DIY diesel heat gun: instructions for making a homemade product

Heat generators and heat guns, which can operate on various types of fuel, allow you to heat a large space in a short time.Such devices are presented in stores, but if you have some technical skills, you can make them yourself. Do you have any doubts?

We will show that a diesel heat gun can be assembled quite easily with your own hands if the performer has experience in welding and metal processing.

The article describes in detail how a liquid fuel unit works and works, and what types are available on the market. For DIY enthusiasts, we have prepared detailed instructions for assembling a simple thermal device. For those who prefer to use factory equipment, a review of the best manufacturers of diesel heat guns will be useful.

The content of the article:

Operating principle and types of heat guns

Heat guns, which got their name due to their specific shape, are considered one of the most effective ways to increase indoor air temperature.

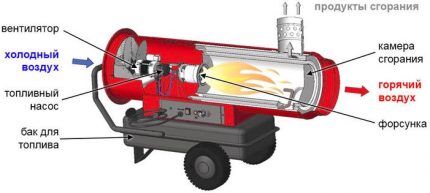

The operating principle of such devices is quite elementary: with the help of rotating fan blades, cold air from the surrounding space is forced into the unit. Passing through the heating element, the air flow is heated to a high temperature, after which it is pushed into the room and gives off heat.

All units can be divided into two large categories.

- Small in size and power household appliances, used for heating relatively small spaces (basement, garage).

- Large and powerful industrial devices, capable of raising the air temperature in a huge room in a short time.

In addition, heat guns differ in the type of fuel used.

Based on this criterion, the following types of units can be distinguished:

- Electric guns. Environmentally friendly devices operate without odor, noise and emissions of harmful substances. Their disadvantages: attachment to power grids, as well as consumption of large amounts of expensive electricity.

- Gas guns, operating on various modifications of blue fuel, are most often used in production, agriculture or during construction work.

- Steam guns release heat, forming a saturated stream of hot steam. Such environmentally friendly devices are successfully used in everyday life: they not only heat the room, but also improve its microclimate, saturating it with water vapor.

- Infrared guns. The special design of these devices makes it possible to convert thermal energy into infrared radiation, which is used for heating. Such devices are often used in open spaces, for example, to heat restaurant terraces or a festive area.

- Multi-fuel guns, for which the cheapest types of fuel are used: used transport or household oils. Thermal guns being tested versatile and economical to maintain.

- Diesel guns. They operate on such types of fuel as diesel and diesel fuel.

Despite the general principle of operation, each of the above types has its own design features and recommended scope of application. A detailed classification of heat guns with a description of their operational features is given in this article.

Types of diesel heat guns

Guns of this type are also called liquid fuel: they can use either diesel, kerosene or diesel fuel as fuel. It is strictly forbidden to use gasoline, alcohol or other flammable liquids to refuel such devices.

The choice of fuel must be approached very carefully, since the use of low-quality or contaminated fuel may clog the injector and/or filter, which will require the intervention of repairmen.

Diesel guns are distinguished by their high power, high efficiency, and compact size, making such units quite mobile.

All units operating on economical diesel fuel can be divided into two groups of heat guns: with direct and indirect heating.

Devices with direct heating. The operation is based on an elementary principle: a burner is installed inside the housing, through the flame of which air blown by a fan passes. As a result, it heats up and then bursts out, releasing heat into the environment.

Such devices are characterized by high power of 200-250 kW and almost 100 percent efficiency. They are inexpensive and easy to install, but have an important drawback: not only the heated air flow enters the outer space, but also combustion products: soot, smoke, fumes.

Even good ventilation will not be able to completely rid the air of unpleasant odors and tiny particles, and if it is completely absent, living creatures in the room can become severely poisoned.

Indirect heating device much more difficult. In such models, the air is heated indirectly, through a special chamber - a heat exchanger, where heat is transferred to the air flow.

In such units, heated exhaust gases, together with heat, enter a heat exchanger, from where they are discharged into a smoke duct, to which a special pipe is connected. With its help, combustion products are removed from the enclosed space to the outside, providing fresh air in the heated room.

Heat guns with indirect heating are often used to heat a garage.

