Do-it-yourself heated summer shower: step-by-step construction instructions

Country life attracts people with the opportunity to enjoy fresh air and unity with nature.Outside the city everything is fine, except for difficulties with hygiene procedures. Agree, would it be nice to make a heated summer shower with your own hands to solve this problem?

This option will help increase the comfort of staying at the dacha, but will not greatly affect the family budget. We will show you how to realize this idea.

The article examines in detail the best design solutions and technologies for constructing booths. Helpful advice on choosing the materials required in construction, arranging drainage, and simply and quickly heating water will provide effective assistance. The information presented is supported by photo and video applications.

The content of the article:

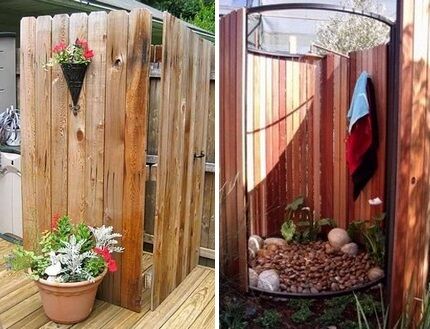

Shower design options

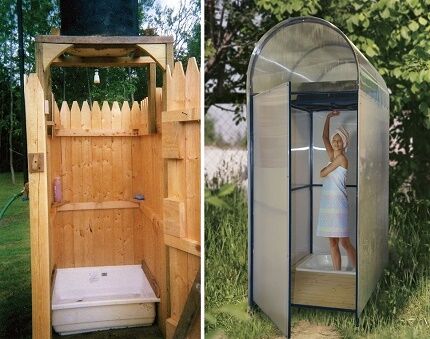

The comfort and ease of use of the structure depends on how well the summer shower is designed. The task of a thrifty owner is to build an economical, easily constructed and at the same time maximally functional shower, equipped with heating.

The easiest option to implement is an open shower.

When choosing this arrangement option, the tank is installed on the load-bearing wall of the building, positioning it in such a way that the sun's rays hit it at a right angle.

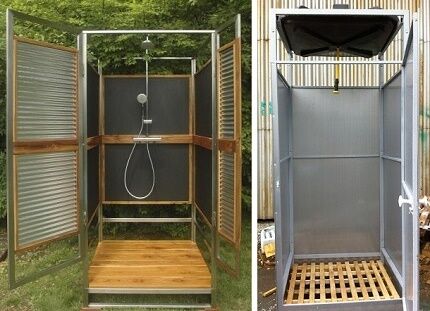

Do you prefer closed designs that are convenient to use both in the warm season and in the cold months? Build a stationary summer shower with a simple heating system. It can be a frame structure or a permanent structure.

Traditionally, when building a shower with enough space for an adult to bathe, they focus on the following parameters:

- height — 2-3 m;

- width — 1.5 m;

- length - 1.9-2 m.

These dimensions are convenient when building a structure from wooden boards. Taking into account the thickness of the walls in its finished form, the area of the structure is approximately 2 * 1.5 m, of which an area of 1 sq. m will be allocated for the shower stall. m, and for the locker room - 60*40 cm.

When using boards of standard sizes, the material is consumed with virtually no residue.

In addition to wooden planks, the most commonly used building materials for the construction of cabins are:

- polycarbonate sheets;

- moisture-resistant plywood;

- sheet metal;

- flat slate;

- lining;

- brick.

When choosing a facing material, it is important to focus on the exterior of the site so that the building harmoniously complements the already created architectural ensemble.

Polycarbonate shower cubicle:

Recommendations for choosing a tank

You can buy a ready-made water tank by choosing one of the models you like, or make a tank yourself from scrap materials, for example, from a 200-liter barrel.

Ready-made tanks can be made of plastic, metal or galvanized steel. On sale there are containers of simple design, the design of which has a bevel and holes for installing heating elements, and models that are already equipped with heating elements.

When choosing a tank, you should be guided by two criteria:

- the material from which it is made;

- capacity of the tank.

