How to make a fan heater with your own hands: instructions for making a homemade device

A fan heater is an extremely convenient device: mobile, easy to use, resistant to breakdowns, and efficient.Using such a device, you can heat a living room in just a few minutes.

It is designed so simply that, if desired, you can make a fan heater with your own hands. Some of the materials needed to implement such a project can be found even among all the junk that has accumulated in the garage.

How to do this and what exactly you will need - we will look at all this in our article. Here are 4 instructions for making various fan heaters from scrap materials. For clarity, we will supplement the material with photo selections and video instructions for assembling various versions of the device.

The content of the article:

Operating principle of the device

Household fan heaters are compact devices that can easily be installed in almost any suitable place. To operate the device, you need electricity: both for the fan and for the heating element.

Such devices are often used in apartments, garages, and even for heating workshops, greenhouses and other premises. It all depends on the power of the device.

Any fan heater model has three components:

- fan;

- a heating element;

- frame.

The fan drives a stream of air through the body, the spiral heats this air, and the warm air flows throughout the room.

If you add automatic control elements to the device, you can set an acceptable air temperature.The device will turn on and off without human intervention, which will save energy.

When operating the fan heater, you must adhere to safety rules. Do not place any objects or materials directly on the fan heater body or too close to the protective grille.

If the device is equipped with an overheat protection system, it will simply turn off. But if this module was not installed during assembly, the device may overheat, break down, or even catch fire.

A self-made fan heater can be of almost any suitable size and power. As a housing, you can use a piece of asbestos-cement pipe, a metal pipe, a rolled sheet of metal, or even a housing from an old system unit.

Usually, a fan is first selected and a heating coil is made, and then the type of device housing is determined depending on its filling.

The most important point when creating this heating device is safety: fire and electrical.

The heating coil in homemade devices is most often of the open type; it is simply twisted from suitable wire. Direct contact with a heated coil can lead to fires, burns, etc.

Therefore, the spiral must be properly secured inside the case, and the outside of the device must be covered with a reliable grille. The installation of the device's power supply also requires attention.

All contacts must be insulated; the base below is usually made of materials that do not conduct current: rubber, plywood, etc.

Options for a homemade heating element

Before you start making a homemade fan heater, it is important to choose the right heating element for your device. Let's look at which options are suitable for these purposes.

The following can be used as such a heater:

- metal spiral;

- heating element;

- ceramic device.

You can make a spiral coiled from wire yourself without any problems. This limits the advantages of metal spirals as heaters. When the device operates for a long time, there is too little moisture and oxygen in the surrounding air.

Therefore, the room will have to be ventilated frequently, well ventilated, and also take care of air humidification.

The heating element is a metal pipe containing sand inside, which accumulates heat well and then gradually releases it to the air flow.

Heating elements do not dry the air and do not require oxygen, so they are much safer than coils. The heating element for the fan heater can be removed from an old household appliance, for example, from an electric stove.

We recommend looking at more information about the types of heating elements for heating and the features of choosing the appropriate option in this article.

Ceramic heaters are complex and expensive elements, but extremely safe and effective. They are a complex of plates with an uneven surface, similar to a honeycomb.

Such elements do not heat up too much; the effect of their influence is achieved due to the large area of contact of the heaters with the air.

The likelihood of getting burned on a ceramic heater is much lower than when using a metal coil. But in home-made devices, it is spirals that are most often used, since they are simple and affordable.

Fan Heater Assembly Instructions

Having understood the principles of the design of a fan heater and the features of choosing the appropriate type of heating element, you can create a device from the materials at hand and give it a suitable configuration.

Option #1 - fan heater made of asbestos cement pipe

A piece of asbestos cement pipe is an excellent option for creating a fan heater. This material does not conduct current, which will make the device safer. A pipe with a diameter of about 15 cm and a wall thickness of 10 cm is suitable. The length of the body should be approximately half a meter.

One of the options for constructing a fan heater based on an asbestos pipe will be shown in the photo selection:

To make cutting asbestos cement easier, it is recommended to pre-wet the area where the cut will be made for two hours. You can cut with a regular hacksaw, but a grinder with a diamond attachment is better.

The manufacturing process can be represented in the following steps:

- Manufacturing of the body.

- Making a heating coil.

- Connecting the spiral to the electrical wire, checking its operation, adjusting the characteristics.

- Fastening the spiral inside the housing.

- Installation and connection of the fan.

- Installation of meconite film on top of the body.

- Fastening the handle, protective grille, control elements, etc.

To make a spiral you will need about six meters of nichrome wire with a diameter of 0.5 mm, grade X20H80. This is a common material and will not be difficult to find. You can take thicker wire, then the power of the device will be higher.

You need to cut a piece of wire whose resistance is 30 ohms. The rated power should be 1.6 kW. This indicator can be changed by changing the length of the wire and/or its diameter.

It is most convenient to twist a wire spiral using a vice and a knob located on top. Then this element is stretched so that the distance between the turns is approximately twice the diameter of the wire.

