7 best planer-thicknesser machines: 2023 rating, review, pros, cons, price

Wood is rightly considered one of the most difficult materials to process. Therefore, the scheme and sequence of work with wood were worked out by more than one generation of carpenters.You can also try to plan one piece or board and even it out in thickness manually. But if you need to prepare several hundred parts, then machining comes to the rescue. Today, not a single carpentry workshop, even at home, can do without planer-thicknesser machines.

The content of the article:

What is a planer-thicknesser machine and its functionality

Typically, an experienced carpenter avoids using universal equipment, which has many functions and ways of processing workpieces. As a rule, such a machine provides acceptable quality and accuracy in only one of the modes. For example, you can purchase a jointer and thickness planer separately. At the first stage, it is possible to plan the surface efficiently. A long, rigid cutter shaft will remove all surface defects and make the board fairly smooth. If the thickness and width of the workpiece are not particularly important, then it can be used.

Using a thicknessing machine, you can cut a workpiece “to size” in thickness, width, with or without a chamfer. Full-fledged products are made from such boards or slats. The name “thicknesser” stuck to the machine due to the fact that in the old days, control of output dimensions was carried out using a special template (bracket) or thicknesser. Modern models do not have a surface thicknesser; it has been replaced by more accurate and reliable measuring instruments, but the name “thicknesser” remains.

Several operations can be performed on a planer-thicknesser machine:

- Jointing or cleaning the surface (one or two sides) to a state where the thickness and width of the board can be measured. In this case, the measurement results will not “float” due to high roughness, knots, “bumps” or potholes.

- Trimming the workpiece to size according to the thickness of the board. The operation is possible only after double-sided jointing of the material.

- Trimming material along the end surfaces to a given workpiece width. Usually carried out after finishing trimming the planes.

In some models of planer-thicknesser machines, it is possible to trim planes and the end surface in one go. But in any case, finishing preparation on a planer-thicknesser machine is separated into a separate operation and carried out at the very beginning. The simultaneous trimming mode gives low dimensional accuracy, sometimes the geometry “walks”, the edges are obtained with a barely noticeable arc.

This mode is used primarily for simple parts with large volumes of material. For example, you need to cut a strip or lining blank for wall cladding. If you tinker with each workpiece separately on a planer-thicknesser, the matter will drag on for several days. It’s easier to run the planks to size immediately along the plane and ends. In this case, the jointer-thicknesser option turns out to be more profitable and convenient than two separate ones - a jointer and a thicknesser.

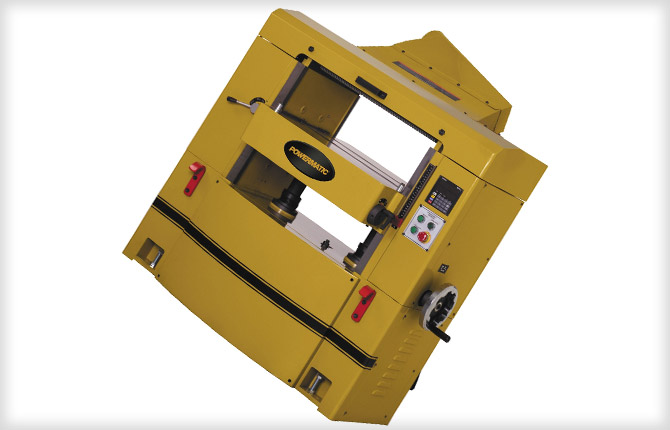

True, such a planer-thicknesser for wood (for example, Powermatic WP2510) is quite expensive, usually these are models for industrial and semi-industrial purposes, so they will not be considered in the ranking of the best.

Article for you: 10 Best Sharpening Machines.

What to look for when choosing

The quality, accuracy and productivity of processing workpieces on a planer-thicknesser machine depend on:

- Engine power. As power increases, the load on the machine body, guide plane and drive increases. The more powerful the planer-thicknesser machine, the heavier and stiffer the bed (frame and frame) should be. It is better not to consider options with thin support legs at all.

