How a hood works in a garage: popular schemes and technology for proper arrangement

A garage is a relatively small room, but its arrangement should not be taken carelessly.It must protect the vehicle from external influences: bad weather, theft, etc. But inside it is necessary to create a microclimate that is useful for people and equipment. This is easy to achieve if the hood in the garage is designed correctly.

We will tell you how best to organize ventilation in the garage space, and how to strengthen it if necessary. The article describes all types of systems tested in practice and discusses the specifics of their design. Taking into account our recommendations, exhaust air removal will no longer be a problem.

The content of the article:

Why ventilate your garage?

Of course, a garage is a technical, not a residential facility, although some car owners may disagree with this statement. If a car enthusiast spends a significant part of his personal time in the garage, and even uses the basement or the garage itself to store food supplies, all the more one should be concerned about the problem of proper air exchange in such a specific room.

To begin with, there is a high concentration of exhaust gases, fuel vapors and other technical fluids. Even a short stay in such an atmosphere is extremely harmful for a person.

The second problem associated with improper garage ventilation is excess moisture. Water vapor accumulates indoors and condenses on various surfaces, including the car. As a result, the risk of occurrence and the speed of corrosion processes increases sharply; in other words, the vehicle rusts.

Vegetables, canned food, and other foods or things that do not have a place in a house or apartment are often stored in garages or cellars built underneath them. Contact with moisture, as well as exposure to technical vapors, will not bring any benefit to all these objects. And the problem can be solved simply, just take care of effective ventilation.

What you need to know about room ventilation?

Anyone who has at least once encountered the problem of indoor air exchange knows that there are natural, forced and combined ventilation systems.With the first option, everything is simple: it is based on the difference in air temperature inside and outside.

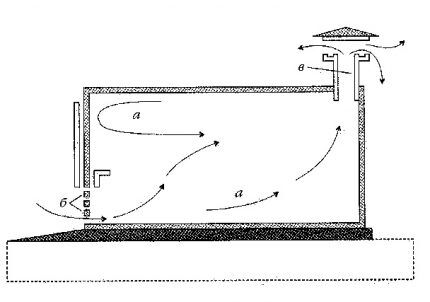

As you know, warm air rises and cold air sinks. The idea is that cool air masses enter the room from the street, rise up and naturally leave through the exhaust vent. At the same time, they must be replaced by new streams of fresh air that comes from outside.

In a garage, such ventilation is not difficult to organize. To do this, you need to provide sufficiently wide openings for air supply and exhaust, but the temperature difference between inside and outside the room will also be of great importance.

No problems arise with this condition in winter, but in summer, when the heat is almost the same everywhere, the efficiency of natural ventilation decreases sharply.

An alternative option in this situation is forced ventilation, i.e. using additional funds. Special fans are installed in the supply and exhaust openings, which, depending on the purpose, pump air into the room or remove it.

But installing two devices at the same time for one small garage is not always reasonable and justified from an economic point of view.It is more profitable to use a combined ventilation system, which requires only one device.

For example, a supply fan is installed, it pumps in fresh air, and the exhaust air masses are forced out through the exhaust hole.

In garages, an exhaust system is considered more acceptable. Install a fan that effectively removes air saturated with harmful vapors and excess moisture. Fresh air masses will enter the room naturally through the supply part of the system.

How to organize natural ventilation?

To ensure proper natural ventilation of the garage, you need to remember a number of basic rules:

- The hole for air flow is placed at the bottom, about 10 cm from the floor level.

- The exhaust hole is made at the top, almost under the ceiling, or even right in the ceiling.

- The best option for placing these holes is diagonally, i.e. if the inflow is in the lower front corner, then the hood should be placed in the upper back corner.

- The dimensions of the holes must be correctly calculated to ensure sufficiently intense air exchange.

- The supply opening should always be two to three times larger than the dimensions of the hood.

If you are in the process of renovating or building a garage, then you will probably be interested in knowing what material and how to make garage floor.

It’s good if the ventilation was calculated and created during the construction of the garage. If this moment was missed, you will have to perform a series of relatively simple installation work. It also happens that ventilation is provided, but does not give the desired results. In this case, you will need to improve the system, for example by installing an exhaust fan.

