Maintenance of split systems: cleaning, repairing and refilling climate control equipment yourself

In any climate zone, the issue of adjusting temperature and air humidity in residential and industrial premises is relevant. For this purpose, various climate control equipment is used. Split systems are one of the options for such devices. They are distinguished by their affordable price, stylish design and functionality.

Like any other equipment, they require regular professional maintenance. As a rule, it is produced by specialized specialists from various companies. But, in some cases, you can carry out maintenance of split systems yourself. Find out how to do this below.

The content of the article:

Split system design

Before you master the methods of servicing, repairing and refueling air conditioning equipment, you need to familiarize yourself with the features of its design.

A split system is quite complex equipment. It is divided into two main elements:

- external unit;

- indoor block.

The body of each block contains certain components. External part Split systems contain a fan, condenser, compressor, four-way valve, filters and piping system. Internal – fan, evaporator and air filter. Refrigerant circulates between the blocks: freon.

It moves through a pipeline system. During operation, equipment exists in two physical states: liquid and gaseous. A specific pipeline is designed for each freon state. They differ from each other in internal and external diameter.

If the operation of at least one element of the system is disrupted, this leads to significant equipment malfunctions. To avoid significant breakdowns, owners of such equipment are recommended to carry out maintenance at least once a year.

If the equipment is located on an industrial site, then the minimum number of preventive inspections should be twice a year.

Self-cleaning of equipment

Due to the fact that split systems pass a large volume of air through them every second, the occurrence of pollution is inevitable.

They are formed on the following structural elements:

- air filters;

- radiator/heat exchanger;

- ventilator

If you do not clean regularly, a layer of dirt will form on these elements. It prevents full air exchange, which causes a malfunction in the operation of the automation. In this case, users may experience insufficient cooling or its complete absence.

Cleaning and replacing filters

Air filters are in indoor unit. They are easily removed from the housing. Manufacturers recommend cleaning them directly every time you clean the room.

This can be done using a vacuum cleaner. The filter cloth is removed and thoroughly cleaned with a vacuum cleaner. Then the filters must be installed in their place.

But, since not all users perform this procedure, the filter becomes more clogged. If a vacuum cleaner does not help to completely clean the filter cloth, you must resort to manual cleaning.

The fabric is washed in warm water using gentle detergents or soap. You can also use specialized detergents designed to care for filters. Be sure to dry the fabric. After it dries, it is installed in its place in the structure.

If the filter has been cleaned extremely rarely or not cleaned at all for a long time, then it is best to replace it with a new one. This is due to the fact that the canvas is designed to trap the smallest particles in the air. As they accumulate, they damage the structure of the material.

Even thorough cleaning will not be able to restore it. By installing a damaged air filter in a split system, the user will not receive protection from air pollution.

In production, the removed filter can be cleaned using a compressor. Air under pressure is supplied to contaminated areas, thereby cleaning them.

Radiator and heat exchanger care

This operation can also be performed independently. The elements are located behind the air filters. Therefore, it is wise to combine filter and radiator care into one procedure.

The radiator and heat exchanger are combined into a single structure. Outwardly, it resembles a metal grill. You will have to clean it manually. A brush with plastic bristles will help with this. With its help, you can clean the device from dust, hair and other dry contaminants.

If there is a greasy film on the radiator, then you need to use a steam cleaner. By carefully directing a jet of steam into the contaminated area, you will be able to remove the film. Remaining dirt should be removed with a dry cloth.

It is advisable to dry clean the radiator at least once a month. This will help avoid costly repairs.

There is also a radiator grille on the external unit. Getting to it is usually problematic. It is advisable to clean it at least once a year. To do this, you need to remove the grille from the block body. It is secured with several bolts.

Next, you need to rinse it with warm water. You can use brushes with plastic bristles and a sponge. Or use chemicals that do not damage the paintwork. After cleaning, wipe the product dry and put it back in its place. You can combine this procedure with cleaning the fan.

