How to cut into a plastic pipe: features of the work and analysis of all the important nuances

Do you have plastic communication systems in your private home and do they require modernization or repair? It’s not difficult to install plastic yourself, thanks to the features of this material, right? But how can you cut into a plastic pipe if it is under pressure? And is it possible to do this yourself?

We will give you answers to your questions. Here we consider several ways to organize a diversion from an existing highway. The insertion options are provided with a detailed description of the process and supplemented with photos, which will allow you to understand the intricacies of the technology for installing cheap and durable plastic pipes.

By following the recommendations given in the videos, you can do most of the work on your own without involving experienced plumbers.

The content of the article:

Features of inserting bends into pipes

There are different types of plastic pipelines. Some are used to supply water, others to drain it.

There are public highways, and there are personal intra-house and intra-apartment networks. And each option has its own nuances of performing the work.

In order to crash into the general centralized system and not get into trouble with the law, it is necessary to undergo preliminary approvals.It is best to delegate the signing of all the necessary papers and the insertion work itself to a specialized organization. This will make life much easier.

But no one is stopping you from cutting into a plastic pipeline inside an apartment or private house. This can be done almost anywhere. You just need to follow the basic rules and not overload the system with an abundance of plumbing fixtures.

The water pressure in the water supply must be sufficient for all appliances and all users. A sewer pipe can only accept the volume of wastewater for which it was originally designed.

There are several types of plastic pipes:

- "PP" – polypropylene;

- "PE" – polyethylene (most often HDPE);

- "PVC» – polyvinyl chloride;

- "PEX" – made of cross-linked polyethylene;

- "REH-AL-REH" – metal-plastic.

Some of them are recommended for use for wiring hot water supply and heating systems, while others only for supplying or discharging cold water. Tapping technologies for all plastic pipes are largely similar.

The differences relate to the methods of connecting them to fittings and to each other in cases where an additional element is inserted into an existing pipeline.

All techniques for inserting a branch into a plastic water supply can be divided into two groups:

- Cutting out a section of pipe and inserting a tee in its place.

- Cover for the pipe clamp (saddle) with outlet pipe.

The first method involves performing welding work with a special soldering iron for plastic or using clamping fittings.

In the second case, the presence of the superimposed part is sufficient. It is simply put on the pipe and tightened mechanically with bolts or applied to a plastic surface and welded to it using built-in heating coils.

Insertion options

The most reliable technology for inserting into a plastic water pipe is the method of inserting a tee into it. In fact, this is a normal installation of a branch using standard fittings. First, a section is cut out of the pipeline, and then a part with an outlet is installed in its place. However, this option is not always possible.

The use of overlays (clamps, saddles) simplifies the process of inserting into the water supply system. And if he is under pressure, then this is the only possible option. To install the tee, the water will have to be completely drained from the plastic pipeline, but for insertion using special saddles this is not particularly necessary.

Method #1 - tee or manifold

The main problem with any method of tapping into a water supply system is water pressure. It's best when it's covered. Then there will definitely be no splashes during the work, which is simply dangerous, since you have to work with power tools. Yes, and according to the rules, welding of plastic pipes must be done dry.

You can use the following as an inserted element to organize a branch:

- ordinary tee;

- a manifold for connecting several outlet pipes.

- a pre-prepared piece of pipe with a soldered outlet.

The end with the outlet pipe can be threaded or soldered. The choice of fitting type depends on types of plastic and the type of installation of the entire piping system.

If the water supply system is initially made in a collapsible version, then the insertion into it should be made with a threaded connection. And if the entire pipeline was carried out welding with an electric soldering iron, then it is better to insert into it in a similar way.

The technology for inserting a tee is as follows:

- The water is shut off and completely drained from the system.

- A pipe cutter is used to cut a section of pipe to size so that an additional fitting can be connected in its place.

- Installation of the tee using a soldering iron (for HDPE and polypropylene) or glue (for PVC).

- Installation of a shut-off valve on the outlet.

After installing the tap on the created branch, further work can be performed with the water turned on. When inserting a branch, plastic pipes can be welded end-to-end or into a socket. Both options are acceptable.

If getting to the water supply with a soldering iron is problematic because it is close to the wall, you can use collet clamps or press couplings. To do this, first prepare a section of pipe with a welded outlet, and only then it is inserted into the place of the cutout in the water supply.

Insertion into a metal-plastic pipeline is made using a threaded (compression) fitting:

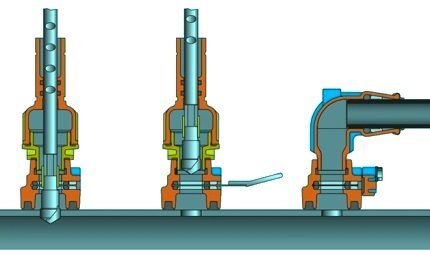

Method #2 - electric welded saddle

An overhead saddle on a pipe is understood as a part of a water supply system, which is intended for organizing branches from the main line.

This element greatly simplifies the installation of branching units and does not imply a violation of the end-to-end integrity of the pipe product. To make a branch in a plastic pipe at the insertion point, only drill a hole of the required size.

