Insulating a wooden floor: popular insulation technologies + expert advice

Heat loss in a house passes not only through the walls and roof, but also through the floor.Losses are especially high for floors made of natural materials. Therefore, insulating a wooden floor will help make the house warm, eliminate or reduce heat loss, and also save on heating bills.

According to the requirements of the standards, the temperature in the living room should not be lower than +18 °C, and in children's rooms +20 °C. To achieve these indicators in winter, it is necessary to insulate the floor.

Today, thanks to the abundance of materials, there are many technologies for carrying out thermal insulation work. Let's look at the most popular of them.

The content of the article:

Methods for insulating wooden floors

The choice of technology depends on many factors, namely: type of room, ceiling height, type of coating, thermal conductivity of materials, budget and occupant requirements.

One of the key factors is the type of wooden floor. There are three of them:

- parquet;

- planks;

- plywood.

Boards or OSB boards are most often laid on joists. Plywood floors, as a rule, are used as subfloors; less often, such material is laid on joists. These two types of floors can be insulated using any technology.

Special parquet dies or individual parquet slabs are laid on both a concrete and wooden foundation. Such a floor can be insulated using a screed, any wood insulation, penofol or penoplex.

Let's consider the most popular technologies for insulating wooden floors.

Method No. 1 - insulating floors along joists

This is the most common method of thermal insulation, especially if the floor is located close to the ground. With its help you can avoid large heat losses.

Insulation along joists is most often used for thermal insulation of floors in private homes.

It is recommended to carry out the work in the following sequence:

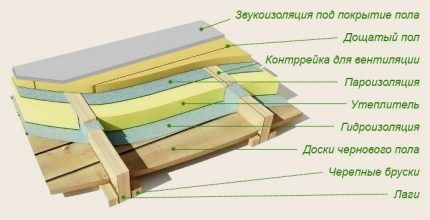

- T-shaped wooden logs are installed at a distance of 45-70 cm, and subfloor boards are mounted on them using special screws.

- The selected insulation is placed between the joists as tightly as possible, and the gaps are filled with sealant or polyurethane foam.

- Then vapor or waterproofing is laid on the thermal insulation layer.

- Finally, the finished floor boards are installed, after which they are processed.

It is very important that there is a ventilation gap of about 20-30 mm between the insulating layer and the boards.

If it is decided to use mineral wool or ecowool as insulation, then a vapor barrier is necessary. It should be laid with an overlap of 10-15 cm, and the edges should be up to 10 cm high. You can use special professional materials, for example, membrane vapor barrier or plastic film.

Detailed instructions on how to carry out floor insulation using joists can be found in this material.

Option No. 2 - thermal insulation on the subfloor

This is an ideal solution for rooms with high ceilings. The technology is a little similar to the previous one.

The difference is this:

- bars are attached to the lags on the sides;

- after that, boards are mounted on them using self-tapping screws or nails;

- make sure that the size of the boards is equal to the distance between the lags;

- When all the boards are installed, the surface of the subfloor is covered with a vapor barrier. For example, film or glassine;

- then insulation is laid between the lags, preferably without gaps;

- after this, the vapor barrier sheets are again, and, as the final stage, they are covered with treated boards;

- The clean floor can be covered with a special solution for shine or some kind of coating can be laid.

If you want to insulate an existing, high-quality wooden floor, then you can use it as a rough floor and lay a layer of insulation on it, but in this case the distance between the floor and the ceiling will be significantly reduced.

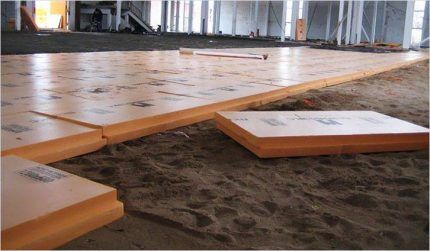

Option No. 3 - using polystyrene foam boards

This is the simplest thermal insulation scheme. This option is suitable even for rooms with low ceilings, since the thickness of the material is not very large.

The laying technology consists of several stages:

- A layer of insulation should be laid on a flat surface/foundation. For example, polystyrene foam or mineral wool.

- If the foundation is uneven, then it should first be leveled using a cement mixture.

- Expanded polystyrene slabs 50 mm thick are laid on the floor in one layer, if this is an apartment.

- The slabs do not need to be additionally fixed.

