Viessmann gas boiler error codes: methods for finding breakdowns and restoring functionality

Autonomous heating has a number of significant advantages over centralized heating.These are affordable prices, efficiency and high efficiency. To organize an independent heating system, you need a boiler that can not only work perfectly, but also not create problems.

New generation models with intelligent control devices and multi-level protection will help eliminate problems. For example, a Viessmann gas boiler will “tell” errors on its own. The smart unit will display on the display an alphanumeric code for an impending malfunction and a breakdown that has already occurred.

We will tell you how to determine from the code in which of the units or systems of the unit a violation occurred. We'll show you how to find the problem and correct the situation in a timely manner to prevent a more serious problem. The owner of the unit will only have to decide whether he will repair it himself or call a specialist.

The content of the article:

- Error codes for Vitopend 100-W boilers

- Fault code: 06

- Fault code: 0A

- Fault code: 0C

- Fault code: CC

- Fault code: F02

- Fault code: F03

- Fault code: F04

- Fault code: F05

- Fault code: F08

- Fault code: F10

- Fault code: F18

- Fault code: F30

- Fault code: F38

- Fault code: F51

- Fault code: F59

- Fault code: F70

- Fault code: F78

- Fault code: F80

- Fault code: F88

- Fault code: F90

- Fault code: F98

- Conclusions and useful video on the topic

Error codes for Vitopend 100-W boilers

The electronic system of the units is configured in such a way that if a malfunction occurs in Viessmann gas boilers, the breakdown is detected automatically. In this case, the error code is displayed on the device display. This allows you not to disassemble the entire boiler, but to accurately diagnose the performance of a specific part.

The interpretation of the symbols is given in detailed instructions for certified electricians and gas workers accredited to perform gas boiler repair this German brand manufacturer.

These boilers are produced as single-circuit and combined boilers. They can operate on both natural gas and reduced gas. They have a closed combustion chamber. The power range is from 10 kW to 34 kW. A modulating burner with a built-in fan allows you to effectively remove gaseous fuel products from the combustion chamber of the boiler.

The standard value of the efficiency factor of this boiler model is 85%. The controller with an integrated diagnostic system is built into a single module with the unit. The Viessmann gas boiler Vitopend 100-W series displays typical error codes on a digital display with white backlight.

Fault code: 06

When this error code appears, the boiler burner is blocked. This is due to too low pressure of the water circulating through the heat exchanger, heated for the heating circuit. At the entrance to the membrane tank, the pressure must be at least 0.8 bar.

To solve the problem, you need to check the pressure in the unit, remove excess air from the radiators and replenish the coolant volume through the make-up valve located at the bottom of the housing.

According to the instructions, it is necessary to fill the installation with fresh water from a centralized water supply system or an individual source. If the water hardness exceeds the manufacturer's recommended limit of 4.5 mEq/L (milligram equivalent per liter), then a filter device must be installed.

The pH value of water that can be prepared with a German-made boiler should be in the range from 6.5 to 8.5. The manufacturer allows the addition of antifreeze to the water.

The pressure test is carried out in a cold installation at a system temperature of less than 30 °C. The minimum pressure at the inlet to the membrane expansion tank should be 0.8 bar or 0.08 MPa. The maximum operating pressure of the coolant flowing through the boiler should be 3 bar or 0.3 MPa.

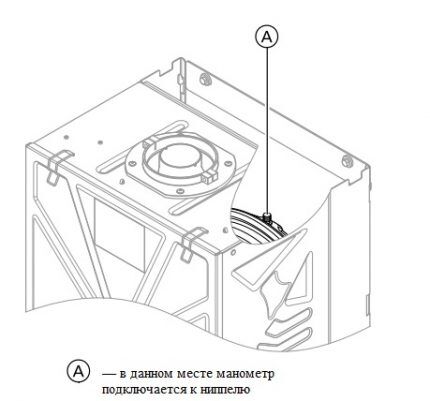

The expansion tank is checked as follows. The water from the installation is drained to a pressure reading in the boiler pressure gauge of 0 bar. If the static pressure of the installation is higher than the pressure in the expansion tank, then nitrogen must be pumped through the nipple at the inlet to a value of 0.1 - 0.2 bar higher than the static pressure.

