How trenchless pipe laying is done: features of the method + example of work

When constructing new pipelines, as well as when repairing or replacing old communication lines, trenchless pipe laying is actively used.

A variety of methods allows you to choose the optimal method, depending on the complexity of the site or the density of the building.

In this material we will talk in detail about methods of trenchless pipeline laying and their distinctive features.

The content of the article:

Advantages and features of BPT

The obvious advantages of trenching over excavation are the following:

- reduction of work time;

- minimizing costs for restoration of amenities;

- maintaining the operation of infrastructure facilities as usual;

- reducing the impact on environmentally sensitive areas.

The choice of trenchless pipeline laying method depends on the diameter of the required well, the characteristics of the landscape and soil, the material of the pipes being laid, and the presence or absence of existing communications.

There are many implementation options, but among them four main methods can be distinguished: rehabilitation, punching and puncture of the soil, horizontal directional drilling.

Reconstruction and replacement of the pipeline using the sanitation method

The rehabilitation method is used in cases where the audit process revealed the need for complete or partial replacement of the existing pipeline.

With the help of sanitation, the following problems are effectively solved:

- clogging of pipeline sections and formation of cracks;

- destruction of local branches of communications by tree roots;

- threat of pipe rupture due to corrosion.

Depending on the state of communications and the assigned tasks, they resort to relining or renovation technology.

Relining technology or “pipe in pipe”

Relining is a rehabilitation option used for pipelines in which an insignificant reduction in diameter is possible. If the actual service life of metal pipes has been exhausted and there is concern that they will continue to work until the next breakthrough, then they are first cleaned of calcium deposits, rust and sand.

A polyethylene liner is prepared in the form of a sleeve, which is first filled from the inside with a polymer composition that is evenly distributed along the entire length. This polymer stocking is straightened inside the pipe under water or air pressure, while simultaneously turning it inside out so that the previously applied composition is adjacent to the walls of the pipeline.

After the hose has filled the entire segment of the worn pipeline, a polymerization process is carried out under the influence of temperature. As a result, both the strength of communications and their throughput increase.

Another relining technology involves laying new polypropylene pipes from inside the existing old ones. In this way, steel, ceramic, asbestos-cement, cast iron, concrete and reinforced concrete pipelines with a diameter of 200-315 mm are replaced.

It must be taken into account that in places PVC pipe connections a seam of about 15 mm is formed, and from it it is necessary to measure the gap between the inner diameter of the old pipe and the outer surface of the new pipe.

Due to the low hydraulic resistance of plastic pipes, the throughput does not deteriorate even with a decrease in diameter.

Upgrading pipelines using renovation technology

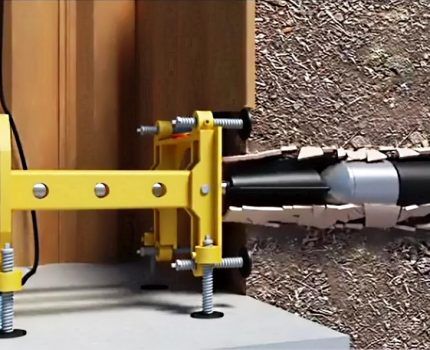

Another rehabilitation option is renovation. It differs from relining in a much less gentle attitude towards existing communications, which are destroyed and compacted into the ground, creating a protective shell for a new pipeline, which often has a larger diameter.

For such trenchless pipe laying, specialized equipment is required - a pneumatic impact machine with an expander cone equipped with cutting ribs is used. The video below the article clearly shows how the cone copes with a 6 mm steel pipe.

The working mechanism is fixed to the traction cable, after which modules made of PVC pipes are gradually attached, the length of which can vary from 600 to 1000 mm, depending on the width of the well. The pneumatic hose is connected to the compressor, after which, together with a safety cable, it is passed through the attached modules.

The entrance to the pipeline being replaced is expanded and a pneumatic impact machine is inserted into it.Moving along the communications, she breaks them, at the same time pulling the laying material behind her.

Soil punching methods

Soil punching is also performed in a significant number of variations. This is microtunneling technology, the use of pneumatic punches, directional auger drilling, controlled and uncontrolled puncture.

