Advantages and disadvantages of ½ inch three-way ball valves - expert advice

For most consumers three-way ball valve ½ looks like a technical oddity. But more than half a century has passed since the invention of the device. Compared to a conventional valve, the three-way valve is better known to specialists involved in heating design.

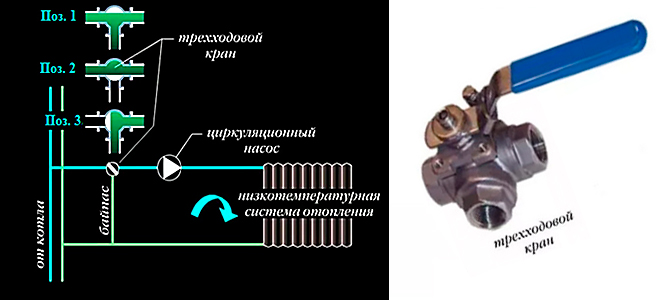

If a conventional ball valve can be used to shut off or resume the flow through pipes, then with the help of a “tee” it is possible to redirect and redistribute the flow, without creating additional resistance for the injection pump.

A three-way ball valve is used for flexible balancing of flows of moving liquid, gas or even a vapor-gas mixture. This may be a division into two flows (with different intensities) or redirection of part of the liquid along other routes.

The content of the article:

What is a ½ inch three-way ball valve?

Before use heating systems you have to select the flow of hot water through each branch of radiators, underfloor heating system, and boiler heat exchanger. This can be done using replaceable washers or using a ½-inch three-way valve.

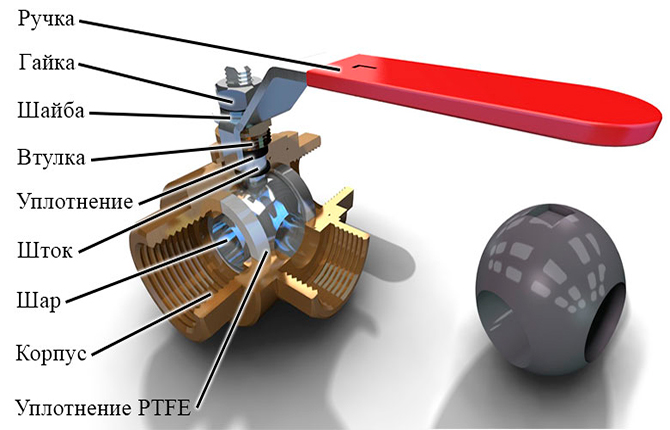

What does the part consist of:

- Brass body. Like a regular ball valve, but with an additional threaded pipe for a coupling or drive. Some models of three-way ball couplings are made of stainless steel.

- Inside the body there is a ball with flow holes - this is the central element for controlling the flow of water.The ball is mounted on an axis and can be rotated through an angle of 90O or 180O, forming the flow part.

- Rotary rod with sealing gland, clamping nut and rotary handle. The latter also serves as an indicator of the position of the ball element inside the brass body.

- The most vulnerable part is the Teflon or fluoroplastic O-ring.

Budget models may have pure fluoroplastic rings, but high-quality three-way models have PTFE-based seals filled with fiberglass or graphite. In the first case, the “tees” operate under pressure up to 15 atm, water temperature up to 80 ℃. The body is made of brass, resistance to mechanical shocks and vibration loads is mediocre.

Valves with composite can be operated at pressures up to 20 atm, temperatures up to 120 ℃. The stainless steel body and the rotary rod are always additionally sealed with a fluoroplastic-4 ring.

Three-way valves of budget and brand quality differ not only in their performance characteristics. The fluoroplastic seal of the “state employee” is easily erased from microparticles of rust and sand. At high temperatures, from 90 ℃ and above, the ring loses its original shape and the ball element loses its tightness.

What to pay attention to

According to their layout, three-way ball valves are of vertical and horizontal type. For vertical models, the axis of rotation of the control rod coincides with the axis of the central or main pipe.

For horizontal models, the axis of the rod is perpendicular to the center line of the main entrance. Small models with ½, 1½ inch inlet connect to pipes using a coupling connection.Large cross-section parts are secured with flanges.

