How to piping a boiler with polypropylene: rules for constructing a pp circuit

Engineering systems made from affordable polypropylene pipes can last up to half a century.Pipe products made of polymer are extremely easy to install; only one soldering iron is needed to connect them. But is this material suitable for heating systems? Will the boiler piping with polypropylene be durable and reliable?

If everything is done according to technology, then plastic pipelines quite safely deliver the coolant to the batteries.

The content of the article:

What is a boiler piping and what does it consist of?

The piping is a set of heating equipment that ensures the transportation of heated water to the radiators and the trouble-free operation of the heater itself.

On the one hand, it helps to evenly distribute heat throughout the rooms of the house, and on the other hand, it increases the reliability of the entire heating system, protecting the boiler from overheating and excessive fuel consumption.

There are certain nuances in the piping of boiler equipment:

Also, piping the heating apparatus means calculating the parameters of all elements of the intra-house heating network and their installation. Heating system must work not only reliably, but also correctly. A large number of additional devices and complex wiring can seriously reduce its effectiveness. Everything must be done correctly.

There are simply no optimal and ready-made heating system options for all buildings without exception.To achieve maximum efficiency from a particular boiler, you have to prepare an internal heating network project for each house individually. But there is a certain set of standard rules and a list of standard equipment.

Depending on the type of fuel used, the size of the house, the model of the heater and its location, polypropylene piping is done according to various schemes.

But all of them contain:

- Boiler (single-circuit or double-circuit).

- Expansion tank. Hydraulic with a membrane or a regular tank, depending on the type of heating system.

- Polypropylene pipes and fittings.

- Batteries (cast iron, steel, aluminum, bimetallic).

- Bypasses (pipeline sections that allow individual devices to be disconnected from the circuit). Recommended for all types of networks, but not always used in simple flow-through circuits.

According to the principle of coolant movement, heating circuits are divided into systems with natural (gravitational) and artificial (pumping or forced) circulation.

In a forced-type heating network, the above set is supplemented by:

- Mayevsky crane.

- Circulation pump.

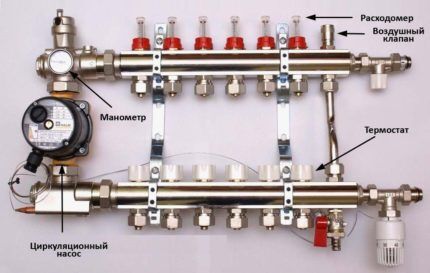

In a circuit where coolant is supplied to each device through the supply and return lines designated specifically for it, a collector - a distribution device - must be included.

In heating circuits that require mandatory adjustment of the qualitative and quantitative characteristics of the circulating liquid or steam, monitoring devices are built in:

- Pressure gauge.

- Thermostat.

- Hydraulic arrow, if there is a need for pressure equalization.

In order to maintain a given pressure in a system with forced circulation of coolant, a expansion tank with membrane. And in its gravitational analogue, an ordinary open tank without any inserts inside will be sufficient.

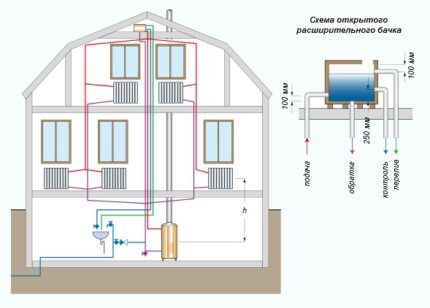

The expansion tank of the simplest heating system with a natural principle of movement is an ordinary container with a pair of pipes screwed or welded into it. One of them is a supply pipe, the second is a signal pipe, indicating that the container is filled with water that expanded when heated. In a more complex version of the tank, four pipes are screwed in.

When the volume of coolant increases above the required norm, the excess is simply discharged through the signal pipe. In the future, the coolant will expand in the same way and take on the same volume, but there will be no overflow into the signal pipe. By analogy, the air is discharged spontaneously, therefore there is no need to install Mayevsky cranes.

Circulation pumps are not used in circuits based on the natural principle of coolant movement.In such a system, water moves under the influence of gravity.

It does not require additional pressure blowers. On the one hand, this increases the reliability of heating (there is simply nothing to break), and on the other hand, it reduces the quality of heating of the distant rooms in the house (the coolant reaches the outermost rooms already cooled down).

