What paint to paint heating radiators with: a comparative review of types of paint for batteries + the best manufacturers

Thanks to painting, heating batteries become more presentable and receive additional protection against corrosion. But the paint for heating radiators must be chosen correctly so that the renewed coating lasts as long as possible.

We will help you in this matter. The article lists the requirements for enamels and describes the advantages and disadvantages of different paints. There is also an overview of companies whose paints and varnishes have proven wear resistance in practice.

The content of the article:

Is it possible to paint batteries?

With painting old good ones cast iron batteries There shouldn't be any problems. You just need to choose the right paint for them. But with radiators made of aluminum or stainless steel, the situation is completely different.

Initially, they are painted in a factory using the powder method with heat treatment. It is problematic to apply a new layer of paintwork on top of this paint coating at home with your own hands.

The vast majority of manufacturers of heating devices not made of cast iron consider unauthorized painting of the surface of the battery as a reason for voiding the factory warranty.

Any damage or peeling of the paint layer on a newly purchased radiator is a manufacturing defect. Such equipment is subject to mandatory replacement. No one has yet canceled the service warranty period.

After drying, enamel paints create a durable and monolithic layer on the surface, through which air, by definition, cannot pass.

If oxygen is left with even a small chance to seep through the paintwork, then you can immediately forget about protecting the metal from corrosion. And protective functions are often the main reason for painting radiators.

At the same time, in the passports for all heating batteries there is a categorical prohibition on painting over the air outlet of the automatic air vent. If you apply paint to it, it will be impossible to bleed air from the heating system if necessary. This point must be monitored during painting work.

Both aluminum and stainless steel are painted in factories using powder paints, which, after application, are “baked” in special boxes at high temperatures. It is impossible to create the necessary conditions at home yourself.

But ordinary oil and other paints do not last long on such radiators. Due to their low adhesion, they will inevitably peel off aluminum and steel surfaces.

Reliably painting aluminum requires specialized painting equipment, as well as epoxy primers and enamels. All this costs a lot of money.

In addition, the slightest failure to comply with the technology inevitably leads to peeling of the applied coating.There is also an option with anodic oxidation, but this is again technologically complex and requires certain knowledge.

If you have successful experience in painting a car body and the corresponding paint and varnish materials, then for painting aluminum battery you can take it on, otherwise it’s not worth doing. It is better to purchase a new heating device or simply cover the peeling one with a decorative screen.

A separate topic is convectors with private fins made of steel plates (“comb”) strung on a pair of pipes. Such batteries were often installed in panel high-rise buildings in the 1970–80s. The lamellar ribs themselves cannot be painted. This will lead to a sharp decrease in heat transfer.

At the same time, it will also not be possible to get to the pipes in the middle even with the help of a very narrow brush. These surfaces are best left alone.

Such radiators usually have dampers and decorative screens made of iron. They can and should be painted to give them an aesthetic appearance. Regular heat-resistant paints will do here.

Requirements for enamel

The main thing in choosing paint for a home heating radiator is its heat resistance. If the labeling of the can indicates that the composition has an operating temperature below +80°C, then you should not use such paintwork for painting the battery.

Conventional paint and varnish materials are not initially intended for painting heated elements of the heating system. After turning on the heating, they will begin to peel off or turn yellow.

The paint for painting the heating device yourself must be at the same time:

- heat-resistant - at least +80°C, and preferably +100°C;

- moisture-resistant and abrasion-resistant;

- non-toxic;

- with high thermal conductivity;

- quick-drying.

Due to inexperience, some choose ordinary non-heat-resistant paint for interiors for batteries. As a result, when heat is applied, it turns yellow or changes its original shade.

This is due to the presence of chalk or polymers in its composition, which are not designed for high temperatures. Therefore, both the binder material and the pigment must be heat resistant.

The paint on the battery is usually applied in two layers. The faster each of them dries, the faster the radiator will be ready for use. Moreover, often the faster the paintwork dries, the more pungent the odor of the composition.

