Pellet boiler wiring: diagrams, rules for installing and connecting a pellet boiler

The main task of the heating system is to maintain a comfortable temperature inside the house.A well-designed pellet boiler piping allows for uniform heat distribution throughout the entire living area, and also protects the equipment from damage and overheating.

It is advisable to entrust this work to a professional. However, having enlisted the support of specialists and studied the principles of connecting a heating unit, you can do the piping yourself. Do you have any doubts?

We will help you resolve this issue. The article describes different piping schemes, identifies the pros and cons of each option, and provides tips on choosing heating equipment. In addition, we have prepared detailed instructions for connecting boilers and putting them into operation.

The content of the article:

What is boiler piping?

The piping consists of all those elements that are located between the heating radiators and the boiler. Today, many home craftsmen do not pay special attention to it; they organize it without adhering to any standards or recommendations of specialists.

However, properly implemented strapping can solve many problems:

- the pressure in the pipeline will never exceed the maximum permissible level;

- scale, slag, sand and similar debris that may be in the water will be removed;

- excessive thermal expansion will be compensated;

- provides the ability to connect more than one circuit to the system;

- the air dissolved in the coolant will be removed;

- allows you to automatically turn on the boiler and accumulate hot water, which will help you save money.

If we talk about pellet boilers, they are not always characterized by high operating autonomy. But if you approach pipeline laying responsibly, you can achieve greater efficiency from such equipment.

Features of pellet boilers

Heating equipment using compressed wood pellets as fuel has appeared relatively recently. But from the moment of their invention, such boilers immediately won the recognition of millions of customers.

If it is not possible to install gas equipment in the house, then it is recommended to purchase pellet boiler.

The advantages of this type of heat generators include:

- Autonomy. Thanks to the presence of a control unit and a system for automatically turning on the burners, once you load fuel, you can forget about it for 2-4 weeks.

- Safety. Pellet boilers have multi-stage protection, which avoids pipeline explosions and fires.

- Efficiency. On average, the efficiency of equipment ranges from 87 to 97%.

- Cheap maintenance. Pellets are inexpensive, and the ash pan needs to be cleaned no more than once a month.

- Durability. The service life of the units is at least 25 years.

- Compactness. Most often, the models are relatively small in size.

If you become familiar with the advantages of this type of heating equipment, it becomes clear why it has so quickly gained popularity among residents of Europe and America.

The widespread distribution of units operating on pellets is hampered by the rather high cost. Not everyone can immediately shell out a tidy sum for the boiler itself, the burner and additional equipment.

Possible options for fluid movement

There are many schemes. But all methods can be divided into two main groups depending on the principle of movement of the coolant through the pipes. Therefore, a specific scheme is selected depending on whether natural or forced pumping is used in the system.

Features of natural circulation

The simplest and most inexpensive solution is piping the boiler, where the coolant will move through the pipes using the laws of physics. Even a beginner can implement such a scheme, and it will take a minimum of time.

System Feature heating with natural circulation lies in the absence of a pump. In this case, the movement of liquid in the pipeline occurs due to the ability of a colder medium to push out a hotter and less dense one.

The advantages of this solution include:

- low installation cost;

- low cost of service;

- ease of installation;

- the ability to quickly restore system operation if a breakdown is detected.

But the scheme with natural fluid movement also has its drawbacks. First of all, it can only be used with a single-circuit system. In addition, such a solution will be effective only in small houses.

Forced circulation option

The greatest demand is for heating systems that use circulation pump. And this is not at all surprising, because such a scheme is convenient, versatile and practical. It can be used in houses and buildings of absolutely any size.

But even despite the unique advantages, forced circulation circuits coolant have some significant disadvantages:

- high cost of installation - the average cost of a pump is about 150-160 dollars;

- complexity of implementation — the circuit consists of a large number of elements, which significantly complicates its implementation;

- need for balancing — all components of the home heating system must be precisely aligned relative to each other;

- dependence on the availability of electricity — the heating pump will only work if current is supplied to it.

When organizing a heating system for a building with two or more circuits, it is recommended to use the option with forced movement of the coolant.

However, in this case, the fundamental performance factor is the power of the heating boiler.Please note that if it is not enough, the equipment will not be able to heat a sufficient amount of coolant.

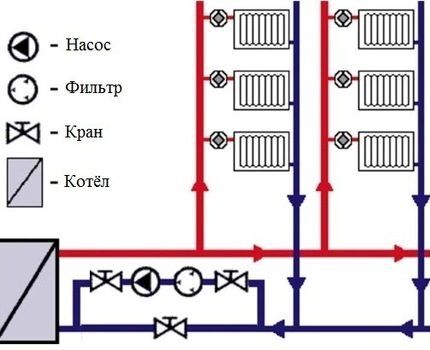

Connecting the boiler with a collector

The two schemes above appeared quite a long time ago. They are divided, depending on the method of assembling the circuit, into tee, manifold and mixed.

