Beko air conditioner errors: identifying the breakdown by code and repair methods

Beko air conditioners are equipped with an innovative self-diagnosis system.Based on its results, the control device, when a malfunction is detected, blocks operation, simultaneously reporting its cause. The equipment reports defects in operation by flashing LEDs that light up in a certain sequence, indicating the number of the detected problem.

You can determine the error of the Beko air conditioner without involving a technician from the service department. To do this, you just need to know how the information included in the program by the manufacturer is decrypted. It should also be remembered that the system displays a high priority fault code.

The content of the article:

What causes Beko air conditioner breakdowns?

Beko air conditioners can be found in offices, apartments, and cottages. These are affordable and high-quality split systems or floor-mounted mobile units. Thanks to their practicality, functionality and reliability, air conditioners of this brand work properly without breakdowns in the most difficult conditions.

However, over time, especially with heavy use, your Beko air conditioner may break down. This can manifest itself not only by turning off the device and the appearance of an error code on the display, but also trivially: the unit will begin to leak, the cooling flow will weaken, and ice will appear.

Main causes of breakdowns:

- wrong unprofessional split system installationcarried out independently or by incompetent craftsmen;

- failure to comply with the operating requirements of the unit;

- ignoring scheduled maintenance;

- normal wear and tear of parts after long-term use.

After repairing the equipment, be sure to study the instructions for routine maintenance of the air conditioner.

When does the Beko air conditioner turn off?

The equipment will turn off on its own if:

- The compressor does not restart within 3 minutes.

- If the temperature at the top of the compressor exceeds 115 degrees. Normal operating temperature should not exceed 100 degrees.

- If the voltage level in the network drops below 175 or rises above 260 Volts.

- If the inverter overheats due to high current or higher voltage being supplied to it.

- If the wires are open anywhere.

- If the fan works more intensely than normal or, on the contrary, weaker (norm is 300 - 400 rpm).

- If the system does not receive zero crossing messages for 4 minutes.

After this, the self-diagnosis system begins searching for defects and malfunctions and, having detected them, displays the required error code on the display.

Error coding principle

Let's look at how to find the cause of a problem with Beko air conditioners using the error code. Let's look at what combinations of letters and numbers can appear on the display of various devices.

For air conditioners types BKL INV, BKC INV:

| Error code | Decoding |

| E1 | there was a problem with the temperature sensor in the internal module |

| E2 | problems with the evaporator temperature sensor |

| E3 | Compressor errors |

| E5 | the connection between the outdoor and indoor modules is broken |

| 1E | defect in the operation of the outside air temperature sensor |

| 2E | problem with the capacitor temperature sensor |

For air conditioners types BKH, AKP, AKH, BS, BKP, AS:

| Air conditioner error | Decoding |

| FF03 | there is overheating of the condenser operating in the “cold” mode |

| FF04 | there is overheating of the condenser operating in the “heat” mode |

| FF06 | problems with the fan in the indoor module |

| FF07 | Room temperature sensor does not work |

| FF08 | problems with the operation of the evaporator temperature sensor |

| FF09 | problem with the operation of the capacitor temperature sensor |

Error codes for BKN and AKN air conditioners:

| Error | Ind. RANNING | Ind. SLEEPING | Ind. TIMER |

| Having problems with the internal solenoid type temperature sensor | starts blinking | starts blinking | starts blinking |

| A room temperature sensor defect is diagnosed | starts blinking | starts blinking | shines |

| Having problems with the external solenoid type temperature sensor | starts blinking | starts blinking | does not light up or blink |

| The fan motor in the indoor module is faulty | starts blinking | shines | starts blinking |

Using the tables above, you can determine the cause of the breakdown. air conditioning and split systems. In almost all cases, the climate system turns itself off.

You need to start diagnosing an air conditioner by analyzing the most common breakdowns.

Problems with Beko air conditioners

Let's look at what malfunctions of the Beko air conditioner owners most often encounter, and carefully consider how to fix it.

If the air conditioner does not cool

There are several reasons why an air conditioner stops cooling. Our list ranks them from most likely to least likely.

To identify the cause of a breakdown, you need to test each cause, starting with the first:

- If the air filter is clogged, air will not be able to circulate through the air conditioner. This reduces its cooling capacity. A dirty filter can cause the evaporator coils to freeze. In this situation, the filter needs to be washed or replaced with a new one.

- If the condenser coils become dirty, they will not be able to dissipate heat as refrigerant flows through them. As debris accumulates on the coils, the air conditioner begins to work longer and harder to produce cold. Eventually it will run continuously. The air conditioner coils can be cleaned.

- Rarely is the cause of such a situation compressor malfunction. First you need to check the compressor capacitor and overload fuse. If a fault is found in the compressor, you will have to call a technician.

- The cause of the problem may lie in the thermostat. The thermostat controls the temperature, when the air temperature increases, the thermostat turns on the fan and compressor.If it is faulty, it will not be able to cool. To test the thermostat, turn on the cool mode and use a multimeter to check for continuity. If it is broken when the air conditioner is operating for cooling, you will have to change the thermostat.

- All systems may work normally, but the cause of the problem may lie in the thermistor - a temperature sensor on the control board. If the air temperature rises, the resistance value on the thermistor decreases. Check the serviceability of the sensor with a multimeter. If its resistance does not change with temperature changes, the thermistor will have to be replaced.

- The cause of the error code can always be a breakdown of the control board.

Some parts can be repaired. In case of some breakdowns, units and components due to which Split system does not cool well, cannot be restored and will have to be replaced.

How to set up climate control equipment for cooling is described in detail in our recommended article.

