Do-it-yourself installation of metal roof gutters: analysis of technologies + installation example

Metal gutters are traditional water drainage systems for protecting the roofs of low-rise buildings.These simple designs have shown reliable, efficient operation over the centuries. Modern options, as a rule, are constructed from ready-made industrial components.

Meanwhile, in the old days, installing metal roof gutters with your own hands was considered commonplace. Moreover, the entire system, from brackets to pipes, was made in a makeshift (manual) way.

In this material we will talk about how to build and install a metal roof drain.

The content of the article:

Drainage technologies

If we turn to existing technologies for constructing metal drainage systems, two options seem relevant for use:

- Based on round gutters and water pipes.

- Based on rectangular gutters and downpipes.

There is, of course, also another (exclusive) technique of execution, for example, based on wood, but this is rare and is not widely used.

Regardless of the technology for installing drains, it is always carried out system calculation taking into account the roof area. Based on the calculated data, the throughput of gutters, funnels, and drainpipes is selected.

Based on the throughput parameters, the diameters, through holes, and overall dimensions of the shaped parts are determined:

- corner transitions;

- slip-on couplings;

- prefabricated funnels;

- bypass branches;

- connectors;

- drain pipes.

Under the condition of complete self-assembly, the master will have to make all the shaped parts of the working kit with his own hands. But if you don’t have the skills of a tinsmith and the desire to produce, you can simply buy the entire marked set of parts. Naturally, in this case, the complete independence of manufacturing the system already seems doubtful.

Which metal is preferable?

The choice of material for a metal drainage system is relatively small: galvanized steel, copper, zinc-titanium alloy. The first material is economical and the most popular of the entire group, but, from the point of view of durability, it is not suitable in any range.

For example, the thickness of the zinc coating on a class 2 metal sheet is 5-10 microns. This protection will be enough for no more than 10 years of operation.

Galvanized steel with polymer coating is a completely different matter. This material is not inferior to red copper in terms of durability. But making parts from such sheets yourself without damaging the polymer layer is problematic.

Again, all that remains is to buy finished products or choose copper sheet as the material. And metal gutters made of copper, and especially zinc-titanium, require substantial capital investments.

Homemade metal gutters

It’s easy to make a gutter with your own hands from galvanized steel. However, difficulties arise if you try to make a gutter of the same length as in factory production (3-4 meters).

To manufacture a four-meter part, you will need appropriate technical equipment, which is usually not available in everyday conditions. Therefore, the standard length of homemade gutters, as a rule, is no more than 1 meter.

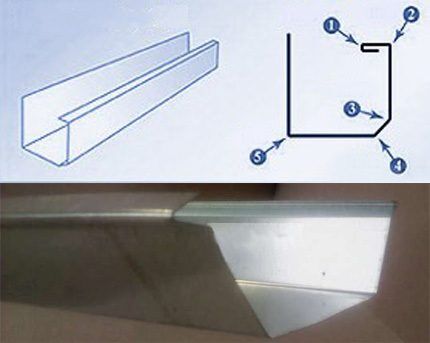

Oval gutter production technology:

- Take a sheet of tin 1 m long and 0.5 m wide.

- Place a piece of sheet on the bench.

- Take a metal pipe of suitable diameter.

- Bend a piece of sheet onto the pipe by straightening it with a wooden hammer to a semicircle.

- An indent of 10 mm is measured along the long front edge.

- Bend the edge line at an angle of 90º.

Then a second fold is made at the trailing edge, cutting off the excess sheet.

Rectangular gutters are made in approximately the same way. Only for straightening use an angular metal blank.

It is even easier to make rectangular gutters, as well as to prepare shaped parts for them. Therefore, it makes sense when choosing a technology to focus on rectangular gutters.

Homemade drain pipes made of tin

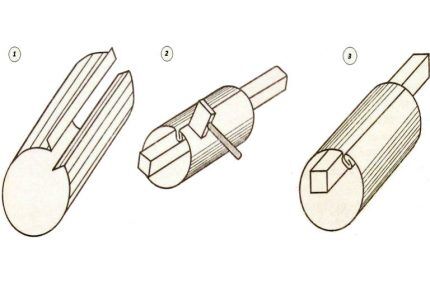

To make a straight drain pipe from tin, measure a piece of galvanized sheet to the length and width and cut it with scissors along the marked lines.

