The best tile cutters in 2023 in terms of price and quality ratio: TOP 10

Even 20 years ago, tiles were cut with ordinary pliers and a carbide roller. This was all done by hand, often suspended or on the floor. The material was cheap, and the method was justified.

For expensive ceramics, it is better to use a tile cutter. This way you can cut as accurately and quickly as possible. Sometimes, especially for thick, wide-format material, this is the only way to correctly trim the edge, as they say, to size.

The content of the article:

What to look for when choosing

There are many models of specialized tools for cutting ceramics. Therefore, to decide which tile cutter is best to buy, you have to compare tools from different manufacturers. There is no point in purchasing the first equipment you come across or the top model you like from an advertisement, as many buyers do. The best tile cutters rarely appear in advertising; the demand for them remains constant even without marketing techniques.

What is the fundamental difference between tile cutter models:

- Frame design and weight.

- Drive type, manual or electric.

- The cutting method and the design of the cutting part.

Each model has its own little secrets that improve working with tiles. For example, the method of fixing and marking the material, the use of a threshold for breaking off.

Tile cutters are divided into manual and electric. In addition, you can also find a conditional division into portable and desktop models.In theory, tabletop devices can be portable, but in reality they are heavier and more powerful structures, designed to work with a team of several people. In order not to get confused, you should note that a desktop device is almost always equipped with an electric drive.

Features of the design of desktop tile cutters

The best electric tile cutters use a cutting disc mounted on a movable support as a working tool. The tile is cut either completely to the full depth of the cut, or a cut is made to a shallow depth along the entire length of the marking. It all depends on the power of the model. Typically, portable tile cutters use partial-cut or half-cut technology, while full-cut tiles are used in tabletop models and stone cutting machines.

To cut thick tiles made of porcelain stoneware or natural stone, discs with diamond powder are used, as well as standard vulcanite. Often complete with water cooling of the cutting edge.

The use of water is not a significant advantage - such structures often fail due to cooling problems and are difficult to maintain. But water makes it possible to reduce disk wear, increase the cutting speed, and most importantly, prevent the formation of cracks due to overheating. Therefore, it makes sense to purchase a water-cooled tile cutter for large volumes or for sawing heavy facade tiles.

What types of portable tile cutters are there?

This category includes all models whose design allows you to carry and store the instrument using special cases, bags or boxes. This review also includes battery-powered models.In such devices, a disc diamond tool is usually used; it can only make a small cut, after which the tile can be broken according to the markings.

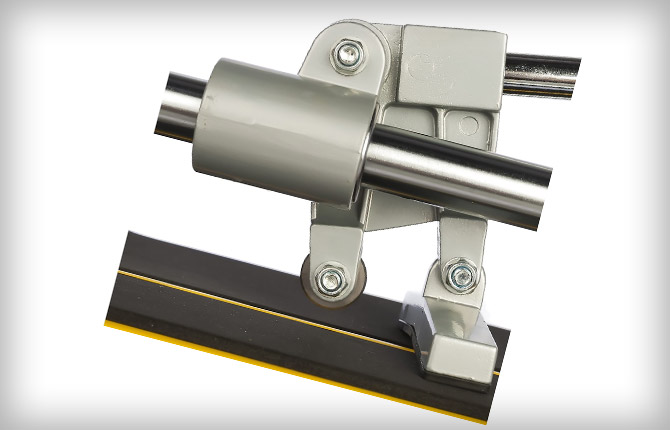

All other portable tile cutters are manual. To cut tiles, you need to manually operate the lever with the cutting head. Typically the cutting tool is a carbide roller mounted on a bearing or bushing. There is not much difference, but it is generally accepted that a bearing tile cutter provides higher accuracy and cutting depth.

The second important point is the design and material of the frame with a guide traverse (monorail), on which the head rests as the roller passes over the surface of the ceramic tile. It is best if it is cast iron or steel, but you can find good tile cutters with an aluminum or stamped base.

A good tile cutter must meet the following requirements:

- The base (slab) is as rigid as possible. It doesn't have to be cast iron, but there shouldn't be any deformation when cutting tiles of maximum thickness.