A 100 liter tank is enough for a family of two. And for water procedures to be carried out by three or four family members, it is better to install the 200 liter option.

Do you want to make a heated tank yourself? There is nothing complicated about it. Buy any suitable container. You purchase heating elements separately on the construction market.

On sale you can find heating elements with remote power regulators, in which the adjustment varies from 0.5 to 2 kW. Their only drawback is that they are not able to maintain the set temperature.

To install the heating element in the center of the tank, maintaining 15 cm from the bottom, make a hole. At the bottom of the container, closer to the edge or in the center of the bottom, another hole is made for arranging a drain. The outer part of the heating element is hidden in an electrical box.

To drill a hole for a heating element with a nut, you will need a drill D 40 mm, for an overflow of ½ inch - a drill D 20-21 mm.

Determining the location of the building

To ensure rapid drainage of water, it is better to place the building on a slightly elevated area. A flat part of the site is quite suitable for this purpose. The main thing is that it is not in a strong depression.

By choosing a sunny area for the construction of a shower, you will ensure that the tank can warm up well naturally. This solution will reduce costs by combining forced heating of water in cloudy weather and natural heating of the water container from the sun on fine days.

When choosing a location, take into account the moment that electricity is supplied to the future building.It will be needed to power the heating element, which will serve as a heating element.

Wooden shower on a slope:

It is not recommended to place the outdoor shower too far from the house. Not everyone likes to make long runs along the street after water procedures, preferring to immediately find themselves in a warm indoor room.

Drain pit equipment

From a biochemical point of view, draining wastewater from the shower and street toilet into a common pit is a gross mistake. It is necessary to build a separate pit under the cabin. To equip a summer shower, which is supposed to be used only from time to time, a drainage hole with a capacity of no more than two cubes is sufficient.

The drain should not be located under the shower building itself or even near its walls, but two to three meters from the building.

This arrangement allows you to solve two problems at once:

- prevent the appearance of unpleasant odors of decaying organic matter;

- minimize the risk of foundation failure.

To construct a drainage pit, dig a pit 2-2.5 m deep. At this depth, wastewater will be discharged into the soil below the fertile layer. Thanks to this, soil microliving creatures will not suffer from such a “neighborhood”.

To make drainage, the bottom is lined with gravel and sand. The thickness of the drainage layer should be 20-30 cm.

When creating a waterproof layer, you should not use clay, since during operation, as a result of the natural erosion process, it can simply break the drainage system.

The upper part of the drainage pit must be tightly closed. The lid can be made from a wooden panel or a piece of sheet metal.

The technology for constructing a drain pit from tires is described in this article.

Purchasing the necessary materials

In addition to making or purchasing a heating tank, you must purchase plastic water pipes D 50 mm. It is convenient to use a flexible silicone hose to supply water.

To set up a system of materials you will also need:

- gutter reinforced with metal mesh;

- ball valve;

- valve with float;

- divider

To make a foundation pour when constructing a cesspool, you will need cement marked M150 and higher. The drain can be covered with waterproofing roll materials or hydroglass insulation.

To make a wooden floor in the shower, it is best to use a tongue-and-groove board, treated with a water-polymer emulsion or oil white.

To erect the structure you will need the following tools:

- building level;

- roulette;

- corner;

- screwdriver;

- self-tapping screws

To pre-mark the area, you also need to stock up on a skein of twine and wooden pegs.

Instructions for building a summer shower

There is no particular difficulty in building a summer shower in your dacha yourself. The only stumbling block for a novice master may be the question of how to install a heated tank and how to organize a wastewater disposal system.

Step 1: Carrying out preparatory work

The scope of work during site preparation depends on the type of building being built. If you plan to build a temporary frame structure, to prepare the foundation, it is enough to remove a 15-centimeter layer of earth from the marked area, and then level the bottom of the dug “pit” and fill it with sifted sand.

When installing a shower stall on very heaving soils, in order to reduce the risk of it tipping over, the thickness of the non-heaving “cushion” of gravel and sand should be increased to 30-40 cm.