- Number and location of milling shafts. Simple planer-thicknesser machines use one shaft mounted in the plane of the guide. In more expensive and powerful models, another one can be added - top-mounted. So when entering, the board is cut to size along two planes at once.

- Overhang of the cutting edge or allowance for processing (removal of the surface layer) in one pass, traditionally 1-5 mm. The parameter must be adjusted with a screw pair, no pads.

- Shaft revolutions. They should be as high as possible if it is planned to process soft wood on a planer-thicknesser machine.

- The number of knives (cutting edges) on the shaft. The more of them, the higher the surface quality and processing accuracy of the surface planer.

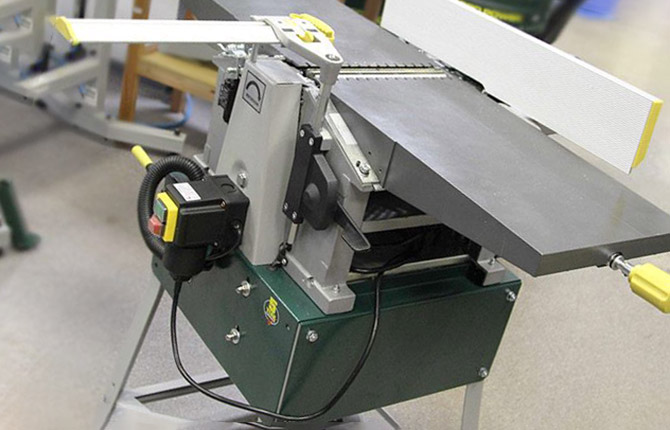

The feeding table can be welded from sheet steel and square pipe. But it is better to choose models with a working surface cast from cast iron and polished using high-precision equipment. For example, like the PT310 CORMAK machine.

Thanks to the hard and smooth surface, it is possible to feed the board onto the jointer with much less effort. In addition, the accuracy of surface planing is higher. The surface is flat, the board is of the same thickness along the entire length, no waves or ripples.

Sometimes, instead of a solid smooth surface, the table is made with longitudinal grooves. This technique increases the accuracy of jointing lumber with large pile. Especially if the boards were cut from raw logs on an old low-speed circular saw.

If you have to work indoors, in a workshop or garage, then you cannot do without a fan with a dust collector. You can easily develop allergies, especially when processing species such as larch or acacia.

Review of the best planer-thicknesser machines

The assortment or machine park for jointing and thicknessing operations is oversaturated with all kinds of models from both well-known brands and relatively new and little-known manufacturing companies. Conventionally, everything that is presented on the market can be divided into 2 large groups - planer-thicknessing machines with a price tag of 180-250 thousand rubles or equipment at the level of 50-140 thousand rubles. Machines of the first group are purchased for a carpentry workshop operating at full load.

The second type of equipment is purchased mainly by single carpenters for their home workshop. They are most often discussed in reviews. These can be inexpensive table-top machines. Most choose equipment for planer-thicknesser operations from the top most popular ones, with an eye toward better processing quality, even at the expense of productivity and the presence of additional functions.

BELMASH JT-2 204/210 S91A

A simple compact planer-thicknesser machine at a budget level. Produced by one of the oldest machine-building enterprises in Belarus. Designed for domestic use, so the weight is only 29 kg. The motor is commutator 1500 W, produces 9000 rpm.

The low weight of planing equipment is explained by the fact that the design uses a large number of cheap components and parts made of aluminum alloys. The price of the machine is 33 thousand rubles, 1 year warranty.

Design Features:

- Double blade shaft with a diameter of 51 mm with removable blades.

- The drive to the shaft from the engine is made using a V-belt drive.

- The maximum board width is 20.4 cm; workpieces up to 10 mm thick can be processed.

- Thanks to the high rotation speed of the planing shaft, the surface quality is high. True, you have to pay for the low engine power with a reduced planing depth per pass - 1.2-2 mm.

Among the shortcomings, one can note the slight rigidity of the desktop. In addition, if surface planing with increased precision is required, then a special device must be used to additionally adjust the reference plane.

