Thermal relay: principle of operation, types, connection diagram + adjustment and marking

The durability and operational reliability of any installation with an electric motor depends on various factors. However, current overloads significantly affect the service life of the motor.To warn them, a thermal relay is connected, protecting the main working element of the electric machine.

We will tell you how to select a device that predicts the impending emergency situations when the maximum permissible current values are exceeded. The article we presented describes the principle of operation, provides varieties and their characteristics. Advice on connection and proper configuration is given.

The content of the article:

Why are protective devices needed?

Even if the electric drive is properly designed and used without violating the basic operating rules, there is always the possibility of malfunctions.

Emergency operating modes include single-phase and multi-phase short circuits, thermal overloads of electrical equipment, jamming of the rotor and destruction of the bearing unit, phase loss.

When operating under high loads, an electric motor consumes a huge amount of electricity. And when the rated voltage is regularly exceeded, the equipment heats up intensely.

As a result, the insulation quickly wears out, which leads to a significant reduction in the service life of electromechanical installations. To eliminate such situations, a thermal protection relay is connected to the electric current circuit. Their main function is to ensure normal operation of consumers.

They turn off the motor with a certain time delay, and in some cases instantly, to prevent destruction of insulation or damage to individual parts of the electrical installation.

In order to prevent a decrease in insulation resistance, protective shutdown devices are used, but if the task is to prevent cooling failure, special devices with built-in thermal protection are connected.

Design and principle of operation of the TR

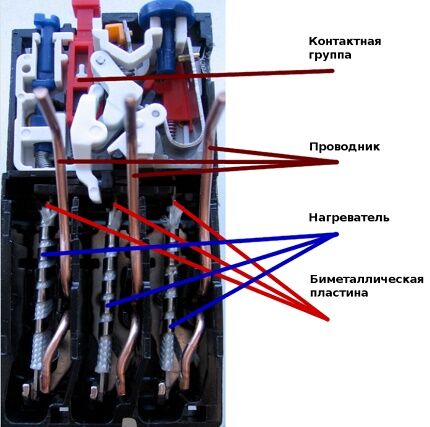

Structurally, a standard electrothermal relay is a small device that consists of a sensitive bimetallic plate, a heating coil, a lever-spring system and electrical contacts.

A bimetallic plate is made from two dissimilar metals, usually Invar and chromium-nickel steel, firmly joined together by a welding process. One metal has a higher temperature coefficient of expansion than another, so they heat up at different rates.

During a current overload, the unfixed part of the plate bends towards the material with a lower coefficient of thermal expansion. This exerts a force on the contact system in the protective device and activates shutdown of the electrical installation in case of overheating.

Most models of mechanical thermal relays have two groups of contacts. One pair is normally open, the other is permanently closed. When the protective device is triggered, the state of the contacts changes. The first ones close, and the second ones become open.

The current is detected by an integrated transformer, after which the electronics processes the received data. If the current value is currently greater than the setting, the pulse is instantly transmitted directly to the switch.

By opening the external contactor, the relay with an electronic mechanism blocks the load. Self thermal relay for electric motor installed on the contactor.

The bimetallic strip can be heated directly - due to the influence of the peak load current on the metal strip or indirectly, using a separate thermoelement. Often these principles are combined in one thermal protection device. With combined heating, the device has better performance characteristics.

Basic characteristics of a current relay

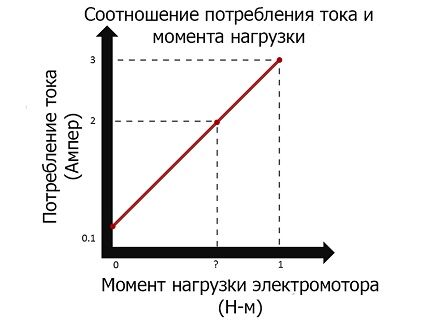

The main characteristic of a thermal protection switch is the pronounced dependence of the response time on the current flowing through it - the greater the value, the faster it will operate. This indicates a certain inertia of the relay element.

Directed movement of charge carrier particles through any electrical device, circulation pump and an electric boiler that generates heat. At rated current, its permissible duration tends to infinity.

And at values exceeding the nominal values, the temperature in the equipment increases, which leads to premature wear of the insulation.

The rated load of the motor itself is a key factor determining the choice of device. An indicator in the range of 1.2-1.3 indicates successful operation with a current overload of 30% over a time period of 1200 seconds.

The duration of the overload can negatively affect the condition of electrical equipment - with a short-term exposure of 5-10 minutes, only the motor winding, which has a small mass, heats up. And if it lasts for a long time, the entire engine heats up, which can lead to serious damage. Or it may even be necessary to replace burned-out equipment with new ones.

