Washing machine faucet: design overview + installation instructions

After purchasing a washing machine, it must be connected to water supply and sewerage. To do this, it is possible to use a number of additional elements, one of which is a faucet for a washing machine.When connecting the unit to a water pipe, this is an extremely important fitting unit.

We will tell you how to select and install a tap that allows you to open/shut off the water supply to the washing machine. We'll tell you what type of device to choose and how to install it correctly. Our recommendations will help home craftsmen cope with the work themselves.

The content of the article:

The role of the tap when connecting the washing machine

The tap that is used to connect the washing machine to the water supply network plays an important role. With its help, you can instantly turn off the water in case of unforeseen circumstances, for example, if the machine breaks down, which can lead to leaks.

An even greater danger is water hammer in water pipes: it can disrupt the integrity of the elastic hose of the washing unit, which will result in a large-scale flood that will cause justified indignation among neighbors.

To prevent this from happening, you need to connect the machine through a tap.It is recommended to place this part in a visible place so that you always have quick access. In an extreme situation, this solution will allow you to gain a few minutes, which can be decisive in preventing flooding.

Types of cutting devices

Specialized stores offer a varied assortment of taps. Let's take a closer look at the most commonly used types.

Among them we can note multi-turn, blocking the flow of water due to the movement of the plate, as well as Ball Valves, which are turned on and off by moving a small ball installed inside the structure.

Ball valves have a number of advantages:

- high tightness;

- prompt response, allowing you to quickly block the flow of water;

- simplicity of design, contributing to prolongation of the operational period.

It is also worth noting the small size of this type of cut-off devices, which allows them to be used even in the most cramped circumstances.

Types of ball valves

There are several types of ball cutters. Let's look at the main ones used to perform the process of connecting a washing machine at home.

Option #1 - pass-through

Such a mechanism has outlet holes on both sides, which allows you to shut off the water, dividing the branch into two parts. Devices belonging to this category can be installed on a separate pipe, which extends from a common riser to any piece of plumbing, or used for tapping.

Option #2 - tee (three-way)

As the name implies, such a device is equipped with three inputs and outputs. One of the holes is directly responsible for shutting off the water flow, the other two serve to combine all water supply outlets into a single system.

Such components, which may have different sizes, shapes and configurations, are typically used to tapping into a water pipe, where they are often combined with other fixtures, such as a faucet. This function is not available to a conventional flow-through faucet due to its design.

Option #3 - corner

The design of this element corresponds to the features of the pass-through fitting. Using this tap, you can divide the outlet pipe into two independent branches located at right angles.

This element is most often used when installing toilets, but is also well suited for connecting non-standardly located washing machines.

The faucets of all categories include sealing rings, fixing nuts, as well as rotary handles, with the help of which the water is shut off and access to it. The last element is attached to the body of the part with a locking nut.

Which type of crane do you prefer?

In the process of choosing a faucet model, you must first of all proceed from the location where you plan to install the washing machine. In small rooms it is better to use corner elements, with which you can reduce the space for connection.

If you need to simultaneously connect two or more plumbing fixtures, it is better to use three-way valve, and if there is an outlet for the washing unit - with a straight-through ball valve.

It is also necessary to pay attention to the diameter of the device, which must match the dimensions of the water pipes. And also take into account the features of the thread - its size, location on the outside or inside. The last parameter can be omitted if the installation of the faucet requires independent thread cutting.

The angle of rotation of the device is no less important: it is not very convenient to use a device whose valve closes towards the wall, touching it.

Installation materials and tools

To connect the unit to water supply network It’s not enough to choose the right valve.

You also need to stock up on tools, which include:

- Adjustable wrench, which is needed to perform installation work: connecting pipes and pipes, tightening nuts.

- Plastic pipe calibrator for adjusting the tap when installing it on a cut-in water pipe.

- Thread cutting tool or similar instrument used for these purposes.

- Drill, file, screwdriver, which may be needed for drilling and other work.

- Plastic pipe shears or a grinder for inserting a tap into a water supply system made of plastic or metal elements.

In addition, you will need a double hose, which can be included with the automatic machine or purchased separately. It is advisable that the length of such an element be slightly longer than required - this will allow for a small margin required when rearranging.

