Forced circulation water heating system: diagrams, implementation options, technical details

Many modern solutions for water heating of houses require the use of a pump group.The design and installation of a heating system with forced circulation must be carried out taking into account technical issues that arise due to the rapid movement of the coolant.

The high pressure in the heating circuit allows for the implementation of many wiring schemes. Agree, this is an important advantage of a heating system with forced circulation. However, the arrangement of such a scheme requires competent design.

We will tell you by what characteristics the main operating components of the system are selected, and we will also describe in detail the possible options for wiring the main line and methods of organizing the heating circuit.

The content of the article:

Technical features of the main components of the system

The forced scheme differs from the natural one by the addition of one or more circulation pumps. Due to the increase in pressure and speed of movement of the coolant, the rules for the formation of nodes and the location of circuit elements change.

This fact must be taken into account in order to ensure high-quality heating with forced circulation.

General requirements for the pump group

Circulation pumps are selected based on the requirements for the volume of water distilled (cubic meter per hour) and pressure (meter). The calculation of both parameters depends on the cubic capacity of the heated housing and the heating method, as well as the length of the water circuit and the diameter of its pipes.

The pump should be selected so that its parameters do not match the requirements of the system.This will allow you to add elements to the circuit, if necessary, without replacing the pump.

Basically, pumps are designed for a voltage of 220 Volts, but there are also those with support for 12 Volts. In case of voltage surges, it is necessary to install a stabilizer to prevent the device from failure.

In case of frequent power outages, you need to take care of the availability uninterruptible power supply. There is no need to take a powerful UPS - devices with a consumption of more than 150 Watts per hour are rarely used to heat private houses.

Conventionally, circulation pumps can be divided into two types according to the position of the engine. Devices with a dry rotor have a higher efficiency, but have an increased noise level and a reduced service life than those with a wet rotor.

If the system wiring provides the opportunity for natural movement of the coolant along the circuit, then the pump must be installed through a bypass. In this case, if it breaks down or there is a power outage, it is possible to switch the heating to the gravitational circulation mode.

Water can also move through a non-working pump, but it will create strong resistance to its movement.

The problem of stopping the pump is especially pressing when using stove or fireplace heating. In this case, the oven will continue to heat the heat exchanger and the water in it may boil and the entire system may fail for a long time.

It's better to do pump installation on the return pipe, because the lower water temperature will extend its service life.If it is not possible to install the pump in a place other than on the pipe leaving the boiler, then a pump with ceramic seals should be used.

Although they can withstand temperatures up to 110°C, if the system boils, they may have problems with functioning.

Useful information on choosing circulation pumps for a heating system is provided in the articles:

- Selection of a circulation pump: device, types and rules for choosing a heating pump

- Circulation pump for heating: ten best models and tips for buyers

Subtleties of choosing boilers and furnaces

The use of electric and gas boilers and long-burning furnaces as heat generators is attractive from the standpoint of ease of control of heat flow through the heat exchanger.

Application solid fuel stoves, especially home-made designs, are fraught with insufficient or excessive heat generation. However, their use is often justified from the point of view of the cheapness and availability of fuel.

There are many models of electric and gas boilers with integrated pump. On the one hand, the built-in circulation system is matched to the boiler power and allows you to avoid purchasing and installing a separate pump. On the other hand, if the built-in pump breaks down, it will not be as easy to repair or replace as a separate one.

The requirements for the boiler when using forced circulation are the same as when using natural circulation:

- Boiler power calculation - the indicator must satisfy the heating needs of the house in the most severe conditions for a certain area. It is advisable to have a small power reserve (10-20%) due to possible force majeure circumstances that may arise in the heating system.

- Warning of coolant boiling in the heat exchanger. This requirement is easier to fulfill when using a “furnace-pump” combination than when using a gravitational model of fluid movement.

To prevent water from boiling in the boiler heat exchanger, it is enough to adjust the power depending on the temperature of the outlet liquid. This method works for any type of circulation.

For stoves with natural circulation, there is no way to prevent boiling of the coolant in the event of an excessive amount of loaded fuel. The only option in the presence of a pump is to increase the volume of liquid driven through the heat exchanger.

Moreover, such an emergency system can be made automatic using a thermostat and a pump speed control unit.

Installation and testing of the water circuit

With a heating scheme using forced circulation, there will be higher water speeds than in the gravity model. Therefore, it is possible to use a smaller pipe diameter with the same building heating parameters. This reduces the cost of water heating in terms of costs for pipes, fittings and fittings.

In addition, smaller diameter contour elements are easier to hide in technological niches or fit into the interior of the premises.

Compared to natural circulation, increased hydrodynamic pressure of the flow will be added to the hydrostatic pressure of the liquid column. Therefore, in order to avoid the formation of leaks or, especially, a breakthrough of the system, it is necessary to adhere to certain rules.

