Attaching the toilet to the installation: step-by-step installation instructions

The desire of designers to improve the appearance of toilets and create stylish bathrooms contributed to the popularization of block and frame structures with a hanging bowl.

The installation itself is not cheap, and you will also have to pay extra for its installation. Therefore, many home craftsmen hone their plumbing skills and carry out installation work themselves. Agree, would it be nice to save money by attaching the toilet to the installation yourself?

We will help you resolve this issue. In the article we describe in detail the device, operating principle and types of structures, and also provide step-by-step technology and photo instructions for installing a toilet.

The content of the article:

Types of built-in toilet designs

If the appearance of the external elements of the installation depends only on the designer’s imagination, then its internal structure can be divided into 2 options: frame and block.

Block view of installation

A distinctive feature of the block installation is that it is mounted exclusively on a load-bearing wall. The design does not provide a support frame, so it can simply be recessed into a niche.

The toilet bowl is mounted separately on the wall using metal rods.

The block plumbing installation kit has the form of a frame with a cistern and a front drain. The device has two pipes for supplying and draining water, as well as a set of fasteners. The use of such a design is justified if there is a special niche in the bathroom.

Frame installation for toilet

A frame drain is more versatile because it can be installed anywhere in the bathroom.

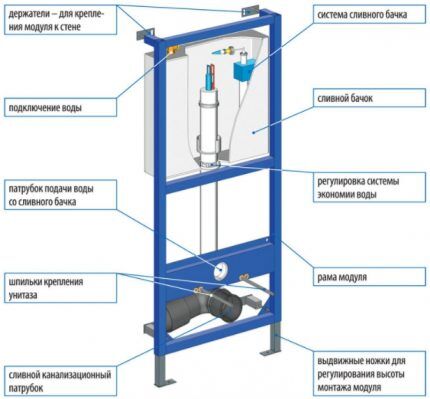

The standard equipment delivery includes:

- height-adjustable metal frame;

- clip for fixing the sewer pipe;

- cistern;

- fittings for water supply and drainage;

- drain button;

- set of fastenings.

Budget versions of designs may not have a drain button, which is purchased additionally by the buyer.

Depending on the installation location, frame installations are divided into 3 types:

- corner;

- wall;

- floor

The advantage of the frame structure is the ability to install it both on a load-bearing slab and on a false plasterboard wall. This is true for products with a double frame. The metal frame is fastened to the floor and wall at the same time. And the toilet bowl is fixed directly to the frame, which can withstand loads of up to 400 kg.

On our website there are several articles devoted to choosing an installation for a toilet:

- The best installation for a toilet: rating of popular models + what to look for when buying

- How to choose a wall-hung toilet: which is better and why + review of manufacturers

- How to choose an installation for a toilet: review of designs + tips before purchasing

- Wall-hung toilet with installation: selection rules, pros and cons of such a solution + installation steps

Design and operating diagram of the installation

Self-installation of a toilet on an installation will become easier if you understand its design and operating principles. Let's look at the elements of a frame bathroom in more detail.

Support steel frame

The metal frame is the main load-bearing element of the installation, which bears not only the weight of the equipment, but also the weight of the person sitting on the bowl.

The frame is fixed simultaneously to the load-bearing wall and the floor, but there are also designs with a double frame for installation in the partitions of large bathrooms.

At the bottom, the frame is equipped with retractable legs for adjusting the installation height. The standard height of the upper edge of the toilet seat from the floor is 40-48 cm, it depends on the height of the apartment owners. Steel pins are screwed into the frame at the front, onto which the bowl is subsequently hung.

Plastic cistern

Each manufacturer has its own shape of the plastic tank, because it is necessary to ensure good water capacity within the narrow confines of the metal frame. The surface of the plastic is covered with a heat insulator to prevent the formation of condensation.