The intricacies of installing a heating system made of polypropylene pipes are described in detail in one of popular articlesposted on our website.

Polypropylene pipes in heating systems

Fittings and pipes made of polypropylene (PPR) are popular due to their low cost and ease of installation. They are not subject to corrosion, have smooth internal walls and serve no less than the 50 years declared by the manufacturer.

There are several types of these pipe products, which differ in technical characteristics and purpose.

In the construction of heating systems, as well as in the installation of hot water supply circuits similar to them in operational parameters, the following is used:

- Pipes marked PN 25. Products with reinforcement made of aluminum foil. Used in systems with nominal pressure up to 2.5 MPa. Operating temperature limit +95º C.

- Pipes marked PN 20. A reinforced version used in DHW branches of double-circuit heating boilers. They will work for the period stated by the manufacturer if the coolant temperature is not higher than +80º C and the pressure is not higher than 2 MPa.

- Pipes marked PN 10. Thin-walled polymer products. They are used if the boiler supplies coolant to the water heated floor system. Operating temperature not higher than +45º C, nominal pressure up to 1 MPa.

Polymer pipes are suitable for all known installation methods: open and hidden.But this material has a high coefficient of thermal expansion. When heated, such products begin to slightly increase in length. This effect is called thermal linear expansion and must be taken into account when constructing pipelines.

To prevent destruction of polypropylene heating pipelines, compensation loops can be installed. But it’s easier to take multilayer pipes, the reinforcement in which is specifically designed to compensate for this stretching. A layer of foil inside PN 25 polypropylene pipes reduces their thermal elongation by half, and fiberglass by five times.

Features of installation of PPR pipelines

When piping the boiler polypropylene pipes and fittings They are connected mainly by cold or hot welding; in the case of connection to metal pipelines, threaded connections are used. Screwing on is much more convenient, but because of them, assembling the system will cost significantly more.

True, if you want to connect a polypropylene pipeline to a metal counterpart, you cannot do without threaded fittings.

“Hot” welding is done with a special apparatus (soldering iron, “iron”). The pipes are heated using a suitable nozzle to a melting temperature of 260 degrees, and then the parts with softened edges are pressed against each other. The result is a reliable and monolithic connection.

Before welding, the foil of reinforced pipes must be cleaned. Otherwise, it will interfere with the connection of polymer products, making the seam fragile. With fiberglass, these unnecessary steps will not be required. It melts easily along with the plastic.

Cold welding involves the use of a specialized adhesive composition. In recent years, this method has rarely been used, because the result is not reliable enough.

In heating systems, threaded connections should be sealed with paronite or high-temperature sealant. Do not forget about the fairly high operating temperature of the coolant.

There is one more nuance of using polypropylene for piping a heating boiler. Antifreeze and plastic are a pretty bad combination.It is recommended to use water as a coolant for a system of plastic pipes.

Selecting a heating system wiring diagram

There are several options for lining the boiler with polypropylene. This scheme is selected individually for each house. What is optimal in one building may be ineffective in another.

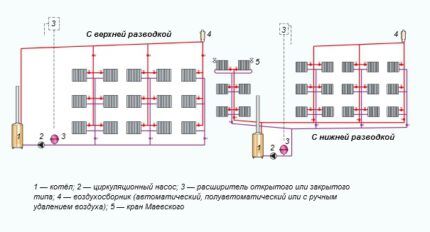

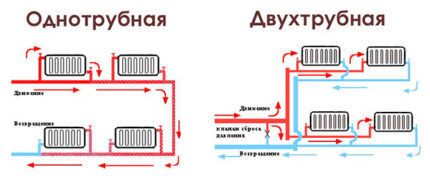

In addition, heating systems based on the principle of water movement are divided into: forced with a hydraulic pump and gravity (gravity, natural), there is also a classification based on the construction of pipelines. According to their structure, they are single- and double-pipe, collector beam or analogues with closed rings.

Which is better: gravity or pump?

