Why is the gas burner noisy: analysis of the reasons + valuable recommendations for eliminating the problem

Agree that many gas stoves produce characteristic noises during operation.But when the sound becomes too loud and unpleasant, this indicates some kind of equipment malfunction, and it is better to contact a gas specialist.

It is simply dangerous to look for the reasons why a gas burner is noisy. After all, any malfunctions in the operation of gas devices can lead to serious accidents, and sometimes even to catastrophic consequences with destruction. What should you do if you find that the stoves sound threatening when you turn on the nozzle?

We will tell you what to do if you notice loud noise that is justifiably causing concern. We'll tell you who to contact to fix the problem. The article we have proposed discusses the options for its occurrence.

The content of the article:

Prerequisites for the occurrence of burner noise

Self-diagnosis of gas devices (especially without proper experience) can lead to an emergency situation. Any gas equipment is considered a high-risk device, regardless of its service life and apparent reliability. Gas is a highly flammable natural resource.

If the burner suddenly begins to make noise, although it was working quietly before, you need to turn it off and then contact the housing and communal services organization. If the sound becomes too strong and there is a smell of gas in the room, you need to call the emergency gas service by calling 104 or 112 (a single emergency phone number).

But usually the noise from gas burners and stoves is not associated with an emergency situation, and the problems that caused it are eliminated as usual.

The most common causes of noise from burners are:

- disturbance of oxygen-gas balance;

- various malfunctions of gas equipment;

- supply of low-quality gas to the system.

Also, due to design features, completely new gas equipment sometimes makes noise. This is due to the innovative technologies that some slab manufacturers use. In such devices, strong noise during operation is not considered a defect.

Violation of oxygen-gas balance

In a simplified way, the operation of any (i.e., new and old) gas stove can be divided into several stages. First, by turning the handle, the shut-off valve opens and the gas begins to move towards the burners. In the section between the stopcock and the burners, it mixes with air.

Gas burners are located on the surface of the stove in different ways:

- single next to each other;

- square;

- diamond;

- semicircle, etc.

Their operating principle will not change. The burner cover, due to its internal rough surface, reflects the mixture of gas and air entering the divider. The gas then flows through the narrow channels of the nozzles and is divided into streams.

After this, it is ignited, and the usual bluish flame appears on the burners. The reflector promotes uniform distribution of the flame along the divider channels. Any malfunctions along this path may cause extraneous sounds.

Problems with increased noise from gas burners may be due to too much gas pressure. Due to changes in pressure in the pipes, noise of varying degrees of intensity may appear. Gas pressure often increases in new areas where intensive construction is taking place.

Also, the gas stove begins to make strong and unpleasant sounds if the balance of oxygen and gas supply is imbalanced. This malfunction can only be determined during professional equipment diagnostics. In new slabs, the problem can be solved by replacing the dividers.

These devices have jets with a large hole diameter, which is responsible for supplying gas. Because The hole is large, and the volume of gas passing through is significant. You can eliminate strong noise by selecting a nozzle hole of a suitable diameter. In older stoves, you can adjust the air damper yourself.

When adjusting the damper, you need to focus not only on the sound characteristics, but also on the color of the flame. If the ratio of oxygen and gas is correct, the flame has a pleasant blue color and does not come off the burner when the tap is fully open.

If the flame comes off, this indicates excess air (oxygen). If the fire has a red top, this indicates a lack of air.

Gas equipment malfunctions

Often noise in gas burners appears due to malfunctions of the nozzles.There is no point in repairing old injectors; they should simply be replaced with new ones. Also, the stove begins to hum if the jets are chamfered.

In addition to technical problems, there may be problems in the condition of the gas stove itself. For example, if the burners are dirty and the nozzles are clogged with food, grease or cleaning agents, the stove may also make a lot of noise and hum. The problem can be solved by washing them thoroughly.

The burner cleaning procedure consists of several stages:

- First, a grate rises from the surface of the stove to cover the burner.

- Then the cover (divider) is removed from the surface of the burner and the burner is taken out.

- To get the nozzle, you need to unscrew a couple of bolts (in some models it comes out freely).

- All dirt under the burner should be carefully removed.

- After cleaning all the parts, they are reassembled and installed in their original position.

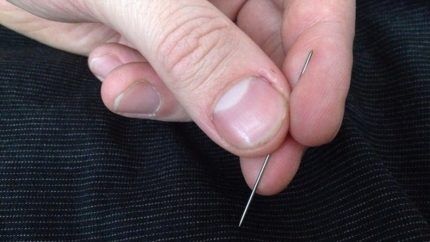

The stove nozzles can be cleaned with a regular needle. If after this the sound does not disappear, you need to adjust the burner. They may be slightly misaligned due to cleaning.