For relatively thin workpieces, up to 30 mm, the power of a planer-thicknesser machine is sufficient. The manufacturer recommends using the machine for preparing lining, plywood blanks, manufacturing small-sized parts for wall cladding or sheathing for roofing.

12 month warranty.

Holzstar ADH 200

German brand. The company develops equipment for wood and metal working. This is a desktop model, so the dimensions are small. Table length – 800 mm, height – 400 mm. Weight – 29 kg.

Characteristics:

- Electric drive power – 1500 W.

- High speed shaft – 8000 rpm. With a correctly selected feed, the planer-thicknesser machine ensures a surface quality at the level of a ground surface.

- The maximum cutting depth for a single pass is 2 mm, both for jointing and thicknessing processing. Accuracy within 0.4 mm.

- The machine can process workpieces up to 20 cm wide and up to 17 cm high.

- It is possible to make beveled side edges within 30-80O.

The design provides for fan-assisted collection of dust and chips. The waste is sucked by a fan into a dense synthetic filter bag.The volume is enough to process up to 2 m3 lumber. That is, you can work on a planer-thicknesser machine indoors.

Significant disadvantage of the model Holzstar ADH 200 – prefabricated frame. According to user reviews, the frame needs to be properly reinforced with sheet steel gussets. In this case The planer-thicknesser can be used without restrictions.

Robland NXSD 410

A model that will interest many carpenters, both amateurs and professional craftsmen. The planer-thicknesser machine is manufactured at the company's machine-building plant in Belgium, known for the high quality of its machine tools. The mechanical quality of the Robland NXSD 410 is higher than that of inexpensive planer-thicknesser machines produced in China.

Features of the Robland NXSD 410 device:

- Electric motor power – 3750 W, 5500 rpm, power supply 380 V.

- Shaft 70 mm with three knives. Blades can be removed for sharpening. To reinstall the knives, a special device is used.

- The frame and base of the body are made of cast iron, weight 320 kg.

- The machine is two-shaft, the design includes 2 shafts and 2 cast iron tables.

- There is an automatic feed of the workpiece at a speed of 10 cm/sec. In manual mode, you can enable protection against the workpiece being thrown back towards the operator.

- In one pass, planing depth is up to 4 mm.

In one processing, the planer-thicknesser machine is capable of simultaneously processing 2 planes. The maximum height of the workpiece is up to 23 cm. In addition, it is possible to cut the end edges at an angle of up to 45O. A V-belt drive is used to drive both shafts; the equipment operates quite quietly and does not require personal noise protection.

The planing depth is adjusted using two handwheels. The set size is reflected on a mechanical indicator counter located in the center of the disk. This is much more convenient than traditional rulers or metal carpentry thicknessers, the accuracy of which is usually low.

Proma HP-250/2-230

The design was developed in the Czech Republic and produced in the People's Republic of China. Planer-thicknesser machine for use in home carpentry workshops and by individual carpenters.

The capabilities of the equipment are sufficient to produce floorboards, linings, facing strips and even furniture panels. Price – 120 thousand rubles, weight – 115 kg.

Characteristics:

- Drive power – 2.2 kW, 220 V asynchronous motor. Transmission is carried out using a steel multi-link chain.

- Three-knife milling shaft with a diameter of 75 mm, performs 4000 rpm.

- The depth of wood removal is 3 mm for the jointing mode, 1 mm for the planer. Finishing accuracy of 0.2 mm on a hard dry board with minimal workpiece feed.

- Cast iron table, steel and cast iron frame, prefabricated structure.

- The maximum width of the workpiece is 250 mm.

The planer-thicknesser machine is interesting because it can be used in two modes. By using Proma HP-250/2-230 planes workpieces quickly, with high feed. Surface quality and accuracy are average. If you set the shaft to high speeds and minimal feed, the surface quality will noticeably improve.

CORMAK PT310 +FM300

Planer-thicknesser machine for a small furniture workshop with a staff of carpenters of 2-3 workers.The layout is standard, a 120 cm long cast iron table is mounted on a welded structural steel frame. An asynchronous motor of 3000 W, power supply of 380 V is used to drive the shaft.