Classification by functions performed:

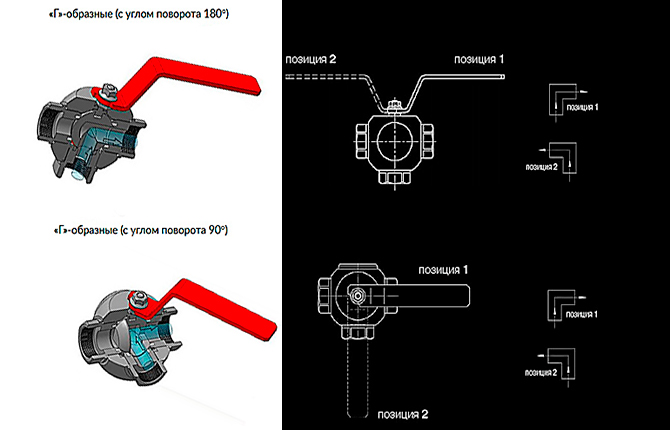

- Three-way switching devices. These include models in which the flow part inside the sphere is made in the shape of the letter “L”. There are two cylindrical channels connected at right angles. This is a switching type of device.

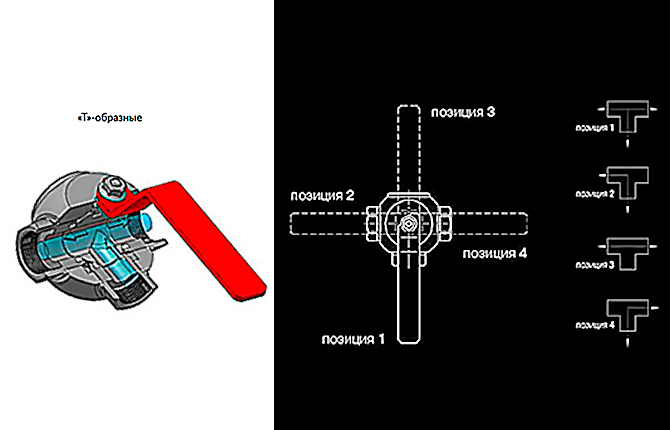

- Distribution devices. The cavity inside the ball is shaped like the letter “T”. The same pair of channels as in the previous case, but one of them intersects the sphere right through, the second connects to the cavity of the first at a right angle. This is a mixing type ball valve.

For both types of three-way valves, the connection is made using threaded fittings with a clamping nut. For ½ inch models you can even do without a nut. The left and right threaded pipes are turned out of the body; it is advisable not to lose the sealing rubber bands. Next, screw the FUM tape onto the thread of the drive, return the elastic band to its place, and wrap the assembly back into the body.

How L-models work

In a three-way ball valve with an L-shaped flow path profile, the working fluid enters through the central pipe. For vertical models, the ball element can be rotated on the rod at an angle of 180O. Thus, the supplied flow, depending on the position of the handle, will be stopped or directed in one of two opposite directions.

The rotary handle of a vertical three-way valve serves as a kind of indicator showing the direction of the outlet cavity of the ball element. If the axis of the handle is located perpendicular to the “input-output” line, then the L-faucet is closed.

For horizontal model L type, the rotation of the handle is limited to 90O. The flow of water or gas entering the tap can be redirected in one of the opposite directions.

These three-way valves do not have a “closed” position. The handle can be positioned parallel to the inlet pipe, the valve will be open, and the channel of the ball element will redirect the flow to the left channel. When turning the handle to the right 90O the ball will switch the water to the left channel.

Horizontal taps turn out to be more durable, but the position of the handle is uninformative. At the same time, three-way valves with a vertical axis are inferior in reliability, but are more informative.

The handle of the three-way valve must be marked with the letter “L”, as well as arrows indicating the direction of rotation of the handle.

How T-models work

The second option - a T-type three-way ball valve is classified as a distributing or mixing type of device. In appearance, the T-valve may not differ from the L-type three-way valves. Often, a faucet can be distinguished only by the letter “T” on the handle, so when purchasing a ball tee, it would be correct to check its operation and the correspondence of switching for different modes.

