Insulation for floors in a wooden house: materials for thermal insulation + tips for choosing insulation

Good thermal insulation reduces heat loss by 20–40%, and in some cases more. At the same time, correctly selected floor insulation in a wooden house not only reduces heating costs, but also directly affects the microclimate in the rooms. You need to know how to pick it up. Do you agree?

You will learn everything about thermal insulation options acceptable for arranging a wooden floor from our proposed article. We will tell you what criteria influence the choice and how to take them into account. Our recommendations will help you correctly arrange the lower floor in a structure made of timber or logs.

The content of the article:

Thermal insulation of floors in wooden houses

There is no universal thermal insulation material for all cases. To insulate each structure in a private house (foundation, load-bearing walls, ceiling), you should select your own optimal option.

And even in the same cottage, floors in different rooms often have to be insulated with different thermal insulation. The requirements for thermal conductivity of floors often differ.

It is necessary to distinguish between floors in a wooden house:

- basement and first floor;

- residential floors.

In the second case, insulation is usually not performed.Above and below there are heated rooms with approximately the same microclimate parameters. There is no need to separate them from each other with additional thermal insulation.

But the floor above the basement in a wooden house will have to be insulated in any case. And it doesn’t matter whether the basement is being used in any way or whether the wind is blowing from below between the supports of the pile foundation.

Only the insulation option and its thickness will change. But you will still have to install thermal insulation, otherwise heat loss through the uninsulated ceiling will be quite noticeable.

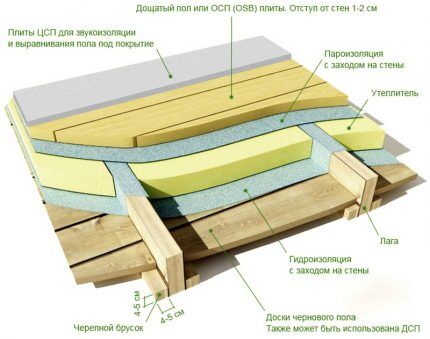

The floor in a wooden house on the ground floor is installed:

- on the ground;

- on joists or screed;

- along the beams.

The first option is usually used for low strip foundations. The second is with a foundation in the form of a monolithic slab. And the third - in all other situations.

And in each case, the insulation should be selected individually. For example, you cannot place mineral wool on the ground; with such installation it will quickly become damp and deteriorate.

The main reason for damage to the “pie” of the insulated floor on the first floor above the basement is excess moisture. The heat insulator and structure of such a floor in a private wooden house are affected by moisture from the ground and condensate formed due to temperature changes, as well as water spilled during cleaning.

Polymer waterproofing films are used to protect the insulation. But if the floor insulation system is designed without ventilation, then films that interfere with the free drainage of condensate can even cause harm.When the insulation gets wet, it will lose its insulating properties and become an excellent breeding ground for fungus.

Possible materials for insulation

There is an incredible amount of insulation on the domestic market. But for floor insulation devices In a low-rise house made of logs or timber, not all of them are suitable.

On the one hand, one should take into account the compatibility of the selected thermal insulation material and the wood from which the residential building is constructed. On the other hand, we should not forget about the environmental friendliness of all building materials used.

The main advantage of a wooden cottage is its environmental friendliness. The floor should be insulated with synthetics only as a last resort.

Among the variety of insulation materials for a wooden house, the following are recommended:

- stone wool;

- ecowool based on cellulose;

- expanded clay;

- sawdust;

- fiberboard

Also in certain situations you can use extruded polystyrene foam. But it is best to do without this material, giving preference to more environmentally friendly insulation from the list above.

Option #1 - stone mineral wool

Mineral wool is made from fiberglass, blast furnace slag and rocks. In wooden houses, it is worth using the last of these types - cotton insulation made from basalt fibers. It is the safest for humans and environmentally friendly - it contains virtually no synthetic binders.

Stone wool has:

- low thermal conductivity 0.034–0.04 W/(m*K);

- excellent vapor permeability;

- good noise absorption.

Basalt insulation is not subject to rotting, does not burn and can easily withstand heating up to 700 °With no loss of characteristics.

Option #2 - ecowool made from cellulose

This material is environmentally friendly, mold resistant and non-flammable. When producing ecowool, cellulose (paper production waste) is impregnated with antiseptics and fire retardants.

Fire and fungi are not afraid of her. At the same time, this heat-insulating material is capable of absorbing moisture up to 15% of its own weight.

Also, ecowool cannot be installed near the bases of main chimneys, foundations of stoves and fireplaces. When exposed to high temperatures, cellulose will smolder. Due to the abundance of fire retardants, it will not catch fire. But the gradual smoldering of the paper will inevitably thin the insulation layer and lead to an increase in heat loss.

