Heating collector: principle of operation, installation and connection rules

One of the effective options for modernizing the heating system, making it more efficient and reliable, is the installation of a manifold block.The device, which replaced traditional linear structure designs, is designed to improve the ease of use and maintainability of the system.

Let’s take a closer look at how a heating collector functions and what installation features should be taken into account.

The content of the article:

Operating principle of the distributor

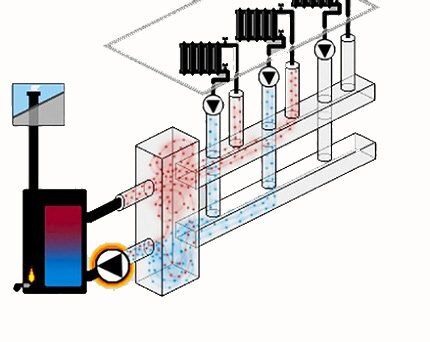

The main purpose distribution manifold – evenly distribute heat flows coming from the main line along the system circuits and, through circulation, return the cooled liquid to the boiler.

In this case, individual branches of the system connected to the collector become independent of each other.

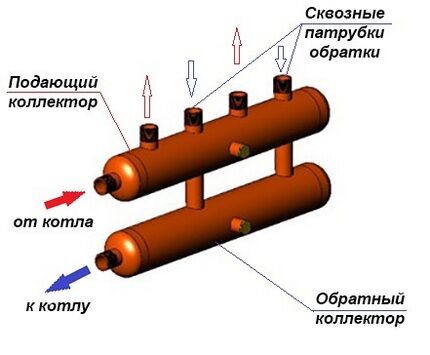

The device is an intermediate distribution unit, the key elements of which are two interconnected parts:

- feed comb – responsible for the supply of coolant;

- reverse – performs the function of removing cooled coolant to the heat generator.

Together they form a collector group. From each comb there are several leads for connecting circuits leading to heating devices.

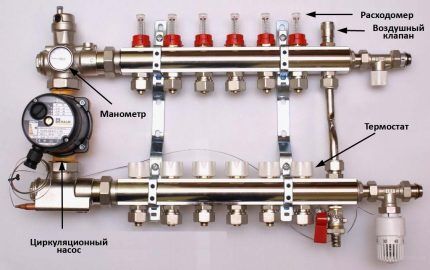

Each outlet of the device can be equipped with outlet valves and a shut-off or control valve.

Their presence makes it possible to regulate the pressure inside each circuit and, if it is necessary to disconnect a branch for repairs, for example, shut off the coolant flow.

To increase the performance of the system and be able to control all heating processes in each room of the heated house, the housing distributor comb also used as a platform for installation:

- air release valves;

- drain valves;

- flow meters;

- heat meters.

The operating principle of the collector system is quite simple. The liquid heated by the heat generator enters the supply comb.

Inside the intermediate assembly unit, the speed of fluid movement slows down due to the increased internal diameter of the device; it is redistributed between all outlets.

Knowing the coolant flow rate equal to the power of the heat generator and the speed of water movement, it is easy to find the required cross-sectional area. Just first convert liters to a convenient unit for calculations: mm3.

Through connecting pipes, the cross-section of which is smaller than the diameter of the pipe of the collector unit, the coolant enters separately laid circuits and moves to the radiators or to underfloor heating grids.

Thanks to this distribution, each element is properly heated, supplied with a coolant of equal temperature.

Having reached the battery and given off the heat received during heating, the liquid is directed through another pipe in the opposite direction to the distribution block. There it enters the return comb, from where it is redirected to the heat generator.

For a country cottage manifold system is rightfully considered the most effective and reliable.

The only thing that can stop a zealous owner is the cost. After all, installing such a system will cost more than installing a conventional tee-type system.

Types of collectors in heating systems

Collector installations used in the design of closed circulation heating systems come in three varieties.

Depending on the purpose of the design, the following are available on the market: radiator and solar systems, as well as devices equipped with a hydraulic arrow.

Type #1 - radiator collector heating

Whatever type of heating is designed in the house, radiators are always present in it. Therefore, collectors that distribute coolant flows directly to batteries installed in rooms are the most popular type.