Fan doesn't work

If the fan stops working, check it for the following faults, starting with the most common:

- The fan motor has a 2-shaft design. Such an electric motor has bearings that wear out first. To determine if this is the case, rotate the shaft. This is the most expensive failure because if the shaft does not rotate, the fan motor will have to be replaced.

- If you turn the blades by hand and they do not rotate freely, this also means that the motor bearings are worn out. If the blades are spinning, check the power input. If there is power, but the motor still does not work, you will have to change it.

- If the defect occurs in the relay board, it means that voltage will not be supplied to the motor.The relay board can be replaced and is inexpensive.

- The temperature control thermostat may burn out contacts. To check, you need to use a multimeter to check its continuity.

- A malfunctioning thermostat may prevent the fan from operating. To check, you need to set the air conditioner to cooling mode and check the thermostat for continuity of wiring with a multimeter. If damage to the wire is detected, it must be replaced and loose contacts restored. If this is not the case, you will have to change the thermostat.

All errors can be generated by a damaged control board. Naturally, in this case there must be a replacement.

Also, the reason the fan stops may lie in a malfunction of the thermistor, capacitor, or rotary switch. If the cause of the failure is the fan motor, it will have to be replaced. Worn out or burnt out fan motors cannot be repaired.

Compressor does not work

If the compressor stops working, you should check:

- Temperature control thermostat electrical contacts that may burn out. In this case, the thermostat will turn on the fan motor, but not the compressor.

- The temperature control board may stop supplying current to the compressor. The board can only be replaced.

- The thermostat controls the temperature and when it rises above normal, the thermostat activates a switch to send current to the compressor and fan.

- The fuse may blow over time. You can check if this is the reason using a multimeter.

- Very rarely, the compressor itself also fails. First you need to carefully check the serviceability of the fuse and capacitor. The compressor can only be replaced in a workshop.

Even more rare causes of compressor failure are problems with the thermistor, breakdown of the relay board, or a defect in the main control board. The capacitor may burn out.

If the equipment was installed unevenly, the drains will become clogged first, and then the engine and radiator will break.

Why is the air conditioner so noisy?

The split system can operate noisily, and no error will be displayed on the display. In this situation, it is important to react in time and find the causes of the noise. Otherwise, the breakdown may worsen and lead to failure of the climate control equipment.

What could be the reasons for noisy operation:

- Compressor wear. It should be noted that even a noisy compressor can still continue to work for years.

- Over several years of operation, the bearings of the fan motor may become caked with grease.

- During prolonged use, the fan blade may become damaged or deformed and begin to touch the fan housing. It will have to be replaced.

- The fan wheel must be stable. If it is loose, it will have to be replaced.

A noisy air conditioner, of course, creates certain inconveniences during operation, but this does not mean that you need to immediately change spare parts. First you need to find out the cause of the noise; perhaps it is not so serious.

Water is leaking from the indoor unit or floor unit

If a puddle collects under the indoor module, there may be several reasons:

- If from a monoblock unit water leaks onto the floor, which means it is not level when installed and falls forward. The floor-standing unit should be positioned so that it has a slight slope of 1-2 degrees.

- The drainage is clogged: you need to clear or blow out the clog.

- The drainage pipeline was installed incorrectly. Everything needs to be fixed.

- Pump failure.

Regular cleaning of the drainage pipeline is specified in the instructions for use.

After the split system is installed correctly, nothing should drip from anywhere, unless this is a feature of the drainage system.

Fighting heat exchanger freezing

A freezing heat exchanger is a fairly common problem and most often occurs due to lack of regular cleaning or replacement of the air filter. If it is clogged, the air flow through the evaporator coils is reduced.

Maintenance of the air conditioner must be carried out regularly in accordance with the requirements of the accompanying instructions.

Beko air conditioner care

So, as you can see, many problems in the operation of the air conditioner arise due to untimely cleaning. Wherever the air conditioner is installed, urban or rural dust, not even visible to the eye, will quickly clog the pores of the filters, and the operation of the air conditioner will be impaired.

How to clean an air conditioner to extend its service life?

Or when signs indicating that the equipment is clogged appear: noise or smell during operation, water leakage, icing of the evaporator coils.

For cleaning you need:

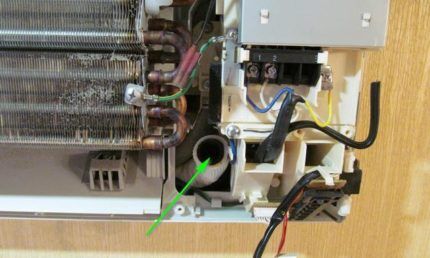

- open the cover of the external module;

- remove the dirty filter;

- rinse the filter and dry naturally;

- turn on fan mode;

- Spray all air conditioning cleaner in the work area;

- clean the filter in the same way;

- wipe dusty blinds with a napkin or rinse under running water;

- install the filter in place;

- close the lid.

For split system maintenance You can call a technician from a service workshop accredited by the manufacturer to carry out all types of work on its air conditioners. He will do everything: from installation to simple cleaning. But it’s better to read the manual and do some of the work yourself if you don’t want to spend too much money on maintaining air conditioning equipment.

Conclusions and useful video on the topic

Watch the video that explains in detail how to properly clean your air conditioner:

The ability to detect breakdowns at an early stage will extend the life of the air conditioner. Problems caused by insufficient care of the unit can be solved independently. If the breakdown is caused by defective parts and components, it is better to call a specialist. Knowing the error codes and diagnostic sequence will help you quickly navigate this issue.

Would you like to talk about how you determined the air conditioner problem using the error code? Do you have useful information on the topic of the article? Please leave comments in the block below, post photos and ask questions.