In addition, extraneous sounds may arise from a problem with the flame diffuser. Its malfunction is also indicated by a change in the color of the flame. If the flame diffuser becomes clogged, it must be carefully removed and washed thoroughly, briefly soaking it in clean running water.

The duration of soaking depends on the degree of contamination. You can use old toothbrushes and toothpicks to remove large amounts of grease and dirt. After this, the part must be dried and reinstalled.

If the flame arrester has been deformed during operation, it must be replaced.It is necessary to wash the burners, clean the nozzle holes and check the condition of the components once every three months, regardless of the intensity of use. You also need to wipe the hob daily to remove grease and food debris.

The burner body is involved in the subsequent mixing and distribution of the gas-air mixture. Deformation of the burner body from constant thermal loads leads to disturbances in the combustion of the flame belt and the appearance of extraneous whistles.

In this case, it is useless to repair the burner; it needs to be replaced. If the stove is new, but the burner is already deformed, you should contact the company where the product was purchased to have everything replaced under warranty.

If we are talking about stoves with electric ignition, then small whistles when igniting the gas may be associated with its malfunction. Checking the ignition condition is quite easy. To do this, you need to turn off the lights in the kitchen at night and press the electric ignition button without turning the gas tap.

If there is a slight noise during ignition, and the spark itself is yellow or orange, then this indicates a serious malfunction of the entire electrical ignition unit. It is not repaired, but completely replaced.

Supply of poor quality gas

Sometimes gas burners make noise due to the supply of low-quality gas to the system. This occurs when the gas is diluted with air. As a result, the gas burns when the burner is turned on, and the air remains in the pipes and causes a hum.

This is especially true for houses with bottled gas. The gas in the cylinders is a mixture of propane and butane, but some unscrupulous manufacturers can dilute it. Will familiarize you with the rules for using gas cylinders next article, which we strongly recommend reading.

Also, a slight hum may appear if the cylinder with “summer” gas mixture Leave in the cold season in an unheated room. In winter, you should switch to a special winter gas mixture or heat the room in which the cylinders and hose are located.

Design features of gas devices

Some gas stoves of certain European brands are noisy by definition. This is due to their design features and the introduction of technologies aimed at saving resources. These technologies allow you to save gas.

To maximize gas consumption, this stove uses the turbo effect. Some modern burners have two or three rows of perforations (unlike older devices), which results in faster heating. But this can also cause additional background noise.

Those. The combustion intensity increases, but due to all the innovations, the burners begin to make a lot of noise. In addition, on new stoves, the burners suck in air directly under the flame, which is why characteristic sounds are heard (whistles, hissing, tapping, etc.).

On old tiles, this process took place inside the burners, so it was barely audible.If the noise is too loud, you can try to reduce it by increasing or decreasing the gas.

Also, the appearance of background noise when a gas stove is operating may be associated with the installation of inappropriate parts. A set of new plates often contains additional elements that can be mistaken for spare parts, but they are not.

In most cases, such parts are designed for different gas pressures. But only an employee of the GorGaz branch with whom the owner of the residential property has entered into an agreement should replace parts of the gas stove with new suitable elements. service contract gas units and supply of blue fuel.

If a regular gas stove was moved from an apartment with main gas and installed in the country house, connected to the cylinder, and it begins to make noise during operation, then in most cases this is due to unsuitable jets.

The jets are responsible for supplying gas in the required volume at a certain pressure. The fact is that the gas in the main pipes and cylinders has a different composition, therefore the nozzles differ in structure and size.

Conclusions and useful video on the topic

It is better to learn about the reasons for the appearance of extraneous noise during the operation of gas burners in theory. Below is a video that talks about cleaning the jets of a gas stove to reduce noise during its operation. But you cannot repeat such actions without similar experience:

Repairing gas equipment yourself is too risky and dangerous. If a gas burner whistles, the only thing you can do is wash it, clean it and straighten it if it is askew. If this does not help, you need to call the gas workers.Any other action may result in an accident.

Would you like to tell us what you did when you detected noise when gas was supplied to the burners of your gas stove? Do you have useful information that is worth sharing with site visitors? Please leave comments in the block below, post photos related to the topic of the article, and ask questions.

Good afternoon. I have a composite cylinder for 18 liters, at the gas station, by mistake, they blew out 16.7 liters instead of the allowed 15. Afterwards, we connected the cylinder to the stove, and the reducer and partly the pipe began to freeze. We decided to release the excess gas into the field, after which everything returned to normal. Tell me, what was the reason for the rapid icing and how dangerous is it? Thank you