In the event of a transition from gravitational circulation to forced circulation, it is necessary to eliminate all, even minor, leaks in the circuit. As the pressure increases, the flow rate will increase, which, in addition to the problem in the room, will cause a decrease in the amount of coolant and its excessive aeration (air saturation).

Before the onset of the heating season, it is necessary to carry out hydraulic tests of the strength of the circuit with the maximum used or even slightly higher pressure. This will allow you to identify problems and eliminate them before the onset of cold weather, when a long shutdown of heating for repairs is undesirable.

Since the coolant movement speed will be greater than 0.25 m/s, according to SNiP 41-01-2003 there is no need to maintain a constant slope of the pipes to remove air from the circuit. Therefore, with forced circulation, the installation of pipes and radiators is a little simpler than with a gravity circuit.

Heating options with forced circulation

The use of forced circulation allows us to move away from the principle of designing the wiring with the obligatory consideration of the hydrostatic pressure difference, which is necessary for functioning in a gravitational circuit.

This adds variability when modeling the geometry of the water circuit and provides the opportunity to use solutions such as collector heating or large-area underfloor heating.

Application of upper and lower wiring

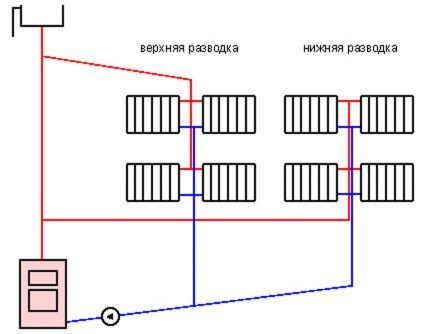

Any heating scheme can be conditionally classified as upper or lower wiring. With overhead wiring, hot water rises above the heating appliances, and then, flowing down, heats the radiators. With the bottom - hot water is supplied from below. Each option has its positive sides.

Upper wiring is also used for natural circulation. Therefore, heating circuits of this type allow the use of both types of circulation. This, firstly, provides the opportunity to choose, and secondly, increases the reliability of the system.

In the event of a power outage or pump breakdown, the movement of water along the circuit will continue, albeit at a lower speed.

When using bottom wiring, the total length of pipes is shorter, which reduces the cost of creating the system. In addition, there is no need to lay risers on the upper floor, which is good from the point of view of room design. The lower hot water supply pipe is laid either in the basement or at the floor level of the first floor.

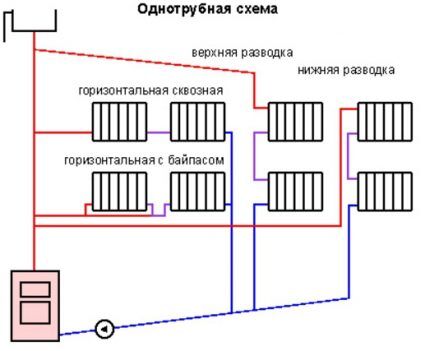

Varieties of one-pipe connection schemes

The single-pipe scheme uses the same pipe to supply hot water to the radiators and discharge cold water to the heating boiler. With this layout, the length of the pipes used is almost halved, and the number of fittings and shut-off valves is reduced.

However, the radiators are heated sequentially, therefore, when calculating the number of sections, it is necessary to take into account the gradual decrease in the temperature of the supplied coolant.

Single-pipe circuits can be implemented in horizontal and vertical versions. With forced circulation, if vertical risers are used, hot water can be supplied not only from above, but also from below.

The feasibility of using one or another option depends not only on the convenience of pipe installation, but also on the maximum permissible number of radiators on one riser of a single-pipe circuit.

There are two ways to connect heating radiators:

- Serial connection — coolant flows through all radiators.In this case, a minimum number of pipes is required, but if it is necessary to turn off one of the radiators, the entire branch of the system will have to be stopped.

- Bypass connection — the coolant can flow bypassing the radiator through the installed branch. Using a tap system, you can redirect the flow past the radiator, which will allow it to be repaired or dismantled without stopping the heating.

A single-pipe circuit is often used for heating, but if there are a large number of radiators, another option is used to heat them evenly.

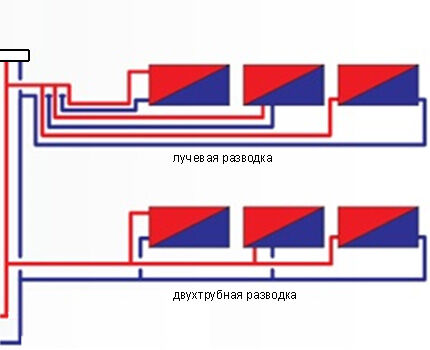

Methods of using the two-pipe version

A heating circuit diagram using a second pipe to drain cooled water to the boiler is called two-pipe system. The pipe footage increases, as does the number of connections and devices.