Each of these trenchless installation methods is in demand and relevant depending on the location of communications.

Pipe case or unguided puncture method

With this method, the casing pipe is pressed into the soil, and at the same time it is removed. More often, augers are used for sampling; less often, compressed air and water washout are used.

Uncontrolled puncture is used in any type of soil, although difficulties may arise in the case of non-cohesive soils and in the presence of large stones, when the casing is compressed by the soil or its progress is blocked.

At the stage of preparation of work, the casing pipe is placed in the pit clearly along the axis of the puncture. Due to possible obstacles, the trajectory of movement can be adjusted by using two pipes, one of which is selected with a larger diameter than required, and a string of pipes of the required diameter is laid inside it.

The outer pipe serves as a kind of case and protects the working pipeline, which is important in cases where installation is carried out under railway or tram tracks, as well as under highways with heavy loads.

The difference in diameter is usually 150-250 mm, and the interpipe distance is subject to backfilling - filling with cement-sand mortar.This reduces the soil pressure on the working pipe, reduces the load on it from transport, and also provides protection from the influence of other communications located nearby.

The length of casing pipe segments ranges from 3 to 12 meters; During the laying process they are welded sequentially.

Differences between controlled punctures

This method differs from uncontrolled puncture by the additional use of whipstocks - steel plates fixed to the front of the casing. They are raised using hydraulic cylinders, thereby correcting the direction of the puncture.

In both cases, a bentonite solution is used to reduce friction, which is pumped out after laying the pipeline and can be reused after filtration.

You can read more about the technology of laying pipes using the puncture method in this material.

Using pneumatic punches in dense soils

Using pneumatic punches to pierce the soil is the most inexpensive, fastest and most effective method, due to the relatively high accuracy of trenchless excavation.

This method does not require the manufacture of additional stops for hydraulic jacks, it uses small and easy-to-transport equipment, and imposes minimal requirements for preparing the construction site.

Due to the compressed air, sufficient impact energy is developed, under the influence of which an open steel pipe up to 80 meters long is driven into high-strength soils.The average laying speed is 15 meters per hour. After installation, the pipes are cleaned of soil with water and compressed air. Large diameter pipes are cleaned manually.

Advantages of microtunnelling technology

The microtunnelling process is fully automated. Casing and working pipes are made not only from steel, but also from ceramics, fiberglass, cast iron and reinforced concrete. The average driving distance without reinstalling the jacking station is from 100 to 250 meters.

The distance range varies depending on the type of soil, the power of the punching frame with which the microtunnel complex is equipped, as well as the material of the pipes used - depending on how much compression force the pipe can withstand.

Use of directional auger drilling units

The use of auger installations is a cheap alternative to microtunneling. Such installations make it possible to lay casing pipes with high precision and compliance with the design slope, which is important for gravity communications.

Quicksand and large solid soil inclusions may limit the use. The driving distance usually does not exceed 80 meters.

The use of hollow shaft augers allows drilling to be carried out without developing a reception pit.

Horizontal directional drilling method

Perhaps this is the most expensive method of all existing in trenchless pipe laying, but also the most high-tech.

HDD is used not only when it is necessary to drill over long distances and lay large-diameter pipes, but also in cases where it is necessary to lay a small section of a pipeline with a small diameter in close proximity to private property or objects of cultural value.

The process uses drilling fluid, which reduces friction when pulling a string of pipes, maintains the developed soil in a suspended state to prevent compression of the laid material, cools and lubricates the equipment, and carries the developed soil to the surface.

Drilling fluid is prepared by diluting bentonite with water - a natural mineral with a complex of special additives. The resulting suspension prevents the collapse of canals and eliminates the need for partial or complete pumping of groundwater, as it is able to perform its functions even in permeable soils.

Horizontal directional drilling in water-saturated soils requires precise control of the pressure and flow rate of the drilling fluid, as well as the use of special additives in its preparation.