In order to protect the object as much as possible from overload, you should use a thermal protection relay specifically for it, the response time of which will correspond to the maximum permissible overload ratings of a particular electric motor.

In practice, collect voltage control relay for each type of motor is impractical. One relay element is used to protect motors of various designs. At the same time, it is impossible to guarantee reliable protection over the full operating interval limited by the minimum and maximum load.

Therefore, it is not absolutely necessary for the protective device to react to every, even slight, increase in current. The relay should turn off the electric motor only in cases where there is a danger of rapid wear of the insulating layer.

Types of thermal protection relays

There are several types of relays to protect electric motors from phase failure and current overloads. They all differ in design features, the type of MP used and their use in different motors.

TRP. Single-pole switching device with combined heating system. Designed to protect asynchronous three-phase electric motors from current overloads. TRP is used in DC power networks with a base voltage under normal operating conditions of no more than 440 V. It is resistant to vibrations and shocks.

RTL. Provide engine protection in the following cases:

- when one of the three phases fails;

- asymmetry of currents and overloads;

- delayed start;

- jamming of the actuator.

They can be installed with KRL terminals separately from magnetic starters or mounted directly on the PML. Installed on standard type rails, protection class – IP20.

PTT. They protect asynchronous three-phase machines with a squirrel-cage rotor from a delayed start of the mechanism, prolonged overloads and asymmetry, that is, phase imbalance.

TRN. Two-phase switches that control the start-up of an electrical installation and the operating mode of the motor. They are practically independent of the ambient temperature; they only have a system for manually returning the contacts to their initial state. They can be used in DC networks.

RTI. Electric switching devices with constant, albeit small, electricity consumption. Mounted on contactors of the KMI series. Work together with fuses/automatic switches.

Solid State Current Relays. They are small three-phase electronic devices with no moving parts.

They operate on the principle of calculating the average values of engine temperatures, for this purpose constantly monitoring the operating and starting current. They are impervious to changes in the environment, and therefore are used in hazardous areas.

RTK. Starting switches for temperature control in electrical equipment housings. They are used in automation circuits where thermal relays act as components.

It is important to remember that none of the devices discussed above are suitable for protecting circuits from short circuits.

Thermal protection devices only prevent emergency conditions that occur during abnormal operation of the mechanism or overload.

Electrical equipment may burn out even before the relay starts to operate. For comprehensive protection, they must be supplemented with fuses or compact circuit breakers of a modular design.

Connection, adjustment and marking

The overload switching device, unlike an electrical circuit breaker, does not break the power circuit directly, but only sends a signal to temporarily shut down the facility in emergency mode. Its normally switched contact works as a contactor “stop” button and is connected in a series circuit.

Device connection diagram

In the relay design, there is no need to repeat absolutely all the functions of the power contacts upon successful operation, since it is connected directly to the MP. This design allows for significant savings in materials for power contacts. It is much easier to connect a small current in the control circuit than to immediately disconnect three phases with a large one.

In many schemes for connecting a thermal relay to an object, a permanently closed contact is used. It is connected in series with the “stop” button of the control panel and is designated NC - normally closed, or NC - normal connected.

An open contact with such a scheme can be used to initiate the operation of thermal protection. Connection diagrams for electric motors in which a thermal protection relay is connected may vary significantly depending on the presence of additional devices or technical features.

This will provide reliable protection against electrical equipment overloads. In case of unacceptable excess of current limit values, the relay element will open the circuit, instantly disconnecting the MP and the engine from the power supply.

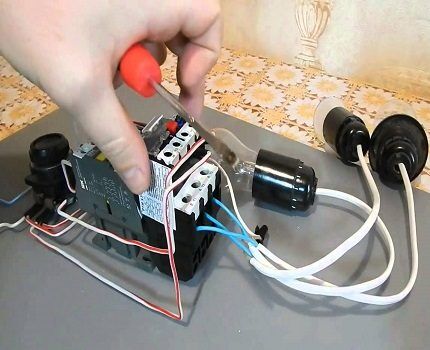

The connection and installation of a thermal relay, as a rule, is carried out together with a magnetic starter designed for switching and starting an electric drive. However, there are types that are mounted on a DIN rail or a special panel.

Subtleties of adjusting relay elements

One of the main requirements for electric motor protection devices is the precise operation of the devices in the event of emergency operation of the motor. It is very important to select it correctly and adjust the settings, since false positives are absolutely unacceptable.

Among the advantages of using current protection elements, one should also note a fairly high speed and a wide response range, and ease of installation. To ensure timely shutdown of the electric motor during overload, the thermal protection relay must be configured on a special platform/stand.

In this case, inaccuracy due to the natural uneven spread of rated currents in the NE is eliminated. To test the protective device on a bench, the fictitious load method is used.

