Wiring diagram for an indirect heating boiler + rules for its installation and connection

To provide the home with the required amount of hot water, an additional device is used - an indirect heating boiler (IBC).Its use can be considered one of the most rational and economically justified.

We will try to find out which piping scheme for an indirect heating boiler is most effective and how to connect the equipment to avoid common mistakes.

The content of the article:

Selecting an indirect heating boiler

Before purchasing and connecting a buffer tank-accumulator (as BKN is also called), you should understand the design features of the most popular types. The fact is that there are many types of equipment, including combined models that operate from heating systems and alternative energy sources simultaneously.

We will look at traditional coil boilers that use hot water as a heater.

Design features and operating principle

What does indirect heating mean? Directly heated devices operate by connecting to electricity or a gas burner; BKN has a different heat source.The water is heated by connecting to the hot water supply, that is, it turns out that the source is the coolant - hot water (or its substitute).

If we consider new models of well-known brands, we will notice that gas boilers and boilers KN often have the same design. They are mounted side by side or one under the other - this way you can save on the placement area.

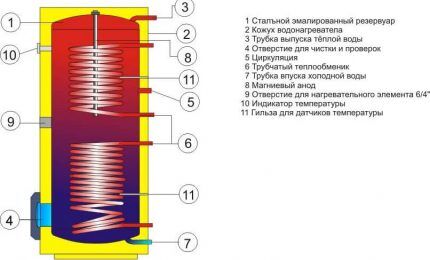

The main element that performs the heating function is a steel or brass heat exchanger (coil) with a large surface area, which is located inside a metal tank coated with a protective layer of enamel. To prevent the water from cooling too quickly, the outer side of the housing is surrounded by a layer of thermal insulation, and some models are surrounded by a casing.

An important part that most heating devices are now equipped with is a magnesium anode. A rod fixed to the top of the device protects metal parts from corrosion, as a result the water heater lasts much longer.

Barriers to high pressure are safety valve and built-in thermostat. If the tank is not equipped with a safety group, it is installed separately when installing the piping.

Often the water circulating in the heating system does not exceed 65-70 °C. Many people doubt its effectiveness when it acts as a heat source for heating in a BKN. In fact, the indicated temperature is sufficient, because the speed and magnitude of heat transfer largely depends on the area (quite large) of contact of the coil with water.

How does the heating process occur? Cold water intended for heating enters through a separate hole and fills the entire container. Water also flows from the boiler into the heat exchanger, but already heated. The hot walls of the coil transfer heat to cold water, which at the outlet already has a temperature suitable for taking a shower or washing dishes.

Advantages of controlled equipment

Controllability is a characteristic that affects the assembly of the entire water heating system. There are two types of BKN: simple (cheaper) and with a built-in control function.

A distinctive feature of controlled models is the additional equipment with a temperature sensor and the ability to supply/stop the supply of water to the heat exchanger. Such equipment operates automatically.

To start you need to connect:

- inlet/outlet for hot water from DHW;

- supply of cold water to the tank;

- manifold for distributing heated liquid at the outlet.

After this, you can start the boiler - the water will begin to heat up.

The process of connecting and piping an indirect heating boiler occurs in one of the following ways (described below).

How can control affect water temperature? Almost nothing. The maximum value that the outlet temperature can reach does not exceed the parameters of the coolant in the DHW system. Most likely, it will be 1-2 °C lower.

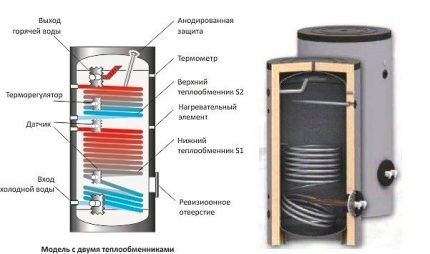

If more intense heating is required (this can happen if the boiler usually operates in low temperature mode), then it is better to choose a model with a built-in heating element.

It is advisable to purchase such equipment together with boilers operating on solid fuel (the water remains hot even after the boiler has cooled).

Types of devices with additional functions

Tanks with a simple design are only part of the range presented on the water heating equipment market. There are many boiler models, whose functions are very useful for integration into a DHW system.

For example, one of the purposes of more expensive models is heat accumulation. If power outages are possible or daily consumer tariffs are too high, the accumulation mode will be very useful. The design features of such models are enhanced thermal insulation and increased tank volume (300 liters or more).

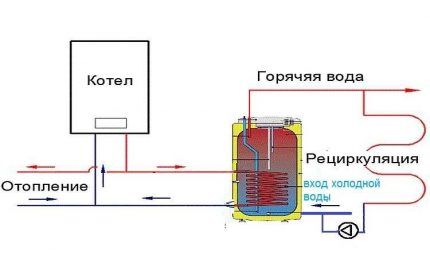

Another option that provides the fastest supply of hot water to water collection points is a boiler with recirculation. Unlike the usual design, this one is equipped with three pipes for communication with the hot water supply system. Two supply hot water, one supply cold water. Water is supplied using a pump.

