How to check the compressor of a split system air conditioner: diagnostic nuances + tips in case of breakdown

A significant component of a split system, of course, is the refrigeration compressor.It is thanks to this component of the technological scheme of a household or other machine that the cooling effect, as well as the effect of air humidification, is achieved.

If it happens that the compressor unit does not work for some reason, the split system essentially turns into an ordinary windmill. The desired effect from such a “mill” can no longer be obtained, and it’s time for the owner of the system to think about repairs.

However, in order to repair, you need to know how to check the split system air conditioner compressor for malfunction. This is exactly the question we will deal with in our article. We will also consider the module design, common types of faults and provide repair recommendations.

The content of the article:

Compressor module design

To begin with, briefly about the refrigeration compressor, as a module that forms part of the air conditioner. This equipment belongs to electromechanical devices, the distinctive feature of which is the complete sealing of the internal contents.

That is, in case of any mechanical (electrical) malfunctions, you cannot simply take and disassemble such a device, like many others, in order to get to the faulty unit. Everything is much more complicated here. In some cases you will even have to perform dismantling the split system.

That is why, in case of serious malfunctions, it is easier to replace a split system refrigeration compressor with a new one rather than try to repair it.

Generally speaking, the mechanical design of a refrigeration compressor resembles that of a traditional air compressor.

The machine also contains a connecting rod and piston system, although often of a rotary type, bearing units, and a valve system. But all this is contained in a hermetically sealed metal case.

There, inside the housing, the electric drive is mounted. The drive system is made in such a way that the winding of wires, which does not have air cooling, receives cooling from the working refrigerant - freon

This fairly effective method of internal cooling ensures the longevity of compressor motors. In practice, malfunctions of electric motors are observed, but quite rarely.

Signs of a compressor malfunction

It should be clear that when the split system is not able to provide the specified temperature, this factor may indicate that the compressor is not working.

In addition, the operation of the air conditioning compressor unit is clearly determined by the characteristic noise effect created by the refrigeration unit.The noise of the equipment cannot be said to be strong, but when the unit is operating, it can be heard reliably.

By the way, again, based on the noise level, some types of defects in the compressor machine are determined. So, if an increased clicking or grinding sound is noted during operation, most likely, wear or damage to the valves can be detected.

With such a malfunction, the performance of the compressor drops sharply, and the body of the device becomes very hot. Ultimately, the internal thermal relay, machine operation is blocked.

Often there is a situation where almost immediately after starting the compressor, its operation stops. However, the device itself is actually intact and functional.

The cause of the defect in this situation is usually a lack or overfilling of the refrigerant circuit. An emergency stop is provided by a thermal relay, which, by the way, can also fail.

Finally, the owner of a split system may be faced with a working moment - when the compressor unit simply does not start. At the same time, the air conditioner is quite functional in terms of all other functions.

The compressor does not give rise to any evidence of defects—outwardly it looks intact and unharmed. The traditional reason for this option, as a rule, is the inoperability of the starting capacitor with a capacity of 10 μF or more.

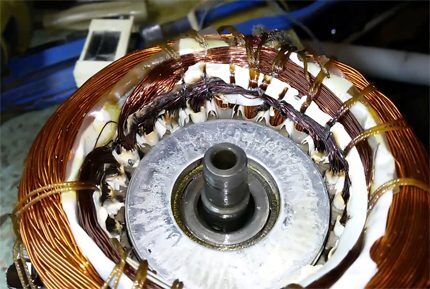

The most severe and practically irreparable defect of a split system compressor is an interturn short circuit in the stator windings of the drive motor. True, we should pay tribute - in modern designs of hermetic compressors such a malfunction rarely occurs.

Checking the device depending on the defect

Let's consider the possible actions of a mechanic or split system user, taking into account all the faults noted above.

But first you should take note of the following points:

- Such equipment is serviced by specialists. We talked about cleaning the split system yourself Here.

- The system is filled with chemically harmful substances.

- The device operates from a high-potential network.

- Electrical, electronic and mechanical knowledge is required.

- There is a danger of harm to health.

A calm, reliable and qualified way to check the system is, of course, to turn to professional technicians.

However, the possibility of using personal skills and abilities at your own peril and risk is not excluded. For the second option, we will consider ways to check equipment for malfunctions.

Problem #1 - high level of mechanical noise

So, if a machine makes increased noise that is not typical for normal operation, we can state with high confidence that the internal components are destroyed.

These can be bearing units, valve group parts and others. In such cases, the only possible option is to replace the unit.