The T-scheme three-way ball valve has four operating positions:

- General mixing mode. The water flow from the middle pipe can be freely divided into two parts, redirected to the left and right fittings;

- Left port connection mode. The flow flows from the middle pipe only to the left fitting;

- Linear flow mode from left to right fitting, without turns. The third channel in the ball element is blocked by the “blind” wall of the housing;

- Mode of flow redirection from the middle pipe to the right cavity.

The reverse scheme of work is also possible.

The flows meet inside the ball element of the T-valve, and the direction of movement of the total flow will depend on the pressure in each of the cavities. In general, the three-way T-valve is considered more versatile. But for high pressures and water flows, the use of three-way T-patterns is undesirable, especially small sizes of ½ or ¾ inch.

Types of three-way ball valves ½

Manual control of the position of the ball element is usually used only for the initial balancing of heating systems. It is inconvenient to constantly tighten the valves, therefore, based on ½-inch three-way ball valves, several automatic and semi-automatic models have been developed that operate without human intervention.

For example, a mechanical ball valve-mixer that maintains the water temperature of the main hot stream by adding cold water from an additional pipe.

Body made of plumbing brass, cast. On the axis of the rod there is a platform with a handle, inside of which a bimetallic plate is folded. It is possible to regulate the response temperature of the three-way valve. It is used in shower faucets and boiled water cut-off machines for non-electric water heaters.

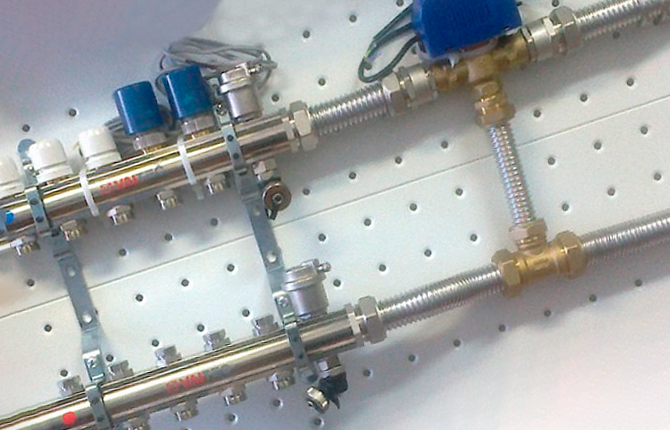

For heating systems, a three-way ball valve with an electric drive is often used.

Moreover, the hydraulic part, the body with a ball insert, is used from a conventional ½ or ¾ inch three-way valve. The handle is removed and the motor with gearbox is attached to the rod. The tap is controlled by an automatic water temperature control system.

Where is a ½ three-way ball valve used?

The three-way valve is used primarily in heating and hot water supply systems. For example, when installing a bypass on one of the radiator lines in a private house.We can argue about bypass designs, but in this case, a ball valve is great for blocking and redirecting hot water.

The idea is to temporarily turn off radiators in unheated or non-residential areas. The system must have a circulation pump, otherwise the batteries can defrost.

Often homeowners do not close the three-way valve completely, believing that a small amount of heat in the radiators of an unheated room will prevent the system from defrosting. Accordingly, the circulation pump can be abandoned.

This is not quite the right solution for two reasons:

- If the tap is not closed, most of the heat will be lost on the first heating radiator. The rest will remain cold.

- Even with the three-way L-cock completely closed, a small amount of warm water will enter the disconnected heating circuit due to leaks. But in this position, the fluoroplastic seals will be reliably protected from erosion.

The circulation pump at low speeds will accelerate the water and prevent it from freezing in the radiator, regardless of their number in the room.

Three-way taps are also used in hot water supply systems in cases where a water heater is also connected to the pipe.