Cleaning Fan Blades

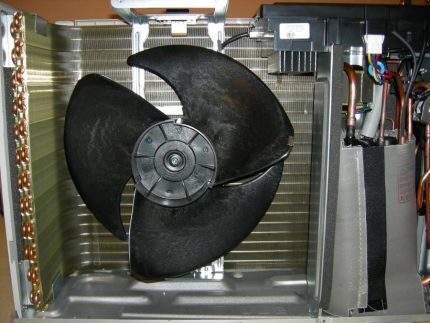

A lot depends on the fans in a split system. They supply air in the right direction. With their help, warm air is removed to the street and cooled air is supplied. Fans consist of DC motors and impellers with blades.

Fan contamination can reduce engine speed.This can cause it to overheat and quickly fail. Also, bulk contamination can damage and bend the impeller blades. In this case, the direction of air supply will change and the productivity of the split system will decrease even after cleaning.

Cleaning the fan is not very difficult. You just need to be careful so that water and cleaning fluid do not get on the control board and connectors.

Removing the housing cover and filters will reveal the fan. Its blades must be wiped with a damp cloth. You can pre-vacuum the blades if there is a lot of dust on them.

It is recommended to service the outdoor unit fan if there is easy access to it. If it is not there, then it is better to seek help from specialists.

Refilling the system with freon

Under normal operating conditions, refrigerant must be recharged no sooner than 18 months after purchase. This is due to the natural property of freon to evaporate. Evaporation occurs at pipeline joints or through microcracks in the material.

But the need to refuel the system may arise earlier. The following events can lead to this:

- mechanical damage to the pipeline;

- factory defects - failure of automation in production;

- non-standard installation of a split system - increasing the length of communication pipes;

- carrying out system repairs without subsequent refueling - for example, replacing a compressor.

These are the reasons why there may be a lack of freon in the system.It is also worth noting the fact that the refrigerant will evaporate even from equipment that has never been connected to the network. Therefore, you need to take this feature into account and pay attention to the production date of the equipment.

On average, the volume of freon in the system is reduced by 8% per year. A significant lack of refrigerant can lead to irreparable consequences: jamming of the compressor and its complete breakdown. Therefore, it is recommended to check the freon level once every year and a half and after each repair.

Stage No. 1 - preparatory work

You need to study the technical documentation of your split system. This is necessary in order to determine what type of freon is charged into the equipment and what is the optimal gas pressure in the system.

Next, based on the information received, you need to buy a refrigerant cylinder. The most commonly used brands of freon are R410A and R407C.

The first type of substance can be used to top up the system without pumping out the remaining freon. The second type of substance can be refilled with a split system only after complete removal of freon residues from the pipelines and compressor.

To work you will need the following:

- freon of the required brand;

- a pressure gauge that will be connected to the cylinder and split system;

- wrench of the correct size.

There are several methods for refilling a split system with freon. The most practical method for self-implementation at home is the method of monitoring the pressure in the system. Most often it is used by professionals.

To replace the refrigerant, you will need free access to the outdoor unit.It has two outlets for replacing freon. Gas is pumped and pumped through them.

Stage No. 2 - replacing freon

Work order for replacing refrigerant can be divided into the following stages:

- Turning on the split system in maximum cooling mode.

- Connecting a pressure gauge to the outdoor unit.

- Removing residual gas from the system - if necessary.

- Setting the cooling temperature to the middle position.

- Portional supply of gas to the system, with verification of readings on the pressure gauge with factory pressure readings.

- Stopping the freon supply at the moment when the pressure has returned to normal.

- Disconnecting the hose and pressure gauge from the manifold.

- Tightening the leads for refueling.

- Checking the operation of climate control equipment.

If everything is done correctly, the equipment will not need to be repeated for at least another year and a half.

If there is a need to top up too often, this indicates a refrigerant leak from the system. How to fix this will be discussed below.

Self-repair of split system

It is not advisable to repair such equipment yourself. To fully correct a malfunction, you need to know not only the operating principle of all structural elements, but also own certain tools.

You also need to remember that the split system operates on mains voltage. And it is dangerous to health and life. Therefore, if you do not have confidence in your abilities and skills, then it is better to entrust the diagnosis of faults and their elimination to experienced specialists.

In order to understand what measures you can take on your own to repair the split system, you need to know the main causes of malfunctions. Some of them will be discussed later in the article. But a qualified specialist can most accurately and quickly identify problems and damage.