Increased noise can also be observed due to excess refrigerant charged into the system. However, in this case, the nature of the noise is clearly different from mechanical noise, and after a short period of operation, the compressor is usually turned off by the automatic system according to the high pressure parameter.

Checking for these two options is accompanied by the following actions:

- Connect the pressure gauge station to the pressure side.

- Close the system tap on the circuit line.

- Monitor pressure readings.

With faulty valves, the noise level usually increases, but the pressure does not actually change or changes only slightly. If the bearings are faulty, an increase in noise will be accompanied by an increase in pressure.

An excessive amount of refrigerant in the circuit will also show an increase in pressure with an increase in noise and subsequent shutdown of the compressor by the automation system (pressure switch). We wrote more about the design of this unit, its operating principle, connection and adjustment in next publication.

Problem #2 - overflow or lack of freon

A “fault” of this kind is determined, again using a pressure gauge station. It is necessary to disconnect the split system from the network, wait a little, then connect the pressure gauge station and start the air conditioner. Observe the readings on the instruments.

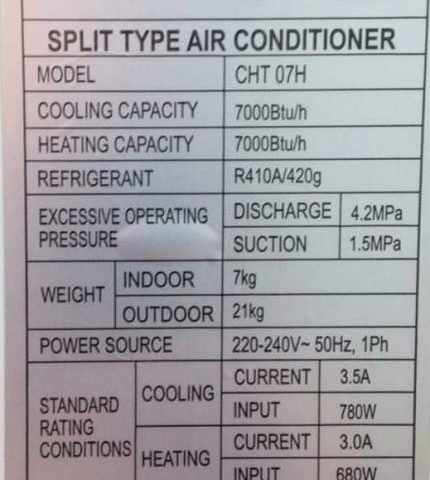

The operating pressure for a household split system of a specific configuration can always be determined by the technical tag (plate) attached to the body of the external module. There, on the plate, the boundary pressure parameters of the discharge and suction contour sections are indicated.

If the table limits are exceeded, this indicates that the system is clearly overfilled with refrigerant. However, the table gives only upper pressure values.

Therefore, the lack of refrigerant is determined somewhat differently. The average suction pressure for household split systems is approximately 4-6 Bar (ATI), depending on the configuration.

When the pressure indicator of the suction part of the circuit at the pressure gauge station is significantly less than the specified range of 4-6 Bar, this factor indicates a lack of filling.

This condition also affects the operation of the compressor, with abnormal noise and intermittent activation of protective systems.

Problem #3 - refrigeration compressor does not start

A common compressor-related defect in split systems is the complete lack of starting time for the refrigeration compressor. In this case, the system successfully switches to cooling mode, all automation devices work normally. Another issue is the condenser fan.

In this condition of the split system, the condenser fan shows somewhat unusual operation. When the air conditioner starts, the fan impeller begins to rotate, but almost immediately the rotation stops.

The indoor unit of the air conditioner continues to function when the compressor of the outdoor unit is not working.

This defect, as a rule, appears on systems that have successfully operated for several years (more than 5). And the reason for this behavior of the system is the starting capacitor connected to the power supply circuit of the compressor motor.

Diagnosing a faulty capacitor is easy. How to do this is below.

Problem #4 - turn-to-turn short circuit of the stator winding

How to determine such a malfunction is a far from ambiguous question. For example, when there is a short circuit of 2-3 turns in a short section, it is almost impossible to determine the defect without the use of a specific tool.

Other variations, when sufficiently distant sections are closed to each other, can, in principle, be determined by simply measuring the resistance of the working windings of the motor stator.

Typically, the winding where there is a “short” winding gives less resistance relative to other windings. However, an accurate motor diagram will be required.

Tips for repairing equipment

Internal defects of the split system compressor are corrected exclusively in professional workshops.At home, repairs of such complexity by the owner himself seem irrational, with an extremely low percentage of successful completion.

If the normal operation of the compressor is disrupted due to excess or lack of refrigerant, it is quite possible to solve the repair problem yourself.

In the first case (excess freon), it is enough to simply remove some of the gas from the system. In the second case, you need the opposite - recharge the system additional gas volume.

When the cause of the compressor inoperability is the starting capacitor, you should open the top cover of the external system unit, having first disconnected the machine from the power supply.

Remove the capacitor and check with a tester in resistance measurement mode (mOhm), alternately touching the working terminals with the probes. A non-working capacitor will not show the discharge effect. This is the reason for replacement.

Conclusions and useful video on the topic

This video was filmed by specialists and may be useful to those who are eager to repair a split system compressor that has serious damage.

