Wooden bathtub: device, types, parameters, instructions for self-production

An interesting design solution is a wooden bathtub.Such an original move will surprise guests and friends and create a unique atmosphere. One problem is that the cost of wood products is quite high. Not everyone can pay 5,000-25,000 euros for plumbing fixtures.

But if you really want to, then you can come up with the best way out of the situation - this is the construction of a wooden sanitary bowl with your own hands. We'll tell you how to do it better. We'll tell you what technologies are used in the home production of sealed wood crafts.

The content of the article:

Construction and parameters of a wooden bath

Having decided to create an original and colorful plumbing fixture made of wood, you will need to become more familiar with its structure and parameters. This is not an easy task - you simply don’t see such a product on the market. Well-known companies that have been producing plumbing fixtures for decades are proud of them.

How does this type of plumbing work?

A bathtub made of wood is a functional container designed for bathing, just like its steel, acrylic, and cast iron counterparts. Therefore, it has all the elements characteristic of this kind of product - a hole for drainage, an overflow, and legs.

Moreover, depending on the model, it can be equipped with additional devices - nozzles for hydrotherapy or air massage, lighting for chromotherapy, music, remote control and other features.

The bathtub model may offer various installation options. Sometimes a pedestal or wooden legs are required. In the first case, there must be a large room where the bowl will occupy a central place. And in the second, you can get by with a more modest room.

Parameters of a wooden bathtub

A wooden bathing container can have different dimensions, weight, shape, and wall thickness. The characteristics depend on the features of the model you like.

If this product is in the shape of a barrel, then we are talking about the height of the sides and the diameter, which is affected by the capacity - for one, two, four, six or more people.

Italian companies offering wooden models of sanitary ware focus on developments and special technology that allows them to create a bowl whose wall thickness is on the verge - this is an exquisite thin-walled bathtub.

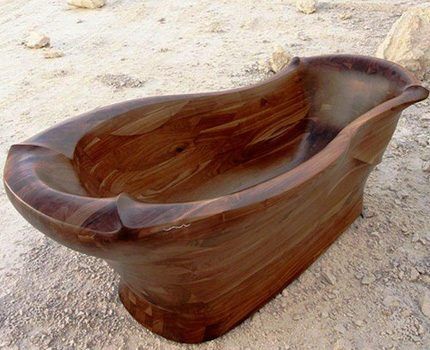

A fundamentally different approach is taken by manufacturers who make distinctly rough designs that are in demand for creating interiors in country houses in the Rustic or Primitivism style.

The length of a bathtub made of such material can be 1.8-2 m or more, and the width can be 70-76, 78, 90 and this is not the limit. The main feature is that most bowls are made to order. Therefore, during the manufacturing process, the wishes of a specific customer are taken into account.

Also taken into account bathtub rim height, which is essentially the distance from the floor to the top edge. This parameter, as well as the overall dimensions of the bowl, actually repeat the standards of conventional types of plumbing fixtures.

The weight of the product depends entirely on the dimensions and can range from 60 kg to 300 or more. If the option you like weighs less than 30 kg, then you should think about its wood origin - most likely, a cunning seller is trying to sell a polymer bathtub at the price of a wooden one.

As for the volume, it is also influenced by the dimensions - it can be either 280 or 500-700 liters, for example, if the container is intended for 3-4 people.

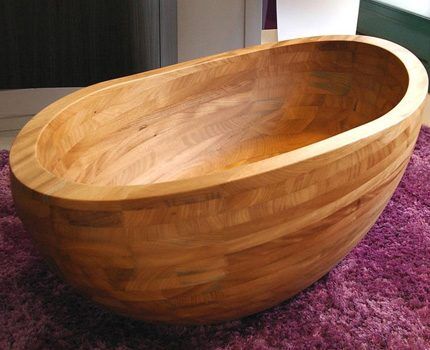

Existing types and forms

In order for a wooden bathtub made by yourself to please the eye and bring pleasure during the procedures, you should familiarize yourself in great detail with the existing forms of products and their features.

It is the option you like that will have to be brought to life - some of them can only be reproduced in a carpentry workshop using wood processing machines. The shapes of sanitary containers for ablutions are very different.