Are you planning to build a major heated country shower? To erect it, you will need to lay the foundation. The depth of the foundation depends on the type of materials used. For example, for a brick building, a foundation buried 30-40 cm is sufficient.

The foundation is laid in the following sequence:

- Territory marking. To create the correct foundation, wooden stakes are driven into the outer corners of the future building and string is pulled between them.

- Digging a pit. A layer of soil is removed from the marked area, going 15-40 cm deep depending on the type of building.

- Preparing the site for laying pipes. Dig trenches and level the bottom in such a way as to ensure unimpeded flow of waste water in the direction of the drainage hole.

- Installation of drain and discharge pipes. A reinforced gutter is installed on the leveled and compacted bottom, not forgetting to maintain the angle of inclination.

- Pouring concrete mortar. To create a level base, pouring is carried out using a level and guides.

At construction of a wooden frame It is advisable to raise the shower stall 20-30 cm above the ground.

When installing the floor between the shower stall and the locker room, in order to minimize the likelihood of water flowing in, it is worth providing a low threshold.

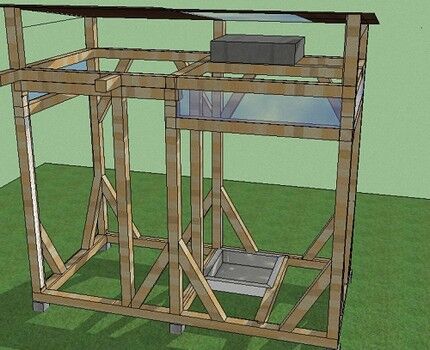

Step 2: Construction of the shower cabin

To build a simple frame structure, you will need to install support posts. Since a tank filled with water will be installed on the frame, the frame should be made strong enough.

Support posts can be made from the following materials:

- wooden beams with a cross section of 10*10 cm;

- aluminum profiles;

- metal poles.

To extend the “life” of wooden structural elements, it is advisable to treat the workpieces twice with a moisture-repellent and antiseptic composition. For greater reliability, the lower part of the support pillars, which are planned to be buried in the ground, should be treated with bitumen mastic.

In accordance with the markings for the size of the shower, supports are installed at the corners of the foundation and every 1.5 m of the contour.

To make holes, it is convenient to use an auger or a garden auger, which can be rented at a building materials center. Depending on the type of design of the lower ends of the supports, they can be deepened by driving or by screwing into the ground.

When arranging a doorway, two adjacent support posts are placed, maintaining a distance of the width of the door. Mechanisms and a frame are attached to them, which serves as the frame of the future door.

Having deepened the supports, they begin to bandage the pillars. To simplify the task, the frame is first assembled on a horizontal, flat surface. The finished structure is secured to the supports with long bolts. To create floor joists in the shower, a bandage is performed inside the frame structure. The roof in the shower stall is made simple and sloping.

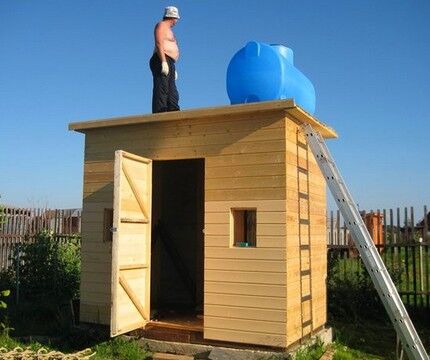

Step 3: Heated Tank Installation

A tank is installed on the roof of the structure, the outer walls of which are painted black. Dark colors attract the sun's rays well, thereby promoting rapid heating of the surface.

Ready-made shower tanks are already equipped with tap holes. If you make a tank on your own, for example, from a barrel, then before installing it on the roof, you must first make an outlet for the thread in one of the walls. The diameter of the hole must correspond to the cross-section of the pipe connecting the ball valve with the installed watering can.

An important point: when choosing a storage location, consider: the greater the distance between the spout point equipped in the upper tank and the sprayer, the greater the water pressure.

Since heating elements are very sensitive to anhydrous environments and can even burn out if there is not enough water, it is important to monitor the filling level of the tank. To do this, a plumbing valve is mounted on the installed tank, which indicates the amount of water.

