasket.

The main thing is to choose a place for installation so that the valve can be accessed. It may have to be checked or dismantled in the future. All this requires free space.

Mixing valve insert

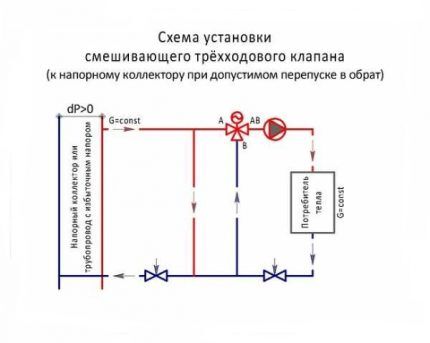

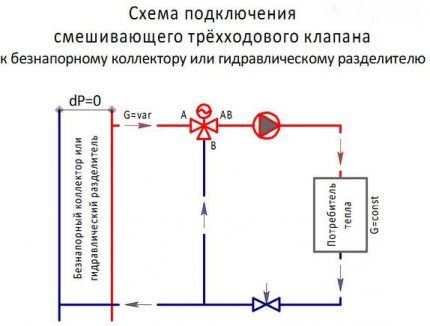

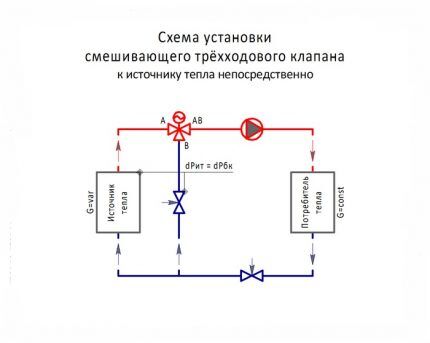

When installing a three-way mixing valve into a district heating system, there may be several options. The choice of circuit depends on the nature of the heating system connection.

When, according to the operating conditions of the boiler, such a phenomenon as overheating of the coolant in the return is permissible, excess pressure necessarily arises. In this case, a jumper is installed that throttles the excess pressure. It is installed parallel to the valve mixture.

The diagram in the photo is a guarantee of high-quality regulation of system parameters. If the three-way valve is connected directly to the boiler, which is most often the case in autonomous heating systems, a balancing valve must be inserted.

If you neglect the recommendation regarding the installation of a balancing device, significant changes in the flow rate of the working fluid, depending on the position of the rod, may occur in port AB.

Connection according to the above diagram does not guarantee the absence of coolant circulation through the source.To achieve this, you need to additionally connect a hydraulic limiter and a circulation pump to its circuit.

The mixing valve is also installed for the purpose of separating flows. The need for this arises when it is unacceptable to completely isolate the source circuit, but bypassing the liquid to the return is possible. Most often, this option is used when there is an autonomous boiler room.

Please be aware that some models may cause vibration and noise. This occurs due to inconsistency in the flow directions in the pipeline and the mixing product. Because of this, the pressure at the valve may drop below the permissible level.

Installation of separating device

When the source temperature is higher than the consumer needs, a valve is included in the circuit that separates the flows. In this case, with a constant flow rate both in the boiler circuit and by the consumer, superheated liquid will not reach the latter.

For the circuit to work, both circuits must have pump.

Based on the above, general recommendations can be summarized:

- When installing any three-way valve, pressure gauges are installed before and after it.

- To avoid the entry of all sorts of impurities, a filter is installed in front of the product.

- The device body must not be subjected to any loads.

- Good regulation must be ensured by inserting devices in front of the valve that throttle excess pressure.

- When installed, the valve must not be above the actuator.

It is also necessary to maintain straight sections before and after the product recommended by the manufacturer. Failure to comply with this rule will result in a change in the declared technical characteristics. The warranty on the device will not apply.

Conclusions and useful video on the topic

Installation nuances, taking into account which guarantees proper operation of the valve:

Details of valve installation when installing heated floors:

A component in the heating system such as a thermostatic three-way valve is necessary, but not in all cases. Its presence is a guarantee of rational use of the coolant, allowing for economical fuel consumption. Additionally, it also acts as a device that ensures the safe operation of the TT boiler.

However, before purchasing such a device, you must first consult about the feasibility of its installation.

If you have the necessary experience or knowledge on the topic of the article and you can share it with visitors to our site, please leave your comments and ask questions in the block below.

Guys, the time in the video is 9:25. Where will he get cold water from in order to dilute the temperature of the coolant in the heated floor to the required value if you have a check valve there (it must take water for dilution from the return line)