One of the variations of the oval theme can be considered the shape of the product, repeating the outline of a boat - here the flexible lines and grace of the floating device are combined with the natural structure of the material, which gives an indescribable feeling of lightness and naturalness.

In addition to unusual shapes, manufacturers offer a combination of various materials with wood - polymers, glass, metal.

Due to light weight and unstable position acrylic bowls And steel baths placed on a frame made of durable metal alloy. It is necessary to increase the user's confidence during procedures and to minimize the risk of injury.

Sometimes instead of the usual metal structure build a frame, for which lumber or aluminum profiles are used. The frame is complemented with a decorative ladder, making it easier to get inside the bowl.

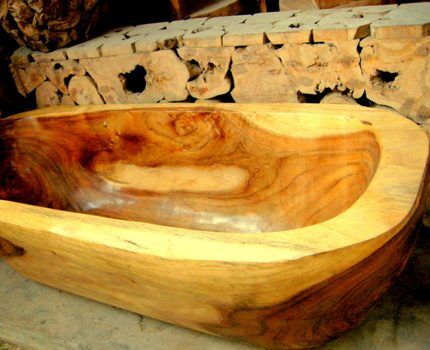

In addition to the shape, the products differ in the type of material - a solid piece of wood is not always taken to make an original container.

Based on the appearance of wood, bathtubs can be made from the following elements:

- whole tree trunk;

- large fragments of material;

- blocks;

- planks or they are also called rivets;

- from veneer.

The last option applies to cheaper products. There are natural and artificial veneers.In the first case, the product is related to natural material. Moreover, when finishing luxury yachts, valuable wood veneers are also used.

But the second is modern technologies that make it possible to create the structure of wood. Such a bathtub has its advantages, but it is in no way connected with wood, with the exception of the pattern on the polymer coating that imitates the structure of wood.

To recognize the latter option, you should study the company’s offers - if the same model is offered in different colors - ash, oak, cherry, walnut and other variations, and the price is almost the same, then the future product has nothing to do with wood.

About the cost of plumbing products

Often the desire to have a bathtub made of natural wood is broken by its incredible cost. Not every user can easily take 25,000 dollars/euro out of their wallet and pay for a bathing container. Even if it is original, made using manual labor.

The desire to save money can lead to buying a fake. It’s one thing if a person takes this step consciously, but it’s quite another when he is firmly convinced that he has bought a worthwhile thing made of natural wood.

The following signs will indicate deception:

- uniform repeating pattern;

- fairly light weight of the product;

- suspiciously low cost;

- Models are offered in various colors - walnut, cherry, golden oak or imitation black metal.

Such a proposal will be alarming - to make the bowl they use species of trees familiar to us and more exotic ones. Moreover, the best option is considered to be exotics that are accustomed to living in conditions of high humidity.

The main purpose of the treatment is to give the material water-repellent properties. Ideally, use valuable rock that has been subjected to many years of flooding. Although in the absence of this expensive material, artificial methods are used.

All procedures carried out with wood before making a bath are expensive and take a lot of time. Plus, the cost of the material - some tree species are amazing with their price per 1 linear meter.

It is not surprising that the yellow-orange teak wood, mottled with dark stripes, the reddish-brown solid mahogany or the black-brown tone of ebony simply screams that the natural color and texture of the material should be preserved during production.

Cheaper materials are larch, oak, cedar, linden, pine. All of them are perfect for constructing a bathing tank. And they are successfully used due to their ability to weakly absorb water.

Self-production instructions

Having decided to decorate your bathroom with an original font and not having enough money to purchase the option you like, you will have to undergo instructions on how to make a wooden bathtub from inexpensive wood with your own hands. Moreover, it can be done at home.

Preparation for work

To work with wood, you will need carpentry tools, including a grinder and multifunctional woodworking machines. You will need to buy products to give the future container the necessary characteristics - impregnation, primer, sealant, glue, wood varnish.

It is important that all mixtures used in manufacturing do not contain toxic impurities and can easily come into contact with liquid with a temperature of about 70 degrees. After all, in the future we will have to fill the bathtub with hot water.

The simplest option for creating a bathing container is to assemble a wooden barrel. Here there is no need to treat with additional compounds - just fit the rivets tightly and properly fasten the metal belt.