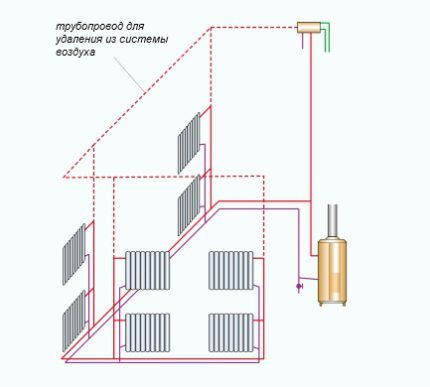

IN gravity circuit heated water flows to the radiators from the boiler by gravity. A hot coolant that has a high temperature always tends to replace a colder liquid. This heating boiler piping system is the easiest to assemble. In addition to the heater, it contains polypropylene pipes, radiators and an expansion tank.

In the version with top distribution, water, after heating, rises to the highest point - into the expander, and from there it goes down to the batteries. After the heat is released, it returns to the boiler, where it is heated again, then starting a new cycle.

This is how heating is installed in many houses in our country’s villages. Only there is a solid fuel stove. This is the simplest and cheapest way to organize heating for a small cottage. However, it has limitations both in the number of connected radiators and in the distance of the outermost one from the water heater.

More complex and expensive coercive system. However, it greatly simplifies the creation of comfortable temperatures in individual rooms. The coolant moves in it due to the stimulation of its movement by the pump.

The choice of polypropylene pipe layout and the boiler itself are closely related. The natural circulation system is energy independent. If the water heater does not require power from the electrical network, then even during power outages the house will be heated.

In a forced circuit, the pump requires a constant power supply to operate. Therefore, it is best to select a boiler for it that is dependent on electricity, which has additional capabilities. But in order to insure against voltage problems, you will have to purchase a backup generator or uninterruptible power supply.

Which heating scheme is better to choose?

There are many ways to route polypropylene pipelines from the boiler to the heating radiators.

But all these schemes are divided into:

- single-pipe;

- two-pipe.

IN single pipe systems heated water supplied as a coolant is supplied and discharged through one pipe. In two-pipe systems for supplying coolant and return, i.e. to drain cooled water back into the boiler for heating, separate lines are constructed.

According to the method of connecting the working components, heating circuits are divided into:

- tee;

- collector

Tee types can be used for both gravity and forced circulation. The collector circuit can only work if there is a circulation pump.

The single-pipe method involves laying one looped line and connecting batteries in series to it. In a two-pipe scheme, two independent pipelines with hot water and return flow from the boiler. And radiators are already connected to them.

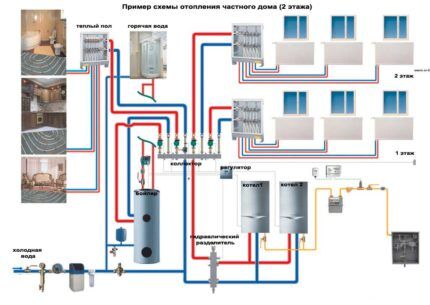

At manifold piping One or two collectors are built into the system, from which separate pipes are routed to each battery. Also, such a distributor allows you to connect a “warm floor” made of the same PPR to the boiler.

The use of collectors and separate risers for each battery leads to a significant increase in the cost of both design and installation. At the project preparation stage, more complex calculations have to be made. And during assembly, a much larger volume of polypropylene is consumed. But what we get is a system, each part of which can be adjusted to specific conditions and requirements.

Polypropylene circuit for different boilers

Most manufacturers of water heaters recommend making the first meter of the pipeline from metal. This is especially true for solid fuel devices with a higher outlet water temperature. When piping, polypropylene should be connected to this outlet, otherwise if the boiler malfunctions, it will suffer a thermal shock and may burst.

Option #1: Gas water heater

It is recommended to piping a gas boiler with polypropylene using a hydraulic arrow and a manifold.Often, gas models are already equipped with built-in pumps for pumping water. Almost all of them are originally intended for compulsory systems.

The most reliable in terms of safety will be a scheme with circulation equipment for each circuit behind the collector.

In this case built-in pump will pressurize a small section of the pipeline from the boiler to the distributor, and then additional pumps will be used. They will bear the main burden of pumping coolant.

If the gas boiler has a cast iron heat exchanger, then when piping it into the system, an additional heat accumulator should be installed. It will smooth out sudden changes in water temperature, which have a negative effect on cast iron. If the coolant is heated or cooled abruptly, it may even burst.