A regular saddle is fixed to the pipe with clamps and bolts. Its electric-welded counterpart has built-in heating coils in its design. When voltage is applied to them from the electrical network, these elements melt the plastic, which, after cooling, forms a reliable connection between the fitting and the water supply.

The technology for installing an electric welded saddle is based on electrodiffusion welding. Moreover, all heating elements are already built into its body at the factory.

You just need to connect them to the power supply for a few minutes. In terms of the welding process, this resembles the method using a soldering iron-iron, only in the case of a saddle, everything is already assembled in it.

A similar overlay is intended for inserting into HDPE pipes. It is polyethylene that, when heated, first transforms into the desired elastic state and then hardens without loss of strength characteristics. As a result, the plastic of both welded parts is combined into a single mass that is difficult to break.

After cooling, the saddle and pipe become an indivisible whole. Such a connection can withstand a water pressure of 16 atmospheres, which is more than enough to install water supply in an apartment or cottage. Electric welded saddles come with or without a built-in cutter - the first option is designed for work on pressure pipelines without shutting off the water.

Installation of such a fitting is extremely simple. It consists of one or two parts. In the first case, it is simply an overlay on the pipe from above, and in the second, a clamp is also connected to it from below for greater reliability. This saddle simply needs to be installed on the desired section of the water supply and glued by applying an electric current to it.

After the plastic has hardened, all that remains is to drill a hole in the line through the pipe and connect a hose or pipe to the outlet to the plumbing fixtures to be connected. Diameter plastic pipeline and the embedded bend can be very different. You just need to choose the right size pad.

Drilling a hole is done with a thick drill or an annular cutter. The main thing here is not to press too hard on the plastic pipe so that it does not crack.

If the cutter is already in the saddle, then just turn it with a wrench and then remove it from the drilled hole. Then all that remains is to connect the outlet water conduit - and the branch is ready.

Method #3 - crimp clamp (overlay)

In addition to the electric welded saddle, there is a simpler analogue - an overhead clamp. It consists of two separate parts bolted together. One to put on top of the plastic pipe, and the second from below to pull the top part.A sealing gasket is additionally inserted between them to prevent leaks.

Typically, the upper and lower overlay parts exactly match the dimensions of the pipe. But there are also universal clamps, in which the top is made small, and instead of the bottom there is a metal strip for a tie.

Outwardly, they resemble repair analogues for connecting with a hose or closing fistulas. Only in the upper part do they have a pipe for connecting the outlet.

Clamps for inserting into a plastic pipe are:

- with shut-off valve;

- with built-in cutter and safety valve;

- with a flanged or threaded end made of metal;

- with a plastic end for soldering or gluing.

To make an insertion, the clamp is put on the pipe and secured to it with nuts or bolts, depending on the design. Afterwards, drilling is carried out through the existing outlet pipe. And then the branch itself from the main is connected.

It is not recommended to drill a pipe without installing a clamp or saddle on it. You can make a mistake with the drill diameter and drilling point. It is best to do this through the branch pipe of the fitting already installed for the branch. So the drill will definitely be slightly smaller in size than the internal section of the embedded outlet and will be installed exactly where it is needed.

A compression fitting is placed on a metal-plastic pipe using press pliers:

The nuances of working on a water pipeline under pressure

For tie-ins into the pressure pipeline Electric-welded saddles and clamps with a built-in cutter are used. It is located in a special sealed nozzle housing. To drill into plastic, it is often enough to turn it with a hex key. But there are also models for a drill.

Some similar designs have a built-in valve. Then, after drilling is completed, the cutter is raised, the valve is closed, and the attachment with the drill is removed. Instead, a drain pipe is installed.

However, there are also products on sale with a discharge pipe, which is directed sideways from the drill (parallel or at an angle to the connected water supply).

The use of linings with an internal cutter allows you to cut into any water pipes. It doesn't matter whether they are under pressure or not. But such attachments are much more expensive than conventional clamps and saddles.

They greatly simplify the insertion process, but you will have to spend money on them. At the same time, in terms of the tightness of the resulting connection, they are neither superior nor inferior to standard solutions.

Conclusions and useful video on the topic

There are many nuances in connecting a branch to a plastic pipeline. There are different types of plastics, fittings in design, and insertion methods. To avoid serious mistakes, we recommend that you watch the videos below on this topic.

Video #1. Tapping into a HDPE pipe under pressure using a saddle with a cutter:

Video #2. Features of installation of an electric welded saddle:

Video #3. The nuances of inserting into a polyethylene water supply:

It's rare to cut into existing plastic plumbing. But sometimes you need to change pipes, install water meters, or simply connect additional plumbing. There are several different types of fittings and tapping technologies available for this purpose.

For any case, there is an optimal option so that you can carry out the installation yourself. It is necessary to entrust these works to professional plumbers only in the situation of connecting to a public water supply, where preliminary approvals are required.

Please write comments in the block located under the article test. Tell us how you made the insertion into the polymer pipe with your own hands. Share information useful for site visitors, ask questions, post posts with your opinion and photos on the topic.