Collectors used for radiator heating, depending on the architectural and interior features of the room, can be connected in various ways.

According to the connection method, the radiator heating system can be made in any of the options listed below execution:

- top connection;

- bottom connection;

- side installation;

- leading diagonally.

The lower connection method is still the most widespread. With such a layout, the contours hidden under the surface of the baseboard or floor are not so striking.

And calculations confirm that with a lower connection, all the advantages of private heating are fully manifested.

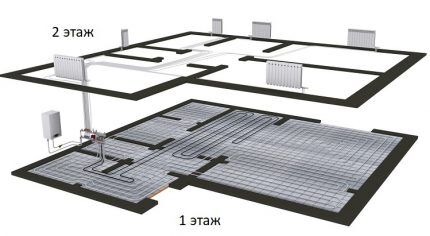

Each floor of the house is equipped with a collector for radiators. Install it in the center, masking the device in a niche or in a cabinet specially built for it on the wall.

The installation location should be chosen so that, if possible, branches of equal length are supplied to all devices.

If it is impossible to achieve equality of the rings connected to the collector, then each outlet is equipped with its own circulation pump.

In fact, all branches connected to the distribution node represent an independent circuit with its own shut-off valves, and sometimes automation.

A striking example of a collector heating circuit is water heated floors.

Underfloor heating pipelines are assembled from copper pipes or their plastic analogues; permanent fittings are used for connections.

Valves are installed in the heating rings, with the help of which they regulate the supply of coolant, and, if necessary, disconnect the “warm floors” from the general heating network.

Such systems are always equipped circulation pump. It is placed in an intermediate collector unit at the entrance to the return pipe.

The number of pipes on the distribution unit depends on the number of rooms connected to one comb.

The number of collector groups is determined based on the length of the circuits. The calculations are based on the ratio in which 120 meters of pipeline are allocated to one collector group.

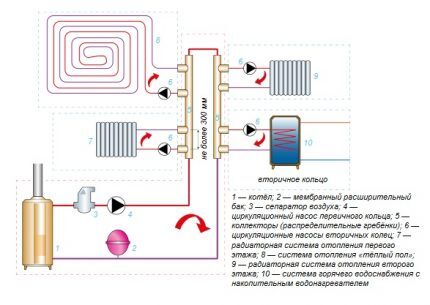

Type #2 - hydraulic arrow

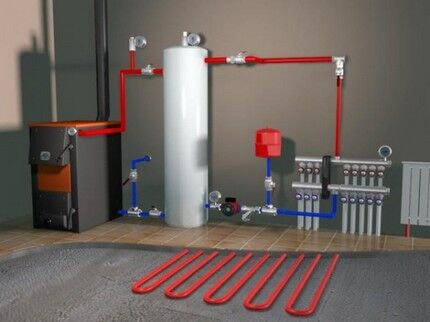

When installing powerful and extensive heating systems, which are designed in residential buildings with a large area, distribution manifolds equipped with thermohydraulic distributor or hydraulic arrow.

When installing a connecting link, a heating boiler circuit is connected to it on one side, and radiator heating or “warm floors” on the other.

The presence of a hydraulic distributor allows you to solve several problems at once:

- avoid sudden changes in temperature in the pipes, which have a detrimental effect on the service life of the system;

- by mixing and secondary circulation of part of the coolant, maintain a constant volume of boiler water, as well as save fuel and electricity;

- if necessary, compensate for the flow deficit in the secondary circuit.

Maintaining temperature balance is achieved due to the fact that the device allows you to separate the hydraulic circuit of the boiler from the secondary circuit.

Optimal operation of a system equipped with a hydraulic arrow can be ensured if each circuit is equipped with its own circulation pump.