Fault code: 0A

The appearance of error 0A on the display is accompanied by a burner blockage, and the cause of its occurrence is a reduced value of the dynamic gas pressure. According to the instructions, the dynamic pressure of natural gas should be in the range from 8 to 25 mbar, and the pressure of reduced gas - from 27.7 to 57.5 mbar.

The pressure in the system is checked using a gas pressure gauge with scale divisions of 0.1 mbar. If low pressure is detected in gas pipes, you must contact the organization supplying gas to find out the reasons.

If the pressure value corresponds to the indicator specified by the manufacturer, then it is necessary to begin checking the functionality of the pressure control relay built into the boiler. If a relay failure is detected, it is advisable to contact a service center.

You can buy a gas pressure control relay for this boiler model from the official Viessmann parts supplier. However, repairs, installation and replacement must be carried out by certified technicians who have passed certification and received permission from the manufacturer to repair boilers of this brand.

Fault code: 0C

This error code appears on the display if the mains voltage has dropped significantly. In this case, the burner is blocked, and to solve the problem it is necessary to check the network voltage and find out the reason for its drop. The network may sag if several electrical appliances are connected simultaneously.

Sometimes a decrease in voltage is associated with a breakdown in the contact connection at the junction of the internal wiring. The problem of lack of network voltage can also arise when selecting a cable with an insufficient cross-section. The owner himself must solve these problems.

A seasonal low voltage situation often occurs.When many users turn on heating equipment at the same time, and the voltage in the distribution network is not enough to satisfy the increased consumption. In such cases, you must contact the organization that provides the electricity supply.

Problems with voltage drop in the electrical network supplying volatile devices of Visman brand boilers are solved by installing stabilizer for gas boiler.

Fault code: CC

The CC error indicates a malfunction in the external expansion module. The reason for this error message is a loss of communication between the external expansion module and the device controller. Most often, a simple check of the cable connecting these parts can resolve the problem.

If the contact comes loose, then the cable just needs to be connected. If the cable is broken or broken, it must be replaced.

Fault code: F02

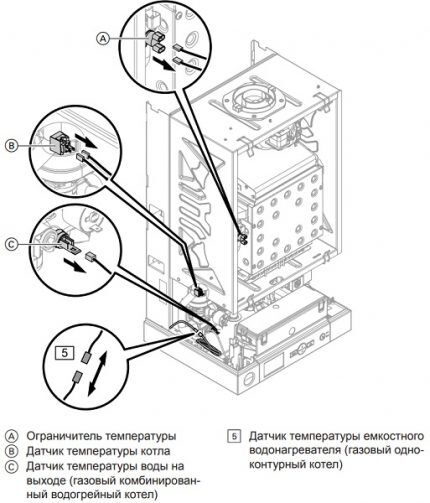

The appearance of code F02 on the display indicates a burner malfunction. This alphanumeric designation appears when the temperature limiter is activated. First of all, the user should check that the system is full of coolant and release excess air from the circulation pump and radiators.

If after carrying out these procedures the error continues to be displayed, then you need to check the temperature limiter for a malfunction. It is also necessary to check the connecting cables.

The limiter is checked as follows:

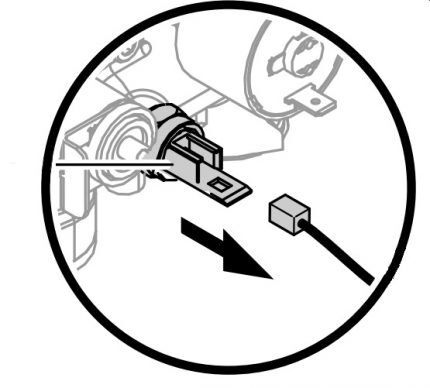

- The sensor cables are disconnected;

- It is determined whether current flows through the temperature limiter (this is done with a universal measuring device);

- The faulty limiter must be removed;

- The installation site is lubricated with heat-conducting paste;

- A new limiter is installed;

- Unlocking is carried out by pressing the MODE and OK buttons until the reset symbol starts flashing on the display;

- Reignition is in progress.