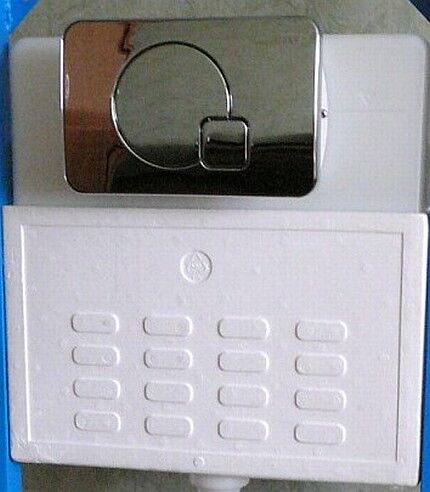

On the front surface of the tank there is a small area where manufacturers try to accommodate all the equipment: a pipe for connecting a water hose and a device for mounting a release button. It is this limited installation rectangle that will be accessed for repairs after the final installation of the equipment.

Drain dosing has already become a standard, so each flush tank has regulation of the volume of water discharged.

Types of toilet bowls

The bowl is the most beautiful element of the installation, on which designers work more than engineers. The traditional oval seat shape remains the best-selling, but rectangular, round and shaped bowls are also in demand.

Small components of the installation (fasteners, fittings, drain button, etc.) vary depending on the manufacturer, so it is better to familiarize yourself with the features of their installation in the installation instructions.

Myths about hanging plumbing

Although primitive flushing blocks were used back in Soviet times, people are still afraid to install modern block plumbing structures in their apartments. Below are some misconceptions about installations and wall-hung toilets.

Myth No. 1. A wall-hung toilet may fall under the weight of a person.

Installations are usually secured with 12 mm thick bolts. The frame structure itself and the support rods are designed for a weight of 400-450 kg. The only reason for a toilet to fall can be the collapse of the wall to which it is attached.

Myth No. 2. It is necessary to dismantle the decorative box when broken cistern.

The drain button frame is secured with latches and can be easily removed. Underneath there is a hole for connecting a water hose with a compact tap. Within this “mounting” window on the front wall of the tank there is also float mechanism, which can be unscrewed from the tank by hand and repaired without dismantling the box.

Myth No. 3. A wall-hung toilet takes up minimal space.

Block and frame installations require an additional 20-25 cm of bathroom space. Therefore, these structures take up even more space than a floor-mounted toilet. The only option for reducing space is to place the installation in a wall niche.

Myth No. 4. There are no spare parts for block installations.

The sizes of components are standardized by most manufacturers, because repairable models have priority when purchasing. In plumbing stores, picking up a broken part will not be difficult. In addition, execute installation repair you can do it yourself.

Step-by-step installation of the installation and toilet

Installing a plumbing installation yourself is not difficult. The main danger is the leakage of the joint between the sewer pipe and the toilet pipe after final installation.

To avoid such problems, you must follow all the rules for step-by-step installation installation. Next, installation schemes for toilets with various designs will be considered.

Required Tools

To install the installation and attach the toilet to it, the following tools and materials are required:

- Screwdriver.

- Adjustable wrench.

- Hammer drill with drills.

- Pliers.

- Dowels and bolts.

- Hammer.

- Level.

- Roulette with marker.

- Silicone.

The minimum tools and materials that will be useful when installing the installation itself are listed. When installing the box, other devices are needed, but this work is best left to professionals.

Installing a block installation

There are two ways to install a block installation:

- In a specially prepared niche in the wall.

- On a concrete slab, which is then covered with plasterboard.

Regardless of the type of installation, the list of steps to assemble the installation remains the same.

Step one. Applying markings in the bathroom. In small narrow rooms the toilet is installed along its axis, and in large rooms it is better to place the bowl along the axis of the drain.

First you need to draw a line with a marker or chalk from corner to corner of the room along the wall where you plan to install the installation. Then, along the axis of installation of the bowl, you need to draw a line perpendicular to the first, using a construction corner.

Step two. Formation of attachment points. In accordance with the intended axis of installation of the bowl, the locations for fixing the block structure are determined. If the axis of the bowl and the wall is distorted, you can place wooden or plastic spacers under the fastenings to achieve an angle of 90 degrees.

It is necessary to center the location of the dowels relative to the middle of the toilet drain hole. If the distance between the mounting points of the block is 60 cm, then each hole for the dowel should be drilled at a distance of 30 cm from the axis of the bowl.

After marking, you need to drill holes with a drill and insert the fasteners supplied with the product into them.

Step three. Fixation of block structure. The drain tank is screwed to the wall with screws or anchor bolts. After this, a water hose is connected to the structure, and pipes are connected that will connect to the toilet bowl.