The operation of modern split systems shows quite long-term operation without the need for repairs. Moreover, if we are talking about serious defects, such as interturn short circuits or mechanical wear.

Simple faults can be repaired quite simply, and in the case of complex defects, replacing the split system with a new one seems like a reasonable solution. Serious repairs will force you to spend the same amount of money as required purchasing a new split system.

Would you like to share compressor diagnostic methods that we did not talk about in this material? Write your comments, additions and recommendations in the block below.

If you are trying to independently figure out the reason for the breakdown of your split system and find yourself in a difficult situation, do not hesitate to ask for advice from our experts and other site visitors in the comments to this article.

I have the following problem - the compressor does not start, and after about 5 minutes the machine to which the air conditioner is connected knocks out. In this case, the voltage approaching the outdoor unit is zero, and when one of the compressor wires is disconnected, it is normal. But both the compressor and fan casings are cold. What could be the problem? The resistance of the compressor windings is approximately 2 ohms.

Hello! The air conditioning compressor (outdoor unit) does not start working immediately when cooling starts, but after 2-5 minutes. This is normal and this is how all compressors are designed, and the higher the power of the split system, the more time passes between its turning on and the start of the fan.

When the fan starts, the load on the electrical wiring increases sharply, as evidenced by the 2 Ohm resistance on the windings, which knocks out the RCD (plugs). Perhaps the issue is a low-quality or outdated machine. Try replacing it, and if the problem persists, then the problem must be looked for in the wiring or socket.

To check them, you can do the following: instead of the air conditioner, connect an energy consumer of the same power and if the RCD trips, then the reason is definitely in the wiring.

Please note that this operating mode has a negative impact on the operation of the external unit. It is necessary to first eliminate the malfunction and then operate the split system.

Does the compressor turn on with the fan?

The compressor does not turn on at the same time as the fan. There is a temperature sensor on the external unit on the exchanger, so it gives the removal command.

Good day. When you turn on the air conditioner, it turns on and starts blowing, the compressor and fan turn on after 3-4 minutes, sometimes together, sometimes first the compressor and then the fan.

After working for some time, especially if the sun shines on the external unit (outside), the compressor turns off, although power from the internal unit is supplied through a relay, the fan spins, but the compressor is silent. If in the evening, when the sun is not shining on it, the compressor turns on and works. It’s not very cold, the pressure is low (I can’t measure the high pressure, the fitting is only at low pressure) with the air conditioner running 5 bar.

Thank you very much in advance for your advice.

Hello. When turned on, the air conditioner first cools, but not much, then after 10 minutes it stops with a current overload error. What is the reason? When there is a short circuit or short circuit of the windings, it should immediately give an error.

Rinse the external unit of the air conditioner, it is on your street, I use a car wash (in common parlance a Karcher) - there is a danger, do not wash at high pressure and do not bring the spray close to the honeycombs, although they are easy to clean, first disconnect the air conditioner from the network completely and not remote control Remove the top cover, it is on the screws, then the front cover, lifting it up.Wash from the side of the fan, if pieces fly off, you are on the right track, good luck. An air conditioner is not a refrigerator, but a vacuum cleaner and needs to be cleaned every year. Measuring pressure for overheating is also bad if it is on the sunny side, but not fatal.

It is normal that the compressor and fan turn on after 3-4 minutes. Usually the fan then the compressor, depending on the ambient temperature. If you have R410A freon, then the pressure in the system when the compressor is running at low pressure should be about 7 or 7 kg. If you refilled the air conditioner, you may have allowed air to enter the system, then it is better to drain the freon, evacuate it and refill it with a new one by weight. How many kg of freon is written on the plate of the outdoor unit on each air conditioner.

Hello. When moving from one store to another, we dismantled the air conditioner. Unfortunately, all the freon came out at the same time. When the air conditioner was installed in a new location, the compressor stopped turning on (the fan was running). We tried changing the capacitor, but it didn't help(.

Could the compressor not start because there is no freon in the system? Or should I refuel it first and then check it? Thank you.

Ruslan, of course you need to fill the freon, the protection will not allow you to start it without it, before filling it you should evacuate it thoroughly.

Be sure to vacuum it, and then add freon according to the instructions on the external unit.

And everything will work for you. There is no gas...

What should he squeeze?))))

Of course, without freon, your compressor will not start. You need to evacuate the system and fill in the required kg of gas and what kind.

