Installing corrugation on a toilet and the specifics of connecting plumbing with it

Lightweight but durable plastic plumbing fixtures have greatly simplified the installation of many appliances.In particular, the corrugation for the toilet allows you to connect the outlet of this type of plumbing to the sewer outlet much faster and without much difficulty.

Do you want to install the corrugation yourself? We will tell you how to do this - the article discusses the procedure for installing corrugations and options for connecting toilets with different types of outlet. Installation tips and recommendations for choosing the best corrugation are also provided.

Thanks to a detailed analysis of important nuances, the connection procedure is quite accessible even to a non-professional.

The content of the article:

Types of corrugations and tips for choosing

Corrugation belongs to the class of drainage fittings. This is a durable stretchable adapter made of polymer materials and shaped like an accordion. Its properties remain unchanged even when it is heated and stretched.

The corrugated pipe has the shape of a sleeve with a plastic cuff that has a rubber seal inside. With its help, toilets with different types of flush - oblique and horizontal - are connected to the sewer system.

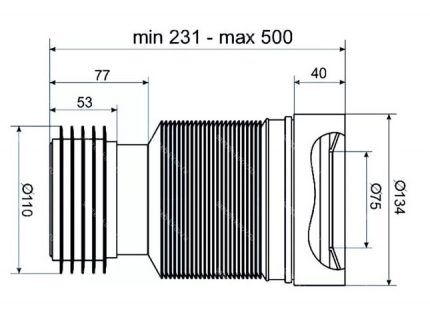

Its dimensions range from 21.2 to 50 cm. The end of the pipe with the outlet has a cross-section of 11 cm, and the one connected to the outlet has a cross-section of 7.5 cm inside and 13.4 on the outer surface.

Types of corrugated pipe

Corrugations available for sale are unreinforced or soft, reinforced with walls reinforced with stainless wire, and rigid.The first ones are relatively cheap and do not have very high strength characteristics.

Soft corrugation fits any structure and is easier to install. The bad thing is that after a few years of operation, difficulties with draining may arise due to sagging of the corrugated adapter.

Reinforced pipe has much higher characteristics, it is more reliable and durable, but also more expensive. These corrugated pipes have a rigid pipe with a turn, and its continuation is the corrugation. They are indispensable when you need to connect a toilet with an oblique outlet to the drain.

Detailed information about the types of toilets and types of release is discussed in another our article.

Corrugations are also divided according to such criteria as length - they come in short and long. The length of the folded short corrugation is 21.2 cm, and if stretched it is 32 cm. The compressed long corrugation has a length of 28.5 cm, and it can be stretched up to 0.5 m.

Do not pull the connector end to end - this may lead to leaks. When choosing a corrugation, you need to look at the density of the material, the condition of the seals, and the uniformity of the cuff.

The corrugations and direction of the bell differ. It can be straight or curved at either 45⁰ or 90⁰.

When is corrugation used?

The use of corrugation is justified in 3 cases:

- When the bowl and bell have different types of outlet. This happens often because... The design characteristics of toilets are different. Not all types of these plumbing fixtures can be connected in a standard way, and then the corrugated pipe can act as an adapter.

- The toilet is offset in relation to the sewer pipe. This situation is possible when tiles are laid on the floor or when the location of the toilet is changed. It will not be possible to connect mismatched elements with any other pipes, and only the use of corrugation can easily solve the problem.

- As a temporary option for connecting a toilet.

Using corrugation provides many advantages, but this method is not without its disadvantages. The plastic walls are thin and if something sharp accidentally gets into the pipe, they will be damaged. Dangerous for corrugations and boiling water. All this reduces the service life of the plastic connector. If the corrugation is stretched and not fixed, it will sag.

Features of choosing corrugations

When buying corrugation for connecting a toilet, you need to choose the highest quality one. This will reduce the possibility of leaks to zero and will make the product last longer. The difference in prices is small, so it’s better to pay a little extra and save yourself from unnecessary problems in the form of pipe contents on the floor.

Any comparisons between domestic and foreign corrugations are not in favor of the first. Our corrugation does not cover the pipe walls well. No tricks help - the domestic corrugation does not completely adhere to the inner surface of the sewer pipe.

Often a corrugated pipe forms waves, which causes a leak. Even professional installation will not help you avoid such troubles.

The best corrugated producing countries are Italy, the Czech Republic, and England. Having visited the market, you will notice that most of the products are supplied from China. Don’t be tempted by their cheapness; they won’t last long and what seems like savings will turn into additional costs.

When choosing a corrugated sleeve, you should look at the thickness of its walls. If the other characteristics are equivalent, then you should buy the one with thicker walls. It’s bad that this information is not always indicated in the description attached to the product.