The temperature limiter is checked to ensure that after an emergency shutdown, the gas burner control does not reset when the water temperature in the boiler is below 90 °C.

Fault code: F03

Code F03 indicates that the flame signal appears before the burner starts. Repair of Visman gas boilers that produce this error consists of checking and repairing the ionization electrode.

Additionally, the connecting cables should be checked. It is necessary to turn off and restart the mains switch. You can also carry out the reset procedure described above.

Fault code: F04

This error indicates that there is no flame signal. In most cases, the problem is resolved by restarting the boiler or performing a reset. If this method does not help, then you need to check the condition of the two ignition electrodes. After which the ionization electrode is checked. Perhaps they have mechanical damage or have changed their position relative to each other.

Then you should check the connecting cables.If damage is detected during inspection, these parts must be replaced with new ones or repaired. Dismantling of broken products and installation of new ones must be carried out strictly according to the instructions.

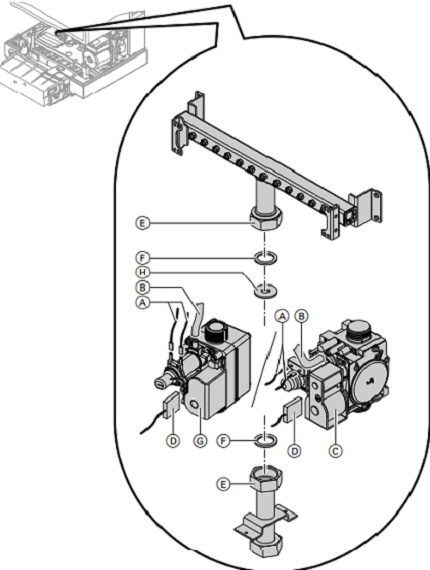

In addition to malfunctions with ignition, problems with the gas supply are possible. It is necessary to check the gas pressure and inspect the gas control valves. Next, you should diagnose the ignition and the ignition module. If problems are identified, you must replace it or contact a service center to repair the parts.

Fault code: F05

Indicates a malfunction of the combustion control unit. The error appears due to the fact that the air pressure switch does not open when the burner starts. Also, the relay may not close when the ignition load is reached. To determine the cause of the problem, it is necessary to inspect the Air/Combustion Products system.

When examining it, you can find the following problems:

- The chimney is covered with ice. The removal and entry of combustion products is difficult. The problem is solved by removing the ice build-up.

- Incorrectly installed coaxial chimney. Correct installation must be carried out.

- The fan has failed. In this case, you need to replace the part.

- The melted venturi tube needs to be replaced.

- The pressure switch needs to be replaced.

After replacing the air pressure switch, the error disappears.

Fault code: F08

The error is caused by a blocked solenoid valve relay. In this case, the burner of the device does not turn on.

It is necessary to check the functionality of the relay, the valve itself, and the connecting cables.The lock may disappear after resetting or rebooting the device.

The solenoid valve is checked by fire or instrumental methods. In the first case, it is necessary to install a new thermocouple. Then light the pilot light and bring the flame to the end of the thermocouple. If the automation is activated, then the valve is working properly. In the second case, it is necessary to dismantle the sensor, insert it into the repair contact and apply voltage. If the valve closes, then the automation is in order.

Fault code: F10

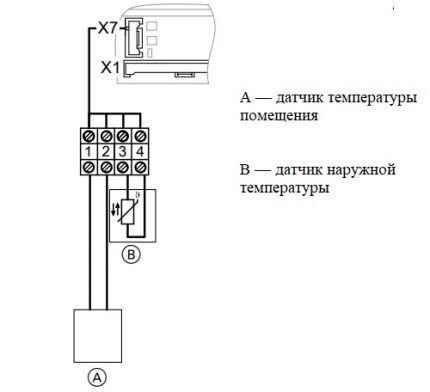

When this error occurs, the device continues to operate in constant operation mode. Code F10 indicates a short circuit gas boiler sensors. It is necessary to inspect the outside temperature sensor and the room temperature sensor.

If the indicators have a significant deviation, the sensor should be replaced.

