Proper wall insulation - work technology

To create a comfortable microclimate in a house or apartment, thermal insulation is installed on the walls.Wall insulation technology involves installing protective material on internal or external surfaces, depending on the type of thermal insulation coating.

The content of the article:

Condensation in the apartment

The technology for insulating walls from inside the room involves installation vapor barrier layer. Failure to comply with this rule will result in condensation.

At low ambient temperatures, the wall cools down, while the room inside is warm. When cold and hot air interact, moisture condenses and accumulates under the insulation.

When interacting with a humid environment, the properties of thermal insulation change. Some materials lose their characteristics. Fungus and mold grow in the fibers. The canvas undergoes rotting and quickly deteriorates, losing its properties.

During installation canvas from the outside Condensation does not form inside the apartment. The area of interaction between hot and cold air shifts to the outside of the wall.

How to properly insulate brick walls

The technology for insulating a brick wall involves installing a heat-insulating layer on the surface or using additional lathing. Materials intended for insulating brickwork are divided into several categories:

- Slab. Produced by manufacturers in the form of separate panels. They have sufficient strength for fastening to brick with dowels and adhesive. The plates have different dimensions.The thickness of the panel is selected separately for each case, taking into account its characteristics.

- Rolled. They have a less dense structure. The flexibility of the canvases allows them to be mounted on surfaces of complex geometric shapes without violating their integrity.

- Bulk. The technology for insulating walls in this way involves preparing additional sheathing. It is necessary to hold the bulk mass. A heat insulator is poured into the cavity of the sheathing and the finishing is installed.

- Liquid. They are a composition that adheres to the surface. After application, it dries, forming a monolithic layer without cold bridges. Specialized equipment is used for application.

The installation method is selected separately for each case. The technology for insulating brick walls involves applying protective compounds to the surface. They prevent the formation of fungus and mold.

Features of using polystyrene foam for insulating walls in an apartment

For insulation of walls from the inside foam is used. Manufacturers produce it in the form of panels. The thickness of the slabs differs and is selected separately for each case. The technology of internal wall insulation involves the use of 50mm thick foam plastic. An increase in this indicator will lead to a loss of usable area.

Polystyrene foam has a number of advantages:

- Low cost. Compared to other materials, the price of polystyrene foam is lower.

- Easy to install. Polystyrene foam can be mounted on the surface or additional sheathing.

- Good thermal insulation characteristics.

The disadvantages of polystyrene foam include a high fire hazard. When burning, polystyrene foam emits acrid smoke.

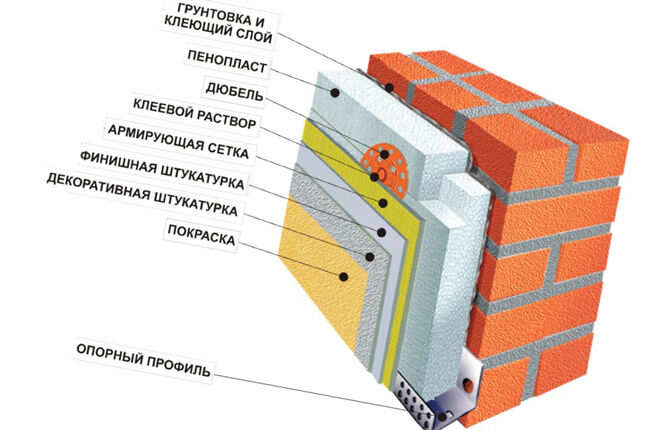

For installation foam plastic no specialized education required.A person with minimal technical knowledge can handle the task. According to the technology of insulating a brick wall, the panels are fastened in the following sequence:

- The surface is cleaned of dirt and treated with an antifungal compound.

- Apply glue to the wall. Use a specialized solution or mixture for ceramic tiles.

- Mounting the panels. The sheets are installed with offset seams.

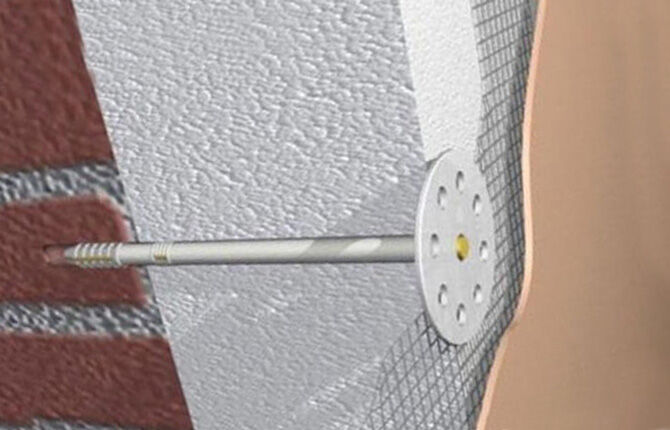

- The panels are secured with dowels. To prevent the slab from pressing through at the fastening point, dowels with a wide head are used. 5 dowels are installed per 1 m² - 4 in the corners and 1 in the center.

