What to do if the chimney of a gas water heater freezes: effective ways to protect the chimney

There are often cases when a gas boiler or water heater may stop working due to freezing of the gas pipe. But no one wants to be left without hot water or even heating on a winter evening, right?

Therefore, let's talk about why the chimney of a gas water heater or boiler freezes, what measures need to be taken to cope with this problem, and what can be done to avoid a recurrence of a similar situation in the future. We will supplement the presented material with thematic photos and videos.

The content of the article:

The main reasons for freezing chimneys

Among the reasons for freezing of chimneys, first of all, adverse weather conditions: wind, low air temperature, high humidity. All this leads to freezing of the gas boiler pipe. Among the reasons are snow getting into the pipe, and mistakes made on installation stage. In this case, the result is the same: the mini-boiler room stops functioning.

The most important rule that must be strictly followed: strictly follow the manufacturer’s recommendations, take into account the length and angle of the pipe, its location.

Another reason - occurrence of condensation. Condensate is the presence of water vapor in combustion products. At the same time, its temperature is lower than the dew point. When water droplets freeze, a crust of ice forms.It prevents the access of air that supports the combustion process. If the boiler is located on the upper floors of the house, it is impossible to get to the terminal to get rid of the ice crust.

The main signs that the chimney pipe of a gas boiler in a private house is freezing are as follows:

- the appearance of the “Flame break” error on the boiler display;

- formation of condensation on the surface of the air duct;

- After turning on the boiler, it goes out after a short time.

There are ways to reduce the amount of condensation: insulation chimney channel; careful care of the system (timely cleaning); application steam trap.

The latter is a container made of stainless steel. Its purpose is to collect emerging moisture.

If we talk about preventive measures, we can note the following:

- at the stage of building a house, comply with all standards;

- install the chimney in strict accordance with the project;

- do not forget about cleaning the smoke duct using special products;

- improve existing pipes (insulation measures, use of stainless steel liners);

- monitoring equipment power and, if necessary, cleaning the chimney.

This approach is entirely justified, since preventing a problem is always easier than eliminating it. We recommend that you read more about prevention methods condensation formation

Ways to get rid of icing

The purpose of the chimney is to remove compounds formed during fuel combustion. Fuel consumption, that is, the efficiency of the boiler, largely depends on its design.

The efficiency of the system depends on the following factors:

- material of manufacture chimney;

- height, diameter and location of the pipe.

Reduced efficiency, excessive gas consumption, wet walls, carbon monoxide penetration into the room, freezing of the chimney pipe - all these problems can arise due to the fact that the chimney is selected and installed incorrectly.

Now let's talk about what measures can be taken to prevent the formation of ice. Partial solution to the problem - removing the stub at the top of the boiler. Combustion products will continue to come out as before. The air that is necessary for the combustion process will be directed into the system from the room. Therefore, for safety reasons, it is so important to arrange the correct ventilation for gas boiler.

However, the plug must be returned to its original place when the ice build-up melts. This regime cannot be maintained continuously. The fact is that impurities contained in the air of the room (dust, soot from the kitchen) will quickly damage the heating unit. You can use this method if cases of icing are rare, no more than twice a year. For regular frosting, use the “anti-ice».

In addition to drawing air from the room, there are other ways to de-ice.

Method #1 - reducing the temperature difference

If the boiler equipment does not include regulators and (or) programmers, then it is turned on according to the difference between the temperatures of the heating circuit lines: supply and return. If the equipment model is programmable, then the indicator can be adjusted.

To prevent the coaxial chimney from freezing in winter, set the temperature difference to a minimum. Thus, the time interval between turning off and turning on the unit is reduced. It is advisable to carry out work at air temperatures below -10 degrees.

Method #2 - increasing boiler power

An increase in boiler power leads to an increase in the temperature of the gases, which heats the pipe more strongly. Of course, fuel consumption will increase, but there will definitely not be a problem with icing.

Regulating the power of gas equipment without professional skills is a risky and dangerous activity. If changing the gas flow rate at the valve is a process unfamiliar to you, then it is advisable to use the services of a representative of the organization with which you have contract signed for service. The specialist will perform the work efficiently and quickly.

Method #3 - improving the coaxial pipe

For column and boiler coaxial pipes installed with a slope towards the street. This is necessary so that the condensate formed in the air channel flows out.

Sometimes the cause of water accumulation is that the outermost part of the air duct is severely deformed.Good results can be achieved by cutting off the outer part of the pipe by 150-200 mm or making holes in it. The length of the inner tube remains unchanged.

Method #4 - insulating the chimney pipe

The chimney is insulated in order to prevent condensation from occurring due to the difference between the internal and external temperatures. In addition, thermal insulation serves to protect the roof in the immediate vicinity of the chimney of the boiler or water heater.

The following methods are used for insulation: plastering slag mortar, brick, mineral wool, slag concrete slabs.

