How heating systems with pump circulation work: organization diagrams

Even experienced craftsmen are not always able to ensure natural movement of the coolant along the heating circuit.It happens that water moves through the system, but a sufficient amount of heat does not enter the house.

Increasingly, owners of private houses prefer to install heating systems with pump circulation, which are quite diverse and convenient. In this article, we examined the basic schemes for organizing forced heating, supplementing the material with visual illustrations and photos.

We have also selected useful videos with recommendations from specialists for installing pumping equipment for a heating system. This will allow you to understand in detail the issue of installing the pump.

The content of the article:

The principle of operation of the system with duress

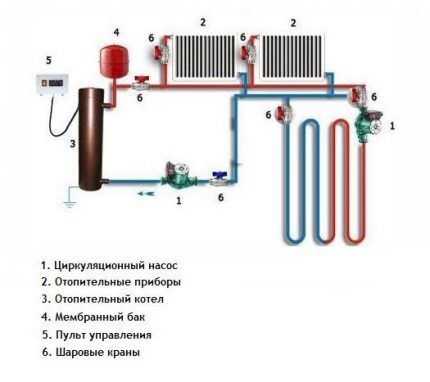

A circulation pump is a small electrical device that is extremely simple. There is an impeller inside the housing; it rotates and gives the coolant circulating through the system the necessary acceleration. The electric motor that provides rotation consumes very little electricity, only 60-100 W.

The presence of such a device in the system greatly simplifies its design and installation. Forced circulation of the coolant allows the use of small-diameter heating pipes and expands the possibilities when choosing a heating boiler and radiators.

Very often, a system originally created with the expectation of natural circulation, works unsatisfactorily due to the low speed of coolant movement through the pipes, i.e. low circulation pressure. In this case, installing a pump will help solve the problem.

However, you should not get too carried away with the speed of water in the pipes, since it should not be excessively high. Otherwise, over time, the structure may simply not withstand additional pressure for which it is not designed.

For residential premises, the following maximum speed limits for coolant movement are recommended:

- with a nominal pipe diameter of 10 mm - up to 1.5 m/s;

- with a nominal pipe diameter of 15 mm - up to 1.2 m/s;

- with a nominal pipe diameter of 20 mm or more - up to 1.0 m/s;

- for utility rooms of residential buildings - up to 1.5 m/s;

- for auxiliary buildings - up to 2.0 m/s.

In systems with natural circulation expansion tank usually placed on serve. But if the design is supplemented with a circulation pump, it is usually recommended to move the storage tank to the return line.

In addition, instead of an open tank, you should install a closed one.Only in a small apartment, where the heating system is short and has a simple structure, can you do without such a rearrangement and use the old expansion tank.

Calculations for forced heating systems

A properly organized forced circulation system requires complex engineering calculations. But some formulas allow you to assess the condition of the system and get a more accurate idea of the necessary alterations, especially if we are talking about a small house or apartment. The power of heating equipment is usually selected based on the size of the rooms that are supposed to be heated.

Manufacturers usually recommend that the coolant flow rate, measured in liters per minute, correspond to the number of kilowatts of boiler power. This means that for a 40 W boiler, the most suitable coolant flow rate is 40 l/min.

In the same way, water consumption is calculated for a separate room or group of rooms. In this case, they are guided by the total power of the radiators installed on the site.

The diameter of the heating pipes is determined in accordance with the established coolant flow:

- at a flow rate of 5.7 l/min, half-inch pipes are required;

- at a flow rate of 15 l/min, three-quarter inch pipes are required;

- at a flow rate of 30 l/min, inch pipes are required;

- at a flow rate of 53 l/min, pipes of an inch and a quarter are required;

- at a flow rate of 83 l/min, one and a half inch pipes are required;

- at a flow rate of 170 l/min, two-inch pipes are required;

- at a flow rate of 320 l/min, two and a half inch pipes, etc. are required.