If you consider natural ventilation to be ineffective, then it is possible to modernize the system, for example, by increasing the height of the exhaust pipe:

Upon completion of the preparatory process, we proceed directly to assembling the system and fixing the tall pipe with guy wires:

How to calculate everything correctly?

Ventilation calculations in many cases require special knowledge and the use of complex techniques. If there is a desire and your wallet allows, the creation of a project can be ordered from specialists.Luckily, the garage is a small space with a simple configuration.

The dimensions of the ventilation holes are calculated using the formula:

Pslaughter=Pgar×15

Wherein:

- Pslaughter — cross-sectional area of the ventilation hole;

- Pgar - garage area;

- 15 - coefficient reflecting the size of the ventilation hole per unit area of the room.

Those. you need to multiply the garage area by 15 mm. According to this simplified technique for a garage of 24 square meters. m. (6*4) you will need an inlet hole with a diameter of 360 mm. These calculations are very arbitrary, since the technique does not take into account the height of the room and its other features.

In practice, these indicators can be varied. For the garage discussed above with an area of 24 square meters. m. in one specific case, two 150 mm pipes were successfully used in the inflow and one such pipe in the exhaust.

To increase the efficiency of natural ventilation, you can use additional means:

- Deflector - a special cap that is installed on the edge of a vertical section of the exhaust pipe in order to create a rarefied atmosphere inside the structure and accelerate the movement of air masses.

- A diffuser is a weather vane for the outer part of the supply pipe; wind pressure is used to operate it.

- An ordinary incandescent lamp - it is installed inside the exhaust pipe and heats the air flow, accelerating its movement.

These simple devices can significantly improve the quality of ventilation in your garage.

With general principles calculation of the power of ventilation systems The following article will introduce you, which we recommend that you read.

How to perform installation correctly?

To organize proper ventilation of the garage, you will need to make at least two openings: for the influx of fresh air, as well as for the removal of flows saturated with harmful fumes and excess moisture. The inlet hole is made in the lower part of the outer wall, approximately 10-15 cm from the floor.

Thick walls of residential premises are drilled using special equipment, but such difficulties are not needed for garages. Most often, drilling a hole of a suitable diameter is performed using a hammer drill.

After this, a pipe or pipes for inflow are inserted into the hole and their position is fixed. Polyurethane foam is used to seal the gaps between the pipe and the wall material. The outside of the hole should be protected with a special grille or diffuser.

The cross-section of the ventilation duct can be made not only round, but also square or rectangular. For installation you will need pipes of the appropriate configuration. Typically used for garage ventilation ventilation pipes with a round section.

This is the cheapest and most convenient option; in addition, they create minimal resistance to air flow. Both metal pipes and plastic structures are suitable for ventilation.

The hole for the hood is made right under the ceiling.The pipe is routed horizontally through the wall and then a vertical section is installed. It should be long enough.

A hood that rises at least 50 cm above the roof level is considered optimal. A deflector hood is often installed on top. The inside of both the supply and exhaust openings should be covered with a decorative grille.

Combined and forced ventilation

As noted above, natural garage ventilation is effective only under certain external conditions, i.e. with a sufficient difference in air temperatures inside and outside. The use of forced ventilation eliminates this type of problem.

Effective air removal in the garage is more than important, since the level of pollution here is much higher than in residential premises. Therefore, garage owners prefer the exhaust option of combined ventilation. Implementing this type of project is not that difficult.

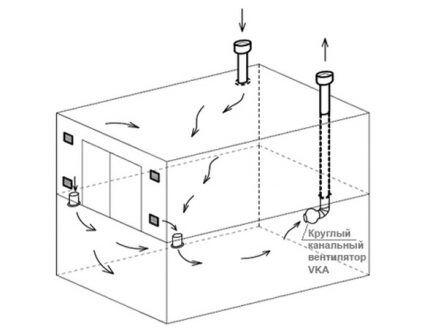

To do this, you need to purchase an exhaust fan and install it at the entrance to the pipe. If such a pipe is missing, it must be installed. This is done in much the same way as when installing natural ventilation. The calculations, materials and tools you will need are the same, the calculations are carried out in the same way, but there are several differences.