It should not turn on if there is no freon; there is foolproof protection on many models. If you run it forcibly without freon or if there is insufficient amount of freon, you will ruin the compressor. To now refill the air conditioning system, you need to evacuate the air conditioner before dismantling it - first close the high pressure tap and after 1-2 minutes, close the low pressure tap, you have saved some of the freon. Then we just unwind the drives and subsequent dismantling. In general, we hire a specialist and he will do everything for you, unless of course you need a working air conditioner, otherwise you can play around with it, there are a lot of interesting things, copper will generally be used for metal.

When turned on, the air conditioner blows at room temperature, the indoor unit works - it is completely cleaned! The outdoor unit turns on in cooling mode - the fan is running, I don’t know the compressor! Tubes with freon from the outdoor unit do not change in temperature! Likewise, nothing changes with heating - the air is at room temperature! Please tell me what could be the problem?!

You definitely need to see if the compressor is working. If not, then most likely there is not enough freon. And perhaps there is a leak somewhere in the system. How many years has your air conditioner been running and if it’s been three or four years, then maybe there’s a tiny leak, you can just add freon, i.e. top up the pressure and it will work Almost the same amount of time will still last until the next refueling, but if it doesn’t work for long, then look for a leak, solder it and refill it.

The situation is similar. The fan spins, but the compressor does not start. The condenser was changed a year ago. The split is 16 years old. Will refilling with freon change the situation or do I need to install a new one?

Hello guys! The following problem happened. One day, when I came home from work for lunch, I saw that the internal unit of the split was very much covered with an ice coat and even bent and opened the lid where the filters were located. When I approached the control panel, I could clearly hear how the compressor (external) was working. I turned off the system completely and from the outlet too. After thinking that the filter was clogged, I completely cleaned the indoor unit. And after that the split does not start at all, or rather it starts but the compressor is silent. I called different repairmen to the house, but they all unanimously insist that the compressor has burned out and needs to be changed, but they don’t want to listen to the fact that maybe something inside the compressor is not working. Well, I have a friend from another city who has been doing splits for 10 years. I was told that the compressor did not burn out, but simply jammed and it needs to be removed from the wedge using a powerful capacitor and connected to other terminals on the compressor. Please tell me if this can be so and how you can fix it yourself at minimal cost. Our technicians all have the same answer: change the compressor, but for some reason I don’t believe them. Answer please!!!

Good afternoon. Tell me what could be the problem? The split is installed directly through the machine. The split does not turn on, the automatic switch goes out

Greetings. The split worked and cooled. Outside the window is +46. Outdoor unit on the sunny side. During operation it began to emit a hum and some vibration. After a while the hum disappeared, but along with the cold. At the same time, the fan rotates, the blades are intact. What could be the reason?

Good afternoon. Please tell me how can I start an air conditioning compressor without refrigerant lines connecting the external and internal units? The question arose in connection with the repair of the external board, with the air conditioner dismantled.

Hello. The multisplit displays error f1, the compressor does not start. The technician says to change the compressor.

I asked the guys to check if the external unit of the air conditioner was working. The guys directly tried to connect the unit to the network. We didn't use a plug, we just tried two wires into the socket. The wire immediately sparked and they immediately unplugged it from the socket, saying that the compressor was shorting out. Are they right or should I have used a fork?

Good afternoon. When the compressor is turned on, the window air conditioner makes a hum (but does not start), the light in the room dims... after 3-4 attempts it starts, but after 10 seconds. stops.

Good afternoon. For an accurate answer as to what exactly the malfunction is, you need to contact a specialist.

Split system NewTek 65D09. New, it worked perfectly for a week, but there was a lot of noise from the outdoor unit. Without disconnecting the tubes, I installed anti-vibration pads under the unit mount. Two days later I discovered that the air conditioner was not cooling. Only the fan was working in the outdoor unit. So the system worked for a day. At the same time, the compressor is very hot to the touch. I checked the windings are intact, the capacitor is also rated. There was no R410A freon in the system. Question: can the compressor be damaged under such circumstances?

Hello! When the Mitsubishi air conditioner starts, the fans of the external and internal units turn on, but no cooling occurs.The fan circulates the air in the room. After half an hour everything turns off and won't turn on again. The indicator flashes 5 times. Shows an error. The compressor doesn't seem to turn on. I checked the voltage to the compressor but for some reason. The technician installed the air conditioner, turned it on and left. He said that the cold would gradually get worse. But he switched off after half an hour. Either he realized that there was a problem with the compressor. Pretended that the air conditioner was working. I just connected the fans. How to check the operation of the compressor? Judging by the contacts of the machine, the supply wire is connected to terminal 3, the wire to the fan comes from it, and the compressor wire is connected to terminal 2