Fault code: F18

The error occurs when one of the two sensors opens. The problem is identified by checking the outdoor temperature sensor cables and room temperature sensor connections. If the contact comes loose, you need to firmly connect it back. If the cables are damaged, they must be replaced.

Fault code: F30

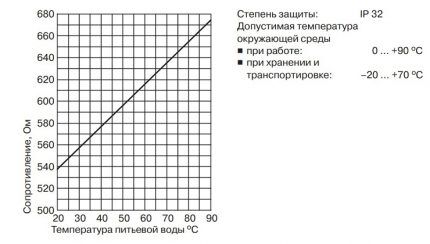

Error F30 appears when the unit temperature sensor is short-circuited. When it appears, the user needs to inspect the boiler temperature sensor. If an external inspection does not reveal a problem, then it is necessary to disconnect the cables from the sensor and measure the resistance.If, when comparing the resistance readings with the curve, a strong deviation is detected, then the part must be replaced.

Fault code: F38

This error appears when the boiler temperature sensor breaks. When it appears, it is necessary to inspect the sensor, identify the location of the cable break, replace or connect the cable.

Fault code: F51

The display of error F51 indicates that the boiler has stopped heating water. The reason is a short circuit of the sensor.

Checking the sensor that measures the leaving water temperature is carried out as follows. First the cables are disconnected. After this, the resistance is measured and its values are compared with the curve. If a significant deviation is detected, the sensor should be replaced.

The resistance of the cylinder sensor t must also be checked and compared with the curve. Before checking, you need to disconnect the plug from the cable harness located on the controller.

Fault code: F59

The cause of error F59 is the opening of the sensors. It is necessary to check the connection of the cable of the water temperature sensor, as well as the connection of the sensor plug of the cylinder. If a disconnection is detected, you must carefully reconnect the plug.

Fault code: F70

Error code F70 indicates a malfunction of the external module. The error is displayed due to a short circuit in the temperature sensor of the collector S1, which is connected to the external expansion module. When this code appears, you need to check the sensor for malfunction.

Fault code: F78

The error is associated with the opening of the collector t sensor S1 installed on the external expansion module. It is necessary to check the condition of the sensor cables and the tightness of the contact.

Fault code: F80

This error also indicates a malfunction of the external expansion module. The reason is a short circuit in temperature sensor S2.

It is necessary to disconnect the sensor cables and check its resistance. If the values deviate from the curve, the sensor must be replaced.

Fault code: F88

The error occurs when electrical contact is lost with the lower sensor S2 of the cylinder, connected to the external expansion module.

It is necessary to find out the cause of the disconnection and eliminate it.

Fault code: F90

Error F90 signals a short circuit in the upper temperature sensor S3 of the cylinder water heater installed on the external expansion module.

It is necessary to diagnose the sensor.

Fault code: F98

The error indicates that sensor S3 is open. It is necessary to check the sensor for openness, connect the cables tightly or replace them if mechanical damage is detected.

He will familiarize himself with the codes of malfunctions and their interpretation adopted by the manufacturer of boilers with the Master Gas logo. next article, which will be useful to both real and potential owners of units of this brand.

Conclusions and useful video on the topic

Error F05 and how to fix it:

Error F02 on the display of the Vitopend 100-W boiler:

Each fault code that appears on the display of a gas boiler indicates a problem in a specific unit of the device. When carrying out repair work, it is imperative to turn off the power supply to all parts of the heating device. You also need to close the gas valve and stop the gas supply.

Elements that perform protective functions should not be repaired for reasons of operational safety. If Viessmann components break down, they must be replaced only with original branded parts or spare parts authorized for use by an official representative of the manufacturer.

Please leave comments in the block below, ask questions, post photos on the topic of the article. Tell us about any malfunctions your boiler had. Share ways to solve the problem.

turns on spontaneously when hot water and heating are turned off. The water heating and heating icons do not light up on the screen. no error code. thanks for the answer.

It’s described in great detail, it’s a pity that I didn’t find the error code for my boiler VIESSMANN VITOGAS 100-F with VITOTRONIC 200 TYP KW4 automation and VITOCOM 100 GSM module. And the error code:

Heizungsanlage

Fault installation control_CD