Ventilation of a vegetable pit in a garage: organizing air exchange in a garage vegetable storage

It’s not enough to grow a crop in a country house or a plot of land in a village; it still needs to be somehow preserved until spring.And practically the only correct option here is a personal vegetable storage. Moreover, such a cellar is often set up in a garage under an inspection hole. This way it’s cheaper, everything is in one place, and the temperature inside doesn’t drop below zero.

But you must admit, if you dig a pit under a garage building and pour potatoes and carrots into it, the vegetables will not even last until winter. Due to excess moisture they will simply rot. Only properly equipped ventilation in a vegetable pit in the garage guarantees the safety of supplies.

We will tell you how to properly arrange storage for crops under the garage with an impeccably functioning ventilation system. The article we presented sets out in detail all the nuances and rules. Our tips will help independent home craftsmen achieve excellent results.

The content of the article:

How much ventilation does a vegetable pit need?

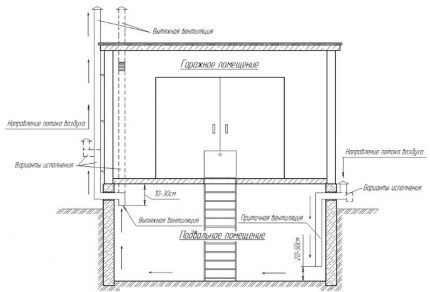

A classic vegetable storage area under a private garage (box) is a room 2–2.5 meters wide/length and up to 2 meters high. The descent into it is usually arranged from a viewing hole using a ladder.

As a result, the cellar for vegetables and jars of pickles is obviously below the soil freezing level, which guarantees that the temperature in it remains above zero even in winter.

Ventilation in a garage vegetable store is arranged to:

- keep the air temperature in the pit at a level from 1 to +10 0C throughout the year;

- remove excess moisture and carbon dioxide with ethylene from the cellar;

- ensure constant air exchange with the flow of clean street air inside.

During storage, vegetables “breathe” and continue to ripen or gradually begin to rot. As a result of these processes, heat and moisture are constantly released. And if they are not removed from the vegetable storage, the humidity inside will reach 95–100%, and the temperature will rise above 10–15 0C. And in the end, this leads to condensation and the development of rot with subsequent loss of yield.

Ideally, the following conditions should be provided in the vegetable pit under the garage:

- temperature – plus 1–5 0WITH;

- humidity – 85–90%;

- air exchange – 1 time/hour (about 50–100 m3/ton of vegetables*hour);

- light - darkening with the absence of direct sunlight, lighting is turned on only when people are in the cellar.

In reality, these indicators can only be achieved by installing a ventilation system with forced airA. Moreover, it will have to include automation for stable maintenance of the microclimate.

This ventilation option will cost several hundred thousand rubles. Spending such amounts is completely unprofitable. Therefore, most often the ventilation in a garage vegetable store is built using the usual natural scheme of a pair of pipes.

Ventilation system design

Ventilation in a garage vegetable store can be natural or forced. The first option is cheaper, and the second is more effective.One more nuance - in the second case, the garage must be electrified; the fan for pumping air operates from the mains.

If everything is done according to SNiPs, then when preparing a design for a ventilation system in a vegetable pit, you need to take into account:

- Winter and summer temperature indicators for the region.

- Groundwater level and soil freezing level.

- The presence of underground communications (especially heating mains and water pipelines) next to the garage building.

- Types of vegetables and root crops that are supposed to be stored in the cellar.

- The volume of supplies stored and the cubic capacity of the storage facility.

- Presence/absence of insulation and concrete floor in the pit.

In order for potatoes, cabbage in forks, carrots, radishes and beets to be preserved in the vegetable store as long as possible, they should be kept in different compartments, if possible with different microclimates.

But in a small personal garage it is impossible to create such conditions due to the limited space available. Therefore, in this case, natural ventilation is usually organized. It is cheaper, easier to install yourself and does not require electricity.

When organizing ventilation in a vegetable storage area under the garage, the following points should be taken into account:

- Air from the garage with car exhaust should not enter the vegetable pit.

- Air from the cellar, saturated with moisture from vegetables, should not enter the inspection hole and rise under the car.

- A forced ventilation system requires electricity and constant supervision.

- A system with natural air exchange practically stops working in hot summers, and in severe frosts in winter (if the inflow is not blocked) it can freeze the cellar.

The vegetable pit is a constant source of moisture. But the descent into it in a private garage is usually organized through a viewing hole.

If there is no maximum airtight door between these two rooms, then the moist air from below from the vegetables will rise under the bottom of the machine. As a result, the car will begin to rust and rot from such a microclimate.

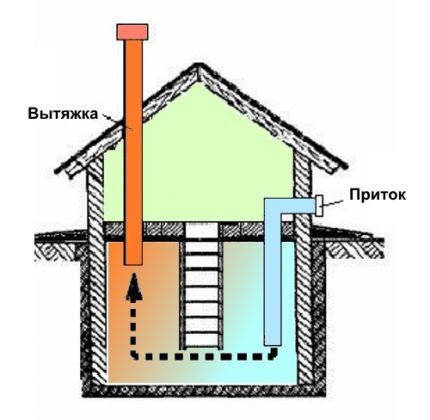

Cold air goes down to the floor, and warm air rises to the ceiling. This is pure physics. And the higher the temperature difference, the faster this circulation of air masses occurs.