To determine the parameters of a suitable circulation pump, it is necessary to measure the length of the entire heating circuit to which it will be connected. For a ten-meter system, a pump head of 0.6 m is needed. By simple calculations, we find that for a system 60 meters long, a pump of 3.6 m is needed.

However, these parameters are only valid for a system in which the pipe diameter is correctly selected, as indicated above. If too narrow pipes are used, a more powerful pump will be needed to overcome the excess hydraulic pressure that occurs in the system due to improper pipe selection.

We have provided detailed recommendations for choosing a circulation pump In this article.

This rule also applies in the opposite direction: if the pipes are wider than required by the standard, the design power of the circulation pump should be reduced.

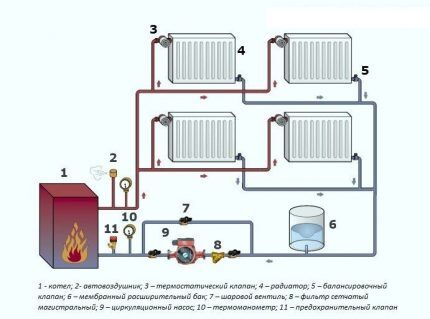

An important component of forced heating systems is the safety group:

Experts recommend purchasing not one, but two such devices at once. One is the main one, and the second is in reserve. It can be installed on the bypass or stored in the pantry.

The circulation pump is usually resistant to breakdowns, but is sensitive to the quality of the water in the heating circuit. To prolong the operation of heating equipment, it makes sense to provide filtration of the coolant and timely measures to flushing the system.

Schemes of systems with pump circulation

Forced circulation heating systems differ as follows:

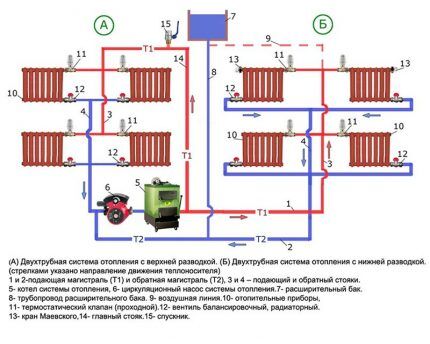

- as one- or two-pipe (an option for connecting pipes to radiators);

- with vertical risers or horizontal lines;

- dead-end or with associated coolant movement

- with top or bottom wiring.

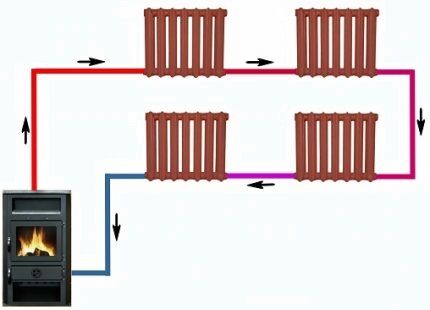

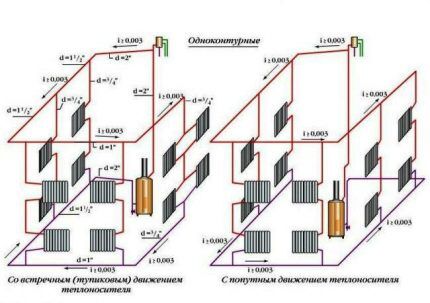

Single-pipe systems are becoming less and less common, since their disadvantages significantly outweigh their advantages. This is a very simple option in which the radiators are connected in series.The coolant passes through each heating device in turn, gradually cooling down.

Obviously, with such a scheme, the first radiators will heat the room better than those located at the end of the system. It is necessary to install more radiators at the final section of the line than at the beginning in order to smooth out the temperature difference.

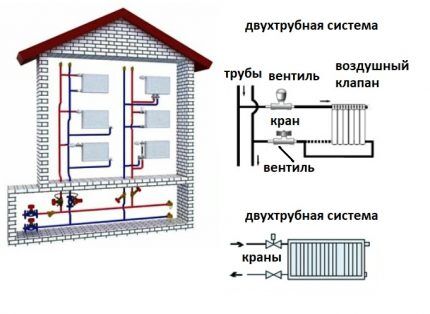

Such a device is extremely inconvenient, since it is impossible to turn off only one radiator in the event of a breakdown; you will have to drain the coolant from the entire circuit. The two-pipe scheme involves connecting each radiator in parallel using two pipes to a common line.