When piping a double-circuit device with parallel heating of water for domestic hot water, additional fine and coarse filters will have to be installed on this outlet. They should be mounted at the entrance to the water heater, where cold water is supplied.

Option #2: Solid fuel model

The main feature of a solid fuel boiler is its inertness when the fuel supply is stopped. Until everything in the firebox burns out completely, it will continue to heat the coolant. And this can have a detrimental effect on polypropylene.

When piping a solid fuel boiler, only metal pipes should be connected to it immediately, and polypropylene pipes can only be inserted after a meter and a half.In addition to this, it is necessary to provide a backup supply of cold water for emergency cooling of the heat exchanger, as well as its discharge to the sewer.

If the system is built on forced circulation, then it will be necessary to install an uninterruptible power supply for the pump. Water must constantly remove heat from the firebox where solid fuel burns, even during power outages.

In addition to it, you can make a small gravity circuit or equip all batteries bypasses for disconnecting individual sections systems. In case of accidents, this will allow you to repair the damaged section while the heating is running.

The solid fuel boiler must be covered with a protective casing, which limits the spread of heat from the walls of the firebox into the boiler room. But even if it is present, the manifold and plastic pipes should be removed away from the stove.

Option #3: Oil and Electric Heaters

The exhaust or diesel boiler is wrapped with polypropylene according to a scheme identical to its solid fuel counterpart. The polymer must be removed from it as far as possible.

Heat coolant in the water heater on electricity up to temperatures critical for polypropylene is practically excluded. When the voltage goes out, it simply stops working.In this case, the pipes are protected from hydraulic shocks by a hydraulic accumulator and valves to relieve excess pressure.

Conclusions and useful video on the topic

Video #1. How to choose PPR pipes:

Video #2. Solid fuel boiler piping technology:

Video #3. How to tie a heater in a two-story cottage:

When choosing a scheme for piping a boiler with polypropylene pipes, it is necessary to take into account all the features of a particular building. The process of installing pipelines and connecting equipment is simple; even a novice master can handle it.

A soldering iron for polypropylene fittings and pipes couldn't be easier to work with. But it is better to entrust the preparation of the heating system project to a specialist; mistakes here are unacceptable.

Do you want to share your personal experience gained while assembling a polypropylene harness with your own hands, have you found any shortcomings or want answers to your questions? Please write comments in the block located under the test of the article.

When I was making my own heating, out of some fright I bought a reinforced PP pipe, Czech eco-plastic shtavi. The diameters were 20 and 25. So, special stripping devices for each diameter cost me a lot, as did the aluminum pipe itself. Although I know there are craftsmen who cut this thing with a knife.

Now I understand that it was possible to save money, namely, use compensators and a cheaper PN-20 pipe. Because I operate a double-circuit wall-mounted boiler at 65ºС. Played it safe, so to speak.

Guys, of course, you are great, but in the photo of the Vailant boiler piping, the circulation pump must be installed correctly. And everything seems to be normal.

1.In video No. 3, the oblique filter next to the electric boiler is positioned incorrectly (when cleaning the filter, all the debris will spill out into the pipeline).

2. The safety group is placed after the boiler, but before the taps; it may happen by accident or on purpose that the tap is closed, then if it overheats, the emergency valve will not work and you will be “HAPPY” to replace the heat exchanger and polypropylene supply pipe. In this case, the warranty automatically expires.

Friends, in my 2nd floor. The house has assembled a collector heating system with a radial connection diagram for 9 radiators. + 2 heated floor circuits, electric. boiler Protherm Skat 9 kW, to the collectors from the boiler there is a PN25 d 32mm pipe, let's call it the main one: supply and return.

Now, there is a need to connect a gas double-circuit boiler, closed by a burner (I am counting on a BAXI ECO FOUR 24F). So, is it possible to add additional gas to the old highway (d32mm). tie the boiler with a PN25 d 25mm pipe?

It should be added that the electric boiler is located on the second floor, the heating and floor circuits are on the first floor, they have a mixing unit with a circulation pump, and the system works perfectly, now in its 3rd year. It just became possible to supply GAS and install a gas boiler into the system, and use the electric boiler as a backup.

I will be very grateful for your qualified answer regarding the diameters of the gas/boiler piping pipes and the tie-in into the main line (d 32mm).