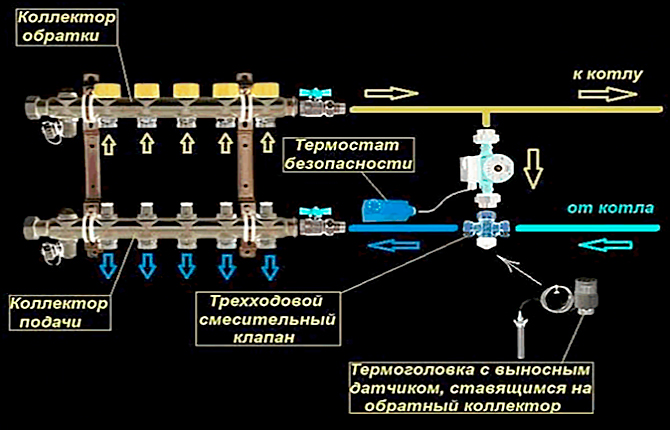

A three-way ball valve is often used to regulate the amount of energy supplied by the boiler to water heated floor. Typically, the heating system heats the floor faster than the air in the room. Therefore, the hot coolant in the floor pipes is deliberately cooled by mixing a small amount of return water.

The process is implemented using a three-way ball valve with a temperature sensor.

What are the advantages and disadvantages of three-way ball valves ½

If a three-way ball valve lasts a long time, then it makes sense to look at the condition and degree of contamination of the ball. Dirt and rust residues in water can be enough to damage the chrome surface.

Most budget three-way valve balls are made of low-alloy steel with a chrome finish. After only a year of use, the chrome peels off, and sharp surfaces cut off the soft fluoroplastic like a knife.

Damage to the seal leads to increased leakage through the ball tee valve. If according to GOST 10944 for a new three-way valve of ½ inch, a leakage of up to 20 cm is allowed3 per minute at 15 atm, then without a filter the leakage can triple in a year. Therefore, any ball valve, especially a ½-inch size, must be used in a heating system with a dirt filter.

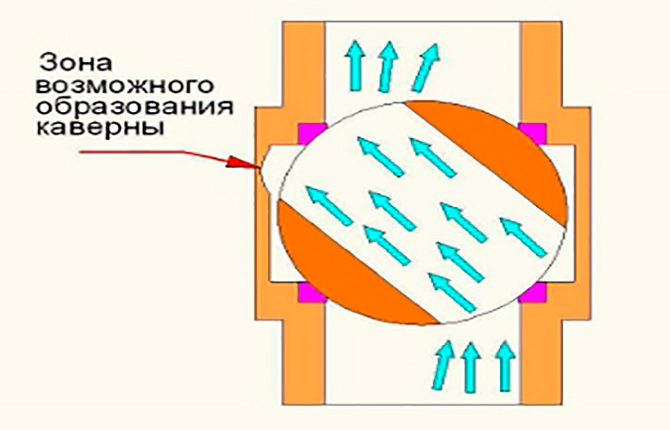

A three-way ball valve with a brass body must not be left in an under-closed, intermediate position. In this case, due to the sharp edge on the ball, a cavitation zone appears, destroying the body material. In theory, it is impossible to regulate the speed of water flow with a three-way tap. If the situation is hopeless, then it is better to use tees with a stainless steel or better bronze body.

The design of the three-way ½ ball valve is simple, reliable, and does not require special maintenance. In working position it does not create additional resistance to water flow. Budget models last 10-15 years. Branded ones, if installed correctly, can last up to 50 years.

Review of three-way ball valve: video

How long did the tee tap last in your home? What problems did you have with service and how did you get out of the difficult situation? Write about your experience in the comments.Save the article to your bookmarks so that useful information is always at hand.

Please advise how to deal with souring of the ball if the tap has been standing for several years. I'm afraid to turn it by force, I might break the rod. You won't be able to disconnect the connectors either. Experts advise disassembling the rod and injecting a little VDshka. I don’t know, maybe just replace the three-way valve with a new one?

I should have thought earlier; before installation, the chrome-plated ball element is treated with hot glycerin if the water is potable. In other cases, liquid pharmaceutical Vaseline, heated to 90-95°C in a water bath, is suitable. Branded three-way drives should absolutely not be touched.

There are special lubricants for servicing the ball valve, but they are expensive, so it is better to replace the tee with a high-quality one.