Performance characteristics:

- The rotation speed of the three-knife shaft is 5300 rpm. With a planing blade diameter of 75 mm, the processing speed is 10 cm/sec.

- The maximum cutting depth for planing is 5 mm, for thicknessing – 3 mm.

- Workpiece width – up to 30 cm, height – 22 cm.

Thanks to the massive body and bed, cast iron table, the design of the machine dampens all vibrations well. Therefore, the equipment does not have to be mounted on a concrete floor, like most floor-standing models. Moreover, the developers additionally provided for the possibility of transporting the machine using a special trolley. That is, the machine can be removed from the premises during downtime.

JET JPT-310 HH

The machine from the Swiss equipment manufacturer “JET” is produced both in Switzerland and in China. Refers to middle-class planer-thicknesser equipment with increased precision. Price – 275 thousand rubles, weight – 230 kg. This type of machine is traditionally used in small private workshops for making wooden furniture.

Characteristics:

- Engine power 3.5 kW, at 5.5 thousand rpm. Supply voltage – 380 V.

- For processing, a milling shaft with a diameter of 70 mm, with 48 carbide blades is used. Thanks to this, the planing error is minimal - 0.1 mm.

- The length of the cast iron work table is 180 cm; the planer-thicknesser machine can process boards up to 250 cm long and 30 cm wide.

- The cutting depth when jointing is up to 3.5 mm, when finishing thicknesser is up to 1.5 mm.

- The minimum thickness of the workpiece is 5 mm.

The machine can process batches of blanks and even make veneer blanks. The design has an automatic feed system; the speed can be adjusted depending on the operating mode and the required processing accuracy. The automatic feeder can be turned off and the workpieces can be advanced manually, for example, in the case of planing wood with a pronounced “twisted” fiber structure of the wood.

The drive from the engine to the shaft is belt, so JET JPT-310HH is one of the quietest in operation. An aspiration dust removal system is used to collect waste. The filter bag can be reused after special cleaning of the filter fabric.

HOLZMANN HOB410PRO 400V

One of the best models of planer-thicknesser machines for a small carpentry workshop for 2-3 workers. Developed and produced by an Austrian company HOLZMANN, a leading manufacturer of woodworking equipment. Price – 370 thousand rubles.

The base of the frame uses parts made of cast gray cast iron and steel. The guide table is also cast iron. Therefore the weight is 420 kg. To drive the milling shaft, a 380 V asynchronous motor with a power of 5.5 kW at 4700 rpm is used.

Performance characteristics:

- The maximum dimensions of the workpiece are width 41 cm, height 20 cm.

- In the jointing mode, up to 5 mm is removed in one pass, with precision thickness planing – up to 4 mm. It is possible to cut the end at an angle of up to 45O.

- The length of the working table is 180 cm, the total height of the planer-thicknesser machine is 110 cm.

- The maximum speed for drawing the workpiece is 12 cm/s. There is an automatic board feed.

Machine accuracy HOLZMANN HOB410PRO 400V on dry hardwood is 0.3 mm at maximum feed.The design uses a chain drive from the engine to the shaft, so the equipment is very noisy. There is a wood dust removal (aspiration) system with a replaceable filter. Users note the reliability and stability of the processing characteristics of the HOLZMANN HOB410PRO.

Even the best planer-thicknessers require constant adjustment of basic planing parameters, such as thickness and feed. Even for semi-industrial floor-mounted models, the cutting parameters under load can arbitrarily “sag”. And tabletop ones need to be adjusted after every 200-300 processed workpieces. In addition, the precise operation of the equipment depends on the experience and skill of the operator.

Additionally we read: 8 best lathes.

Tell us about your experience working with planing equipment. What models of machines, in your opinion, turned out to be the most convenient for a small carpentry workshop?

It is not only the rigidity of the frame that is important. When choosing a machine, you need to look at everything - the shaft with cutters, the belt or chain drive from the engine. You can make the bed yourself, but probably not everything else.

Holtzman is best. Cool equipment. Even after five years of used equipment, this equipment is sold as new. Look at how much Belarusian and Chinese rubbish is sold for. You can always rent it out, it will earn you money if you can’t do anything yourself.