The advantages of such models include:

- Mobility. Although the dimensions and weight of such devices are somewhat larger than their analogues with open heating, they still have a fairly compact size, which allows them to be transported around the room within the length of the connecting element and the chimney.

- Great power. Although this figure is higher for devices with direct heating, the power of indirect diesel guns is enough to heat a large space in a short time.

- Reliability. Such devices have a well-thought-out design, which minimizes the risk of fire and also increases the durability of the guns.

- Availability of a protection system. Many factory models are equipped with a protective complex that automatically turns off the gun immediately after the room temperature reaches a predetermined value.

- Reduced risk of burns. Products manufactured at the factory are equipped with thermal insulating gaskets that prevent the body from heating up, which reduces the likelihood of injury to the user.

- Duration of work. Some models have large-volume tanks, which allows you to use them for a long time without worrying about fuel.

The disadvantage of such structures is the high noise level, especially for high-power units.

Making your own diesel gun

A unit that runs on diesel and diesel fuel can not only be purchased at a specialty equipment store, but also made with your own hands.

It is important to know that assembling that device is a rather complex process.It is available only to experienced home craftsmen who know how to handle a welding machine and other complex equipment.

Having decided to create a diesel heat gun with your own hands, first of all, start choosing the design of the model. Devices with indirect heating have the best technical characteristics, but they are much more difficult to assemble than devices with an open heat source.

Main design elements

To make a diesel device with your own hands, you need to take care of three components, each of which is an independent structure.

These include:

- Frame (casing) of a device that will require a sheet of thick metal or a thick-walled pipe.

- The combustion chamber – galvanized or other thick-walled refractory pipe, the diameter of which is half that of the casing.

- Fuel tank, equipped with a pump and filter. This element, usually located in the lower part of the body, is made of a refractory material, which it is advisable to additionally cover with a heat insulator.

You will also need a fan with an impeller, with a desired power of 220 W. Such a part is necessary to create an air flow, which, after flowing around the heated combustion chamber, will come out.

To install a heat gun, you can use ready-made components or make do with available materials. In the first case, the cost of a homemade device will be higher, but its quality will be close to the factory one.

Assembly instructions

Before you begin assembling a diesel gun, you need to prepare all the instruments and materials, and then carefully inspect them for possible defects.

The casing of the device is made from a pipe or sheet of metal (in the latter case it should be rolled up and the edges joined). A fan is mounted inside the housing through a hole in the housing, with the help of which air from the room will be pumped into the interior of the device.

The combustion chamber is installed and secured strictly in the central part of the casing, at the end of which the nozzle is secured. The element is sealed on both sides, and two technological holes must be made in it: one for the smoke exhaust, the other for the nozzle.

For comfortable use and fire safety, it is advisable to install a piezo ignition in the combustion chamber. For this, a factory version is suitable, which can be purchased at a specialized store.

A fuel tank of the required size and capacity is located below the hull. In the connected space, you need to fix the high-pressure fuel pump and the fuel fine filter.

Using a dimmer, you should connect the fan to a household electrical outlet. Such an element allows you to regulate the temperature of heated air without increasing fuel consumption.

It is also necessary to weld a smoke exhaust pipe to the combustion chamber, where combustion products will be removed.

Finally, you need to cover the ends of the device with a thick metal mesh (maybe in two layers). This is necessary to ensure safety, since the temperature of the air mass at the outlet can exceed 250 degrees.

All connections must be made extremely carefully, avoiding leaks, the consequences of which can be fatal. Before pouring diesel fuel into the tank intended for it, it is important to thoroughly check all components of the device. If you are not confident in your knowledge, it is better to take the help of a specialist.

The advantage of homemade diesel heat guns is their low cost, while at the same time their technical characteristics and ease of use are inferior to factory-assembled models.

Another disadvantage of such homemade products is the difficulty in determining the power of a home-made heat gun, which is why the device may not heat the room enough or too much.

What to use instead of homemade?

If you doubt your technical skills, consider purchasing a ready-made generator model that runs on diesel fuel.

Despite the rather high cost of such a unit, such a purchase is quite profitable: if the required operating rules are observed, diesel heat guns can operate for ten years or more. Below are the leading manufacturers of such equipment.