When using a model with recirculation, you can install an additional useful circuit, for example, for installing a heated towel rail.

The water in such a tank heats up faster than in units with a heat exchanger, but its cost is higher.

Tank size and its meaning

Cylindrical and cubic tanks differ in their sizes. Their volume is indicated in liters: there are small models with a capacity of 80-100 liters, but there are also bulky ones that can hold up to 1400-1500 liters. The size is selected based on the family’s need for hot water.

Dimensions are important during installation. Only lightweight models are suitable for wall installation - up to 200 liters; all others are floor-mounted.Both horizontal and vertical wall-mounted devices have special fasteners; floor-mounted devices are equipped with legs or a small stand.

Rectangular units take up slightly less space than cylindrical units due to their tight fit to the pipes.

Nuances of the strapping device

It is easier to do the wiring and piping if the KN boiler is installed together with a boiler, pumps and other equipment involved in the assembly of the hot water supply system. It is much more difficult to insert an additional device into an existing network.

In any case, for normal operation of the devices you will have to follow a number of rules:

- choose the right installation location - as close to the boiler as possible;

- provide a flat surface for mounting the boiler;

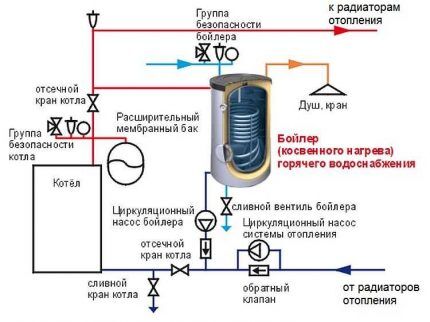

- to protect against thermal expansion, install a membrane hydraulic accumulator (at the heated water outlet), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by installing filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to secure heavy devices to plasterboard or thin wood partitions. Walls made of concrete and brick are suitable.Brackets or other types of holders are secured with brackets, anchors, and dowels.

When installing, the pipes are directed towards the boiler (even if they are masked in the back or behind a false wall). Do not use unreliable equipment, such as corrugated hoses that cannot withstand pressure and water pressure.

For normal operation of an indirect heating storage water heater, the following functional devices must be included in the piping:

Priority connection principle

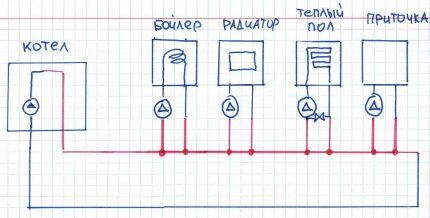

Before installing an indirect heating boiler in the DHW system, you must choose the principle of its connection: with or without priority. In the first case, when there is a need to quickly obtain a large amount of hot water, the entire volume of coolant is pumped through the BKN coil, as a result of which the water heats up much faster.

Once the water temperature has reached the required level (measured by a thermostat), there is a way to redirect the flow to the radiators.

A connection without priority does not allow the entire volume of coolant to pass through, and the boiler serves only part of the total flow. When equipped with such a circuit, the water takes longer to heat up.

The priority scheme is more effective, as it makes it possible to quickly heat the required amount of water without compromising heating. If the heating appliances are turned off for 30-50 minutes, the temperature in the rooms is unlikely to drop in such a short period of time, but there will be enough heated water.

The only condition for equipping a circuit with priority is powerful boiler.

Schemes and rules for connecting BKN

The connection diagram and installation features of an indirect heating boiler depend on the class of the device and heating systems in the house. It is necessary to choose the right installation location, focusing on the location of the boiler, pump insertion and existing wiring. Let's try to figure out what needs to be taken into account when installing heating equipment.

Option #1 - piping with a three-way valve

This is one of the most popular schemes, since when it is used, there is a parallel connection of the heating system and the BKN, equipped with shut-off valves. The boiler must be installed near the boiler, a circulation pump must be installed in the supply, then a three-way valve.

This scheme is successfully used if several heating devices are used, for example, two different boilers.

Essentially, this is a priority system that ensures rapid heating of water in the boiler when the radiators are completely turned off for a while. As soon as the temperature rises to the set value, it triggers again three-way valve and returns the coolant to its original channel - into the heating system. This piping method is useful for those who use the boiler constantly.

Option #2 - scheme with two circulation pumps

If the boiler is rarely used (for example, seasonally or on weekends) or there is a need for water whose temperature is lower than in the heating system, use a scheme with two water heating systems with forced circulation: diagrams, implementation options, technical details of circulation pumps. The first is installed on the supply pipe, directly in front of the BKN, the second - on the heating circuit.

There is no three-way valve in this scheme; the piping is equipped using simple connecting tees.

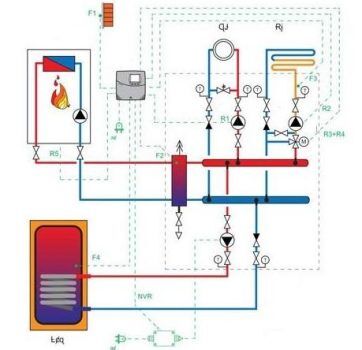

Option #3 - piping with a hydraulic arrow

This connection is used for volumetric boilers (200 liters or more) and branched heating systems with many additional circuits. An example would be a heating system in a two-story house, where in addition to a multi-circuit radiator network, warm floor.