So that the family is not forced to inhale these ambers, it is often easier to remove the heating device from the pipes and paint it somewhere in the garage or on the street.

When choosing between a glossy and matte option, you should remember that the slightest irregularities are noticeable on a shiny surface. For rough and lumpy cast iron batteries, it is better to choose a paint with a dull shade that will not produce glare from lighting.

Radiator cast iron often has metal streaks and chips. When using glossy enamel, all of them will definitely be visible.

At the same time, you should not be overly zealous in leveling the cast-iron surface of the battery with sandpaper before painting. This can lead to thinning of the radiator fin and the subsequent appearance of a fistula.

Selecting paintwork materials for a heating radiator

Everything seems to be clear with the selection parameters.Now it remains to understand what kind of paint is best to paint heating radiators in an apartment or private house.

There are many varieties of paints and varnishes. Plus, there are a huge number of manufacturers of various enamels on the market. Choosing the right paint and varnish material is often difficult.

Heat-resistant paints for heating radiators made of cast iron are:

- oil based on vegetable oils and drying oils;

- water-based (acrylic);

- alkyd.

Plus there is “silver” and hammer paint. Each of these options has its own set of advantages. You should choose carefully.

Option #1: oil

Previously, oil paints were used everywhere for painting batteries. They are usually made with organic drying oils and are inexpensive. After they are applied and dried, a coating that is sufficiently resistant to elevated temperatures, mechanical stress and moisture is formed on the radiator.

Among the negative aspects of using oil-based paints are:

- Unpleasant smell — a sharp “aroma” when painting and drying.

- Fragility of the coating - The battery will have to be repainted every two to three years.

- Large thickness of paint layer — as a result, a decrease in heat transfer from the radiator.

- Drying time — depending on the room temperature, drying time can take up to 2 days.

- Possibility of drip formation, especially if the application technology is not followed.

If you take ordinary oil paint rather than heat-resistant paint, it is unlikely to survive even one heating season. The coating on the battery will immediately begin to crack as the temperature rises.

It is better to use coatings based on drying oils only as a last resort, when there is simply nothing else on sale, or when a heating radiator needs to be painted cheaply for only one season.

Option #2: water-dispersed (water-based)

These paints are based on PVA or polyacrylates. You shouldn’t take the first ones for painting radiators. They have low resistance to moisture. They are intended exclusively for interior painting of walls and ceilings.

On metal, on which you may have to place wet mittens to dry, such paints and varnishes are absolutely not suitable. They will immediately be erased from the surface of the heating device.

Heat-resistant acrylic enamels for radiators have the following advantages:

- dry quickly;

- form a durable coating;

- do not have a pungent odor;

- abrasion resistant.

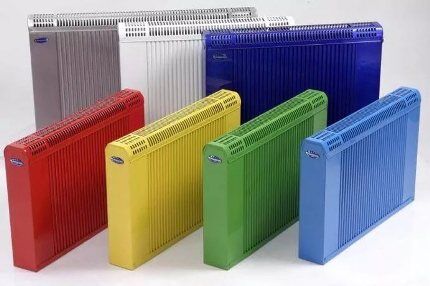

Most water-based paints on sale are white. To give them the desired shade, you need to add the appropriate color to the composition. The coating formed with their help resembles plastic with a slight shine. It is easy to clean and does not crack.

Option #3: alkyd

Paints based on alkyd resin are superior to the first two options in terms of heat resistance and resistance to water and detergents. This is the most practical and optimal choice for painting batteries.

But most of the similar enamels presented in stores are not suitable for radiators. Here you should choose a heat-resistant composition as carefully as possible.

Depending on the solvents and modifying additives contained in the composition, this enamel is divided into many varieties. Of all, it is worth highlighting the organic and organosilicon species. The first paint has a pungent odor, and the second has increased heat resistance.