However, the system has an important advantage - coolant of the same temperature is supplied to each radiator. This makes the two-pipe option very attractive.

For water heating with forced circulation, both horizontal and vertical wiring are used. Moreover, with the vertical version, it is possible to use upper and lower hot water supply.

Since the temperature of the water supplied to all radiators is the same, the geometry of the circuits depends only on the following factors:

- material savings — minimizing the length of pipes and the number of connections;

- ease of contour drawing heating through walls and ceilings;

- aesthetic appeal - the ability to fit heating elements into the interior of the premises.

Depending on the movement of hot and chilled water, two-pipe circuits are divided into two types:

- Related. Movement in both pipes occurs in the same direction. The coolant cycle has the same length for all radiators in this part of the system, so their heating rate is the same.

- Dead-end. In a parallel scheme, radiators located closer to the boiler heat up faster. However, for systems with forced circulation this is not very important due to the significant speed of water in the circuit.

When choosing between the associated and dead-end options, they are guided by the condition of convenience of installing the return pipe. In vertical schemes, with the lower wiring, a dead-end system is obtained, and with the upper wiring, a passing system is obtained.

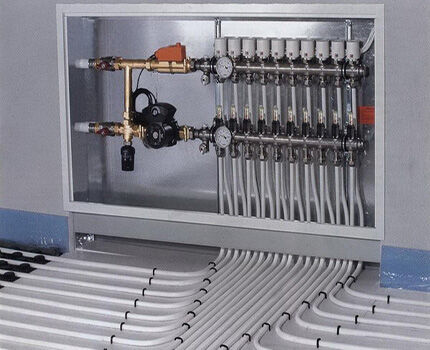

Using a heating distribution manifold

Another popular way to organize heating now is creating a collector circuit. To some extent, this scheme can be called a subtype of two-pipe, although it is also used in the organization of single-pipe heating circuits.

Only the distribution of hot coolant and the collection of cooled coolant occurs not from the main riser, but from special distribution node devices - collectors. Such a system operates stably only using forced circulation.

The distribution unit for a two-pipe system is a complex combination of supply and return manifolds, with the help of which a coolant supply is balanced in temperature and pressure.

Each branch of the device powers one heating element or a small group of them.The branches are usually located under the floor, each floor of a multi-story building is served by one centrally installed collector.

Despite the obvious advantages of this type of heating arrangement, the collector system has two significant disadvantages:

- longest pipeline length, therefore, this option for organizing a water circuit requires considerable financial investment;

- difficulty in changing the contour — pipes with this option are usually located under the floor or in the walls, so if you add heating devices it will be very difficult to make any adjustments.

All collectors are usually mounted in a special cabinet, since the shut-off valves are located there and access is required. Placing the taps in one place is very convenient.

If there is a need to turn radiators on or off or an emergency occurs, it is enough to have access to the cabinet and there is no need to visit all rooms.

Distribution manifolds can have a simple structure consisting of two combs and a minimum of shut-off valves.Complex components may also include automatic thermostats, electronic valves, mixers, automatic air outlets, sensors and control units, a water drain valve, and a separate circulation pump.

These systems can most accurately regulate the temperature in your home, but require a good understanding of the basics and nuances of hydronic heating.

Heating using underfloor heating

One of the most comfortable heating methods is considered organization of heated floors. It should be noted that the installation of this heating option for living rooms, showers, kitchens and other premises is quite complicated.

Water heated floors over a large area are only possible with forced circulation, since it is necessary to create pressure in a long system of narrow pipes.

Pressure is necessary to overcome the resistance of narrow pipes with many bends. In addition, it is necessary to achieve a pressure that allows air to be removed from the underfloor heating pipes, which are located horizontally.

There are a large number of tube laying combinations:

- for small rooms use circuits with one input for hot water and an output for chilled water;

- for large rooms organize more complex floor heating systems using a distribution manifold.

Often, separate circulation pumps are installed for parts of the circuit with heated floors.

Conclusions and useful video on the topic

A detailed description of a two-pipe and rather complex heating scheme for a two-story house:

Closed system for a three-story house based on a gas boiler:

The use of pumps for water heating of premises greatly simplifies the design of the circuit, making possible options that are not available for the gravity model. The correct selection of equipment will solve the problem of heating your home, making this process convenient and simple.

Do you have anything to add or have questions about organizing a heating system with forced circulation? Please leave comments on the post and participate in discussions. The contact form is located in the lower block.

We have central heating, but since we live in a private house, we can turn on the heating at any time. But the problem is that it flows very weakly, there is no pressure, and it is only given when the heating season begins. Therefore, when it is cold, you have to turn on the pump. We installed it at the end of the branch, after 5 minutes of operation the pipes are already hot, I think that for us the pump is the best option, it doesn’t use a lot of electricity, you can run it around the clock.