The water gun equipment allows you to avoid thermal shock, since the water pressure in each circuit will be the same. It is quite difficult to make the piping according to this scheme yourself, so it is better to turn to professional installers.

Option #4 - using coolant recirculation

Recirculation is useful when there is a circuit that requires a constant supply of hot water - for example, a heated towel rail. If it is connected to the heating system, the coolant will constantly circulate, and the dryer will function and at the same time serve as a heating device.

But this scheme also has disadvantages. The main one is an increase in fuel costs, because constant heating of the water cooled in the circuit is required. The second disadvantage is mixing water in the boiler. Typically, hot water is located in the upper part, and from there it flows to the water supply points, where it is mixed with cold water, as a result of which the outlet temperature is slightly lower.

There are models of boilers with built-in recirculation, that is, with ready-made connections for connecting a heated towel rail. But it’s cheaper to buy a regular tank using tees for connection.

Option #5 - system with a non-volatile boiler

A distinctive feature of this scheme is the installation of the boiler at a higher level than the boiler and heating appliances.Preference is given to wall-mounted models that can be hung at a height of 1 m above the floor.

The non-volatile type of heating is based on the application of the laws of gravity, therefore, the coolant will circulate even when the electricity is turned off. In normal mode, you can connect circulation pumps.

Connection progress for an indirect heating boiler

After choosing a circuit, it becomes clear what equipment will be required. In addition to the main devices, you may need valves, ball valves, distribution combs, valves (three-way or check).

Procedure:

- prepare the installation site (on the floor or on the wall);

- make the wiring, marking the hot/cold water outlets in red/blue;

- install a tee and a pressure relief valve, securing the connections with sealant;

- screw on the hot (top) and cold (bottom) water taps;

- connection to a power source, install a thermostat and automation;

- select heating mode;

- test the connection.

These are general guidelines needed to present the scope of work. When connecting a specific model, you must follow the instructions that come with the kit.

Conclusions and useful video on the topic

The following videos will show you how to decide on the connection diagram and install the equipment correctly.

General information about connection diagrams:

Practical tips for connecting equipment:

You can learn how to properly piping an indirect heating boiler from the following video:

Professional review of an 80 l boiler:

In addition to installing and connecting the BKN, regular maintenance will be required. It consists of flushing the internal cavity of the tank, removing deposits and scale, and replacing the magnesium anode. Caring for the equipment does not require much effort. If the piping is done correctly, immediate repairs will not be required, but if problems arise with the equipment, we recommend contacting specialists.

Do you have any questions about piping an indirect heating boiler, have you found any inaccuracies, or do you have anything to recommend to visitors to our site? Please leave your comments below.

I installed a powerful 200 liter boiler at home. The master said that this boiler should be enough to bathe two people one after another. I agreed, but my joy was short-lived: my mother, who came to visit me, came in for a swim and didn’t have enough water. The water was cold and did not have time to warm up.

The heating element was agreed upon with the installer, but my disappointment remains to this day. I checked, you can use it, but you need to turn off the water all the time, and my mother is an old-school person, she needs the water to flow continuously. What should I do with this 200 liter boiler and what is the way out of my situation?

Hello. To be honest, I'm confused. We have a 100 liter boiler and it is enough to fill a full hot bath 2 times (this is with dilution). What kind of boiler do you have and what is the temperature setting on it? And what size is the bathtub?

Hello. Is it possible to connect the circuit of a double-circuit boiler to the coil of an indirect heating boiler? (pressure increases as temperature rises)

Hello. Theoretically, it is possible through the first circuit. The piping will go through the distribution manifold. Be sure to connect the pump and remote thermostat. The scheme is complex and impractical. It is better to purchase a single-circuit boiler with the ability to connect a boiler to it.

Tell me, can option 3 and option 4 be combined into one option? Or do you think that the recirculation piping is something supernatural and so separate that it is highlighted as a separate item.

Both options 1 and 2 fit perfectly with option 4. Together and at the same time.

Good afternoon. Tell me which scheme to choose correctly. The coolant in the boiler does not exceed 40 degrees. Single-circuit gas boiler SIME RMG70, Kospel boiler 400 liters, main heating underfloor heating. 7 circuits: 1 for the boiler, 1 for the ground floor, 2 for the first floor and 2 for the second floor. House of 350 sq.m.

Mahmud, how will it heat you up if the coolant is 40 degrees?

There were many options when choosing a storage water heater, all of which were not very successful. We bought a 100 liter Atlantic boiler, there are 3 of us. Boiler installation carried out quickly, the volume is enough, we are satisfied.

Good afternoon, is it possible to install option #4 using hot water recirculation, but not use an expansion barrel; instead, just an emergency valve connected to the sewer to drain excess water?

Boiler 160 l.

Hello, please tell me how to connect the indirect heating boiler FED 300 smart?