Of course, for this you will have to use more materials, the total cost and time for installation will be higher than when using a single-pipe option.

Shut-off valves are installed on each radiator with a two-pipe connection. This makes it possible, if necessary, to remove or turn off only one radiator, while the remaining elements of the system continue to function as usual.

Warming up with this scheme is carried out evenly, since the coolant enters each radiator through a separate line, and then returns to the boiler for heating, rather than moving through the remaining radiators.

Vertical risers are used in multi-storey buildings; it is convenient to connect radiators located on different floors to them.The vertical design facilitates the rapid removal of air trapped in the system, which significantly reduces the likelihood of air locks forming.

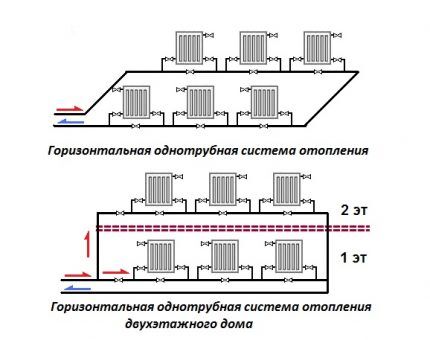

In horizontal circuits, the main line, to which radiators are connected in parallel, is located, as the name implies, in a horizontal plane. This type of system is suitable for heating single-story buildings with a large area.

A relatively inexpensive option is not immune to the formation of air jams. To prevent this type of problem, automatic air vents are used. We detail the rules for removing an air lock from a heating system. reviewed here.

Uneven heating is typical not only for single-pipe systems, but also for dead-end heating options, which are quite widespread.

In this scheme, the coolant flows in the direction opposite to the return flow. As a result, radiators appear in the system, receiving somewhat cooled coolant, which then flows into the return pipe.

As a result, more heat flows into the radiators first from the riser, and less heat flows into the radiators further away. In small areas this point may not be so noticeable, but in spacious houses it will be noticeable.In this situation, it is recommended to make several shorter lines rather than one long one, so that all the coolant circulates through the branches at approximately the same temperature.

The associated scheme is based precisely on the same length of circulation rings throughout the house, which makes it possible to achieve extremely precise uniformity of heating. But implementing this wiring option is not easy, since a large number of pipes will need to be installed.

The upper and lower wiring are named after the location of the supply pipe. In the first case, the coolant enters the system from above, and in the second - from below.

With top wiring, the expansion tank is installed at the highest point of the system, the coolant spreads throughout the system under the influence of gravity. The return line here will be below the radiators. To implement such a project in a private house, an attic is needed, in which the tank is installed.

If there are no conditions for upper distribution, use the second option, when the coolant is supplied from below and the return is installed above the radiators. The task of moving the coolant at a sufficiently high speed is assigned mainly to the circulation pump.

This scheme is installed gradually, from the lower floor to the upper one, while the supply line is made with a slight slope to prevent the occurrence of air jams.

To remove air pockets, heating communications are equipped with automatic air vents:

Where to put the circulation pump?

Most often, the circulation pump is installed on the return side, and not on the supply side. It is believed that there is a lower risk of rapid wear and tear of the device, since the coolant has already cooled down. But for modern pumps this is not necessary, since they have so-called water-lubricated bearings. They are already designed specifically for such operating conditions.

This means that it is possible to install a circulation pump on the supply side, especially since here the hydrostatic pressure of the system is lower. The installation location of the device conventionally divides the system into two parts: the discharge area and the suction area.A pump installed on the supply, immediately after the expansion tank, will pump water out of the storage tank and pump it into the system.

If the pump is installed on the return line in front of the expansion tank, then it will pump water into the tank, pumping it out of the system. Understanding this point will help take into account the characteristics of hydraulic pressure at various points in the system. When the pump is running, the dynamic pressure in a system with a constant amount of coolant remains constant.