Today, the first option is gradually being replaced by a more innovative one - collector. Its main advantage is its high efficiency. But to implement it you will have to invest a considerable amount.

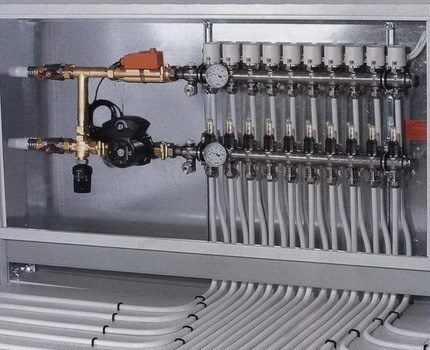

This kind of wiring involves installing a special water collector behind the pellet boiler - heating manifold. Each pipe, radiator or tap connected to the building's heating system is connected to this element.

The collector is installed in a specially equipped cabinet. Hot water flows to it immediately after heating by the boiler. Only after this the coolant is distributed through the pipeline.

The advantages of this scheme are obvious:

- the home owner gets the opportunity to separately control each heating circuit;

- stable water pressure is maintained at any point in the heating system;

- Only one pipe goes to one radiator from the collector; accordingly, they can be of a smaller diameter.

It is important to understand that this level of comfort will come at a cost. After all, each individual component of the heating system will have to lay its own pipeline.

As a result, this will lead to the need to increase the budget, greater consumption of fittings, pipes and other fittings.

Main stages of the connection process

As mentioned above, a properly laid pipeline will significantly increase the efficiency of the heating system and make its operation as safe as possible. Therefore, before going to the store or starting installation, it is recommended to understand each stage of the work in detail.

Selection of equipment and necessary parts

When starting to implement the pellet boiler piping scheme, first of all you need to correctly select the necessary parts and additional equipment. It is recommended to buy quality products from reliable manufacturers. It is not worth saving, as this will lead to frequent breakdowns and make the operation of the heating system unsafe.

To get started, you need to purchase the following items:

- Circulation pump. It is designed to ensure uninterrupted movement of coolant through the pipes.

- Air valves. These elements remove air from the system, which gets there along with cold water.

- Expansion tank. Excess coolant accumulates in it, which is subsequently discharged into the sewer system.

- Collector — distributes hot water along the circuits.

- Sump. Its main task is to remove various debris from the system: slag, sand, scale, etc.

- Hydroarrow, aka hydraulic separator. Used to connect to a circuit system where a coolant with other parameters moves.

You will also need heating radiators. They must be metal or bimetallic.Today you can choose models that fit perfectly into the interior. Although they are quite expensive, they will last for several decades.

Pellet boiler wiring

If you have knowledge and experience in arranging a heating circuit, then you can do the connection process yourself. Here it is important to strictly follow the manufacturer’s recommendations given in the instructions for a specific pellet boiler model.

First of all, install the pellet boiler by connecting the components:

- Selecting a room for the location of the unit. To do this, you need to read the instructions supplied by the manufacturer. Most often, it contains detailed recommendations for arranging the premises.

- Burner connection, which must be purchased along with the boiler by selecting the desired type.

- Installing a fuel container. This is a bunker sold together with the heating unit. The area of the room to be allocated for the boiler room depends on its size.

- Auger connection — a device responsible for supplying pellets.

- Connecting the car remote control — it is necessary to ensure uninterrupted automatic operation.

The entire process of piping a pellet boiler is divided into several stages. So, first you need to choose the location of the collector, after which it will be connected to the radiators.

For this purpose, plumbing fittings with a diameter of 1 inch are used. If some of the distributor holes are left unoccupied, they must be closed with plugs.

Then do the following:

- Gasket from the boiler pipe, the diameter of which is 1.25 inches.

- Installation of a distribution pipe on the inlet line.

- Inserting into a contour or installation of a circulation pump behind the distribution valve. The device must be installed in a horizontal axis position. It is recommended to protect it from debris and dirt that may enter from the outside by installing a mesh filter.

The first stage is completed. Next, you can install additional parts such as sensors, expansion tank and safety valve. Also, do not forget about the organization of the chimney.

Installation of expansion tank

After heating, the volume occupied by the coolant increases, so care must be taken to provide enough space for it to avoid explosion. This is exactly why an expansion tank is needed - all excess hot water goes into it. In addition, such an element allows you to maintain stable pressure in the home heating system.

An inexperienced buyer will undoubtedly have questions related to which expansion tank is best to choose. They differ from each other in color and purpose. The heating system uses equipment painted red.

At choosing an expansion tank special attention is paid to its size. Determining the optimal volume is not difficult. To do this, you need to calculate how much water will be used in the system and add 10-12% to the resulting number.