- The roller should not slip or deviate from the marking when the lever is pressed. If a sleeve fit is used instead of a bearing, then all parts of the rotation support must be metal (bronze, brass or steel).

- Correct length of lever and transmission link. The higher the force on the tile cutter lever, the worse the quality of the cut.

Often, due to the “heavy” lever, a portable tile cutter must be installed on the floor so that you can cut by leaning on the drive with your whole body. It is clear that the quality decreases, and if you need to cut tiles with a relief pattern, you may end up with a defect.

It is also desirable to have a special supporting edge, on which the tile is chipped off with a sharp but gentle blow to the surface.As well as a square frame and a special rubberized coating on the base plate.

Rating of the best portable tile cutters

Most of the models are made in the form factor of a slab with an overhead arrangement of one monorail or a double traverse. In this case, you have to cut with a lever in small “stitches”, after first resting your other hand on the tile.

When buying a manual tile cutter you need to pay attention to:

- Reference plane. You don’t have to check with a level, but you need to apply a standard plumber’s ruler to the surface. If there are any comments about the plane (waves or deflection), then the tile will crack the first time you try to cut it.

- Supports for a monorail or double traverses should only be cast, metal or plastic, it doesn’t matter.

- The monorail should preferably be chrome plated, solid aluminum or steel. In the process of cutting tiles, it accounts for up to 60% of the total load.

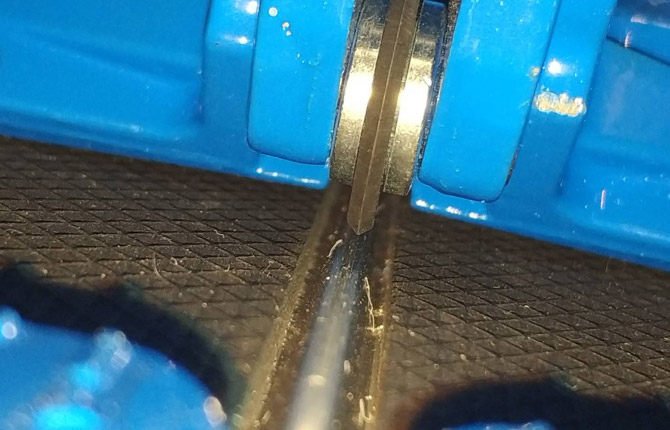

In addition, you need to pay attention to the quality of fastening of the cutting roller. There is usually a groove underneath the cut line. So the roller and the groove must be in the same strictly vertical plane.

Fifth place – BISON “EXPERT” 33193-50

The tool is manufactured in China, but judging by the quality of material processing for the bed and monorail, we can say that the tile cutter is made using full-fledged engineering equipment, casting and grinding machines. This means that the design is designed for constant use, heavy loads and significant cutting forces.

Distinctive features of the BISON:

- Massive bed – tool weight 5.8 kg.

- The cutting element is a carbide roller.

- Use of bearings in the cutting head.

- Dimensions 500x150x150mm.

- The maximum tile thickness is 16 mm.

The head with the roller moves along the tiles using a monorail.Tough enough to prevent the cutting edge from slipping on raised tiles.

Overall, the tile cutter is a reliable and moderately convenient tool. Even if you cut several dozen tiles on it every day. BISON is often referred to as professional equipment for cutting veneer ceramics, but this is not entirely true.

According to reviews, the BISON often ends up on the counter in a “raw” form - the nuts are not fully tightened, the carriage travel is poorly adjusted. The device has no design defects, but the build quality may be poor. Therefore, when purchasing a tile cutter, you need to be prepared for the fact that some parts and parts of the tool will need to be disassembled and reassembled. This is not a defect, you just need to spend a little time setting up and calibrating the cutting head, and the machine will cut the tiles with virtually no problems.

The price of the device is 6500 rubles.