To check the operation of the spiral, its ends are connected to the electrical cable using ceramic pads. Now you need to turn on the heater and check its operation.

To do this, the spiral is wound onto a pipe and placed between two supports that do not conduct current. After this, the heater is turned on for just four seconds. During this time the element will warm up.

In this case, you should pay attention to the color of the spiral; it should be bright red. Yellow and white glow indicates a high probability of interturn short circuit. In such places you need to check the condition of the spiral, stretch it to increase the distance between the turns.

Now you need to secure the heater inside the fan heater housing.To do this, you can use either standard fasteners, for example, bolts and nuts, or cotter pins made from the remnants of the nichrome wire from which the spiral is made. To do this, 2 mm holes are drilled in the places where the heating element is attached.

A piece of wire is bent in half, the spiral is hung on this loop, and the ends of the cotter pin are brought out through the hole to the outside of the body and moved in different directions.

The pattern of hanging the spiral is not very important. It should be distributed evenly, avoiding sagging. It is also necessary to avoid contact of individual parts of the spiral with each other.

Now the ends of the spiral are reconnected to the network cable. To do this, ceramic adapter pads are fixed to the body.

Now you need to install the fan. Devices of suitable size and power are sold in specialized stores; there is no need to make such a device yourself.

The fan is fixed to the end of the pipe opposite to where the heater is already located. You need to make sure that the air flow from the room is sucked in from the end of the case where the fan is located, and exits past the spiral, heating up in the process.

The device is powered by connecting the contacts to the same ceramic adapters to which the heating element is already connected.

If you use a constant voltage fan, you will need a special power supply to connect it. At this stage, you should also consider and implement the possibility of installing additional modules that will improve the operation of the device. For example, a filter that will trap dust particles may be useful.

The thermostat and fuse will protect the device from breakdowns, overheating, etc. It makes sense to install a toggle switch, otherwise you will have to use an electrical plug to turn the device on/off. Now the body needs to be insulated using meconite film.

It is simply wound on top and secured. The end of the housing on which the spiral stands is covered with a protective grille. To make it more convenient to carry the device, a handle is attached to the top, for example, from an old door.

Option #2 - heat gun for large rooms

Large models of fan heaters are often called heat guns. Such devices are often used to heat large rooms, such as a garage or warehouse.

To make this version of the fan heater, you first need to make a base from 16 mm plywood, dimensions approximately 50X70 cm. The base should be treated with sandpaper to eliminate sharp corners and irregularities.

Then a fan and a closed-type heating coil are fixed to the base; it is already enclosed in the housing. Now you need to connect these two elements with a coupling through which the air flow will move.

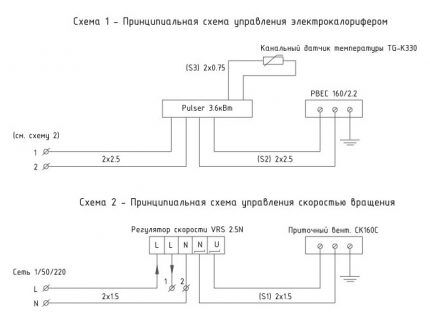

After this, control elements are fixed to the base: a switch, a temperature sensor, a thermostat, a device for adjusting the fan speed.

All elements are connected in accordance with the diagram and connected to the power supply. All connections should be carefully insulated. To secure individual parts to a plywood base, you can use 16 mm self-tapping screws.

The device is not very compact. To make it easier to move it from place to place, four wheels are attached to the bottom of the base.

On our website there are instructions for making other versions of the heat gun - using different types of fuel. As well as useful recommendations on choosing a ready-made device in case you change your mind about assembling the device yourself.

The listed material is discussed in the following articles:

- Do-it-yourself electric heat gun: pros and cons of homemade products + assembly guide

- DIY diesel heat gun: instructions for making a homemade product

- DIY waste oil heat gun: step-by-step manufacturing instructions

- Do-it-yourself heat gun: manufacturing options for different types of fuel

- Do-it-yourself heat gas gun: step-by-step assembly instructions

- Electric heat gun: types, how to choose, review of the best manufacturers

Option #3 - fan heater from the system unit

If there is an unusable system unit in the house, it is quite suitable for creating a homemade fan heater, especially since there is already a fan inside the device.

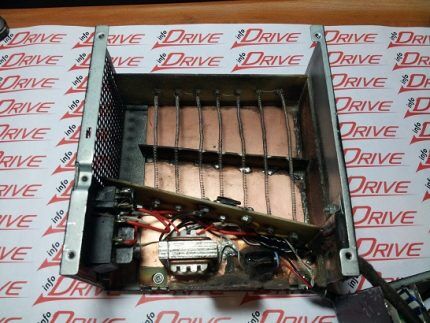

The body of the unit will be used for a new device, so externally such a fan heater will have the shape of a parallelepiped. But the insides will have to be completely removed, leaving only the cooler intact.