With combined ventilation, it is not necessary to install the hood strictly diagonally from the inlet, although this position is desirable. You can choose another location for both the supply and exhaust openings. But the first one still needs to be placed at the bottom, and the second at the top.

Another important point is the presence of furniture and other objects in the path of air flows. This is a common mistake when designing ventilation. The fewer such obstacles, the better the air exchange will be. An exhaust fan should be installed in the top pipe.

This can be a channel model, which is installed inside a pipe, or an overhead version, such devices are mounted directly on the wall. After this, the fan should be connected to the power supply.

To improve the functioning of such a hood, you can equip the fan with additional automatic control modules. For example, a timer that will turn the device on and off at a certain time.

This will slightly reduce energy costs, as well as ensure ventilation of the garage even in the absence of its owner. If the garage already has natural ventilation, but it does not work efficiently enough, the optimal solution would be to install an exhaust fan in a ready-made duct.

If natural ventilation is sufficiently good in winter, then the fan can only be used in summer.

Forced ventilation involves installing both a supply and an exhaust fan in the appropriate openings. In ordinary garages, such systems are usually not used, since the problem is solved using simpler options: natural or combined systems.

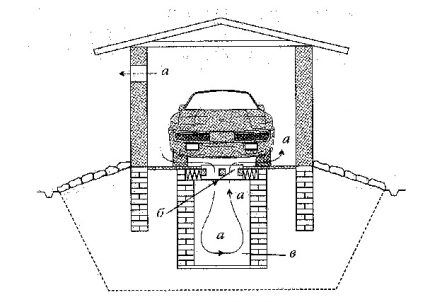

It makes sense to install forced ventilation in a garage only in cases where you simply cannot do without it. For example, for a garage located underground, forced ventilation is the only possible option. It happens that it is planned to carry out paintwork or other work in the garage, during which good air exchange is of particular importance. This is where forced ventilation will come in handy.

Those wishing to equip a garage with an effective exhaust system, which is required to remove toxic substances generated during welding and painting work, will find it useful to familiarize themselves with the following photo selection. It represents the process of constructing a hood with movable hose made of corrugated pipe:

Cellar and inspection hole

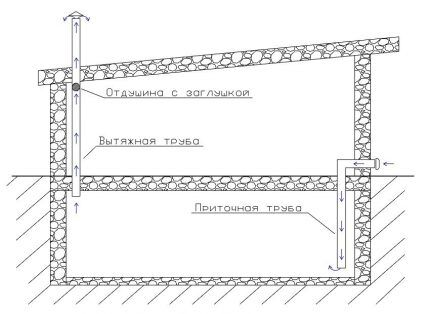

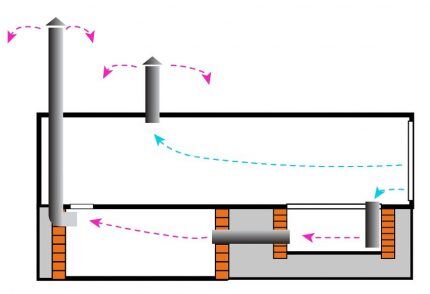

The option of ventilating a conventional garage was discussed above. If there is a basement and/or inspection hole inside, these objects should be taken care of separately. In the case of a basement, a separate ventilation duct will have to be installed. This is necessary because much more moisture accumulates below than in the upper part of the room.

If there is no ventilation, this moisture will enter the garage and cause damage to the vehicle stored there. The ventilation installed in the garage, even when using forced methods of air supply and removal, usually cannot provide a sufficiently intense exchange of air masses.

For effective basement ventilation two holes should be made: supply and exhaust. It is recommended to ensure air intake in the southern part of the cellar, and air flow outlet from the north.

The supply pipe is usually introduced into the cellar through the garage floor and lowered as low as possible. The hood is installed in the opposite corner; this pipe is led up and out through the floor of the garage. As with installing ventilation in a garage, the cross-section of the inlet openings should be two to three times larger than the dimensions of the hood.