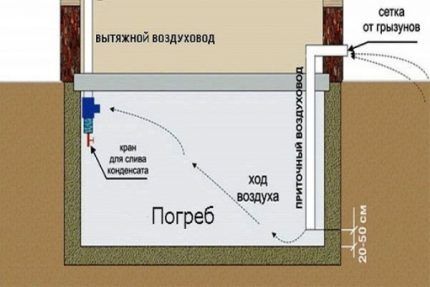

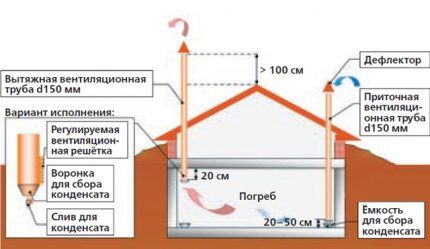

If the supply pipe from the street is brought to the floor of the vegetable pit, and the exhaust pipe to the outside is mounted under the ceiling or connected to the common garage hood, then natural draft is formed in such an air duct system.

And if the ventilation ducts are designed correctly, then the air exchange will be more than sufficient to remove excess heat and moisture from the vegetable storehouse to the street.

When the supply and exhaust pipes are narrowed, the air exchange rate in the garage cellar will be low. And if you install them too wide, the circulation will be excessive. In the first case, the pit will be too warm and humid, and in the second, the vegetable storage area may freeze in the winter.

The optimal duct diameter for a natural ventilation system in a garage cellar with an area of 3–6 m2 – 100–150 mm.

Choosing pipes for air ducts in the garage

To organize natural ventilation in the garage box itself, it is enough to build one ventilation duct in it for exhaust through the roof of the building. In this case, the air flow will be through the open door and the vents on both sides of it below in the wall.

To ventilate a vegetable storage area in a garage, use the following: types of air ducts:

- plastic (PVC or polyethylene);

- galvanized iron;

- asbestos;

- aluminum.

The cheapest option is asbestos and PVC. Moreover, if the first is non-flammable, then the second does not absorb moisture. Metal pipes are more expensive, but they are more durable and can withstand frost better.

Fighting condensation and ice

It is impossible to completely get rid of the constantly formed moisture in the vegetable storage. In the pit it comes from vegetables, the ground underfoot and condensation from the walls. At the same time, it is also not recommended to excessively dry the air in the cellar. This is harmful to stored supplies.

When warm air enters a cold cellar, condensation immediately forms on the walls and everything in the vegetable storage room. If the hood does not work well, then the latter will remain inside and contribute to the development of mold on vegetables. And with a sharp cold snap, it will instantly turn into ice, which is also unpleasant.

The wider the ventilation pipes, the stronger the air exchange occurs.However, this is good in the summer, but completely unnecessary in the winter. In winter, on the contrary, the air flow must be reduced as much as possible so as not to unnecessarily lower the temperature inside.

To ensure maximum control over what is happening in the vegetable pit, you should provide:

- control valve on the supply pipe;

- the ability to completely shut off the inflow and exhaust of air in case of severe frosts;

- insulation of both air ducts;

- possibility of installing an electric exhaust fan for forced drying of the cellar.

Also, if there is lighting in the basement, condensation can lead to a short circuit. Therefore, the better the vegetable pit itself, the garage above it and the ventilation pipe are insulated, the better.

Installation of ventilation in a vegetable storage

Before you start making ventilation in the vegetable pit of the garage, you should calculate everything and prepare all the necessary materials in advance. Also, you should not neglect drawing up a small floor plan of the room indicating the location of the air ducts.

Looks like you only need to make a couple ventilation ducts. But without a preliminary drawing, even with their installation, you can do something tricky.

To organize natural ventilation in the room in question, you will need pipes 8–9 meters long (3.5–4 m for supply and at least 4 m for exhaust). This takes into account the presence of an inspection hole.

If it is not there, then you need to start from the depth of the cellar and the height of the ceiling of the garage box. Plus you will need a glass for condensation with a drain tap, metal grilles for ventilation holes from the street and a cap or deflector.

Installation of ventilation in the garage and vegetable pit is carried out as follows:

- Holes for the supply pipe are made in the wall near the garage door at a distance of 20–30 cm from the ground and through the ceilings down into the cellar.

- Holes for exhaust are made in the roof of the garage and the ceiling of the pit.

- Ventilation pipes are installed (a collecting glass for condensate is installed on the bottom of the hood).

- A valve is installed on the air supply pipe.

- If necessary, ventilation ducts are insulated with moisture-resistant foam plastic or penoplex.

- A rain cap is installed on top of the exhaust pipe.

To prevent rodents from getting into the vegetable store through the ventilation, a metal grill should be installed at the vents for air flow from the street. In this case, the distance from the edge of the exhaust pipe to the ceiling of the vegetable pit should not exceed 20 cm, and the supply pipe should rise above its floor by a maximum of 50 cm.

The inflow duct in the pit should be positioned so that incoming street air does not fall on jars and vegetables. In winter it is cold and needs to warm up slightly first.

Otherwise, the overall temperature in the cellar will be at +5 0C, and locally near the ventilation pipe everything will freeze. For the same reason, this ventilation duct should be moved away from the wall at least 30–50 cm, so that a coat of frost does not grow next to it.

Will familiarize you with the rules and formulas for calculating the area of air ducts next article, which we recommend to independent home craftsmen.

Conclusions and useful video on the topic

Ventilation in the vegetable storage area under the garage:

How to make ventilation in a vegetable pit:

Owners deciding how best to arrange ventilation in a garage vegetable pit have only two options at their disposal. You can make a forced system with a fan or organize air exchange with natural air circulation. The first method is energy-dependent and expensive, but is also effective in any weather.

In the vast majority of cases, the second one is used. A pair of pipes for supply and exhaust, spaced diagonally in the cellar in different corners, is usually quite enough to ensure the required level of air exchange in the room in question.

If you have any questions on the topic or have your own comments on how to properly ventilate a vegetable storage area in the garage, write below. We will definitely help you understand all the nuances of organizing ventilation in a vegetable cellar.