Insulating walls with foam plastic: myths and reality

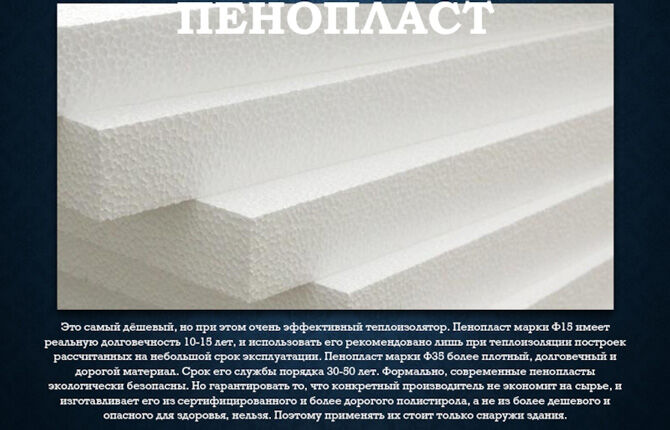

Foam plastic is a foamed plastic material with a cellular structure and various properties, which is widely used in construction and everyday life.The variety of types, their differences in thickness, density, strength and durability have given rise to many myths about this material that have nothing to do with reality. Insulating walls with foam plastic is a procedure in demand today. It allows you to insulate the room and increase the resistance of the walls to negative external influences (wind, rain, snow, temperature changes).

The content of the article:

- Myth 1: Insulating a façade is expensive

- Myth 2: Mineral wool is cheaper

- Myth 3: It doesn’t matter what you insulate with

- Myth 4: A facade insulated with foam plastic “does not breathe”

- Myth 5: Polystyrene foam is a highly flammable material

- Myth 6: Polystyrene foam is not durable

- Myth 7: Foam plastic is not environmentally friendly insulation

- Myth 8: Decorative plaster over insulation is not necessary - just paint it is enough

- Myth 9: Wall insulation will not significantly increase heat in the house

- Myth 10: It doesn’t matter who insulates

- Myth 11: The higher the density of the foam, the warmer it is.

- Myth 12: Foamed polystyrene foam (styrodur) is more reliable than simple polystyrene foam

Myth 1: Insulating a façade is expensive

It is believed that wall insulation polystyrene foam is an expensive pleasure. This cannot be answered unequivocally. For example, an owner living in the southern regions can choose an inexpensive material and get good thermal insulation, while an owner living in northern latitudes will have to look for a type that is more resistant to low temperatures, and therefore more expensive.

Maintaining the thermal insulation properties of foamed plastic mass depends on the operating temperature. If they exceed the value of its destruction, that is, destruction, it will be impossible to use the material for insulation.

In general, foam plastic allows you to save energy resources.In just a few years, it is possible to recoup the costs of insulating wall facades with this material.