Using a file, carefully clean the edges from burrs and process them until they are smooth. Along the long side, bend both edges of the sheet in one direction to a width of 10-15 mm.

A galvanized sheet is tapped on a rigidly fixed pipe of a suitable diameter until it is given a round shape. Then the previously folded edges are placed on top of each other.

Using a wooden hammer and a metal rectangular block, “wrap” the edges into a lock. Carefully tap with a hammer along the seam until a securely pressed joint is obtained.Align the shape of the product on the blank pipe, trying to obtain a cylinder close to an ideal circle.

Having the skills to manufacture straight drain pipes from galvanized steel, it is not difficult to master the technology for producing inlet funnels and other parts of the system. With the same success, self-taught craftsmen make brackets for metal gutters and for attaching drainpipes.

Here the production technique is quite simple. For the job you will need a bench vice, a hammer, a file, a drill, a tape measure, a pencil and a strip of soft steel with a cross-section of 20x1.5 mm.

Manufacturing technology of steel (copper) bracket:

- Cut a piece of steel strip 300 mm long.

- File the end parts.

- Step back 10 mm from either end and make a 90º bend.

- Consistently moving the strip and fixing it in a vice, bend it in an arc to the size of the radius of the gutter.

- On the remaining straight part of the strip, drill holes for the clamp and fasteners.

Brackets for drainpipes are made in the same way, but in the form of a clamp consisting of two oval-shaped strips, the curved end edges of which are supplemented with holes for tie bolts.

There are several articles on our website with detailed instructions on making roof gutters, we recommend that you read:

- Do-it-yourself roof gutters: instructions for making your own drainage system

- How to make roof drains: do-it-yourself recommendations for arranging drainage

Technology for installing drainage parts

Let's take a closer look at how to install do-it-yourself parts of various shapes. Each technology has its own characteristics.

Detailed photo instructions

The following selection of photos will familiarize you with the standard procedure for installing a drainage system on a pitched roof:

Installing a gutter is only part of the work of installing a drainage system. Now you need to assemble and secure the drainage funnel, connect the drainage riser to it and organize a container to receive rainwater. Next we proceed as follows:

Self-installation of oval gutters

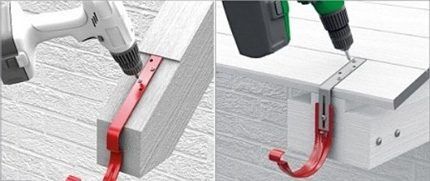

The process of assembling oval gutters with your own hands begins as usual with the installation of bracket holders. An important nuance is worth noting here. If the gutter material is galvanized, steel brackets can be installed underneath it. Traditionally, do-it-yourself brackets with a shank (long) are used.

It is highly not recommended to place steel holders under copper parts, just as aluminum and plastic ones are undesirable. Copper always requires only copper as a pair, and departure from these principles is at a loss. The costs are, of course, significant, but they are compensated by the durability of the pure copper structure.

The same principle should be noted in relation to the zinc-titanium system. You should not skimp on fasteners, giving preference to expensive drainage structures.

How to install a long bracket

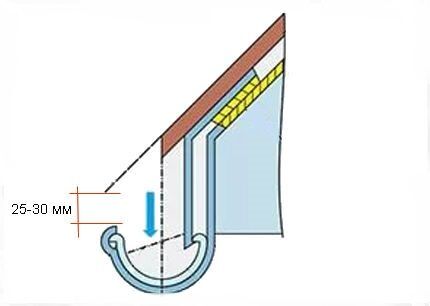

The tail of the first bracket is placed on the end of the outer rafter and secured with screws. Before fastening, you need to move the bracket forward to such a distance that a conventional vertical line running along the edge of the roofing intersects the gutter at the central point of its bottom.

Compliance with this rule is the key to correct collection and drainage of water for the maximum possible calculated value of precipitation intensity. Another important point is that the level of the front upper edge of the bracket rim should be 25-30 mm below the level of the ramp line.