Since the water for preparing the solution is taken from bodies of water located in the immediate vicinity, it is necessary to take into account the presence of mineral salts and the pH of groundwater, since these parameters can affect the stability of the suspension. This approach avoids uncontrolled erosion.

Carrying out HDD work can be divided into several stages:

- drilling trajectory planning;

- preparation of the work site;

- execution of a pilot well;

- well expansion stage;

- reverse pull;

- restoration of the territory.

Let's consider each point of the plan.

Planning stage and well trajectory calculation

Before drilling begins, it is necessary to calculate and plan the trajectory of the well.

Take into account not only the length and depth of the path, but also possible obstacles, such as:

- soil compaction, porosity and stickiness;

- moisture content and groundwater level;

- the presence of large stones and rocks;

- underground structures adjacent to the drilling zone.

Possible risks are identified and notifications are sent to emergency services and the Traffic Police Department.

A drawing of the drilling trajectory is drawn up or markings are made directly on the surface of the territory. A serious engineering approach takes into account the entry and exit angles of the drill, as well as the minimum permissible radii of curvature of the rod string.

The greatest load on the installation occurs during the simultaneous expansion of the pilot well and laying of the pipeline, therefore calculations are performed adjusted for the power of the equipment.

Organization of a horizontal directional drilling site

The HDD complex is delivered to the site, unloaded, and displayed at the work site. It is necessary to check the angle of inclination of the drilling frame and anchor the installation.

Without such fastening, the drill itself, its drive and the drill frame wear out faster, so you should not neglect fixation. Then you should test run the mixer for the suspension and the installation engines, and make sure that the connection of the hydraulic system hoses is stable.

Execution of a pilot well

Pilot drilling consists of passing the entire length of the well trajectory with a small diameter sufficient to pull a string of rods.The first segment is loaded into the guide rod, the threaded connection is generously lubricated and connected to the drill head - a device consisting of a locating system transmitter, the drill blade itself, and a suspension supply filter.

Then the bentonite solution is supplied and the pressure is adjusted to ensure that the suspension passes through the hoses into the drill rod, enters the barrel, filter and nozzles of the drill head, and then exits with the required pressure.

The operator of the installation makes an inlet hole perpendicular to the soil surface relative to the longitudinal axis of the drill head, after which he drills, successively increasing the string of rods.

The locating system operator marks drilling positions, depths and angles, checks against the planned trajectory, and plots the actual trajectory if reorientation is required. Once the drill head appears at the exit point, pilot drilling is completed.

Stages of well expansion and tunnel construction

In the process of pilot drilling, a well with a width of 75-100 mm is formed, which is sufficient when laying communications of small diameter. If the diameter of the well is narrower than required, then a rimmer-reamer is pulled in the opposite direction.

Often this stage is combined with laying communications, then a swivel is installed behind the rotating expander so that the laid material does not twist.

In some cases, taking into account the forces required for tightening, the well is expanded separately so that the size of the tunnel ensures the laying of material of the required diameter.

Reverse pulling is also carried out with the supply of drilling fluid to reduce friction of the material against the walls of the well. As the string is tightened to the length of the rod, the HDD operator turns off the supply of suspension, stops the rotation and disconnects the rod, after which he resumes operation of the installation.

The procedure is repeated until the expander appears from the well inlet.

Completion of work and restoration of landscaping

After the trenchless pipeline installation is completed, the installation engine is turned off, the laid line of communications is disconnected, and the connectors, swivel and filter are removed.

All devices are cleaned of soil and treated with waterproof lubricant. The remainder of the suspension is pumped out, the pit is filled up and, if possible, the natural or close to natural landscape is restored.

Conclusions and useful video on the topic

Drilling a well with improvised means on a private plot:

Video about using the relining method:

The principle of renovation is the destruction of a steel pipe:

Step-by-step instructions for using a compact HDD installation:

The use of a trenchless method of laying communications involves the use of special equipment and certain devices. However, over short distances you can drill a well with a diameter of 50-100 mm, having ordinary electrical appliances on hand. The main thing is to make the calculations correctly.

Do you have any questions, have you found any shortcomings in our material, or can you supplement it with valuable information? Please leave your comments in the block below the article.