Step four. Screwing in the bowl support pins. After fixing the block mechanism, the toilet bowl is attached to it.Metal rods are inserted into the holes for its fastening and the places for their fastening on the wall are determined so that the height of the toilet seat is 40-48 cm.

After this, the toilet is removed, and holes are drilled in the concrete slab for the rods, which are then fixed in the wall with fasteners.

Step five. Installation of sewer drain. The toilet bowl is hung on support pins and a pipe for draining water from the tank is inserted into it. After this, the sewerage scheme is determined and its installation is carried out with rigid fixation of the 110-mm outlet pipe.

Step six. Covering a block installation and installing a toilet bowl. After installing the sewer system, the toilet bowl is removed and decorative cladding of the entire plumbing structure with tiles or moisture-resistant plasterboard begins.

When the cladding work is completed, the drain button is installed, and the bowl is placed on the drain pipes and metal support pins. After this, the toilet is attached to the wall with nuts.

Instead of lining the drain hole of a block structure, support rods and sewers, they are sometimes filled with concrete.

To do this, after the fifth step, a common wooden formwork is installed around these structures, and its internal volume is filled with concrete. 5-7 days after pouring, the formwork is removed, and the toilet bowl is docked with support pins rigidly fixed in concrete, sewer pipes and a cistern drain.

Installation of a toilet with frame installation

The installation of a frame installation with a toilet can be carried out in any place in the bathroom. Single-frame structures are attached simultaneously to the wall and floor, and installations with a double frame can be installed in the middle of the room in a special partition.

The installation of both design options differs only in the location of the metal frame and the shape of the decorative cladding, so their installation will be discussed in one step-by-step instruction.

Step one. Assembly of the frame structure. Installation of the installation begins with the assembly of the metal frame. To compensate for uneven floors and walls, the frame design includes retractable legs. After adjusting the position of the frame according to the level, the legs are rigidly fixed in the required position.

The installation is applied to the installation site, and a marker marks the places where it is necessary to drill holes for dowels.

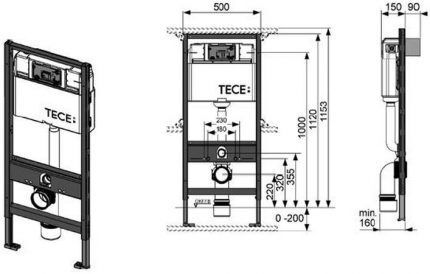

Step two. Installing the tank on a metal frame.The height of the water tank can also be adjusted, but not in all installation models. The recommended height of the release button is 1 m from the floor surface.

Based on this parameter, the level of location of the drain tank inside the metal frame is selected. Fittings for draining water are installed together with the tank.

The frame structure often has a height-adjustable horizontal metal strip. It has holes or clips for attaching the support rods of the toilet bowl, pipes for draining water from the tank and sewerage.

Step three. Sewerage installation. A 110 mm sewer pipe is laid to the frame.

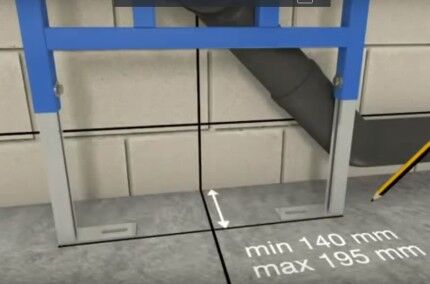

Step four. Fastening the frame structure. Holes are drilled to attach the metal frame, and then it is screwed with screws or anchor bolts to the wall and floor at the designated points. The optimal distance from the frame frame to the wall is 140-195 mm.

The sewer pipe is fixed to the frame using available fasteners.

After the frame installation is completely assembled, it is necessary to ensure that the supporting heights of the pins and pipes are adjusted correctly. To do this, a toilet bowl is hung on the structure.

Step five. Checking for leaks. A water pipe is connected to the drain tank and the tap is opened. After filling the tank, a test drain is performed.If there are no leaks, the toilet bowl is removed and the installation begins.

Step six. Forming a box around a frame installation.

There are two ways to close a metal frame:

- sew up with plasterboard;

- cover with bricks and tiles.