Myth 2: Mineral wool is cheaper

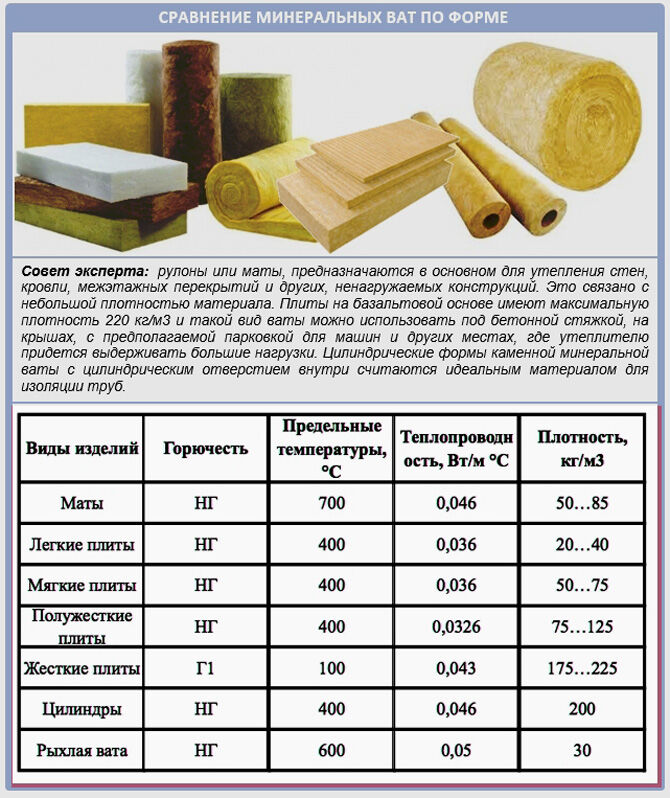

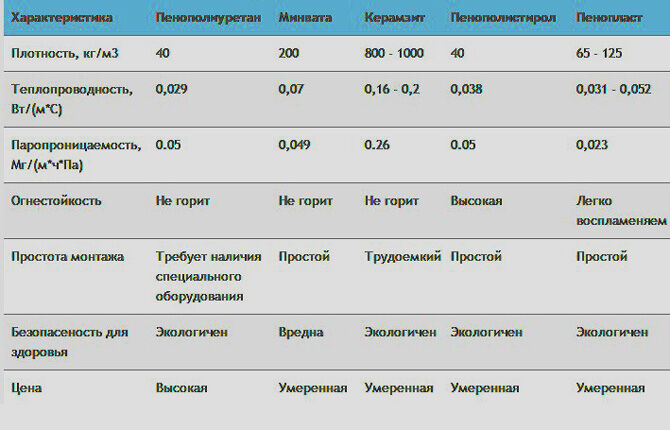

Both raw materials are actively used in construction to insulate the walls of buildings and other structures, but the differences in their properties must be taken into account. The two most important of them are the tendency of materials to burn, as well as their ability to accumulate and transmit moisture.

Mineral wool not only retains heat in the room, but also protects the building from fire. It is not afraid of open flames and does not support combustion, which cannot be said about polystyrene foam. It does not resist high temperatures well, so fire retardants are often added to it to improve its performance. This increases the cost of the finished product.

On the other hand, mineral wool is also rarely used in its pure form when insulating walls. Usually it is impregnated with compounds designed to maintain the desired shape and protect the material from the effects of fungus, mold, damage by insects and rodents. This also affects the final cost.

Typically, foam is chosen when it is necessary to protect a room or supporting frame from moisture. Mineral wool is more often used on facade walls, slabs, and attics - it is used to insulate gables.