- The seams are sealed with polyurethane foam. This prevents the formation of cold bridges.

- Cut off the remaining foam. Pruning is carried out with a knife with replaceable blades.

- Attach a layer of waterproofing.

- Install the trim.

The finishing method is selected by the owner of the room separately for each case. When applying decorative plaster, a reinforcing mesh is used. It makes the surface resistant to mechanical damage.

Errors and nuances of insulating a house with polystyrene foam can also be learned from the video.

Wall insulation with mineral wool

Manufacturers supply the material in panels or rolls. The low degree of thermal conductivity of the material is due to the interlacing of fibers. This structure provides high noise insulation properties and the ability to transmit steam. Cotton wool is resistant to damp environments. Advantages of mineral wool:

- Soundproofing. The canvas prevents the passage of noise.

- Fire safety. The material does not ignite when exposed to an open flame or high temperature.

- Rot resistant. Fungus or mold does not appear in mineral wool.

- Environmental friendliness.No harmful substances are released during operation.

- Easy to install.

When the material gets on exposed skin and in the respiratory tract, it causes irritation. When working with mineral wool, use personal protective equipment (gloves, respirator, etc.).

The mineral wool insulation technology involves installing the material in the following order:

- Treat the surface with primer. Select liquids with an antifungal effect.

- Install additional sheathing. The technology of insulating a wall with mineral wool involves making lathing from a metal profile or wooden beam.

- Fix the mineral wool to the sheathing.

- Install finishing materials. During interior work, plasterboard is attached to the sheathing. On the outside of the walls, the finishing material is siding, plastic, etc.

If mineral wool is used in panels, the installation technology is different. The slabs are attached to the surface without additional sheathing using dowels with a wide head.

Features of using a plaster layer in wall insulation

The technology of wall insulation involves the use of plaster. It is used as a finishing layer. Plaster improves the thermal insulation of walls. Plaster can be applied to various thermal insulation materials.

To improve the strength of the surface, the plaster is reinforced with mesh. The work is carried out in the following sequence:

- Throw on the first layer of mortar (manually or with a specialized machine). Its thickness is about 1 cm.

- Glue the reinforcing mesh. The mesh is fastened until the solution hardens.

- Throw on a second layer of mortar 3 cm thick.

- Wait until the solution hardens.

- The plaster is puttied with a finishing compound. The solution is made from fine fraction components. The fine filler is sifted through a sieve. It is possible to use ready-made mixtures.

According to the technology, paint and varnish coating or other finishing materials are applied to the plastered surfaces.

Insulation of concrete walls

Unlike brick structures, there are no seams on the concrete surface. To improve adhesive properties, apply a specialized primer. The thermal conductivity of a concrete structure is reduced using the following materials:

- Styrofoam. Supplied in slabs of various thicknesses.

- Extruded expanded polystyrene. In its structure it has a large number of air bubbles that prevent the passage of heat and sound.

- Foamed polyethylene. Available in the form of a two-layer fabric. Foamed polyethylene is equipped with aluminum foil.

- Mineral, basalt or stone wool. Insulation technology involves the use of fabrics made of interwoven fibers. Cotton wool is resistant to high temperatures.

- Ecowool. Bulk insulation. Manufacturers make ecowool from cellulose fibers. The use of waste paper in the production makes ecowool affordable.

- Liquid polyurethane foam. Forms a monolithic layer without cold bridges. The installation technology involves the use of specialized equipment.

Fastening elements are selected separately for each case, depending on the heat-insulating material used.

Insulation of walls with cork panels

Cork panels have high thermal insulation properties and strength characteristics. Their size is 0.5-1m. Cork has a cellular structure. This provides reliable thermal insulation.

According to the technology, specialized glue is used for fixation. It is applied to the panel or base. The method of preparing glue varies depending on its brand. Before use, study the instructions supplied by the manufacturer.

The panels are glued together. To avoid the formation of cold bridges, the seams are filled with a sealing compound.

Wall insulation technology involves the use of various materials. The installation method depends on the characteristics of the canvas and is selected individually for each case. Following the installation instructions will make the microclimate in the room comfortable at different ambient temperatures.

Have you insulated the walls yourself? What kind of thermal insulation layer was used? Leave comments and share the article on social networks, save it in bookmarks.

The video below will talk about insulating the walls of a frame house according to SNiP.