Welding machine for polyethylene pipes: which one is better to buy and how to use it correctly

Polyethylene pipes are lightweight, easy to install and relatively inexpensive. To lay communications of this type, you need a welding machine for polyethylene pipes.Proper use of equipment and adherence to work technology allows you to obtain a reliable, almost monolithic connection that will last for many years.

We will tell you how to choose the right device for forming strong and tight connections. The article we presented describes in detail the features of welding sections of a polyethylene pipeline. Those who wish to carry out the work themselves will find useful recommendations from us.

Features of welding polyethylene structures

One of the useful features of polyethylene pipes is some design flexibility. Welding allows you to preserve this property at the junctions of individual sections of the pipeline, which ensures uniform characteristics along its entire length.

Such pipes are welded for both trench and trenchless installation, if a steel or fiberglass pipe is used as the main “case”.

Most often, two types of welding are used to connect polyethylene structures: butt and electrofusion (also called thermistor). Before choosing the right equipment, you should familiarize yourself in detail with welding technology, which must be observed when making connections.

When working with polyethylene pipes, the ends of the structures are first heated to the melting temperature, then they are connected and compressed under pressure. It sounds simple, but in practice, to obtain a high-quality weld, you need good professional skills.

It is necessary to correctly determine the time of each stage, as well as the working pressure that will be applied to the working surface during its heating and connection.It is recommended to carry out work at ambient temperatures within -15...+45 degrees. This method is not suitable for structures with a wall thickness of less than 4.5 mm.

Butt welding can be performed by two specialists, without the need for heavy equipment. The work time and energy costs for their implementation in this case will be very moderate.

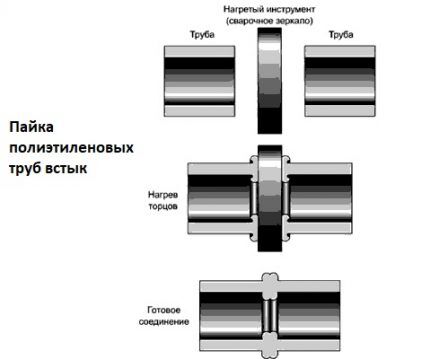

In more detail, the operation diagram for butt welding is as follows:

- The ends of the communications at the junctions should be cut to remove dirt and eliminate unevenness.

- After this, the ends of the pipes are heated using a welding machine to form a primary flash.

- Heating is continued for some time to reach the melting point of polyethylene.

- Now the welding machine is removed, and the hot ends of the pipes are carefully connected, forming a finishing flash.

- All that remains is to wait for the structure to cool and check the quality of the weld.

To trim the ends, use a special tool - an electric trimmer. This device allows you to cut strictly perpendicular to the axis of the structure.

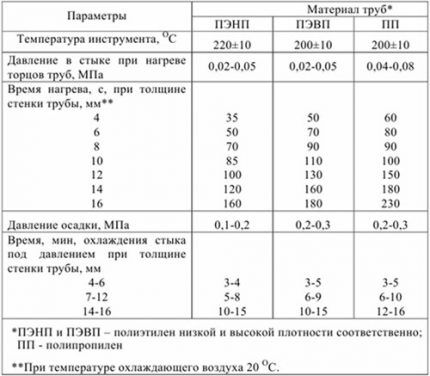

Trimming is performed in microlayers until a continuous strip of polyethylene is obtained at the cut site. The temperature and time of exposure of the heater to the ends of the pipes is determined taking into account the grade of material.

It is very important that the ratio of these indicators, as well as the pressure on the working surface, is maintained with maximum accuracy. This is the defining moment for obtaining a high-quality weld.

At the end of the heating stage, you need to very quickly and carefully move the heater of the device to the side so as not to damage the integrity of the working surfaces and to avoid accidental contamination.

When connecting ends heated to the required level HDPE pipes it is necessary to provide the same pressure as when heating the surfaces. Cooling of the weld must also be done very carefully. Do not remove the connected pipes until the heated polyethylene settles.

If all operations are performed correctly, a neat, symmetrical collar is formed at the junction of the elements. If the seam looks uneven or sloppy, it means that serious flaws were made during the welding process. The strength of such a connection will be very doubtful.

If it is necessary to connect pipes with thin walls (less than 4 mm), it is recommended to give preference to electrofusion welding, which is also called thermistor welding. This option also allows you to create a high-quality connection, while the process of completing the work is even simpler than using the butt method.

To perform this type of welding, follow these steps:

- Clean the surface of the ends and the part of the pipe that will be under the coupling from contamination, with a good margin.

- Degrease work surfaces.

- Remove the oxide layer.

- Place the coupling on the working surfaces.

- Center the structure.

- Warm up and weld the joint.

- Wait for the welding area to cool completely.

All preparatory work should be carried out with great care, since the presence of even the slightest contamination can significantly deteriorate the quality of the connection. If, after removing the oxide layer, foreign substances accidentally get onto the surface, cleaning should be repeated.

The cooling process is subject to the same requirements as when using the butt method. Any change in the position of the pipe during this period can be fatal to the weld. Electrofusion welding is performed using fittings in which metal heating coils are placed during manufacturing.

To start the process, you should install the fitting at the connection point and attach it to the welding machine, which will perform the heating. During the welding process, the fitting material expands, providing the necessary pressure and sufficient sealing. At the end of the work, the power supply is disconnected, and the fitting remains at the connection point.

Another interesting one method of welding polyethylene pipes - socket This is the least popular option, which, unlike the technologies described above, can only be used for laying internal communications. This is also a fairly simple method, technically very similar to the process of soldering polypropylene pipes.