Biemmedue: quality + Italian design

The Italian company, established in 1979, specializes in the production of heaters, generators, dehumidifiers and other heating equipment.

The products, which include both household and industrial models, are distinguished by durability, reliability and excellent quality.

The manufacturer pays attention not only to technical characteristics, but also to design. All lines developed by specialists Biemmedue, are distinguished by their compact size, mobility, and aesthetic appearance.

Master: a company with vast experience

An American company that has been producing portable heating systems, including various types of heat guns, for more than half a century. For the manufacture and design of units, only high-quality materials are used, thanks to which the company’s products are distinguished by high technical characteristics.

Thanks to the innovative technologies used in the production of models, heat guns have many useful additional options, for example, a flame control function or emergency automatic shutdown in case of an unusual situation.

Kroll: innovative technologies

Heating equipment manufactured by a well-known German company Kroll, is distinguished by a high level of assembly and the use of high-quality materials, primarily stainless steel.The latest engineering and scientific developments are widely used in the production of products, including diesel heat guns.

Every year you can see interesting new items in the product range: for example, the latest models of the company’s heat guns are equipped with a heat heating function, thanks to which the devices can operate successfully even at low temperatures.

Safety precautions when using heat guns

Heat guns, especially homemade ones, are devices that pose an increased fire hazard.

When using them, it is important to follow the safety rules:

- It is necessary to exclude the presence of flammable and combustible substances near the heating device.

- It is strictly forbidden to direct a stream of hot air towards gas cylinders or containers with flammable liquid (for example, gasoline).

- The body of a homemade gun made of metal usually gets very hot during operation, since, unlike factory models, they do not have thermal insulation. To avoid troubles, it is better to include in the design a stable base that prevents the cylinder from rolling, as well as a handle that does not heat up when the device is in use.

- To ignite the burner, it is better to use a piezo lighter with a long handle or provide a built-in device.

- Before turning off the heat gun, it is advisable to let the fan run idle for several minutes, without supplying fuel. This will help cool the unit somewhat.

- Heat guns (especially direct heating) are only allowed to be used in well-ventilated areas. In this case, preference should be given to forced ventilation.

- If the unit is horizontal, its configuration should not be changed.

- Do not plug in the device with wet hands.

In both homemade and factory models, it is important to periodically check the pipeline in order to notice fuel leaks in time.

The appliance should never be left unattended. It is not advisable to use a diesel heat gun in a room where there are children or pets.

On our website there is a block of articles devoted to the manufacture of heat guns using different types of fuel, we recommend that you read:

- Do-it-yourself heat gas gun: step-by-step assembly instructions

- DIY waste oil heat gun: step-by-step manufacturing instructions

- Do-it-yourself electric heat gun: pros and cons of homemade products + assembly guide

Conclusions and useful video on the topic

In the presented video you can see the process of assembling a diesel burner and a gun using scrap materials.

Although there is nothing complicated in installing a diesel gun, such work requires accuracy and responsibility. By thoroughly getting down to business, it is possible in a short time to create an effective heating device that can be used not only in the garage, but also in other utility rooms.

With high-quality assembly and proper operation, a diesel heat gun will serve for more than one season.

Do you have experience in manufacturing and operating a diesel heat gun? Please share information with our readers. You can leave comments, ask questions and attach photos of your homemade products in the form below.

We bought a diesel heat gun when we were building a garage. It was in the fall during the rainy season, the walls and plaster hardly dried out at all, so we had to take such measures. I think that if you don’t understand this, then it’s better not to do it yourself. The result can lead to the most dire consequences; it’s better to spend a little money and buy a new one in the store, well, or to order. This thing is quite useful; it warms up a room of 10 square meters in a matter of minutes.

Sergey, of course, if you don’t understand anything, then it’s better not to do it, but in this way you won’t begin to understand. The design of a heat gun is not simple, but with the Internet at hand, it’s quite possible to figure it out and make it yourself. It will turn out much cheaper than if you buy it in a store. The only thing is that you can’t do without welding. Therefore, you either need to know how to do it yourself, or ask someone you know.

I need a heat gun to heat my garage, I’m choosing which one to buy. But I read it and thought - maybe I should really try to assemble it myself? Can someone tell me how much cheaper it will be? Preferably with at least approximate numbers.