Myth 3: It doesn’t matter what you insulate with

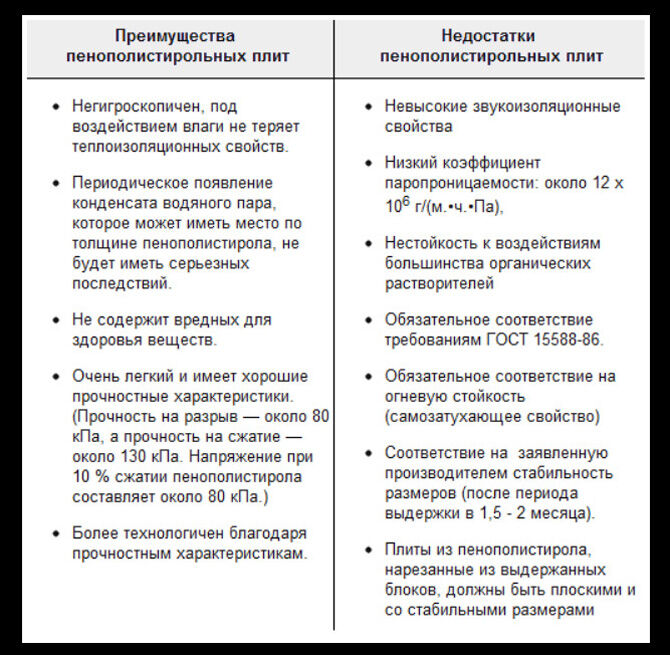

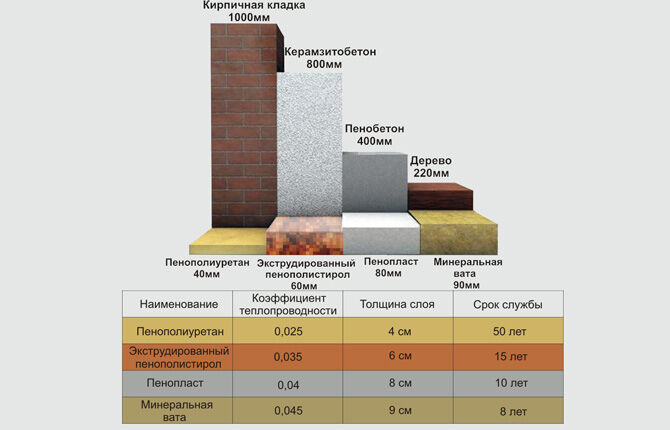

Debunking the previous myth shows that this is not so. There are a lot of insulation materials. They all have their own advantages and disadvantages, which are taken into account when choosing. Even among foamed polymers, the differences in thermal insulation, sound insulation, weight, and moisture insulation are so wide that they ultimately determine the appropriateness of use in certain conditions.

It must be remembered that polystyrene foam easily deteriorates and becomes unusable when in contact with certain industrial liquids - solvents, dyes. Therefore, the type and type of finishing materials used in further construction comes to the fore.

You should not skimp on the mixture for fixing to the walls and reinforcing the foam plastic material. You can save money when insulating wall surfaces if you purchase finishing from a domestic manufacturer. But it is better if it is done using Western technologies. Mineral decorative plaster costs less, acrylic plaster costs more, but the latter is more uniform, durable, and rich.

Myth 4: A facade insulated with foam plastic “does not breathe”

Against the background of high-quality wall insulation with a high degree of heat retention, foam plastic demonstrates low water and vapor permeability. However, this is both its advantage and its disadvantage at the same time. During installation, it does not require additional moisture-proofing agents - membranes and films. It itself prevents water from entering the building.

Polystyrene foam does not allow moisture to pass through, but it also cannot accumulate it. The steam escaping from the rooms of the building gets out through the unevenness and gaps of the material. This provides the necessary “breathing”.

Myth 5: Polystyrene foam is a highly flammable material

Polystyrene foam is quite flammable. When exposed to fire, it emits toxic substances, which limits its use as insulation for the surface of walls of buildings. However, impregnation of the material with fire retardants eliminates this drawback and improves performance characteristics.

An important point is that with prolonged and persistent exposure to fire and high temperatures, the effect of fire retardants ends over time.

Myth 6: Polystyrene foam is not durable

This is a controversial criterion even among experts. It’s one thing when the owner buys a plot and builds a house to last forever, personally choosing materials for construction, monitoring the progress of the entire process of construction and insulation of the walls of the house. He can take measures in advance so that in the future, during reconstruction, repairs and other manipulations, mixtures with acetone and other technical liquids that can destroy the foam or spoil it are not used.

It’s a different matter when an apartment building, industrial building or outbuilding is being built, the owners and management company of which often change. The person responsible for the reconstruction of the building may simply not know what type of foam and in what quantity was used to insulate the surface of the walls.

Myth 7: Foam plastic is not environmentally friendly insulation

This myth is not without foundation. Once upon a time, freon was added to the composition of this cellular material, which released toxins hazardous to health. Today it is no longer used in the production of raw materials for wall insulation.

Polystyrene foam is a non-toxic material. It does not pollute the atmosphere with toxic substances. On the contrary, some of its types, for example, expanded polystyrene (60% consisting of gas enclosed in a polystyrene shell) are actively used in everyday life, for the production of children's products. In particular, food packaging, travel thermoses for baby formula bottles, and disposable tableware are made from this material. The main thing that the person using them should know is that such products cannot be heated.

If we talk about insulation, then it is not forbidden to use foam plastic for external insulation of wall facades. For interior decoration, it is better to choose an alternative - roll insulation.

Extruded polystyrene foam as insulation: pros and cons of the material + tips for use in our article link.

Myth 8: Decorative plaster over insulation is not necessary - just paint it is enough

Polystyrene foam is a raw material with a cellular structure, so it cannot be left without an additional layer. The paint will just lie unevenly, but that's not the most important thing.