The device does not turn on

The reasons for this may be the following:

- dead battery in the control panel;

- damaged outlet or circuit breaker;

- damaged network cable;

- lack of voltage in the network or its shortage/excess.

The easiest way is to replace the batteries yourself. You can check the outlet with another working network device. If damage is noticed on the cable, you must immediately stop using the device and replace the cable with a new one of the same cross-section.

The voltage in the network must be checked with a multimeter or AC voltmeter. If the voltage is significantly lower or higher than 220 V, then you need to think about purchasing additional equipment to normalize the voltage - stabilizers or converters.

The equipment does not cool well

The most common causes of this malfunction are the following:

- lack of freon in the system;

- obstructed air outlet in the indoor unit;

- worn out compressor;

- fan malfunction;

- clogged capillary tubes.

Due to the small amount of refrigerant in the pipelines, the operation of the compressor is disrupted.Modern split systems signal a problem in advance, thanks to the presence of a pressure sensor in the design of the device.

Freon could evaporate or leak out gradually. The lack of refrigerant is indicated by the following: there is fan blowing, the compressor works constantly with rare shutdowns or does not work at all (due to overheating with an extremely low freon content in the system). This problem is solved by searching for a refrigerant leak and refilling it.

Obstacles in the path of cold air are the most common cause of lack of cooling. As a rule, they are presented in the form of a layer of dirt consisting of fluff, wool and dust. The air output should be restored by cleaning the air filters of the indoor unit.

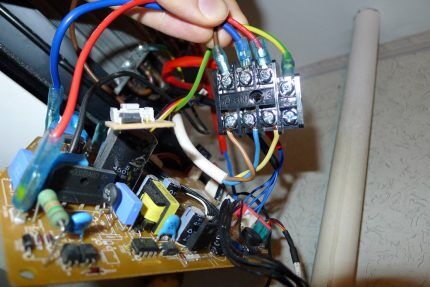

The compressor is the most loaded element of the system. Its wear can lead to lack of cooling. Obvious features of a compressor breakdown: the fans are observed to operate, but there are no sounds of the compressor operating, as well as the cooling itself. But, this may also indicate a failure of the capacitors (starting and operating) or the thermal relay.

To identify the exact cause of the breakdown, you need to check each element separately. To do this you will need a multimeter and some knowledge of electrical engineering. The damaged part is replaced with a new one. If the compressor has been replaced, the freon volume needs to be replenished.

Broken fans can also result in poor cooling performance.In this case, there is a sound of the compressor operating, but no blowing occurs - the air flow from the split system is not felt. To repair, you will need to open the unit cover, disconnect the fan from the housing and control board and replace it with a new part, observing the polarity of the connection.

If the capillary tubes are clogged, the circulation of refrigerant through them is disrupted. This leads to freon boiling and evaporation before entering the evaporator. In this case, the compressor can work constantly, with rare shutdowns, but the cooling will be weak.

If the blockage is severe, the compressor will work without shutting down, and the user will receive warm air. The problem is solved by washing the tubes with special solvents or water under pressure. If this does not help, then the tube is replaced with a new one.

Another common breakdown is a leak from the internal split unit. Why this happens and how to deal with this problem we told in this material.

Conclusions and useful video on the topic

You can see the process of cleaning the split system more clearly in the video:

Carry out independent repairs and cleaning split systems It is possible with the right approach to the matter. It is highly advisable to study the design of the equipment, its documentation and the features of the device being serviced.

It is also necessary to adhere to safety precautions. If the breakdown cannot be diagnosed and corrected yourself, there is no need to reconnect the faulty split system to the network. It is best to contact a specialized company.

If you have questions about the topic of the article, you can ask them in the comments section. There you can share valuable advice or tell how you cleaned the split system yourself.

I called the technicians a couple of times to clean the air conditioner. To be honest, the way this is done did not satisfy me. After “cleaning” them, the stench became worse than before. I had to dig around, read, figure it out, and now I’ve been doing it myself for several years.

The simplest thing is to wash the filters, but the radiator grille is more difficult; I do this in July, when the poplars have finished blooming, there is a lot of fluff!