The benefits of thermal insulation include:

- significant reduction in the deposition of chemically aggressive combustion products on the inner walls of the pipe. The flow of smoke and heated air removes them almost completely;

- reducing the temperature difference between the pipe walls and the hot air that comes out of the firebox;

- minimization heat loss, height energy efficiency systems - heat loss in the presence of an insulator is significantly reduced;

- additional stability of the chimney - thanks to the insulating casing, it becomes more resistant to bad weather and wind, the pipe is less damaged by external factors.

If the insulation is selected correctly and all work is done correctly, you should not be afraid of freezing even in forty-degree frost. In addition, areas of the roof located in close proximity to the chimney suffer much less from high temperatures. Next, we will consider the main methods of insulation.

Applying a layer of plaster

Application area plastering along the grid - external insulation of brick pipes. If the work is done correctly, the level heat loss decreases by about a quarter.

To do this, prepare a mixture based on slag, cement and lime. The solution is applied to the reinforced mesh in a layer of 30 mm. After the mixture has dried, mineral wool is placed on top of it. Next comes a layer of plaster and fiberglass mesh.

When the entire multilayer structure has dried, the pipe is coated with a layer of primer and painted - you can use any paint for exterior use. As an external cladding, you can use metal siding.

To the benefits plastering pipes include: low cost of work, aesthetics of the final result, availability of implementation for almost everyone.

Use of mineral wool

The area of application of mineral wool is the insulation of pipes made of asbestos or metal. Compared to the usual plaster, the use of mineral wool has a number of advantages: low weight, minimal labor intensity, resistance of the material to high temperatures, non-flammability and low cost.

Insulation procedure mineral wool next:

- cleaning outer surface of the pipe;

- production of sheathing from profiles - guides are secured with dowels;

- securing vertical posts, connecting them to the guides - the interval between the posts corresponds to the thickness heat insulator;

- laying mineral wool in the lathing - a layer of polyethylene is placed on top of the heat-insulating layer, the joints are sealed with aluminum tape.

The final stage is the installation of cladding from corrugated sheets.

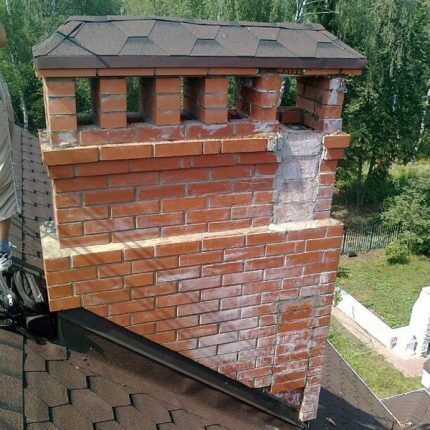

Construction of a brick casing

Building a casing made of brick is one of the most common methods of thermal insulation of metal chimneys.

This design has many advantages: beautiful appearance, durability, moisture resistance, and the ability to use improvised materials. There are also disadvantages: high labor intensity of work, the need for certain construction skills. In addition, additional costs for thermal insulation can't be avoided.

To make the structure reliable and durable, you need a small foundation.

- Dig a hole to a depth below the freezing level of the soil. Otherwise, after the first frost the structure will become deformed and collapse. The length of the pit and its width must exceed the design parameters of the same name by 100-150 mm.

- The bottom of the pit is compacted and the walls are leveled. A 100 mm sand cushion is poured onto the bottom and compacted.

- Formwork is installed inside, possibly non-removable. To do this, buy a ready-made structure or make it yourself from polystyrene foam. The formwork also serves as additional waterproofing.

- Using a 10mm fiberglass or metal reinforcement, make a sheathing with cross members every 400 mm and dimensions 50 mm smaller than the pit.

- The bottom is laid out with bricks, on which the prepared sheathing is placed. The resulting structure is poured with concrete and compacted with a vibrator. The foundation is left for 3 weeks to harden.

After the base is completely ready for use, proceed to installation of the casing. Its dimensions are such that the internal distance to the pipe is about 50 mm. For masonry, use a ready-made building mixture or mix cement, fireclay sand and crushed brick in a ratio of 1:3:1. First, mix the dry ingredients and only then add water.

Before starting work, the foundation is protected from water with a layer bicrosta or roofing felt. Brickwork is done in a circle with binding. Every 3-5 rows a metal mesh is laid out. The plane is constantly monitored by level. As the casing is laid out, the void between the pipe and the masonry is filled with insulation.

Usage extruded expanded polystyrene

Scope of application of slabs from extruded expanded polystyrene - external insulation of chimneys made of brick. Properties penoplex And technoplex - high level of strength and impermeability to water.

It is advisable to use as heat insulator heat-resistant brands with a flammability class G2. Product classes G3 And G4 It has less fire resistance, so it is not used at high (more than 600 degrees) temperature of the exhaust gases.

For insulation work penoplex you will need:

- insulation (the required amount is calculated individually);

- pendants;

- metal profile;

- fastenings;

- construction foam;

- Tools: drill or hammer drill.