- Then the insulation should be covered with a layer of vapor barrier if this is the first floor or the installation is on the ground.

- After this, two layers of plasterboard slabs are laid, which are fixed using ordinary self-tapping screws. You can also use cement screed or plywood sheets.

- The cement screed should be laid in two layers, and the insulation should be covered with plastic film so that the screed does not penetrate between the slabs.

- After the screed has completely dried, the finished floor can be laid.

If you are laying laminate flooring, you should use a special thin underlay underneath it. All layers of materials are laid with staggered seams.

The screed is used as one of the insulation layers. Dry screed is applied only after the wood has shrunk; sometimes this process takes quite a long time.

From a physical point of view, the screed is a mixture of cement and sand in different proportions. There are ready-made products in stores, but you can create them yourself. It requires increased waterproofing, as it can become deformed due to moisture.

The floating screed is somewhat different from the previous one. Although it also consists of a mixture of cement and sand. It is poured directly onto the insulation sheets and therefore does not have close adhesion to the floor.

Foam or a similar material is most often used as insulation with a floating screed. This type of thermal insulation is rarely used for wooden floors.

Option No. 4 - heated floor system

Water-heated floors can be mounted directly on a wooden base.If the boards are rotten, they should be replaced. To work, you will need plasterboard or gypsum fiber sheets (gypsum fiber sheets), a foil backing, a thin pipe, and equipment for supplying and heating water.

Please note that heated floors should not be placed under large furniture. Since sofas and cabinets will heat up, energy efficiency may decrease.

An electric heated floor system requires the installation of special heating elements under the finishing coating. It is better to entrust complex work of this kind to specialists.

The entire system operates from the mains, so it is worth protecting yourself from power surges and unscheduled power outages.

Installation of such a floor, both water and electric, is quite labor-intensive and complex, as well as an expensive process.

Work technology:

- lay the foil backing in layers with the foil facing up directly on the wooden floor and secure it with a construction stapler;

- 9.5 mm thick sheets of plasterboard are placed on it and secured with screws;

- lay a tube made of cross-linked polyethylene, securing it with special plastic clips;

- You can use special fixing mats or reinforcing mesh as a substrate for the tube;

- fill the structure with gypsum self-leveling floor;

- at the last stage, the pumping and mixing unit should be assembled and installed and the entire system should be connected.

Within one room there may be several pipes connected to the boiler. Each of them forms a contour. Such circuits can be turned on one by one if the room is large, or all at once.

For detailed instructions on installing heated floors on a wooden floor, read Further.

We reviewed the most popular technologies for insulating wooden floors. Each of them has its own advantages. The type of material that is best suited for the work also depends on the technology.

A few words about materials

Today there are a large number of different thermal insulation materials on the market. We will look at the most popular and frequently used ones.

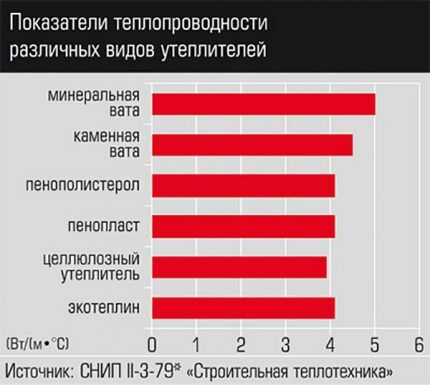

The insulation must have a certain set of qualities. Therefore, you should pay attention to: weight, environmental friendliness, thermal conductivity, compressive strength, moisture resistance, service life. In addition, the insulation must have average, or better yet, high adhesion to the wooden surface.

Also, one of the criteria for choosing insulation is its thickness. This indicator is critical for residents of multi-storey buildings.

In addition, the choice of material is influenced by the type of foundation and floor, the presence of a basement, as well as the features of operation - permanent living space or summer house.

Wool (mineral, stone, glass wool). This material requires high-quality waterproofing, since any cotton wool quickly gets wet.

Most often used to insulate wooden floors. mineral wool combined with good waterproofing. Mineral wool is produced in the form of rolls and compressed slabs.It is quite easy to work with, as it is light and cuts easily.

To insulate the first floor, it is worth using mineral wool with a thickness of 20-30 mm, and for the second floors and above - 10-15 mm.

Classic insulation involves laying mineral wool between joists or directly on the subfloor.