Safety valve: is it necessary?

The main task of this element is to protect the boiler from sudden increases in pressure, which significantly extends its service life. After it reacts, part of the coolant flows out of the heating system - this allows the pressure to be reduced.

Shut-off valves must be selected depending on the performance of the boiler and the maximum temperature of the water pumped by it. It is better to buy models that operate if the pressure exceeds the operating parameters of the system by 20-30%.

It is worth considering that the diameter of the safety valve inlet must be equal to the size of the pipe or be larger.

There are several types of protective fittings. The most universal model is the bypass valve protection mechanism.

There are models of pellet boilers with built-in security team or without it. In the first case, the system assembly diagram will be much simpler - there is no need to install a pressure gauge, safety valve and air vent for the heating line.

Features of connecting a pellet boiler

When purchasing this type of heat generator, you need to understand that it does not have the function of adjusting the heat supply. To put it simply, the combustion of pellet fuel cannot be stopped.

This means that in the event of a power outage, the circulation pump will stop and the movement of coolant in the system will also stop. To prevent further pressure build-up and system failure, several emergency circuits are used.

To ensure that the operation of a solid fuel boiler is as safe as possible, it is necessary to ensure:

- timely supply of cold water to equipment;

- During operation, keep doors, inspection hatches, and heating system filler pipes closed;

- use only the specific fuel specified by the manufacturer in the instructions for your model;

- organize another additional emergency circuit.

If you take into account all the nuances when connecting pellet equipment, you can create a self-regulating system that is minimally dependent on humans. But you will have to spend a little more time and money on this.

Chimney installation rules

The efficiency of the boiler largely depends on how good the draft is. If the chimney was designed correctly, it will provide excellent air removal at any temperature and wind strength.

The first nuance that is worth paying attention to is the diameter of the chimney, which should be identical to the size of the outlet pipe. It is also necessary to install an element that removes excess moisture.

Don't forget about the cap. If installed correctly, it will not block the pipe or create an aerodynamic barrier.

In most cases, metal is used pipes for organizing a chimney. Therefore, they need to be properly insulated and equipped with hatches for cleaning - each elbow should be properly equipped with an inspection door to make it convenient to remove soot and other combustion products.

It must be remembered that heating equipment operating on pellets cannot tolerate either too little or too much draft. It is important to carefully monitor the traction during operation.

To protect the boiler room from fire when the draft overturns, manufacturers install a corrugated plastic tube between the hopper and the boiler - if reverse draft occurs, the plastic will burn and fuel will not flow.

Connecting and setting up equipment

After the piping scheme has been implemented and the boiler has been installed, it is time to begin setting it up and connecting it. The equipment is connected to all communications: heating and plumbing systems.

Many modern models of pellet boilers are equipped with a burner powered by electricity. Therefore, check whether the device requires power supply.

Connection and configuration must be approached with maximum responsibility. Don't rely on factory adjustment. You will have to do this when you first start up the heating equipment, and you need to take into account the chimney draft, the condition of the fuel and the power of the equipment.

Incorrect tuning will lead to various problems, including low efficiency, high fuel consumption, frequent breakdowns and much more.

Therefore, manufacturers of many models of pellet boilers recommend that these stages be carried out by employees of specialized organizations that have permission to carry out this type of work.

Common problems and errors

Low efficiency and frequent breakdowns of heating equipment are a clear sign of mistakes made during its installation.

Mistake #1. Most often, problems arise due to insufficient heating of the coolant. As a result, this leads to the appearance of a large amount of tar or soot.

Mistake #2. Incorrect adjustment or lack of protection against boiling water is one of the most common problems. Because of this, the coolant heats up excessively, which negatively affects heating appliances, pipes and other equipment.

Mistake #3. If the heating system is not highly efficient, then you should pay attention to the quality of the sealing. To do this, you need to check whether the boiler and other structural parts of the system are reliably insulated.

Mistake #4. It often happens that the owner of the house allocates only a few square meters for the boiler room. As a result, he is faced with the following problem - servicing the heating system becomes extremely inconvenient and even unsafe. Recommendations for arranging a boiler room are given in this article.

Conclusions and useful video on the topic

Video #1 review of improper organization of the heating system:

Video #2 analysis of a typical pellet boiler piping scheme:

Video #3 installation of a solid fuel heat generator and boiler:

Pellet boilers have proven themselves to be efficient and easy-to-maintain equipment. But in order for such a heating system to reveal all its advantages, and for its operation to be uninterrupted, it is necessary to approach the selection of fittings and equipment with all responsibility, and to implement the piping scheme in a high-quality manner.

Share with readers your experience in installing and operating pellet boilers. Please leave comments on the article, ask questions and participate in discussions. The feedback form is located below.