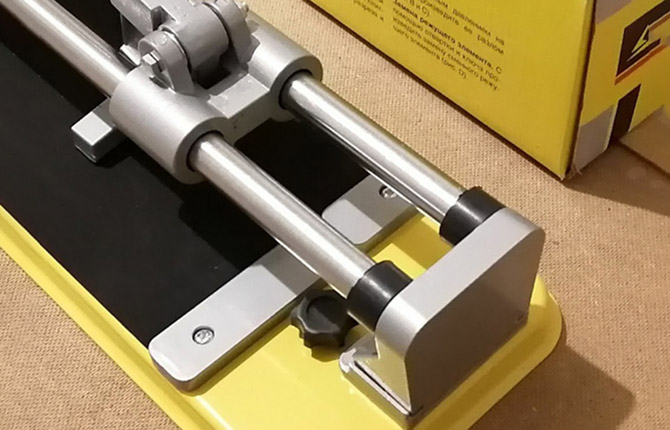

Fourth place – BOSCH PTC 640

It features an unusual design with a wide bed and a dual monorail. The design uses a cutting roller with a diameter of 20 mm made of titanium carbide. This tool can cut like butter any tile up to 12 mm thick. All components and parts of the tile cutter run perfectly, without play.

The stroke length of the cutting edge along the bed is 640 mm. You can note the carefully thought-out design, the location of the base plate fastening and the tile cutter lever. The only thing that confuses us is that the device weighs too much – 9.1 kg. Typically, manual models weigh a maximum of 7-8 kg. The maximum thickness of cut ceramics is too small for a professional tool.

This is rather a tool for an amateur tiler, but of good quality.The lever force is moderate, so after making several dozen cuts there is still time and energy left to lay the tiles on the walls.

In addition, the BOSCH PTC 640 is a convenient device for breaking off tiles along the cutting line.

The cost of the tool is from 18 thousand rubles.

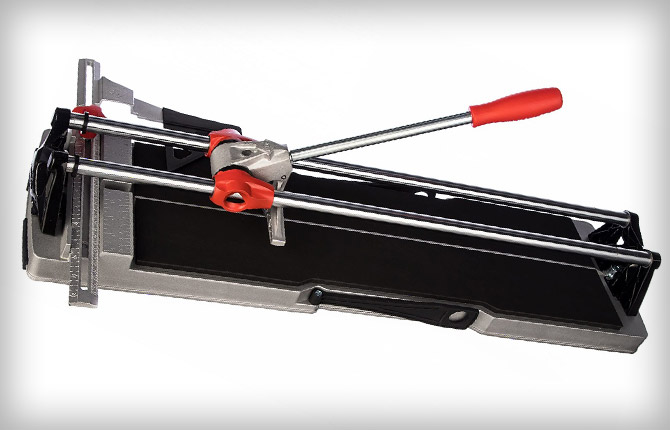

Third place – RUBI SPEED 62 N

The tool is quite heavy due to the reinforced base and cutting head drive. The total weight is 7.5 kg, which is about average for a good quality tool. Dimensions – 785x220x270 mm.

It is produced in limited quantities in Spain, the main part under license in China.

Main characteristics:

- The cutting element is a 20x1.5 mm roller made of tungsten carbide.

- The maximum tile thickness is 15 mm.

- Cutting line length – 630 mm.

For a diagonal cut, you can use tiles no larger than 440x440 mm.

The tile cutter base is made of aluminum alloy with an insert. Two chrome-plated thin-walled steel pipes are used as a guide. We can note the high quality of the mechanical drive and carbide roller.

The tile cutter does not belong to the class of professional tool, but in terms of service life and cutting quality it is not inferior to the best pro-class models.

The only disadvantage we can note is the high cost of the tile cutter - 32,000 rubles.

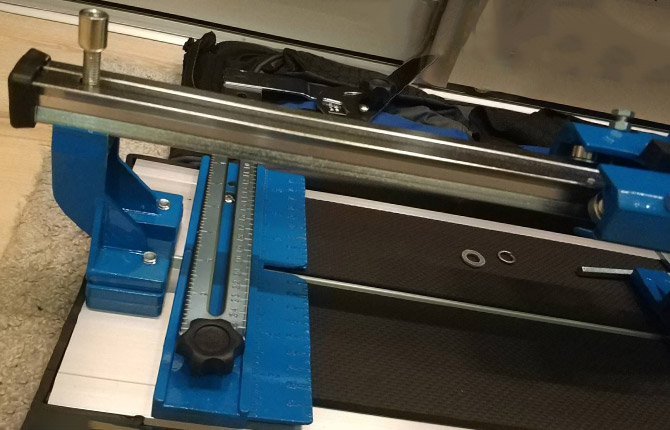

Second place – STAYER PROFI 3318-60

The design was developed in Germany, but production is carried out at production facilities in China. Therefore, the tile cutter turned out to be convenient, but the build quality can vary even within the same batch.