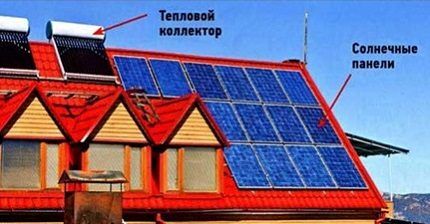

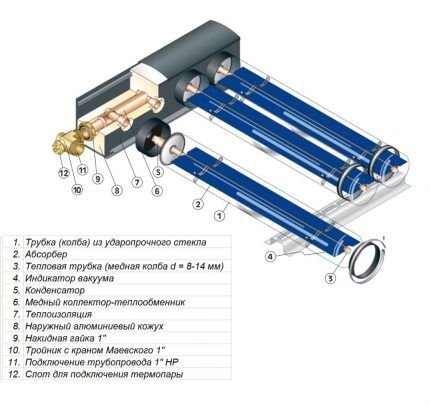

Type #3 - solar collector installations

Devices of this type are chosen when installing an autonomous water supply system in non-gasified areas where the level of solar radiation is quite high.

The design of solar installations is slightly different from traditional counterparts. In essence, they are a kind of greenhouses that accumulate solar energy.

The natural circulation of the coolant in them is carried out due to convection currents and under the action of fans attached to the absorbing plate.

The solar absorber is a small flat box covered with a black absorbent plate. This heat-receiving plate accumulates heat.

The accumulated heat is transferred to the coolant, which can be air or liquid circulating through the pipes.

On sale you can find moving collector systems powered by solar energy. Their design is designed in such a way that mirrors and heating elements “monitor” the movement of the sun, thanks to which its energy is absorbed to the maximum.

But due to the high cost of equipment application of solar installations It is unprofitable as the main source of heating in the climate conditions of even the southern regions of our country.

Therefore, they are more often used as an additional source of heat when installing heating systems using solid fuel and gas boilers.

Modifications of distributor combs

Today, there are many types of collectors for heating systems on the equipment market.

Manufacturers offer both connecting links of the simplest design, the design of which does not provide for the presence of auxiliary fittings for regulating the equipment, and manifold blocks with a full set of built-in elements.

The simple-to-use devices are brass models with one-inch branches, equipped with two connecting holes on the sides.

On the return collector, such devices have plugs, instead of which, in the case of “expanding” the system, additional devices can always be installed.

Intermediate assemblies that are more complex in design are equipped with ball valves. For each outlet they provide for the installation of shut-off control valves. Sophisticated, expensive models can be equipped with:

- flow meters, the main purpose of which is to regulate the coolant flow in each loop;

- temperature sensorsdesigned to control the temperature of each heating device;

- air release valves automatic type for draining water;

- electronic valves and mixersaimed at maintaining the programmed temperature.

The number of circuits, depending on the connected consumers, can vary from 2 to 10 pieces.

If we take the manufacturing material as a basis, then intermediate prefabricated collectors are:

- Brass – characterized by high performance parameters at an affordable price.

- Stainless – steel structures are extremely durable. They can withstand high pressure with ease.

- Polypropylene – models made of polymer materials, although they have a low price, are inferior in all characteristics to their metal “brothers”.

Models made of metal are treated with anti-corrosion compounds and covered with thermal insulation to extend their service life and improve performance parameters.

Parts of the device can be cast or equipped with collet clamps, allowing connection to metal-plastic pipes.

But experts do not advise choosing combs with collet clamps, since they often “sin” by leaking coolant at the valve connection points. This occurs due to rapid failure of the seal. And it is not always possible to replace it.

Recommendations for choosing wisely

The main difficulty lies not only in the installation of the collector itself, but also in the correct choice of equipment.

When choosing a comb model, you should focus on the following parameters:

- Maximum permissible pressure for this model. It determines the type of material from which the hydraulic valve can be made.

- Node throughput.

- Availability of auxiliary devices.

- Number of comb outlet pipes. It must correspond to the number of cooling circuits.

- Possibility of additional connection of elements.

All operational parameters are indicated in the product passport.

To install floor-by-floor independent heating circuits equipped with autonomous control, combs must be installed on each floor of the house.

When selecting and installing floor distributors, they are guided by the parameters of the “subsystem” that they are intended to serve.

This greatly simplifies the maintenance and repair of the heating system.

Since a collector block is not a cheap pleasure, in order to protect yourself from disappointment when the system quickly fails, when choosing a model, you should focus on products from trusted manufacturers.

