Water sensor in a dishwasher: types, device, how to check + repairs

Household dishwashers have deservedly received the status of an integral part of kitchen equipment. They really show high efficiency.But like any other type of household appliance, dishwashers tend to break down from time to time.

A common cause of malfunction is the water sensor in the dishwasher, also called a pressure switch. We will tell you what technical symptoms can be used to identify a malfunction. We'll tell you which breakdown you can fix yourself, and which one is better to contact a service workshop.

The content of the article:

Pressostat function in a washing machine

A special feature of the design of the dishwashing machine is the use of the optimal amount of water with high cleaning efficiency.

Actually, this factor is an obvious point, since the degree of cleaning of kitchen utensils by dishwashers depends not so much on the amount of water, but on its temperature and spray technology.

On the contrary, if the unit uses too much water, the spray function is disrupted due to increased hydraulic resistance, and heating will require more power and time.

That is why an important component dishwasher designs is a water level sensor. The presence of this device allows you to control and maintain the exact water level in the machine.

Meanwhile, correct and flawless operation of the machine is noted, as a rule, during the initial period of operation of the equipment.

Then, at some point in the use of the equipment, the owner of the dishwasher begins to notice malfunctions in its operation. The root cause of failures is usually the pressure switch. And the point here is not at all in its quality.

The quality of the water used to power the dishwasher plays a significant role in this process. Unfortunately, in most cases of operation, there is no need to talk about the high quality of water from a centralized water supply system.

And low-quality tap water quickly destroys plumbing fixtures of any kind. The pressure switches of washing machines are proof of this.

Types of sensors for dishwashers

Level sensors used in dishwasher designs can be divided into two groups: mechanical and electronic.

Operating principle of the pressure switch

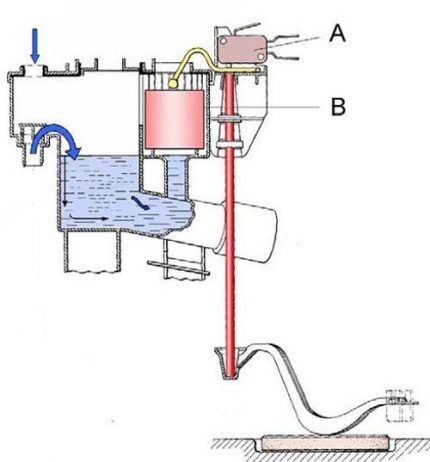

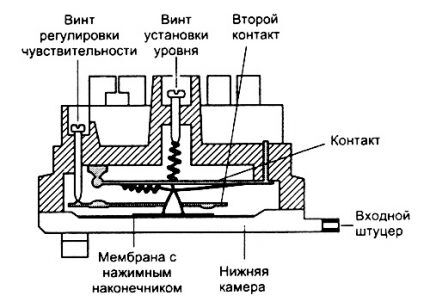

A mechanical device (sensor) operates on the principle of transmitting water pressure to a silicone membrane. The pressure force from the membrane is transmitted through the rod to a contact device (usually a relay).

This force mechanically closes or opens the contacts of the control device, which in turn acts on the water supply element.

The cause of a malfunction of the mechanical action system, as a rule, is the silicone membrane - more precisely, its physical damage in the form of surface breakdown.

Accordingly, in this state, this element stops working - to perceive pressure. As a result, the user experiences a violation of the water level inside the dishwasher tub.

Electronic type sensors work in much the same way. Only in this case, relay components are not used. Instead of relays, the functions of switching modes (operating, emergency) are performed by semiconductor components.

Electronic devices have additional functions - automatic fault detection and display of error messages directly on the machine display.

It is clear that fault diagnosis in the presence of an electronic device is greatly facilitated. The owner can already understand from the error code on the display what needs to be done in terms of repairs.

However, electronic systems are more difficult to repair than mechanical ones.Therefore, you probably can’t do it yourself here. Professional intervention will be required.

Element design

The design of the sensor allows for the most unusual design. For example, in some cars of a well-known brand Electrolux The pressure switch module is made on the basis of two individual sensors.

One of a pair of such devices controls the low water level, and the other, respectively, the high one. Therefore, it is not always possible to get by with simplified dismantling during repairs.

And in another case - when, for example, on a budget Bosch brand models There is only one sensor that monitors the total water level. In this option, disassembly is accompanied by fewer difficulties, but there are difficulties with accessing it on the machine chassis.

This is why it is not always possible to replace faulty sensors on your own. More often it is necessary to attract a specialist from a specialized service workshop.

Meanwhile, on an Electrolux dishwasher, where two sensors are used, the device that monitors the high level is used as a backup control element.

If during operation of the device the low level control sensor does not operate, then when the water reaches the upper limit, the drainage pump is turned on. The signal for this is given by the upper control device.