It is important to remember that all wooden parts of the barrel must be carefully sanded and polished. This option will not surprise or delight everyone. It is optimal for a home bath. And even in an apartment, the barrel will look like the notorious fifth wheel.

Therefore, a model made from fitted bars of various shapes will be more acceptable. It’s worth noting here that while large fragments are quicker to assemble, making a bath yourself will be problematic – it’s a hard, grueling task.

It is convenient to do this in a workshop where there is equipment and all processes are computerized - there is a program, a drawing of the future product, there is a grinding machine and a woodworking machine.

Wooden Bowl Making Guide

The easiest way to assemble a product at home is from small bars.To do this, it is advisable to choose a simpler model. This exquisite product can be placed in a small bathroom in a high-rise apartment.

First, measurements are taken so that the future bathtub ideally fits its owner in size. It is important to make a sketch indicating all dimensions. You can assemble a prototype and try it on yourself.

Then there is the purchase of wood. It is better to settle on an inexpensive breed to implement your first project. It is necessary to cut planks of the same length and thickness to assemble the bottom, carefully adjusting each one. It is important to ensure reliable grip here.

It is worth immediately cutting a drain hole for bath siphon connections, the model of which must be selected in advance. When forming technological holes, it is better to adhere to standards so that, if necessary, you can replace a worn or damaged part.

The next stage is assembling the walls of the container.Before you start, you need to cover the upper surface of the bottom with tape. This will protect the product from accidental damage during work.

When carrying out surface treatment, a wood primer is applied, which will ensure reliable adhesion to the future coating. Before completing the labor-intensive process of making a bathtub, it must be tested for tightness.

Only when the test shows that there are no leaks can you begin decoration and finishing work. All work is carried out sequentially, each process must be given utmost attention.

As for the treatment of the internal surface, various options are possible:

- polish thoroughly and do not apply anything;

- coat with 2-3 layers of polymer coating;

- apply varnish.

It is better not to use the latter option - due to temperature changes, the coating may crack and begin to peel off. There is a varnish with a service life of up to 25 years, intended for finishing yachts, but it is very expensive and is produced abroad.

Polymer coating for wooden surfaces consists of a transparent polymer and a hardener. Everything is mixed in the proportions specified by the manufacturer in the instructions. Then apply 2-3 layers to the inner surface and leave until completely dry.

Such a surface requires regular updating, about which the user is honestly warned. But this is not a problem - the mixture can always be purchased and updated, following the recommendations.

The polished option is the most pleasant. Here, maximum effort will be required to create a perfectly flat surface. As a reward, the bathtub owner will receive ultimate contact with natural wood without the interference of any foreign materials.

Conclusions and useful video on the topic

You can make a bathtub from wood yourself.To do this, you will need skills in working with wood, carpentry tools, wood, impregnations, varnish, and sealant.

You should start by choosing the simplest model that is ideal for a specific bathroom. Overview of wood options in the video:

You can make a bathing container from large fragments of material. How to do this is demonstrated in the video:

If you have a wood processing machine, you can make a bath of any size. The video shows how to do this using a sink as an example:

After familiarizing yourself with the possible options for making a wooden bathtub and assessing the availability of tools, skills and the availability of the right types of wood, you can choose the optimal model. Making a bowl will require time, labor, and patience.

The end result will be a personal achievement and real pride - it’s not a shame to demonstrate such a product to friends and family.

Please write comments in the block below. Ask questions, share useful information and post photos related to the topic of the article. Perhaps you have information about the original production of a sanitary bowl made of wood?

I received a wooden bathtub as a gift. We have now installed it and are actively using it. Until this moment, I was completely sure that I had an original, but after reading your information I realized that it was most likely a fake. My bathtub is very lightweight and comes in a cherry wood color. I think its cost is several times lower than indicated here. Be careful when choosing plumbing fixtures, you may run into counterfeit products.

Yes, a wooden bathtub is, of course, very original. But, to be honest, I don’t see any practical sense in it.Should you buy it or make it to surprise your guests? In pursuit of environmental friendliness? A wooden bathtub requires a completely different level of care than a regular one. It may begin to rot or, on the contrary, dry out. Well, hemorrhoids. I definitely wouldn't install a wooden bathtub for myself.

Fedor, this is for those for whom money weighs on their pockets :)

This is for those whose hands don’t grow out of ass...

What glue is used for gluing?