You can safely trust such manufacturers as "GREENoneTEC", "Rehau", "Soletrol", "Oventrop" And "Meibes". In each series of leading European manufacturers you can select a complete set of necessary additional equipment.

Auxiliary elements and fittings for the collector block must also comply with GOST and TU.

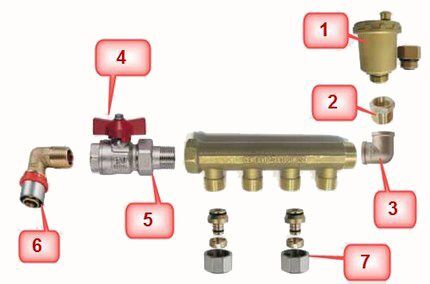

Each of the additional structural elements performs its own function:

- automatic air vent – mounted if the unit and radiators are located on the same floor;

- adapter – will be required when installing an air vent whose diameter is ½ inch, provided that the manifold thread is ¾ inch.

- corner – will allow you to connect the pipes and direct the air vent upward.

- tap – necessary for connecting the pipe coming from the boiler to the device;

- drive, equipped with a cap nut - will allow, if necessary, to shut off the coolant supply and, by unscrewing the cap nut, disconnect the device.

If you intend to connect water heated floor from the collector, you will additionally need to install a tap for refilling.

To fix the collector to the wall, you will also need clamps mounted on plastic dowels. When installing the structure, it is also permissible to use special brackets.

Such designs are convenient in that the upper manifold in them is pushed forward, so that the pipes of the unit do not interfere with the pipeline supply to the lower manifold.

Installation and connection rules

It is best to select and install a collector at the stage of design and installation of the heating system.

Such intermediate structures are installed in rooms protected from excess humidity. Most often, space is allocated for these purposes in the hallway, pantry or dressing room.

On sale there are overhead and built-in models of metal cabinets. Each model is equipped with a door and stampings on the sides.

In the absence of the opportunity to install a metal cabinet, it is easier to do it by fixing the device directly to the wall. The niche for arranging the collector block is placed at a low height relative to the floor.

There are essentially no generally accepted instructions for installing collector distribution circuits. But there are a number of main points regarding which experts have come to a common denominator:

- Availability of expansion tank. The volume of the structural element must be at least 10% of the total amount of water in the system.

- Availability of a circulation pump for each laid circuit. Regarding this element, not all experts are unanimous in their opinion. But still, if you plan to use several independent circuits, it is worth installing a separate unit for each of them.

In front of the circulation pump, on the return line, place expansion tank. Thanks to this, it becomes less vulnerable to the turbulence of water flows that often occur in this place.

If a hydraulic arrow is used, the tank is mounted in front of the main pump, the main task of which is to ensure circulation in the small circuit.

The location of the circulation pump is not important. But, as practice shows, the service life of the device is somewhat higher on the “return” route.

The main thing during installation is to position the shaft strictly horizontally. If this condition is not met, the very first bubble of accumulated air will leave the unit without cooling and lubrication.

The process of assembling and connecting the collector system is clearly presented in the video block.

Conclusions and useful video on the topic

Video guide for sequential assembly of the manifold block:

Video review of the installation and operation of a modular plastic manifold:

Distribution unit for “warm floor”:

Properly selected and installed manifold wiring guarantees the efficiency and reliability of the heating system.

Due to the small number of connections and tees, the likelihood of leaks in such structures is minimized. Well, the ability to regulate the heating temperature of each heating radiator makes operating the heating system especially comfortable.

If you have the necessary knowledge or have experience connecting a manifold heating system, please share it with our readers. You can do this by leaving a comment at the bottom of the article.

In our apartment, the plumber installed such a brass manifold for us with four branches. We did parallel pipe routing when installing the water heater in case there was no central hot water supply. There have been no leaks for fifteen years.At first, it took a long time to get confused about which pipe goes to which device; you need to immediately hang tags with names on the branches when installing them.

3 years ago we had the floor done and a stainless distribution manifold from Elite Metal installed. So far the flight is also normal.