A hose, tap and watering can are connected to the bottom of the tank. In order for clean water to flow from the watering can and not sludge, the selection pipe must be positioned higher. In this case, the hot supply should be 1-2 cm above the mark of the outlet source.

The same requirement should be observed when installing the supply pipe in order to ensure thermosiphon circulation inside the tank. At the same time, do not forget to take into account the fact that the mouth of the supply pipe should be located as far as possible from the source of the outlet pipe.

Wooden cabin with 250 l tank. The tank is equipped with a built-in heating element, heating is carried out from the mains.

The cabin is ready. All that remains is to install the water tank and connect for heating.

Step 4: Ventilation and insulation of the shower

One of the common mistakes when arranging a summer shower is the construction of thick walls that absolutely do not allow air to pass through. Insufficient air flow contributes to the formation of mold in the corners and the spread of fungus on the walls.

To ensure air circulation and water drainage, the floor is made with gaps between the boards, and a gap is left at the top of the wall.

When arranging the drain and laying the floor, you can use ready-made pallets.

To seal the pallet at the installation stage, construction foam is applied along the contour of the cutout. Immediately, before the foam hardens, lay the pallet. The squeezed out excess is carefully removed.

At the installation stage, it is also important to think about how to ensure the water supply.

You can fill the tank with water in one of three ways:

- manually with buckets;

- by pumping with a circulation pump;

- if there is a water supply system by connecting to it.

If funds allow, it is better to make the water supply automated so that every time you need to fill the tank you do not have to climb up a stepladder with a bucket of water.

When planning to use a shower stall in the cold months, you should take care of insulating the structure. The easiest way to solve this problem is to cover the walls with slabs extruded polystyrene foam.

Tips for finishing

For interior decoration, choose facing materials that have increased moisture resistance: PVC film, linoleum, plastic.When choosing wooden cladding, the surface must be treated with drying oil and painted.

The grid is assembled from wooden slats measuring 30-50 mm. Wood preparation is the same. If you want to increase its resistance to shoe wear, treat the material with an acrylic compound used for repairing bathtubs.

If desired, both the internal and external walls of the facing material can be painted and decorated with designs. The original design will allow you to turn the shower not only into a place for taking water procedures, but also into a decorative element of a suburban area.

Additional interesting options for arranging a garden shower are offered in these articles:

- Do-it-yourself summer polycarbonate shower: step-by-step design instructions

- Country toilet project with shower: choice of design + construction instructions

Conclusions and useful video on the topic

In interesting videos you will find a lot of useful information for installing a heated country shower.

Construction and repair of frame structures:

Shower tank from an old washing machine:

Organization of the heating system:

The heated summer shower is ready. To prevent water stagnation, it is advisable to operate the shower at regular intervals. Before a long break in use, so that sediment does not clog the watering can, it is recommended to completely empty the tank.

Do you have personal experience building a heated shower? Do you want to share practical skills or ask questions on a topic? Please leave comments, participate in discussions, and add photos of your homemade shower stalls. The contact form is located below.

It is not very clear what to do with the heating element: how to install it correctly and whether it affects the plastic of the tank. In general, I would like more information specifically about heating water, since many questions remain; after all, safety plays a huge role here. And I also wonder whether it is convenient to pump water with a pump, or whether it would be better to connect the shower to a centralized water supply.

As for installing the heating element in a plastic container, you must embed it so that it does not come into contact with the sides of the barrel and is not too close to them. I will attach a detailed visual diagram with a description for you. I advise you to use a 2500 W threaded heating element with a thermostat.

To organize a summer shower with hot water you will need:

— a plastic tank of the required volume;

— threaded heating element 2500 W with thermostat;

— water level sensor;

— hose and filler fitting;

— watering can with tap 1/2;

- cable and plug;

— 10 A automatic machine.

How you will connect the shower to the water supply is up to you to decide: you can use a pump to distill it or connect it to the central water supply. Implement it the simplest way, it’s not that important.