Some corrugated pipes are designed to attach an elastic band together with a plastic ring. There are models that provide a direct connection - the elastic is inserted into the end and fixed to the herringbone. The second option is more reliable.

The procedure for connecting a toilet using corrugation

The work of connecting the toilet is not difficult, but a certain sequence of actions must be followed. It is more convenient to begin installing the corrugation to the toilet, both new and old, even before fixing it in a permanent place.

When you don’t need to do anything with a product just brought from the store, then the outlet of the old device must be freed from layers of cement or sealant.

The sewer pipe socket also needs to be cleaned. If this place is not cleared of residual materials, it will be difficult to ensure the tightness of the connection.

Then proceed according to the following scheme:

- The end of the pipe that is going to be connected to the sewer is treated with silicone. The end of the outlet should be evenly blocked by a 50-60 mm outlet. You need to tighten it with a turn, without allowing any distortions. To facilitate the process of tightening the corrugations, apply soap to the rubber seal in the socket.

- Insert the corrugated pipe into the inlet of the system at one end, and connect the other end to the toilet.

- Pour water into the toilet to check the joints.

- Mark the toilet mounting points on the floor, first disconnecting the corrugation.

- Drill holes and coat with sealant.

- Attach the toilet to the floor. In this case, the fastening bolts are tightened until the device stops wobbling and becomes perpendicular to the floor. If you increase the force, you can crack the base.

- Reconnect the adapter, treat the joints with plumbing sealant and check them again for leaks.

- The screed is poured and the floor surface is finished.

The outlet shape of a floor-standing toilet can be vertical, horizontal, or oblique. In each case, connecting a toilet has its own characteristics. In old houses, vertical and oblique outlets are most often found, while in new houses - horizontal.

To connect the toilet to a sewer pipe, the outlet of which is in the floor, a corrugated pipe with a socket bent at 90⁰ is suitable. For a plumbing fixture with a horizontal outlet, a corrugation with a socket rotation of 45⁰ is mainly used.

It happens that in a bathroom with a small area it is necessary to place a lot of plumbing fixtures. To do this, the sewer pipe needs to have many branches, and this is not always realistic.

The only way out is to use a corrugated toilet bowl with a drain. It is the only alternative when the bathroom is located almost next to the toilet.

It happens that for some reason the corrugation becomes unusable. Replacing it is easy. To do this, you don’t even have to dismantle the toilet, but you need to prepare rags and buckets.

Shut off the flow of water into the toilet drain, then disconnect the tube intended for water flow. The tank is emptied of water and removed. The corrugated pipe is simply compressed and disconnected from the device. Next, remove it from the socket.

The new pipe is inserted into the socket, compressed, and pulled onto the toilet outlet. All this can be done with a stretched corrugation. If it is extremely compressed, nothing will work. This is a nuance that must be taken into account during the initial installation.

We have other useful articles on our website with detailed instructions for installing toilets of various types and designs:

- How to install a toilet with an oblique outlet: detailed technical instructions

- Toilet with vertical outlet: how it works and works, pros and cons, step-by-step installation instructions

- Corner toilet with cistern: pros and cons, diagram and features of installing a toilet in the corner

- How to connect a toilet to a sewer system: a review of installation technologies for all types of toilets

Some useful installation tips

Despite all its advantages, plastic corrugation is not designed for heavy loads, so it cannot be mounted inside a wall. If the distance from the wall to the plumbing fixture is large, you should carefully select the length of the connector.

The corrugation stretches, but if this property is abused, the walls may become thinner and the strength of the structure will decrease. There is no need to stretch the corrugation before installing it - this will lead to sagging of the outlet.

Stretch it immediately before connecting to the sewer pipe. To avoid blockages, there is no need to allow sagging or counter-slope of the corrugation. When the sewer pipe and the outlet of the plumbing fixture are located relatively high, a support is built under the connector.

When you decide to install a protective screen to mask communications, and use the fenced-off space as a place to store various small items, do not forget that a heavy object can damage the corrugation.

Before installing the plastic corrugation on the toilet, take into account that the product of standard sizes does not allow it to be installed flush against the wall. It's better to use here eccentric.

We must not forget about plumbing standards when choosing a slope. Do not turn the reinforced pipe at a right angle. If the device occupies a non-standard position, an offset connecting element is used.

The corrugation can compensate for quite a significant displacement. Thanks to it, the device can be moved by a maximum of 200 mm. It can also be rotated to any angle you like. To do this, use an option such as a serial connection of two corrugated pipes.

You need to pay special attention to the angle at which the corrugation is bent. If the pressure is too high, draining cannot be carried out effectively. In addition to everything, the corrugation may crack at the point of pinching.