If a hose is purchased specifically, it is better to give preference to a part that has wire reinforcement, which makes it easy to withstand high pressure in the pipes.

The water purification filter is mounted on the thread of the tap, which is connected to the outlet of the water pipe. The small element improves the quality of the water used, thereby reducing the risk of plaque and sediment formation.

If the liquid contains a large amount of minerals, simultaneous use of several filters is allowed.

Sealing rings, winding, FUM tape, spare bolts, which are difficult to do without when installing plumbing products - the listed set will ensure reliable fastening of the faucet and the tightness of this unit.You should also consider the optimal connection option, taking into account the configuration of the room and the placement of plumbing fixtures.

Various crane installation schemes

Let's look at popular connection options that you can do yourself using a minimum of tools and additional parts.

Scheme #1 - installation of a flow element

To install a tap of this type (regular or tee), you must first shut off the cold water supply, which can be done using a tap that shuts off the flow of water from the riser. After this, the remaining liquid is drained from the pipes, which may interfere with further manipulations.

The easiest way is to install a flow valve on a separate branch of the pipe. As a rule, in this case a threaded bushing is already provided, to which you can easily screw a faucet with a two-outlet system connected to the filter. This element is attached to the inlet hose.

After completing all the manipulations, it is necessary to check the fasteners for leaks. If water is noticeable, all connecting nodes should be redone by installing additional gaskets.

Scheme #2 - installation of an end valve

If it's appropriate washing machine installation a special branch of the water supply system has been installed; you can connect the end valve using a tee (mortise clamp). This part is carefully screwed to the pipe so that the guide sleeve faces outward.

After this, holes are drilled in the pipe through which a connection is made to the clamp or section of pipe where the tap is supposed to be installed.

At the end of the pipe, a thread is cut that matches the size and type of grooves applied to the tee. The external thread is wrapped with a sealant (FUM tape) or flax, after which the valve is screwed onto the outer pipe.

A hose attached to the automatic machine or purchased specially is connected to the second end of the tap. The other end of the hose is installed in a special hole, which is located on the back side of the washing unit. It is necessary to remove the transport valve from it.

The assembled structure is checked for leaks. Typically, the angled end of the hose is connected to the washing unit, while the straight end is connected to the water supply. This option is more convenient because the washing device is usually installed next to the wall.

Scheme #3 - installation of a tap with pipe insertion

A more complex process is to install the tap directly on the pipe, since in this case you will have to cut out the section.

In plastic piping this can be done relatively easily using plastic pipe shears. Such an operation will require much more effort if we are talking about a metal pipeline: in this situation you will have to use a grinder.

To determine the size of the cut section, you need to add the length of the tap and the size of the filter. After this, you can make an incision and cut threads at the ends of the pipes that match the parameters with those on the tap.

Following this, a filter is installed that will protect the machine mechanism from impurities contained in tap water. Then a tap is installed to regulate the water supply. To do this, you need to remove the mounting nuts from the part that are used to connect to the pipe.

If the installation is carried out on a polymer structure, this part should be expanded using a calibrator before starting manipulation.

The joints are fixed with tightening rings. The shut-off faucet compartment is connected to the inlet hose of the unit. After this, all nuts are tightened with an adjustable wrench.

It is important to pay attention to the fixation force: a poorly tightened or overtightened bolt can cause enormous damage to the structure, becoming a source of leaks.

All joints are well sealed with O-rings, which are included with the faucet and/or filter, as well as fum tape, flax fibers or other materials. After which it is made connecting the washing machine to the sewer outlet. The final stage is checking the assembled structure.

Special connection options

Separately, we can also mention non-standard types of tap connections. They are often used if it is not possible to make a traditional connection or an unusual method is the most convenient.

Option #1 - installing a faucet on a mixer

This option is found in practice because it attracts users with its simplicity and accessibility. However, it can hardly be called acceptable, since such a scheme has a large number of negative factors.

This arrangement of the tap has a detrimental effect on the condition of the mixer: the latter experiences an increased level of stress, which significantly reduces the service life of the device. In addition, combining two appliances complicates the use of both the tap and the mixer.