The slabs are attached to the surface of the pipe using non-flammable glue (it is also used to seal joints). You can also use construction foam.

The algorithm is as follows:

- Suspensions are fixed at the corners of the chimney on all sides. The vertical distance between them is chosen in such a way that it is possible to secure heat insulator. The pendants are given a U-shape.

- Sheet penoplex apply and lightly press down so that traces of the fastenings remain.

- The insulation is unrolled and through cuts are made in the places where the marks are.

- The reverse side of the insulator is covered with polyurethane foam.

- Metal plates are threaded through the insulation, the sheets are pressed tightly against the pipe.

- The profile is mounted to the hangers. It is necessary to level it, since it is this that serves as the basis for the cladding.

- Sheets are secured self-tapping screws with press washers or rubber seals. The corners are covered with special strips. This is necessary to create a monolithic effect. The gap between the insulator and the profile is closed with a tin plate that prevents the penetration of water.

- A visor is mounted in the upper part.

To form thermal insulation for an asbestos pipe, install a galvanized casing at a distance from the pipe of no less than 60-80 mm. Glass wool is used as insulation. Cement mortar is used to fill the remaining gaps.

You can do without a casing, then as a heat insulator It’s better to choose mineral wool - its consumption will be twice as much.

Construction of a sandwich chimney- pipes

This is an excellent solution that allows you to solve the problem of chimney insulation almost one hundred percent. Sandwich pipes have one drawback: the channels will need to be completely redone or, alternatively, their installation will need to be provided for at the design stage of the house.

A sandwich is 2 pipes with different diameters, the smaller of which is located inside the larger one. They are separated by a layer of insulating material. Condensation does not form on the sleeves, overheating also does not occur, so the system is completely fireproof.

Installation of such a chimney does not cause any particular difficulties, sandwich system assembled according to the principle of a designer. The panels are inserted into each other to the required size. The connection to the boiler is made using special additional adapters.

Common insulation mistakes

The main indicator that a mistake was made when installing thermal insulation is the heating of the external parts of the structure to high temperatures. If there are flammable materials nearby, this situation poses a fire hazard.

The reasons for this are as follows:

- an incorrectly selected or low-quality insulator shrinks;

- violation of the integrity of the internal part of the pipe (happens quite rarely);

- non-compliance with work technology;

- unsheathed heat insulator at the head of the chimney.

Thus, methods of thermal insulation chimney there are quite a lot of pipes.The materials are available for sale, so there will be no problems with the purchase.

How to protect the column from freezing?

Is your gas water heater freezing through your chimney pipe and you don’t know what to do to avoid this problem? Let's take a closer look at this issue.

It is stated in the equipment instructions temperature regime, in which the equipment functions normally. When the outside temperature drops, individual components of the water heater may fail. Just because a device is under warranty does not mean there is absolutely nothing to worry about. The manufacturing company clearly defines operating standards, violation of which may result in loss of warranty.

Freezing can be avoided if drain the water in a timely manner. This applies not only to country speakers, but also to devices that are located in private houses or apartments.

It is necessary to drain the water in the following cases:

- abnormally frosty weather;

- frequent power outages;

- unheated room.

This measure will not hurt if you are leaving for a week or more, which means the gas water heater will not be in use.

To drain the water, turn off the gas valve and the incoming water supply tap.Then turn on the hot water on the mixer and wait until the water is completely drained.

Another case is possible when the column is in a warm room and still freezes. The part of the pipe located indoors remains warm. And that part of it into which the “street” air enters goes into minus. The condensate formed in the pipe turns into ice, which, in turn, constrains the check valve. The removal of gases from the column will thus be blocked - the fan will not be able to open the valve. It will be impossible to turn on the column in such a situation.

The solution to the problem is quite simple. You can use a regular household or construction hair dryer. The device must be turned on in maximum heating mode. Now all that remains is to heat the pipe. The ice will quickly melt and the valve will be released. Now you can turn on the column and let it work for 10 minutes to smoke exhaust the line has completely warmed up and dried out.

Sometimes the cause of freezing is problems with ventilation or defects in case manufacturing. If the device is under warranty, you should contact a service center. If the warranty period has passed, sealing the case helps.

Conclusions and useful video on the topic

A kit for protecting coaxial pipes from ice accumulation in the following video:

Chimney insulation - part 1, video

Chimney insulation - part 2, video

Repairing a broken speaker is quite an expensive proposition.The simple manipulations and precautions outlined in the article will help you save your equipment from breakdown and protect yourself from unnecessary expenses. And the column will delight you with stable operation and hot water for a long time.

Have you also encountered the problem of chimney freezing and want to tell us about your method of solving this problem? Write about your experience, participate in the discussion, ask questions of interest to our experts and other site visitors - the feedback form is located below.

Does the cap on the chimney affect the return flow in the ventilation of the lower floors?