Another popular insulation material is sawdust. They come in several types: wood, sawdust pellets, sawdust, wood concrete. They require very high quality waterproofing. You need to use prepared sawdust that has been lying in a dry place for at least 5-6 months. It is better not to use this material for insulating residential premises, as it quickly gets wet and begins to rot.

Sawdust, in order to reduce heat loss, should be laid in a thick layer, at least 30 cm. This is the best option for insulating a summer house or outbuildings.

No less popular material is expanded claywhich is made from clay. This is a cheap and environmentally friendly insulation. It is most often used for dry screed or simply poured onto the subfloor or between joists.

Foam or extruded polystyrene foam can be used in rooms with high humidity levels. These materials are quite dense in structure and sheets of various thicknesses can be purchased.

Polyurethane foam can also be used as a thermal insulation material. To install it, special spraying equipment is used. It can be used on any foundation, and the foam itself can last up to 10 years.

Penofol - a fairly popular Russian-made thermal insulation material. Insulation sheets with dense reflective foil. Available in several types. The classic version is made in the form of sheets of polyethylene foam covered with foil. There is also self-adhesive Penofol S, and on one side of it moisture-resistant glue and anti-adhesive film are applied, and on the other there is aluminum foil.

Also considered popular fiberboardwith excellent sound insulation. It is made from sawdust filled with liquid cement mortar. Available in slab form.

Isolon insulation is produced in the form of rolls and has low thermal conductivity. Comes in the standard silver color, but in other bright colors. It has excellent sound insulation, despite the fact that the sheets are quite thin.

Most often, insulation is used in the form of rolls, so they are easy to install.

Useful tips from experts

If you plan to carry out thermal insulation work yourself, then check out the tips from professionals:

- all gaps should be treated with sealant or foam, otherwise additional heat loss may occur;

- if you are laying several layers of insulation, then it is worth considering that each new layer should be laid perpendicular to the previous one;

- materials for thermal insulation of the first and second floors of one house may differ;

- To protect a wooden floor from groundwater, it is worth using a regular construction film around the entire perimeter as a waterproofing barrier. It must be fixed with sealant;

- waterproofing can be carried out using PVC slabs, or roofing felt, or using ordinary polyethylene film, or making isoplastic waterproofing;

- Some experts recommend laying a vapor barrier after laying the insulation. Film, parchment or other suitable material can be used as a vapor barrier material.

Before purchasing all materials for insulation work, we advise you to consult with specialists.

Conclusions and useful video on the topic

Several video examples of how you can insulate a floor with your own hands, both for specialists and for beginners.

The video provides an overview of one of the technologies for insulating a wooden floor in a cottage or country house:

A popular and inexpensive floor insulation technology that anyone can handle:

We reviewed the most popular technologies for floor insulation and types of thermal insulation materials. If this is relevant to you, then you can choose the appropriate option for yourself. But before making your final choice, consult with a specialist and remember that cheap is not always bad.

Do you know another way to insulate a wooden floor? Please tell people about it who are encountering this issue for the first time. Leave your comments, ask questions, share your experience in the block below.

Regarding warm floors, here’s what I want to add: firstly, this is not one of the insulation options, but an addition to the insulation. If there is no thermal insulation (or it is bad), then heating the floor with electricity is the same as heating the street. Money for electricity will only fly away in vain.

There are very simple options for laying an electric floor, without any tricks with pouring screed, etc. Film floor, for example. In general, you can simply lay it under the laminate, and it will work great and serve as additional heating. and, by the way, you can do without outside specialists. If you understand a little about electrics, connecting the mats will not be a problem.

Question about polystyrene foam. I want to insulate the floor with it, but someone told my wife at work that this is a material for foundations and facades, but it can’t be used to insulate the inside, it seems to be harmful. Is it nonsense?

I have always liked the advisers that women come across; often these are the same “experts”, female colleagues who are “in the know” about all the intricacies of construction and engineering.

Extruded polystyrene foam is used for the following types of insulation work:

— insulation of internal walls;

— insulation of external walls;

— insulation of conventional and heated floors;

- foundation insulation.

As you can see, the material is used both for external insulation work and for insulation work inside the building. Of course, there are temperature restrictions: you cannot use it near heating devices or in rooms with high temperatures. Since when heated above 80 * C, harmful toxins will be released. In this case, to be on the safe side, many people use other materials inside buildings.

Layout diagram of extruded polystyrene foam plates in the photo in the appendix.