If the fan is broken, it will have to be replaced with a new device.To make a heating device you will need a hacksaw and a sheet of fiberglass. It is necessary to cut out a frame of suitable size and configuration from it.

Nichrome wire is fixed to the frame so that it evenly fills the space.

You need to make sure that the turns of the spiral do not touch. The ends of the spiral are fixed to the body with ordinary bolts. Immediately install a safety device that will turn off the device when heated above 70 degrees.

The electrical cable that will supply power to the heating element is connected to the bolts that secure the edges of the spiral.

A computer cooler is a constant current device. To connect it to a 220 V network, you will need a 12 V power supply. The front part of the case is covered with a grill so that the heated air moves freely around the room.

A rubber gasket, a piece of plywood or any other suitable material that does not conduct current is attached to the bottom of the housing. Now you can turn on the device and check its functionality.

Option #4 - water type device

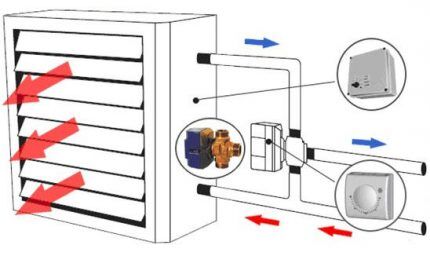

An interesting variant of this type of device is the so-called water fan heater. Here, not a spiral is used as a heater, but a heat exchanger through which water circulates from the heating system of a house or apartment.

Thus, a water fan heater can be considered as an addition to the heating system.

This device is not mobile; it is installed in a specific place. The idea is to circulate air between the heat exchanger pipes and thus improve the rate of heating of the room and the efficiency of home heating.

The installation location of the fan heater is chosen so that it can be easily connected to the heating pipes, and also so that there are no obstacles in the path of the flow of warm air.

First, the device body is cut out and welded to the size of the fan from sheet metal. To do this, cut a strip of metal, the width of which corresponds to the width of the fan heater, and the length is equal to the perimeter of the fan plus a couple of centimeters for fasteners.

A strip of metal is bent and its opposite sides are connected with bolts.

These are the walls of the device. For the front part, a sheet of suitable size is cut, in which many air holes are drilled. This is the equivalent of a safety grille. Now you need to make a heat exchanger. To do this, use a copper tube, which is bent, giving it the shape of a coil.

At this time, it is recommended to fill the tube with sand to prevent the formation of creases. Upon completion of work, the sand is removed.

In the side walls of the water fan heater, you need to drill two holes for the heat exchanger pipes. If the connection to the heating circuit will be made using a thread, it must be cut at the edges of the heat exchanger pipe.

It makes sense to install shut-off valves at the inlet and outlet, and a Mayevsky valve at the top point of the heat exchanger to bleed the air that has entered the system. The heat exchanger is installed in the device body and its position is secured with nuts.

After this, the fan heater is fixed in the selected location so that there is a space of at least 10 cm between the wall and the housing.All that remains is to connect the heat exchanger pipes to the heating system, and the fan to the power supply.

We looked at the most popular options among users for assembling a homemade fan heater. If they seem complicated to you or you don’t want to waste your time making a homemade device, you can always pick up a ready-made one at a hardware store.

We recommend that you look at the article in which we looked at how choose the best fan heater.

Conclusions and useful video on the topic

Here you can see a review of a small fan heater assembled from improvised means:

This video shows a homemade heat gun for the garage. Spirals removed from the electric stove were used as a heating element:

A variant of a fan heater made from a piece of asbestos-cement pipe is presented in this video:

A fan heater is a relatively simple device, and this is what makes it so convenient and reliable.

Obviously, making such a heating device yourself is not difficult. However, one should not forget about precautions so that the homemade device does not cause injury or fire..

Are you using a homemade fan heater for domestic purposes? Share your manufacturing experience and photos of your homemade device by leaving your comments under our article.

Or maybe you are just planning to assemble a fan heater and you still have some unclear points after studying our instructions? Ask your questions - we will try to help you.

You can do everything with your own hands, even a “gas gun”, which is considered the most economical option for heating a garage if you need to work in it in cold weather.I've tried many heater options, including yours, and there are a lot of old fans left over. It’s bad that the high cost of electricity in our garage cooperative eats up all the benefits from such devices.

I put together something similar for my garage, unfortunately, in our garage community the heating is disgusting, so we have to somehow get out of it. I did it according to the instructions on the Internet. I only had to buy a power supply from the computer; I found an inexpensive option on Avito. If you understand at least something about electronics, then there will be no problems with the assembly; it heats well.

There are many options for heating a room using different devices. I seriously began looking for a simple way to heat my garage, because in winter you need to especially carefully monitor the condition of your car. I came across this information; the most suitable option was a fan heater from the system unit. Nothing complicated, of course, I had to spend a whole day to assemble and install, but now the room is warm. If you approach things wisely, you can even make complex equipment with your own hands.