The main function of monitoring the volume of water is assigned to the sensor designed to control the lower level. This device is activated at the initial stage, when the process of filling the dishwasher with working fluid starts.

Nuances of checking the health of the sensor

The sensor switch is connected to the device itself and as soon as the container, called the bath, is filled to the set lower limit, the pressure switch membrane acts under pressure on the rod, moving the switch contacts.

If there is a possible malfunction at this point, you can make sure by checking the low level relay.

To do this, perform the following steps:

- The dishwasher's power is removed.

- The service panel of the control module is opened.

- The diagram determines the relay conductors.

- The device measures the resistance between them.

- Without water in the pan of the machine, the tester should not indicate the presence of contact.

- If there is contact when the water is filled, then the relay is working properly.

In a similar way, the serviceability of the upper level control relay is checked.The check is also carried out through the control panel using the machine's circuit diagram.

You should identify the conductors and contact plaques on the board coming from the high-level relay switch and ring them with an empty and filled tray.

Replacement instructions

Repair as such for pressure switch membranes seems useless and practically impossible. As a rule, such elements of the device must be replaced.

But before changing the membrane, you will have to determine the exact model of the level sensor used. For each particular brand of dishwasher, these details differ significantly.

That is, in any case, the user or service representative will need to disassemble the dishwasher in order to be able to get to the defective part and determine its brand. Let's figure out how to perform this operation if you decide to do the work yourself.

Again, in relation to a specific model of dishwasher, the disassembly sequence may differ.

Consider, as an example, a dishwasher from Bosch that uses a mechanical level sensor design:

- Disconnect the device from the network and plumbing communications.

- Prepare a free area for work.

- Place the machine upside down on the prepared site.

- Unscrew the screws holding the bottom cover of the housing.

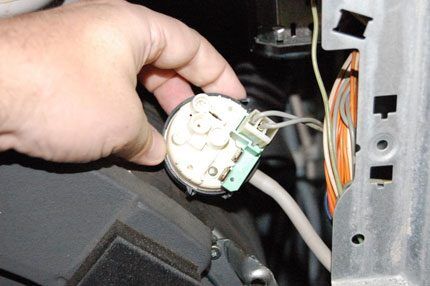

- Remove the cover and use the documentation diagram to find the pressure switch.

- Dismantle the device, first disconnecting all components from it.

After dismantling the sensor, free access to the relay elements and mechanical parts will open. To check and, if necessary, replace the membrane, you will need to disassemble the pressure switch housing. Typically, the two halves of the case are held together with two or three screws, but designs with plastic latches are more common.

You should also check the functionality of the relay elements. Bosch dishwashing machines usually have limit switches. It is easy to check their integrity.

To do this, use a measuring device, which is connected alternately to the switch terminals and manually operates the push-button mechanism. During normal operation of the switch, one of the terminal groups should be short-circuited.

If there is no short circuit and a characteristic click is not heard, the switch is most likely faulty. In this case, this part must be replaced. You should also resort to replacement if there is unstable (unstable) contact between the terminals.

Helpful tips for repairs

Each dishwasher model has its own characteristics. Therefore, if you decide to disassemble it yourself, it is recommended to record the sequence of actions, for example, with notes on a piece of paper. Before starting work, it is advisable to carefully study the instructions and become familiar with dishwasher devicelocated in the passport.

All dismantled parts must be laid out in strict order of removal; It is better to prepare some small dishes or a box for screws. If you follow these rules during the disassembly/assembly process, unnecessary problems will be avoided. And with this solution, assembly after replacing parts is much easier.

Assembly is performed strictly in reverse order. Care and ease of action are required. Many parts of household appliances are often secured with plastic clips, which can easily break off during rough installation. After assembly is completed, you should check the dishwasher for functionality.

To ensure that your favorite piece of household appliance does not create problems or cause headaches, first of all, you should follow Dishwasher operating instructions. In this case, the working life of important technical parts and assemblies will increase significantly, and the owners will not need to look for spare parts for replacement.

Conclusions and useful video on the topic

Video material close to the topic, where the author in an intelligible form tells and shows almost everything he knows about pressure switches - water level sensors used in the design of dishwashing units:

Video about how to repair a dishwasher yourself:

Having familiarized yourself with the design of the sensor and the procedure for carrying out work in the event of its breakdown, you can try to carry out repairs on your own.But almost all modern equipment is produced without taking into account possible repairs, and more often than not, a broken part has to be replaced completely.

Often repairs cost costs that are comparable to the price of a new similar model. Therefore, a more reasonable option is to provide the machine with proper operating conditions, which will ultimately lead to long-term trouble-free operation.

Would you like to talk about how you selected a water sensor to replace in your dishwasher? Do you have useful information on the topic of the article? Please write comments in the block below, ask questions, share photos and useful information.