Experts consider it acceptable to use such a solution only as a temporary option, but it is worth taking care in time to correctly connect the machine.

It is worth especially warning apartment owners against installing a faucet on old-style mixers. To connect the device in this case, you will have to perform a complex procedure that requires material and time costs.

If this particular connection diagram is required, it is advisable to install a new modern mixer simultaneously with the installation of the tap.

Option #2 - installation on old pipes

In older houses, the water supply network is often made of metal (usually cast iron). In this case, the ends of the pipes may be corroded, which complicates installation work.

There are two methods for installing a similar problem:

- File the edges of the pipes. This will allow the ends of the elements to be aligned, so that the hose can be laid close to the pipe.

- Install an extension cord at one end of which you can hide the ends damaged by corrosion. On the other end, this part is mounted with a fixed hose with a gasket.

In any case, it is important to ensure the integrity of the structure and protect the pipes from further destruction, for example, by covering them with anti-corrosion paint. But it’s even better to immediately change the pipes so that connecting other devices does not cause problems.

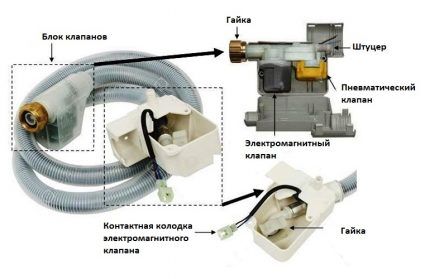

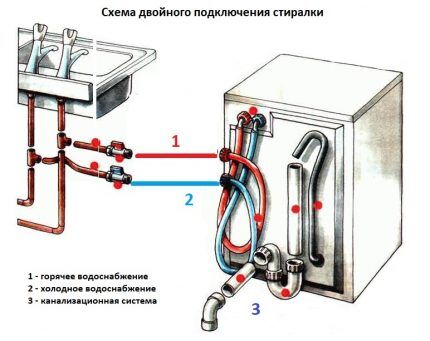

Option #3 - double connection of the washing machine

Some models of washing machines, most often made in Japan and the USA, provide the ability to simultaneously connect to hot and cold water supplies.

Such options can significantly reduce energy costs, since there is no need to specially heat cold water, as in conventional units.

The widespread use of such machines is hampered by the low quality of hot water: it contains a large amount of mineral impurities, which not only increases the risk of mechanism failure, but also reduces the quality of washing.

Conclusions and useful video on the topic

In the presented video you can see three options for connecting the machine’s tap to the water supply network.

Step-by-step instructions for installing a faucet yourself in the following video. The video will help even a novice home handyman understand the nuances of installation work:

Although a team of professionals is often called in to connect the tap to the washing unit, this fairly easy manipulation can be done with your own hands.

To connect the washing machine yourself, you must carefully select the valve and other materials used, and then follow the instructions, strictly following the prescribed procedure.

By carefully performing all processes, you can achieve excellent results, which will guarantee long-term and comfortable operation of the washing machine.

Would you like to talk about how you selected and installed a faucet to regulate the water supply to the washing machine? Do you have technological subtleties in your arsenal that will be useful to site visitors? Please write comments, post photos, ask questions in the block form below.

There is nothing difficult for a man to install a washing machine. Especially if all the wiring has already been done. We bought a used washing machine. The crane was installed at the corner and the machine was connected. After a while, I noticed that where the hose of the machine and the faucet are attached, a leak began. At first a little, and then more, I replaced the gasket, but it didn’t solve the problem. Then I had to change the inlet hose of the machine; they wear out very much during operation, as it turned out.

When installing a washing machine and a tap that shuts off the water supply to the machine, the most important thing is that the tap is reliable so that it holds water. And, of course, its durability in operation, so that you don’t have to change the taps every year or two. And each owner makes the actual choice of model himself, according to his own taste/budget, while taking into account the ease of installation. Personally, I have an angular type of ball shut-off valve installed at home, since the water pipe comes out of the wall. Convenient, easy to install, easy to replace in case of leakage, inexpensive.

This job is nothing if you are a woman. Some men have very crooked hands.