The greater the height difference between the edge of the supply and exhaust, the more effective the ventilation of the cellar will be. A difference of three meters or more is considered optimal. To increase the difference, the vertical part of the exhaust pipe, which goes outside, just needs to be made higher. You can also install a deflector or protective cap here.

Sometimes installing a supply pipe is not possible for some reason. In this case, it is recommended to leave the hatch slightly open so that the fresh air entering the garage moves into the basement. The lack of fresh air will make all efforts to organize effective ventilation from the cellar in the garage useless.

If the garage is heated, condensed moisture may appear on the exhaust pipe in winter. To prevent icing of the pipe, install a special glass for condensate.

For an unheated garage, this measure is not required. In winter, products and items stored in the cellar should be placed no closer than half a meter from the inlet, otherwise they may freeze.

The inspection pit is a small object, so separate ventilation is usually not provided for it. Still, it is worth taking care of good air flow. To do this, on the side of the inspection pit that faces the garage ventilation inlet, you need to make slits of about 10-15 cm. You can open two sides of the pit in a similar way.

On the hood side you also need to make such a gap, but it should be twice as narrow. For safety's sake, you can cover these cracks with boards in some places. When installing the car, you need to make sure that it does not block the exhaust slot, as this is dangerous for the vehicle.

Rules and options for installing ventilation in the garage for independent craftsmen are outlined in the next article.

Conclusions and useful video on the topic

Video #1. Interesting and detailed information on garage ventilation is presented in this video:

Video #2. This video demonstrates the operation of an exhaust duct fan:

Video #3. Here you can see the experience of creating a homemade garage hood made from improvised materials:

Organizing a high-quality hood in the garage is not so difficult. You need to choose the right system and install it, or improve an existing ventilation option. This will have a positive effect on both the condition of the car and the health of the garage owners.

Would you like to talk about how you made or upgraded the ventilation in your own garage? Do you have any useful information or have any questions while reading this article? Please write comments and leave photos on the topic in the block below.

In the purchased garage, after putting things in order, the question arose of ensuring normal ventilation, since the old one was poorly done. I went searching for advice and from the selected options I came across information here. Everything is written in an intelligible language, I read a lot of new things in addition to what I knew before.

The attached videos were also useful; they explain even better what I read.

Now with the acquired knowledge you can practice.

After selling the car, I still had a garage, I decided to grow mushrooms in it, and there was a problem with ventilation. I made it from improvised materials. I installed an exhaust fan at the top, ordered a metal transition to it, to which I attached a plastic pipe for sewerage, inserted tees so that one of the outlets remained free through which the air escapes. But there was no influx of fresh air, for which, it turns out, you need a hole in the lower part of the opposite wall. I'll try to use the above tips, I think everything will work out. Is it possible to apply a ventilation calculation if ample ventilation is needed for my case?

Good afternoon, Oleg. No, a different plan of calculation is needed.

Each type of mushroom has its own requirements for air volume and should be based on it. For example, a ton of oyster mushroom substrate requires 300 m3/hour. Let's assume the dimensions of the garage are 6m x 4m, with a ceiling height of 3 meters.We calculate the cubic capacity 6m x 4m x 3m = 72m3.

We calculate how many times per hour the air in the garage should be replaced, let’s assume for two tons of substrate:

1. 300 m3/hour x 2 = 600 m3/hour.

2. 600 m3/hour: 7 2m3 = 8.33 times/hour the air in the room should be completely renewed, round up to 9 times.

3. 9 * 72 m3 = 648 m3/hour.

The capacity of your ventilation system should be calculated based on an exchange of 648 m3/hour.

When designing, it is important to understand that mushrooms (plants) require the creation of a certain microclimate. Therefore consider:

1. Forced ventilation power. Calculated using an example.

2. The air flow velocity created in this case. Too high can have a detrimental effect on the development of fungi.

3. Outside air temperature. A heat exchanger will be required to maintain the required temperature for rapid growth.

4. Humidification system.

All these parameters must be taken into account and linked together when drawing up a project. A competent approach will provide you with a thriving business.

I didn't understand something with the approximate formula. Is it the cross-sectional area or diameter? In the formula it is the area, in the example it is the diameter. If it’s an area, then for a garage of 24 a pipe of 20mm in diameter is enough?