Polystyrene foam is not a durable insulation material. It gradually collapses on the walls under the influence of wind, precipitation, and sunlight, which is why it is so important to protect it with plasters and putties. They can extend the life of the facade by almost two times and preserve the aesthetics of the walls for a long time.

Myth 9: Wall insulation will not significantly increase heat in the house

The foam mass does not increase heat in the house - it is not a battery or an electric radiator. It traps warm air inside the building, preventing it from leaking out. Foamed polystyrene retains up to 30% heat. In its absence, the owner simply heats the street, and pays money for it.

When the wall surface is insulated with mineral wool, the room cools faster when compared with insulation with foamed plastic. If in doubt, a multi-layer combination of these materials can be used. In this case, the outer layer of the walls is made of mineral wool, and the inner layer is made of foam plastic.

Myth 10: It doesn’t matter who insulates

A person who is far from construction does not know all the intricacies of wall insulation, does not understand the technology and materials used.Therefore, you need to be attentive and savvy yourself in order to control the progress of work. Thus, unscrupulous workers can save money and pocket the difference by using tile adhesive rather than special insulation adhesive.

As a result, within a couple of months the foam will begin to lag behind the walls. Only mechanical fasteners will be responsible for its fixation, and even those can not be used in full by irresponsible and profit-hungry craftsmen. According to the technology, 5-6 umbrella dowels are used per 1 m² of foam plastic material, and not 2-3, as some façade designers do.

Myth 11: The higher the density of the foam, the warmer it is.

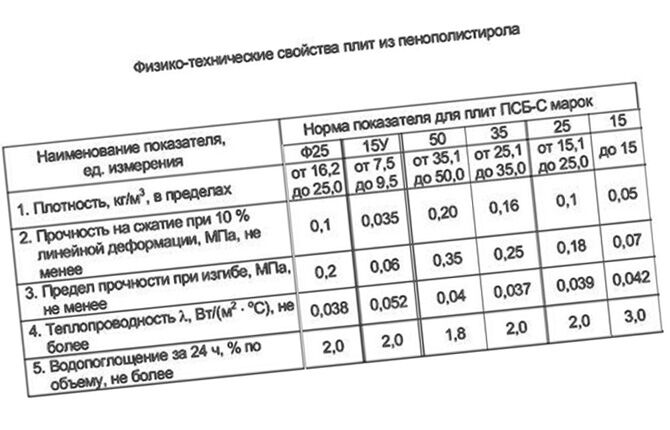

The density of a foam plastic cellular mass is an indicator that reflects the ratio of the weight of the material to its volume. Thermal conductivity, strength, water resistance, and other performance characteristics depend on this value.

The greater the density, the more closely the individual cells are adjacent to each other. Heat from one to another will be transferred faster. Therefore, the thickness of the foam for wall insulation is important.

The less gas inside, the greater the heat loss, so for wall insulation it is better to use lightweight material with large cells.

Myth 12: Foamed polystyrene foam (styrodur) is more reliable than simple polystyrene foam

Styrodur is one of the types of foam plastic. It was called penoplex and became widely used in construction. The material does not shrink as much as polystyrene foam and demonstrates greater resistance to stress and ultraviolet rays. It is denser, more durable, and has increased moisture-proof properties. However, it is impossible to say that one material is more reliable than the other, since both of them are foamed plastics.

Both are equally susceptible to fire and elevated temperatures. If polystyrene foam is more often used for insulating walls and building facades, then styrofoam is used for finishing basement, foundation, and basement elements of buildings. It is convenient for insulating balconies and loggias.

Polystyrene foam costs less than styrodur, so everyone makes a choice between these materials depending on their budget.

Polystyrene foam is a lightweight, warm, durable material. It is great for wall insulation - it helps retain heat in the room. In addition, it is resistant to negative environmental influences. In order for it to last as long as possible, you must strictly follow the technology of its installation on building's facade.

What type of polystyrene foam did you use to insulate the walls of your house? Share your tips in the comments and bookmark this article.

How to properly insulate a house with polystyrene foam. Errors and nuances in the video below.

Links to sources:

- https://ru.wikipedia.org/wiki/Foam plastic

- https://grand-fasad.su/articles/8989