A reduced voltage electric current is passed through the thermocouple to simulate the actual thermal load. After this, the exact time of operation is accurately determined using the timer.

When setting up basic parameters, you should strive for the following indicators:

- at 1.5 times the current, the device should turn off the engine after 150 s;

- at 5...6 times the current it should turn off the motor after 10 s.

If the response time is not correct, the relay element must be adjusted using the control screw.

This is done in cases where the rated current values of the NE and the motor differ, as well as if the ambient temperature is below the nominal one (+40 ºC) by more than 10 degrees Celsius.

The operating current of the electrothermal switch decreases with increasing temperature around the object in question, since the heating of the bimetallic strip depends on this parameter. If there are significant differences, it is necessary to further adjust the thermocouple or select a more suitable thermoelement.

Sharp temperature fluctuations greatly affect the performance of the current relay. Therefore, it is very important to choose a NE that can effectively perform basic functions, taking into account real values.

These restrictions do not apply to temperature compensated relays. The current setting of the protective device can be adjusted in the range of 0.75-1.25x from the rated current of the thermoelement. The setup is done in stages.

First of all, the correction E is calculated1 without temperature compensation:

E1=(Inom-Ine)/c×Ine,

Where

- Inom – rated motor load current,

- Ine – rated current of the working heating element in the relay,

- c is the price of the scale division, that is, the eccentric (c=0.055 for protected starters, c=0.05 for open ones).

The next step is to determine the E correction2 to ambient temperature:

E2=(ta-30)/10,

Where ta (ambient temperature) – ambient temperature in degrees Celsius.

The last stage is finding the total correction:

E=E1+E2.

The total correction E can be with a “+” or “-” sign.If the result is a fractional value, it must be rounded down to a whole number downwards/larger in magnitude, depending on the nature of the current load.

To adjust the relay, the eccentric is transferred to the resulting value of the total correction. A high response temperature reduces the dependence of the operation of the protective device on external indicators.

The adjustment of these indicators is carried out by a special lever, the movement of which changes the initial bend of the bimetallic plate. The operation current can be adjusted over a wider range by replacing the thermoelements.

Modern overload protection switching devices have a test button that allows you to check the serviceability of the device without a special stand. There is also a key to reset all settings. They can be reset automatically or manually. In addition, the product is equipped with an indicator of the current state of the electrical appliance.

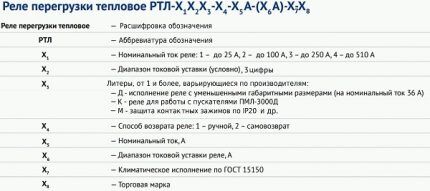

Marking of electrothermal relays

Protective devices are selected depending on the power of the electric motor. The main part of the key characteristics is hidden in the symbol.

You should focus on certain points:

- The range of setting current values (indicated in parentheses) varies minimally among different manufacturers.

- The letter designations for a specific type of execution may vary.

- Climatic performance is often presented in the form of a range.For example, UHL3O4 should be read as follows: UHL3-O4.

Today you can buy a variety of device variations: relays for alternating and direct current, monostable and bistable, devices with deceleration when turned on/off, thermal protection relays with accelerating elements, thermal protection relays without a holding winding, with one winding or several.

These parameters are not always displayed in the labeling of devices, but must be indicated in the data sheet of electrical products.

Familiarize yourself with the structure, types and markings of electromagnetic relays next article, which we recommend that you familiarize yourself with.

Conclusions and useful video on the topic

The design and principle of operation of a current relay for effective protection of an electric motor using the example of the RTT 32P device:

Proper protection against overload and phase failure is the key to long-term trouble-free operation of an electric motor. Video about how the relay element reacts in the event of abnormal operation of the mechanism:

How to connect a thermal protection device to an MP, circuit diagrams of an electrothermal relay:

Thermal overload protection relay is a mandatory functional element of any electric drive control system. It reacts to the current passing to the motor and is activated when the temperature of the electromechanical installation reaches its limit values. This makes it possible to maximize the service life of environmentally friendly electric motors.

Please write comments in the block below. Tell us how you selected and configured a thermal relay for your own electric motor. Share useful information, ask questions, post photographs related to the topic of the article.

If you have ever tried to repair a modern electric kettle, then you have certainly encountered a thermal relay. Most often, this is where the fault lies. The contacts burn out, the resistance increases and the relay begins to heat up. The contact plate melts the plastic base and hardens in it. There is only one option - replacing the entire relay. Otherwise the kettle will not turn on.

Everything is very clear and accessible. I’m studying to become an electrician, and this post really helped me write my thesis on this topic. Thank you very much author.

and the self-recovery in the video is implemented in such a way that the TR will not open the circuit... or am I mistaken?