Connection without corrugation

If the shapes of the outlet of the toilet bowl and the sewer pipe coincide, you can do without corrugation. When connecting a toilet without using corrugations, certain rules are followed. In this case, they use an adapter, which is also called fan pipe or a pipe.

The installation method is chosen depending on the shape of the toilet outlet: in the case of an oblique outlet, installation is carried out on the floor; in the case of a vertical outlet, the toilet is mounted in the wall at an angle of 90⁰; in the case of a horizontal outlet, the toilet is also installed in the wall, but at an angle of 30 to 40⁰.

Option #1 - vertical toilet outlet

The model of this toilet is equipped with a siphon with an outlet pipe.First, a place is marked for this structure, then a flange with a lock is installed.

The sewer pipe is mounted in its center and a plumbing fixture is installed. The toilet is turned until it is completely fixed. The pipe takes its place automatically.

This scheme is good because the wiring becomes invisible because pipes are hidden in the floor. This saves space. The downside is that to eliminate a leak, you will have to crack the floor covering.

Option #2 - horizontal type of release

This release is directed back towards the wall. Here you cannot do without a sealing cuff. First, the toilet is fixed to the floor with dowels. We recommend more about the best methods for attaching a toilet to the floor view here.

Next, make the connection very carefully.

First, the sealing cuff is installed without sealant, then tested by pressing on the drain. If there are no leaks anywhere, the final installation is done.

Option #3 - oblique toilet outlet

To connect using a plastic pipe, mix red lead with drying oil and coat the toilet outlet with this. A seal is made on top in the form of a strand of resin. The seal is coated with red lead. The outlet is inserted into the sewer pipe and the toilet is installed.

A sealing collar can also be used here. Having dressed it for release, the latter is placed in the sewer socket. Be sure to seal the connection.

Conclusions and useful video on the topic

Here you will see how to install a toilet with an outlet and connect it using corrugation:

Here the author talks about his own experience of connecting a toilet:

As you can see, the corrugation used to connect the toilet is a small but very important element of the system. You need to choose it responsibly, and when installing it, you should follow all instructions.

If you follow these recommendations, the structure will be as durable as possible and will last a long time.

Do you know how to connect a toilet to a sewer using corrugation? Perhaps you noticed an inaccuracy in the description of the installation process discussed in our article? Or do you have useful recommendations based on your own experience? Write about it in the comments below.

In principle, connecting the corrugation to the toilet is not a difficult task. But you still need to be aware of all the nuances of installation. There are a few important details you need to know if you are not a professional plumber. Firstly, you should always select the correct length of the corrugation itself, which is exactly what you need, neither shorter nor longer. Secondly, to avoid leaks, never screw the connector end-to-end. And of course, the corrugation itself must be made of high-quality material.

Well, yes, I immediately remember how I installed the toilet. Only my situation is different. Nowadays, manufacturers mostly make toilets with direct flush, and my sewer pipe is still an old cast iron 250. And it is located at an angle. I used corrugation as an adapter.I don't remember the brand or manufacturer. The only thing I know is that I didn’t have to stretch it much. Now I’m thinking, if the thickness of the corrugation wall is small, but I didn’t stretch it much, will it work for me like an expensive analogue?

Hello. Well, one can only guess here. I have the cheapest corrugation that was found in the city, it worked tirelessly for 7 years, the toilet was replaced faster 🙂 Corrugation is afraid of deflections, clogs accumulate in them, which are problematic to remove with a plumbing cable, and the adapter can be damaged. But you don’t have to, you have a slight stretch. In general, the toilet should be used correctly and there will be no problems with components or, especially, blockages.

How to extend the life of your corrugation:

1. Do not flush glass and other sharp objects down the toilet.

2. Be careful when removing blockages using a plumbing cable.

3. Use aggressive toilet cleaning products less often, which can thin the walls of the plastic.

4. Try not to flush large amounts of boiling water down the toilet.

5. Do not flush toilet paper or napkins (especially wet ones).

6. When pouring greasy water into the toilet (many people use it as a drain), try to dilute it with detergents first.

7. If there is still a stretch, install supports under it.

It would seem that you need to install a seemingly ordinary corrugation, but there are so many nuances. To be honest, at one time I stuck a corrugation with an eccentric into the drain and somehow didn’t even think about the correct rotation and angle of inclination. I've been washing it off and on for about 5 years now.

Thank you! A lot of useful information! But maybe you can give me a hint - a toilet has been installed in a new building, but there is a strong unpleasant smell coming from the toilet.At the end of the corrugation there should be some kind of opener-closer when draining, so that odors do not come from the sewer pipe, right? Thank you.

Most likely the corrugation was simply stuck in without sealant. Plus it's cheap in itself. This is a common occurrence in new apartments.