It is important not only to choose the optimal location for installing pumping equipment, but also to install it correctly. We recommend that you familiarize yourself with the details circulation pump installation.

The expansion tank creates so-called static pressure. Relative to this indicator, an increased hydraulic pressure is created in the discharge area of the heating system, and a reduced one is created in the vacuum area.

The vacuum can be so strong that it will reach the level of atmospheric pressure or even be lower, and this creates conditions for air to enter the system from the surrounding space.

In the area of increased pressure, air can, on the contrary, be pushed out of the system, and sometimes boiling of the coolant is observed. All this can lead to incorrect operation of heating equipment. To avoid such problems, ensure excess pressure in the suction area.

To do this, you can use one of the following solutions:

- raise the expansion tank to a height of at least 80 cm from the level of the heating pipes;

- place the drive at the highest point of the system;

- disconnect the storage pipe from the supply and transfer it to the return after the pump;

- install the pump not on the return, but on the supply.

It is not always possible to raise the expansion tank to a sufficient height. It is usually placed in the attic if there is the necessary space there. It is important to adhere to the rules for installing the drive to ensure its trouble-free operation.

We have provided detailed recommendations for installing and connecting the expansion tank in our other article.

If the attic is not heated, the storage tank will have to be insulated.It is quite difficult to move the tank to the highest point of a forced circulation system if it was previously created as a natural one.

Part of the pipeline will have to be redone so that the slope of the pipes is directed towards the boiler. In natural systems, the slope is usually made towards the boiler.

Changing the position of the tank pipe from supply to return is usually not difficult to do. And it’s just as easy to implement the last option: install a circulation pump into the system on the supply line behind the expansion tank.

In such a situation, it is recommended to choose the most reliable pump model that can withstand contact with hot coolant for a long time.

Conclusions and useful video on the topic

You can find interesting information on forced heating systems in this video:

More detailed information on the calculations required when choosing a circulation pump can be found here:

This video describes in detail the design and installation procedure of the circulation pump:

Forced heating systems are not as complicated as they might seem at first glance. But in order to implement such a task, you need to correctly perform calculations and draw up a competent project. Subject to these conditions, you can provide your home with reliable and efficient heating.

Are you selecting the optimal scheme for installing a forced heating system in your home? Maybe you have questions that we haven't covered in this article? Ask them to our expert in the comments block.

Or do you want to supplement the material with practical advice on installing pumping equipment? Write to us - your comments will help many newbies.

In the fall, we bought a private house, a good one, but, as it turned out, with problematic heating. As I managed to understand, this is a two-pipe open system, the water flows by gravity through the batteries. And in the last two rooms they are completely cold. I increased the temperature on the boiler, drained the water, filled it again, everything was the same.

Now I installed a circulation pump, the radiators began to warm up much better. But I encountered another problem: there is no light, cold batteries again. It’s good, at least the lights are rarely turned off.

Good afternoon. I really need your advice. We installed a solid fuel boiler, everything was done according to the video. We took pipes 25, but alas, a problem arose - the circulation pump gets very hot, even when it circulates cold water in the system. In this case, the boiler does not work, and the pump is on fire. What could be the problem?

We racked our brains - we tested it by pumping cold water from a tank to a tank that stands outside in the event of a water outage in the house, just as a reserve. In this case, our pump is cold. The expansion tank is located behind the stove in a homemade box.

Hello. Since you have checked the operation of the circulation pump by running water from another tank with cold water, this eliminates several sources of problems.

Let's look at what could be the reasons for overheating of the circulation pump:

1. The first reason is improper installation, which could lead to airing; the rotor axis could also shift;

2.Blockages in the heating system, which lead to increased load on the equipment, and this in turn leads to overheating;

3. Insufficient pressure, which occurs when the phase is incorrectly connected during a three-phase connection to a heating circuit, which leads to a violation of the direction of movement of the blades and to overheating.

I think that checking one of the above points will allow you to detect and eliminate the cause of overheating.