Before insulating the installation, it is necessary to close its pipes with plugs or plastic bags. For sheathing, it is necessary to use a moisture-resistant plasterboard sheet with a thickness of 12.5 mm. The box will be a decorative element that does not bear any supporting load.

When covering, it is necessary to provide in advance the formation of holes for the pipes and support pins of the toilet bowl.

Step seven. Attaching the toilet to the installation frame. You can begin installing the toilet bowl on the installation immediately after plastering and painting the plasterboard box. If the metal frame was lined with bricks and tiles, then the toilet should be installed on it 10 days after completion of the work.

Before placing the toilet on the support pins, it is necessary to lubricate the rubber gaskets of the sewer pipes and the drain hole of the tank with silicone. Also, a layer of sealant is applied to the back wall of the toilet at a distance of 5 mm from the edge along the entire perimeter of contact with the wall.

The bowl is fixed to the wall with two bolts screwed onto metal pins.After a day, you can perform a test drain to check the operation of the entire installation.

Attaching a floor-standing toilet to the installation

Block and frame installations do not necessarily require the installation of a wall-mounted toilet bowl. It can be installed classically on the floor. The installation scheme for a floor-standing toilet differs from the above methods only in the location of the fastening elements and the sewer pipe.

When installing the toilet on the floor, it is fixed both to supporting horizontal rods and screwed to the floor. Bowl manufacturers choose the type of fastening based on the shape of the product.

When fixing the toilet to the floor, you need to mark and drill two holes in the floor tiles for fastening. After covering the installation with a box, the toilet bowl is mounted to the sewer and cistern drain pipes, and then screwed to the floor using the existing fasteners.

To connect the sewer pipe and the toilet bowl, you can additionally use corrugated pipe.

Covering the installation with plasterboard

To disguise the less attractive side of installing and connecting plumbing equipment, the method of plasterboard sheathing is often used. Behind the box constructed from it, both the support system itself and the supplied communications are perfectly hidden.

The following selection of photos will introduce you to the general principle of plating:

Helpful installation tips

At installation of a toilet with installation There are a number of important nuances:

- It is better to supply water to the opening of the drain tank using plastic pipes, because the service life of rubber hoses is limited to 3-5 years.

- It is impossible to fix toilet bowl support rods in old load-bearing walls.If the drill goes into the slab without encountering much resistance, then it is better to additionally concrete the rods with the sewer pipe and the drain pipe of the tank.

- The frame must be bolted in at least 4 places.

- The water supply pipe must have a separate shut-off valve in a convenient location for access.

Following the proposed instructions will protect the apartment from flooding and prevent the need to dismantle the decorative box during the first years of operation of the toilet.

Conclusions and useful video on the topic

The videos will allow you to put together a complete puzzle of the toilet installation assembly diagram in your head in just a few minutes. After viewing them, the step-by-step instructions described above will become more understandable and meaningful.

Frame installation assembly process:

Installing a block installation in a niche:

Attaching the toilet to the installation frame:

The proposed step-by-step instructions for installing a toilet with frame and block installations take several hours of work, if you do not take into account the time to create a decorative box.

The essence of the installation comes down to smooth and strong fastening of the frame, connecting the pipes and docking the toilet bowl with the flush block. This can be accomplished by every business person who knows how to handle the necessary tools.

Do you have practical skills in attaching a toilet to an installation? Share your own installation experience or ask questions about the topic of the article. The comment block is located below.

I initially wanted a block installation because I thought it would be easier to install. But when I got into it, I realized that it didn’t suit me.This type of installation completely blocks the sewer pipes, you can’t reach them later, I also have taps below. That's why I chose the frame type. It is a little more complicated technically, there is more fiddling with it, but access to the pipes is free.

I have a frame installation, installed 9 years ago, when I was doing renovations. I chose a large tank and flushed with a button in two positions.

The fact that the installation takes up less space than a compact toilet is purely visual. If you measure with a tape measure, the toilet flush is the same or even greater. But in appearance, the wall-hung toilet looks more weightless and less monumental, because it does not have a connection to the floor. And it’s much easier to clean, the space underneath is free. As for the reliability of the design, I didn’t even look inside the entire time.