How to insulate an outdoor gas pipe from condensation: a review of the best materials and installation instructions

Operating parameters in the gas system are maintained due to a number of conditions, including the selection of suitable equipment and pipe material, installation of regulators, competent installation, and compliance with operating rules. No special efforts are made to stabilize the temperature, but in vain.

Despite compliance with all requirements for the installation of gas pipes, users often encounter condensation or freezing of the fuel mixture. To prevent this from happening, thermal insulation measures are carried out. In this article, we will look at how to insulate an outdoor gas pipe so that the system functions normally and provides the house with heat even in severe frosts. We will supplement the material with visual photos and useful videos with recommendations for pipe insulation.

The content of the article:

Is it necessary to insulate the gas pipeline?

It is unlikely that you have seen insulated pipes leading from gas distribution stations to residential buildings in urban areas. Typically, a gas pipeline is laid underground - and then only waterproofing is done, without insulation. Or above-ground, when pipes are also protected from atmospheric and mechanical damage, without worrying about their thermal insulation.

The documents also contain minimal information about additional insulation - and in SNiP 42-01-2002 (about systems in general), and in SNiP 41-03-2003 (about thermal insulation of pipelines).

The lack of thermal insulation is explained by the properties of methane gas, which is supplied to the city slabs and water pumps. Its content in the fuel mixture reaches 70-93%, and the freezing point is -182.5 °C. This means that even when methane is diluted with other impurities, it will not freeze in the winter conditions of the northern regions of Russia.

If methane is not subject to freezing, then propane-butane the mixture that fills the cylinders and gas holders, reacts sensitively to temperature drops. That is why owners of private houses have to either independently or with the help of employees service organization insulate sections of the gas pipeline located on the street.

There are three critical areas that potentially require additional thermal insulation:

- a section of pipe from gas cylinders to the inlet in the wall of the house;

- pipe from the basement entrance to the house, if gas is supplied from gas holder;

- a section of pipe located in an unheated room - in a cold corridor, storage room, etc.

An underground gas pipeline does not require additional insulation. If it is enclosed in a special shell case made of polyurethane foam, it is for the purpose of protection from mechanical damage. The base outlet of the polyethylene pipe from the ground is placed in a case; it is also not thermally insulated.

Passage through a wall, according to the rules, is also carried out in a case: the pipe is enclosed in a piece of metal pipe of larger diameter, and the voids are filled with tow mixed with bitumen. Thus, this small section of the gas pipeline is already insulated.

Whether in a particular case it is necessary to insulate a gas pipe on the street is up to the home owners to decide. If the fuel supply system operates without interruption, then thermal insulation is not needed.

Preparing pipes for insulation

The above fragments of the gas pipeline that require additional thermal insulation can be steel or polyethylene - therefore, materials for insulating such pipes you need to select the most suitable ones. It is better to wrap PE pipes with elastic sheet or tape material, and metal pipes with a heating cable or place them inside a PP shell.

In any case, the gas pipeline must be prepared before insulation. The recommended air temperature for installation work is +10 °C, so it is better to postpone the event until the warm season.

The insulated surface must be thoroughly cleaned of dust, dirt, grease, and adhering street debris. We recommend using a special cleaner-diluent based on ethyl acetate. If you plan to glue the thermal insulation onto a painted surface, you should ensure that there is sufficient adhesion.

Useful tips that will come in handy during the installation of pipe insulation:

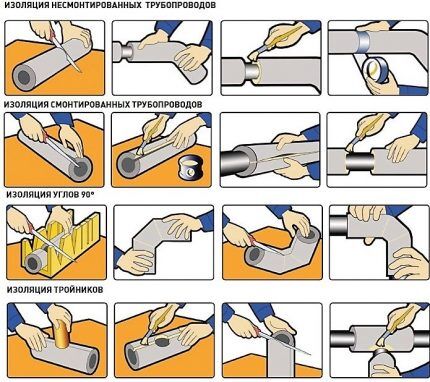

- if you plan to use insulating tees, corners, bends, get ready to fix them first, and then insulate the straight sections;

- expect that glue, if used, will have to be applied both to the surface and to the insulation, and when gluing the ends - both to the ends and about 2 cm to the inner surface of the insulation;

- stretch the insulation during installation, taking into account the linear expansion of the pipes;

- To give a holistic appearance, place all seams on the wall side.

We recommend preparing a set of tools in advance: glue brush, stationery knife, compass, scissors, punches, miter box, ruler, tape measure, marker. A spatula is useful for puttying work.

Before attaching the self-regulating cable, the steel pipe is also covered with a protective paint in 2 layers and grounding is carried out.

Popular types of materials + instructions

Let's consider the types of insulation that are more appropriate to use in modern conditions. There is no point in wrapping pipes with glass wool or covering them with foam if effective materials based on polystyrene foam or polyurethane foam exist. Moreover, in addition to straight sections, you can also purchase ready-made shaped elements - tees, elbows, corners.

Several useful recommendations on how and with what to insulate a gas pipe from condensation will help you eliminate the emergency yourself and maintain the functioning of the gas pipeline until specialists arrive.

Option #1 - thermal insulation based on mineral wool

Often, inexpensive mineral wool cylinders, regular or foil, are used to insulate pipelines.The advantages of insulation include non-flammability, environmental friendliness, biological stability, quick and easy installation, and excellent thermal insulation properties.