Socket welding can be recommended in rooms where the pipeline layout is complex, replete with slopes and turns. To perform operations of this type, almost the same soldering iron is used as for polypropylene structures, and the equipment settings are not much different.

How to cook polyethylene?

Based on information about the features of welding polyethylene structures, you can determine the main points that should be taken into account when choosing suitable equipment:

- pipe characteristics: polyethylene grade, diameter, wall thickness, etc.;

- features of the pipeline configuration;

- the location of the pipes (indoors or outdoors);

- acceptable degree of process automation;

- suitable welding technology, etc.

For butt welding of polyethylene pipes, special equipment is used.

Craftsmen have devices at their disposal that can be used to perform welding in manual, automatic and semi-automatic modes. The easiest way to master the operation of a hand-held device, but it is intended only for small-diameter pipes.

The parameters will have to be determined from tables. The accuracy of welding on manual equipment is not always high enough; in order to successfully work with this kind of units, certain experience is required. Semi-automatic devices are much more convenient; they are equipped with hydraulics: a station and a centralizer, which greatly simplifies manipulation.

These devices are used to connect pipes of larger diameter than when working with manual equipment. Although the movement of the device elements is automated using hydraulic devices, the welding parameters will still have to be set according to tables.

Here the process is completely controlled by the computer processor. The master only needs to enter the necessary parameters, for example, the material from which the pipe is made, the diameter of the structure, SDR, etc.

When using tables, welders operate with concepts such as:

- pipe wall thickness;

- heater operating temperature;

- diameter of the structure;

- end heating time;

- burr sizes;

- welding and preheating pressure;

- heating and changeover time;

- time to create pressure during the settling stage of the structure;

- cooling time.

The temperature of the heater depends mainly on the characteristics of the material from which the pipes are made. To determine this parameter, not only tables, but also graphs are used.

Butt welding equipment from the Swiss manufacturer “Georg Fischer” is of high quality.The assortment is very diverse, characterized by European quality and a justifiably high price. Models from the KL Line and Weld Line lines are relatively inexpensive.

They allow you to weld structures with a diameter of 630 mm or less, and are distinguished by a simplified design that ensures increased reliability of the unit. Suitable for installation of water supply and sewerage pipes, incl. and pressure.

Welding machines from the GF Line line from the same manufacturer have a more complex design and are more expensive. These are automatic devices using SUVI technology. Such units are often used when laying gas pipelines; they are suitable for working with pipes with a diameter of 160-1200 mm.

For electrofusion welding, devices that automate the process to varying degrees can also be used. The quality of welding depends not only on the type of device, but also on the quality of its execution, as well as on operating conditions.

Professional pipelayers prefer to use units for their work. They are equipped with a scanner that scans a barcode provided by the pipe manufacturer.

It encrypts a complete block of information about the features of this material. After scanning, all the necessary settings will be installed. If the pipes are cleaned and prepared, you can immediately begin soldering. Good electrofusion welding machines not only monitor each stage of welding, but also issue a warning in the event of an error.

When choosing the type of machine, you should take into account the following feature of welding equipment.Thermistor devices are suitable for working with pipes of almost any diameter, since heating is carried out through a coupling of the appropriate size. But devices for butt welding need to be taken for a specific diameter of the structure.

Thermistor welding devices, in addition, have a very reasonable price compared to analogues for butt welding. But it should be remembered that when using them, you will have to pay separately for electric couplings. For small-diameter pipes, couplings are not that expensive, but when working with large structures, the price difference can become noticeable.

The fact is that polyethylene pipes of small diameters (110 mm or less) are supplied in coils. In this way, seamless and flexible communication up to 200 meters can be achieved.

To install such a structure, you will need a minimum number of connectors. But when it comes to pipes with a diameter of more than 110 mm, the buyer is provided not with coils, but with sections of only 12 mm or less in length.

Obviously, to install such a pipeline, a significant number of electrical couplings will be required to connect many 12-meter sections. Equipment for electrofusion welding is compact in size.

If work needs to be carried out in cramped conditions, this option may be the only possible one.The minimum diameter of structures when using electrofusion welding can also be almost anything, starting from 20 mm.

Attention should also be paid to the possibility of repairing the pipeline, if such a need arises. Even the geological features of the area where the laying is carried out are important. sewer pipeline or water supply lines. For example, in earthquake-prone areas, butt welding is unacceptable; the thermistor method is required.

When choosing welding equipment, you should pay close attention to such issues as the availability of warranties, access to service, the possibility of regular certification of the device, etc. A reliable seller must have permits for equipment that is usually manufactured abroad.

Conclusions and useful video on the topic

Comparison and useful tips for choosing welding machines:

This video demonstrates the step-by-step process of assembling a welder for PP pipes with your own hands:

Choosing a suitable welding machine for polyethylene pipes is not so difficult. It is better to give preference to products from well-known manufacturers in an acceptable price category. If the welding technology is strictly followed, a reliable connection can be obtained.

Tell us about how you chose a welding machine to assemble a polymer pipeline at home or in the country. Share the arguments that determined your choice. Please leave comments in the block below, post photos related to the topic of the article, and ask questions.

Can you say something about the Protva welding machine for PE pipes? They offered it for suspiciously little money. I doubt whether to take it.

Protva has been in active operation for a year now, no problems have been identified so far

I would recommend the Prosvar device. Best price/quality. There were Protva and Trassa devices, which were still fragile. And they constantly required annual calibration...

I would recommend the Prosvar device. Best price/quality. There were Protva and Trassa devices, which were still fragile. And they constantly required annual calibration...