Designed for manual cutting of tiles up to 16 mm thick with a cutting line of no more than 600 mm.The lever and cutting head are mounted on sleeve bearings, so the tool life is quite long. The force on the lever is no more than 10 kg, but as the roller wears out, the load has to be increased.

The price does not exceed 5000 rubles.

First place – Intertool HT0365

Inexpensive but high-quality tool for cutting glazed ceramic tiles up to 12 mm thick. Most of the structure is made of metal, both stamped and cast. In terms of quality-price ratio, this is one of the best models for home use.

A distinctive feature of the tool is the use of reinforced bearings, more powerful supports for double traverses and a specially configured head drive handle. According to the manufacturer, this design ensures uniform pressing of the tiles onto the rubberized base, which prevents accidental puncture.

The tool is quite light - 6.8 kg, provides cutting of material up to 500 mm wide. The price of a tile cutter is 4000-4500 rubles.

Rating of the best tabletop tile cutters

When choosing, we pay attention to 2 main components - the quality of the electric motor and the spindle on which the cutting disc is mounted. It is best if the engine is made in Germany, South Korea or Vietnam. Chinese motors of unknown origin burn out quickly, and replacement warranty does not apply to them.

The spindle can be manufactured in any country. The main thing is that it should not have any play and should rotate easily on thrust bearings. The cutting disc and spindle must be mounted on a separate axis of rotation with bearing supports, but not on the motor shaft.

Fifth place – electric tile cutter Einhell TC-TC-800

The desktop version is made on a heavy cast frame with a small stamped table and a lower position of the cutting disk. The 800 W motor is hidden under the table. The tile cutter uses a 180 mm cutting disc. The device does not belong to the class of a professional tool, so the continuous operation time is limited to 20 minutes.

The length of the working plane is 400 mm, the weight of the device is 9.2 kg. A simple and relatively compact tile cutter in the form factor of a desktop machine. The price of the device is 10 thousand. rub.

Fourth place – Bison Master EP200-1000N

The device can be recommended to those who are constantly engaged in laying tiles, but at an amateur level. The Bison “Master” is not yet a professional instrument, but close to it. Very heavy, angular, at first glance you may not like it due to its too simple “machine” design. But BISON is a real “hard worker”, inexpensive, with his own temper, but reliable and unpretentious in his work.

The design of the tile cutter provides all the basic functions that professional level devices have. Weight – 11.7 kg, steel frame, work table – 400x500 mm. The only disappointment is the relatively low power of the electric motor - 1000 W, which limits its use for continuous cutting.

Main functions:

- You can cut tiles, ceramics and porcelain stoneware without restrictions.

- There is a built-in system for wet cutting of material.

- Tiles can be cut at an angle, make an oblique cut of the edge at 45O.

- Cutting depth – 40 mm.

There are additional scales for correct orientation of the material on the work table. Cost – 13 thousand rubles, warranty for tile cutter – 2 years.If you register your purchase on the website, the warranty period can be extended by another 3 years.

Third place – FUBAG FB 350

An unusual design of a tile cutter, made according to the scheme of a pendulum saw with an overhead drive. Always present in all ratings of the best tools. Like most professional-class devices, the tile cutter can be used in a desktop version or mounted on additional support legs.

The pendulum drive circuit was chosen to facilitate cutting of curved edges. The Fubag 350 does an excellent job of cutting mosaic tiles, trimming granite and porcelain tiles, and even thick paving slabs.

A distinctive feature of the device is its low noise level.

Characteristics:

- Motor power – 2200 W.