Option #3 - sawdust

If you want to get a home that is as clean as possible from an environmental point of view, then insulate the floor in a wooden cottage you can use sawdust. They are poured in a compacted layer 10–40 cm thick between the joists, which provides fairly high-quality insulation without any chemicals.

Sawdust is the cheapest existing insulation material. They are tested by time and long-term practice. However, this material, like any wood, is flammable.Whether it is worth adding highly flammable fuel to a potential fire in a wooden house is an open question.

Option #4 - expanded clay

Expanded clay can deservedly take second place in cheapness after sawdust. This insulation is made from baked clay. It has the form of granules with many air-filled voids inside.

Of the minuses of expanded clay, only its high hygroscopicity is worth mentioning. If the expanded clay granule is split, it will absorb water like a sponge. Without underlying waterproofing in the form of a thick polyethylene film, such insulation cannot be poured.

Option #5 - polystyrene foam

This material is presented on the market as foam and slab Penoplex (EPPS). If we take it, then for floor insulation only the second option is extruded polystyrene foam. It is denser and absorbs moisture much less.

Expanded polystyrene and wood are often called antagonists. The first does not allow moisture to pass through, while the second, on the contrary, absorbs it well and then releases it to the air.

However, with proper installation, EPS and polystyrene foam can be combined with wooden structures. You just need to leave a gap for ventilation between the polystyrene foam insulation and the wood so that condensation does not accumulate there.

Option #6 - fiberboard

Fiberboards are made from wood chips and cement. This is an excellent insulation material, which is not yet very widespread in Russia.

Fibrolite is characterized by quite high hygroscopicity. It dries quickly, which, however, is only possible under conditions of good ventilation. It is a non-flammable, harmless to humans, non-rotting and breathable heat insulator. Just don’t let it get wet or freeze.

Choosing the best insulation

If you need the most environmentally friendly material, then you should choose sawdust, expanded clay or fiberboard. Basalt wool is also ready to give a serious head start to polystyrene foam in this regard.

It is also recommended to insulate floors in the bathroom, toilet and kitchen with extruded polystyrene foam. These rooms are characterized by high humidity. The more moisture-resistant insulation is used in them or under them, the longer such material will last.

However, if the ventilation in the underground is organized efficiently, then ordinary mineral wool can be used.

For comparison, the table below shows the main characteristics of insulation:

| Material | Thermal conductivity, W/(m*K) | Vapor permeability, mg/(m*h*Pa) |

| Stone mineral wool | 0,034—0,039 | 0,3–0,35 |

| Ecowool | 0,038–0,041 | 0,3–0,67 |

| Expanded clay | 0,1–0,18 | 0,25–0,27 |

| Sawdust | 0,05–0,08 | 0,3–0,8 |

| Fiberboard (with a density of 300–500 kg/m3) | 0,07–0,1 | 0,18–0,3 |

| EPPS | 0,029–0,032 | 0,003–0,005 |

When choosing the best way to insulate the floor in a wooden house, you should compare the available options by:

- thermal conductivity;

- vapor permeability;

- flammability;

- environmental friendliness;

- durability (resistance to moisture and fungus);

- price.

The lower the thermal conductivity of the insulation, the better it is. Vapor permeability affects its ability to breathe and conduct condensation out.

Expanded clay and sawdust are considered the cheapest heat insulators. More expensive are fiberboard, ecowool and EPS.

Familiarize yourself with the design diagrams of the floor insulation system built on joists. next article. We recommend reading this very useful information.

Conclusions and useful video on the topic

Video #1. The nuances of insulating a wooden floor in a timber house:

Video #2. Thermal insulation of the subfloor along the joists using mineral wool:

Video #3. Analysis of possible mistakes when insulating the floor:

When choosing insulation for the floor, you should focus on the characteristics of the room being insulated, the type of foundation and the available budget.

In most cases, the best option is environmentally friendly and non-flammable basalt mineral wool. But if the floor is installed on the ground, then it is better to use expanded clay. And if there is high humidity in the basement, then preference should be given to polystyrene foam.

Tell us about how you insulated the floor in a wooden building with your own hands. Share which thermal insulation option you preferred and why. Please leave comments in the block below, ask questions and publish photographs on the topic of the article.

We bought a small cottage near Novosibirsk, it’s already 20 years old, and this is our first winter. At the first frost, the floor becomes icy. It is unclear how people lived in this house. I am collecting information about insulation materials and in general about what insulation methods exist. One question torments me - won’t rodents live in these warm and cozy insulation? From everything I learned today, I am inclined to use basalt wool; most likely, it will be better suited in our case.

Rodents practically do not settle in basalt wool. There are exceptions, but they are rare.