The average length between the rafters of the roofs of private houses is 800 mm. Considering the high degree of rigidity of metal gutters (compared to plastic), it is permissible to place brackets at intervals of up to 1 meter. That is, subsequent brackets are also fixed directly to the rafters.

If the structure of the building does not allow the specified frequency to be observed, the sheathing should be attached to the surface of the outer boards.

The installed brackets are brought to the required level of slope by slightly bending or bending the rim of each. To mark the required slope, a cord is pulled between the first and last fastening element, setting the required slope values according to the building level.

Having completed the adjustment in all respects, lay the gutters on the brackets, resting their edges under the clamps. Next, all that remains is to install the prefabricated funnels and drainpipes, after which the system is ready for operation.

How to install a rectangular gutter?

From a technical point of view, there are no special differences in the installation of rectangular gutters from oval ones. The technology and requirements for installation dimensions are similar. But there are still some nuances.

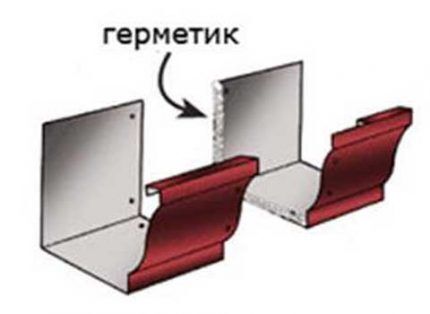

The laying of rectangular gutters on the holding brackets begins in the direction from the receiving funnel to the first bracket. The elements are overlapped one after another, the joints are coated with sealant and then fastened with rivets. The shape of the support brackets is, of course, rectangular.

The technique of fitting shaped parts onto rivets through sealing with sealant is used throughout the entire installation process. True, the installation of receiving funnels is often carried out using self-tapping screws.

Proceed as follows:

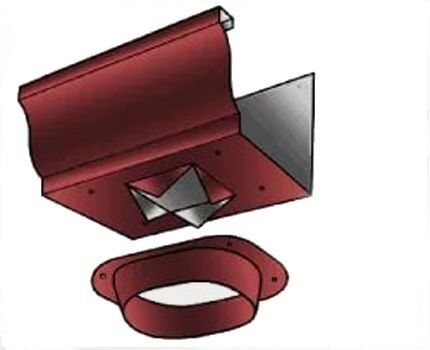

- On the outer lower side of the bottom, at a distance of 100-150 mm from the edge of the gutter, draw a rectangle 80 x 60 mm.

- Two cuts are made along the diagonals of the rectangle from corner to corner.

- Bend the resulting petals down at an angle of 90º.

- Sealant is applied to the funnel flange.

- Place the funnel body against the hole and secure it with self-tapping screws.

Rectangular water pipes are installed from the funnel from top to bottom. The connection of the pipes is done by inserting one into the other.

In this case, on the incoming pipe, the corners along the end edge are crumpled inward, it is inserted into another pipe, and then both parts are fastened along the line of contact with rivets.

The assembled drainpipes are fastened to the wall of the building in a standard way - with clamps.

Conclusions and useful video on the topic

Manufacturers of drainage systems care about proper installation their products, so they are increasingly releasing videos that help you understand all the nuances of installation:

If we compare the technologies for installing gutters (round and rectangular), the design of rectangular systems looks more complicated. Some parts differ in size and configuration. For example, the thickness of the strips of brackets for a rectangular gutter is usually taken to be at least 3-4 mm.

However, from an operational point of view, rectangular systems are more preferable. With savings of 10-15% relative to the installation of round gutters, they provide greater throughput.

Do you have personal experience installing metal roof gutters? Would you like to share your experience or ask a question about the topic of this article? Please leave comments in the block below.

I installed metal gutters in my house myself. I don't think this is such a difficult job that it's worth paying for. By the way, after that an acquaintance contacted me and helped him too. Almost a professional now. I choose only galvanized steel with polymer coating, it has the best reviews, is durable and resistant. After all, you don’t want to redo your work in a couple of years because of low-quality material.

It is worth noting that gutters and pipes with a polymer coating cannot be cut with an abrasive tool, since the paint will melt and a section of up to 7 mm will appear at the cut site, which will be susceptible to corrosion. We cut the elements either with a hacksaw or with special metal scissors, treating the cut edge with repair roofing paint in the same color of the coating.