- Disc – 300 mm.

- Table length – 1240 mm.

- Cutting depth – 105 mm.

- The maximum cutting length is 800 mm.

- The weight of the device is 75 kg.

The frame can be partially disassembled, with the pendulum removed. Therefore, it is possible to transport the machine even in a passenger car. The option is quite mobile, but most craftsmen prefer to abandon the use of stands (legs) in the field in favor of a regular pallet, reinforced with a pair of oak boards.

The cost of the device is 92 thousand rubles. In general, inexpensive, considering that most European “classmates” Fubag 350 are 20-25% more expensive. True, Fubag is much worse repaired; the service life of individual parts (for example, the pendulum saw support) is lower than that of the “Europeans”.

The Fubag 350 is often criticized for its high center of gravity. Of all the options for electric tile cutters, this one is the most difficult to maintain and properly install.

Despite the fact that the manufacturer recommends using outriggers, working on removable stands is extremely inconvenient. You need a solid and level base; you cannot place the tile cutter on soil, sand or gravel.

Therefore, the device is installed either on a pallet or on Workbench. But even in this case, you need to control the vertical stroke of the pendulum to avoid collapsing the cutting plane.

Today, the Fubag 350 system, based on the price-quality ratio, can be considered the optimal solution for the professional preparation of tiles.

Second place – DeWALT 1600 D36000

Professional grade tool. One of the best electric tile cutters. Quite massive, weight 45 kg, the frame is made of cast iron, the remaining structural parts are made of steel and aluminum. Designed for exceptional dry cutting of ceramics.

Main characteristics:

- Power – 1600 W at spindle speed 1200 rpm.

- The diameter of the disc is 250 mm with a mounting hole of 45 mm.

- The maximum cutting length is 920 mm.

- You can change the angle of operation of the disk.

The tile cutter can cut any type of tile, for porcelain tiles and tiles. It is used primarily for cutting blanks for cladding facades and basement surfaces. The disadvantage is the high cost of the device, the average price is 120 thousand rubles.

First place - Brooklyn F1-131

The device is produced by the Italian company Monolit, which occupies a leading position in the manufacture of stone-cutting equipment and tile processing. This is a professional-class tile cutting machine that can be used both in a desktop version and on a special bed.

Designed for cutting ceramic, tile or granite tiles using water cooling.The quality and accuracy of the cut is an order of magnitude higher than that of any amateur or semi-professional class model. For cutting, discs with DNA class diamond powder are used.

Characteristics of the tile cutter:

- Engine power – 2200 W, at 3000 rpm.

- Disc size 250 mm, with mounting hole 25.4 mm.

- The maximum tile thickness is 50 mm.

- The maximum cutting length is 1300 mm.

The model uses a movable carriage-support with an installed motor; during operation, the cutting zone is covered with a casing, which makes it possible to avoid water emissions or chipping of the material.

According to reviews from craftsmen, Monolit machines hold their initial settings well. Despite the fact that the tile cutting machine does not have a heavy cast-iron frame, the machine cuts after several dozen tiles as accurately as during the first pass.

Of all the options for machine-type tile cutters Brooklyn F1 is considered one of the most accessible for independent development and operation. Mass use is stopped only by the high price of the device - 220 thousand rubles. Buying a tile cutter will require significant investment, although with constant loading the machine pays for itself in 8 months of operation.

The choice of a specific model of tile cutter is usually associated with the volume of work to be done. And you don’t have to buy it; you can rent a car. In any case, a good tool will not only speed up the work of laying cladding, it is also a good way to cut tiles without manufacturing defects.

Tell us about your choice of tool - what parameters and details should you pay attention to?

No matter how many times I looked for a good tile cutter, I kept coming across some kind of nonsense. A plate made of aluminum or even stamped, inside there is some kind of OSB panel.We need to try this Bison. It looks like nothing like a tool. Everything else is a maximum of a couple hundred tiles.

I don’t know, maybe you need to learn how to cut tiles before using a tile cutter. I have the cheapest one, only Chinese characters, not a single Russian or English letter. I can't even read the model name. I've been using it for ten years now, no complaints.