Organosilicon alkyd paint based on polyorganosiloxane polymers is used for painting not only batteries, but also stoves, chimneys, boilers and fireplaces. It does not contain salts, which begin to crystallize when heated, thereby reducing the strength of the paint layer.

This enamel can easily withstand temperatures up to +600°C. However, when using it, it is necessary to take care of proper ventilation of the room. When it dries, it emits toxic fumes, so it is best to carry out painting work outside.

Option #4: silver

If white is not a must, you can also use good old silver. This is aluminum powder mixed with solvent and bitumen varnish. At the same time, you should not take ready-made paints (for example, BT-177), which by definition do not differ in heat resistance.

It is best to prepare silverware yourself from PAP-1 powder and BT-577 varnish. When mixed in the right proportions, you can get paint designed for temperatures of 300–400°C.

You just need to follow the ratio of components prescribed in the instructions for preparing this composition. This coating on the heating radiator will last for many years.

Brief overview of manufacturers

Heat-resistant paints and varnishes for painting heating systems, both imported and domestic, are available for sale. Both of them are quite suitable for painting batteries in a cottage or apartment.

Among the main manufacturing companies we can mention:

- Scandinavian TIKKURILA with the Termal series.

- German DUFA series "Thermo" and "Aqua-Heizkorperlack".

- Russian TEX with special “enamel for radiators”.

- Polish SNIEZKA.

- Slovenian BELINKA.

- Russian LAKRA.

There are many options with different prices and composition, there is plenty to choose from. Moreover, when choosing a primer for paint, it is best to opt for products from one manufacturer. There is no point in experimenting with mixing what is cheaper.

An overview of popular thermal paints that are used for painting radiators, metal stoves and other elements of the heating circuit is given in this article.

Conclusions and useful video on the topic

Choosing enamel for painting a cast iron radiator is not difficult, you just need to look carefully at the label. And the selection of video materials below will definitely help you navigate the existing varieties of heat-resistant radiator paints.

Rules for choosing enamel for radiators:

How to properly paint a cast iron radiator:

What enamel should be used to paint batteries:

You should not paint the heating radiator with the first paint that catches your eye. For these purposes, you should choose special heat-resistant enamels.

If you take a regular paint and varnish material, the coating from it will quickly become unusable when the battery heats up. Also, when choosing, you need to make sure that among the components there is no chalk that turns yellow when heated.

Are you looking for high-quality paint for heating radiators? Or do you have experience using heat-resistant enamels? Please leave comments on the article, ask questions and participate in the discussion of the material.

If you come from afar, I don’t understand the point of painting aluminum and steel radiators. But in essence, if so, I would not recommend painting aluminum and steel radiators yourself. This poses a number of problems, including health and safety issues. I believe that only cast iron batteries can be painted, and the paint should be appropriate, not just something from a hypermarket. We personally use two brands; I won’t advertise them, but they are in the body of the text.

We were tired of the white color of the cast-iron radiator in the living room, we decided to update it and paint it in the main tone of the room. For this we used metallic gold spray paint. We also painted part of the wall with it where the radiator is installed. It turned out very cool, stylish, the downside was the persistent smell that took several days to dissipate. But the result was worth it.

In the old apartment they painted old cast-iron radiators with ordinary white paint, and then there was a constant unpleasant smell. But after a few months, the coating we applied turned yellow and began to crack. Once they tried to paint the batteries with car spray paint. It lasted much longer and didn't even change color.But in the end they installed aluminum ones and now there are no thoughts about ways to restore the outer layer.

In your picture, where it looks like a radiator is being painted from a spray can, it says “universal degreaser” on the can, which means “universal degreaser”...

Well, that's right - first degrease, then paint =D

I would like to add that usually experts do not recommend painting radiators in the first year of operation, since paint can hide a factory defect in the radiator housing, unnoticeable during an experimental run, and worsen the situation.