The main disadvantage is fear of moisture. If water gets inside the cylinder, the material breaks down and rust forms on the metal pipes underneath.

Unlaminated, that is, not covered with foil, cylinders cannot be used in a humid environment; therefore, they are not suitable for thermal insulation of a gas pipeline outdoors. They can be used in dry, closed, unheated rooms where the temperature in winter drops below 0 °C.

Requirements for installation and operation of mineral wool insulation can be found in SNiP 41-03-2003, developed to replace SNiP 2.04.14-88.

Warming rules:

- It is better to start fastening elements from flange connections.

- The cylinders are fixed using bandages, packaging and aluminum tapes.

- Unlaminated products must be wrapped with reinforced tape. It is also used if the top layer of foil cylinders is damaged.

- If it is noticed that moisture has penetrated under the insulation, it must be replaced.

Before installation work, steel pipes must be treated to prevent corrosion. But it is better, if possible, to refuse to use mineral wool and choose moisture-resistant insulation.

Option #2 - PPS and PU foam shell

Hard covers made of polyurethane foam and polystyrene foam, as well as basalt shells, are actively used.They have all the advantages of mineral wool, and also practically do not absorb moisture.

They can be used both indoors and outdoors, and the main conditions for a long service life are compliance with installation rules and tightness.

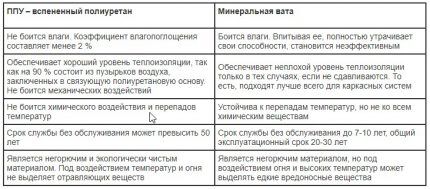

In terms of technical characteristics, mineral wool is inferior to polyurethane foam thermal insulation; the comparison results are shown in the table:

Products usually consist of two equal halves, which are connected during installation according to the principle "tenon and groove". To achieve maximum tightness, seams and joints are sealed with foil tape. But a hard shell is not suitable for insulating fittings - you will have to use other materials.

It is important that the pipe is completely dry before installation! Even slight humidity can cause a greenhouse effect and the development of corrosion.

Option #3 - Thermaflex polyethylene “coat”

Thermaflex products have become widespread due to their versatility, good thermal insulation properties, lightness, and ease of fixation. This is thermal insulation in the form of tubes with a cellular structure made of polyolefin or polyethylene. Suitable for all types of pipes, including gas.

In addition to pipe and sheet material, the manufacturer produces several types of glue for attaching to pipes, polymer and aluminum tape, thermal tape, cleaner, clips and hangers.

Instructions for use:

- Cut a straight piece of pipe material along the technological seam along the entire length, trying to keep the knife perpendicular to the surface.

- Place insulation on the pipe so that the cut edges do not touch.

- Apply glue to the cut, adjacent parts of the pipeline and the inside of the thermal insulation - this is necessary so that the element does not move.

- Wait a few minutes until the glue dries (from 2 to 12, depending on the pipe temperature);

- Connect the edges along the cut line, carefully, from the ends to the middle.

- For greater reliability, use clips, placing them along the seam at intervals of 20 cm.

Before gluing the next fragment, treat the end part, including the surface of the pipe, with glue. After 24 hours, remove the clips and seal all seams with tape.

Pipe Thermaflex is designed for insulating gas pipelines with a diameter of up to 159 mm; if the pipe or fitting is wider, we recommend using sheet material.

Excess material will never be wasted: along with gas pipes, it can also be used for thermal insulation pipelines Cold water and hot water supply, sewerage, tanks.

Option #4 - self-regulating heating cable

Heating cables are used to protect pipelines from freezing or maintain the desired temperature.

Owners of private houses who suffer from condensation and freezing of fuel during the cold season speak positively about the use of a self-regulating cable - it really helps to forget about the troubles associated with the use of blue fuel.

There are no restrictions on use: the cable is used for copper, steel, composite pipes, with and without thread. If aluminum thermal tape is additionally fixed for installation on plastic, then it is not needed for steel gas pipes.

The cable is laid in two ways:

- Drawing 2 or more parallel straight lines over the entire length of the pipeline. For a 50 mm gas pipe, 2 pieces are enough.

- Spiral cable winding throughout the entire pipe, including tees and bends.

To protect both the pipe and the cable, thermal insulation is put on top in one layer, preferably polymer. If bitumen or solvent-containing insulation is used, instead of the usual one you should purchase a cable with fluoropolymer shell - it is important!

The installation procedure is simple: the cable is fixed on a previously prepared surface of the gas pipeline using one of the indicated methods, insulation is put on top, and secured with tape or thermal tape. Then connect to the network using an adapter coupling. We recommend viewing the detailed cable installation instructions.

Conclusions and useful video on the topic

Methods for installing a heating cable:

One of the options for fastening the PU shell:

How to insulate pipe joints with Energoflex:

Insulation with rubber sheet material:

As you can see, the materials and methods of insulating gas pipes in a private house can be different. Their choice depends on specific conditions: location and size of the gas pipeline, technical characteristics, cost. All the materials listed in the article are universal, that is, they can be used for thermal insulation of any pipe communications.

Despite the ease of installation of insulation, we recommend that you first consult with a gas service specialist to avoid both an erroneous choice of material and penalties from the service organization.

Have you recently been insulating a pipe and want to tell other users about your experience? Write your recommendations, add photos of the finished work, participate in discussions - the comment form is located below.

If you still have questions on the topic of the above material, ask them to our experts in the feedback block.