DIY waste oil heat gun: step-by-step manufacturing instructions

Heat guns are auxiliary devices used to maintain a comfortable temperature during repair and construction work. But their application is more extensive: the devices are also used for household needs, and in everyday life they use a lot of structurally interesting homemade products.

We will tell you how to assemble a waste oil heat gun with your own hands. The article we propose presents the most popular schemes and provides recommendations for the competent implementation of developments. Tips for safe and trouble-free operation of manufactured units are provided.

The content of the article:

How do heat guns work?

Heating devices related to heat guns are technologically constructed according to a single principle. The design of such installations usually consists of a heating module and a fan installed in a single housing.

A common design option is electric. In this case, an electric heating element is used as a heater. However, there are also heat guns, where heating is carried out by other heat sources, for example, burners that burn machine oil.

At the level of domestic use heat guns often associated with ordinary potbelly stoves. But a design such as a potbelly stove differs significantly from a heat gun, since it does not provide a system for forced distribution of heated air.

The operating principle of a large group of heaters, united by the technical term “heat gun”, is discussed in our recommended article, dedicated to the structure and types of the unit.

True, home craftsmen who create equipment manage to attach a ventilation module to stoves, thereby achieving the effect of a heat gun. Let's consider the popular design with heating using waste oil, which is often made with your own hands.

Processing as an inexpensive fuel

Used machine (technical) oil seems to be an effective fuel for domestic heating installations. This type of energy resource allows you to save on electricity consumption and at the same time receive the required amount of heat. But from an environmental point of view, burning waste oil is equivalent to chemical emissions.

However, no one pays attention to the environmental aspect. The main thing is to get cheap heat. In addition, self-made waste oil guns are often technologically dangerous equipment.

There are many examples when several private garages burned out at once for the reason that one of the car owners did not have enough heat, and he decided to solve the problem with a homemade cannon during testing.

Therefore, when deciding to manufacture such a heating system, you should approach the matter with full understanding. It is necessary to calculate all design options, to protect personal property and the property of other people.

Instructions for project implementation

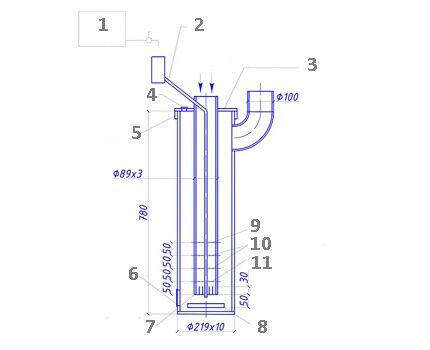

The circuit design of one of the popular designs of a heat gun operating on waste oil involves the use of an ordinary steel pipe D = 219 mm as a housing.

A pipe wall size of 10 mm is quite sufficient for long-term operation of the device. A piece of pipe 780 mm long is closed at the ends with steel caps.

Moreover, the lower lid is welded tightly, and the upper one, increased in diameter to 226 mm, is equipped with lower sides and is made removable. At the bottom of the body pipe there is an oil bowl made from a pipe D=133 mm and complemented by an upper side.

The top cover of the gun body is equipped with two holes. One for the viewing window, the second for the air supply pipe. The air pipe of the heat gun is made with your own hands from a metal pipe D=89 mm.

This structural part, according to the diagram, is passed with tension through the central hole of the upper cover of the housing and is fixed on it (scalded).

The air supply pipe is fixed in such a way that when the cover is installed, the distance between its bottom and the bottom of the oil bowl in the body pipe does not exceed 50 mm.

The air pipe is also complemented by an oil line - a copper tube of small diameter (6-10 mm), which runs inside the air channel, in its central part. The free part of the tube remaining outside is connected to an intermediate container - a waste oil supply regulator.

At a distance of 80-100 mm from the top cover, a hole D = 100 mm is cut out on the wall of the body pipe and an outlet is welded. This is a pipe designed to connect the chimney. And on the opposite side of the body, in its lower part, a hatch with a diameter of 100-120 mm is made for maintenance (ignition). The hatch is located on the same level as the oil bowl.

To carry out work on the manufacture of such a home cannon that functions in testing, it is enough to have on hand a welding machine, a standard set of plumbing tools and pipe material according to the dimensions of the diagram.

You will also need a steel sheet and a metal corner for the support legs. The process mainly consists of welding prepared parts. Preparing structural elements does not take much effort and time.

Operation of the manufactured heater

The operating principle of a homemade potbelly stove using waste oil is simple. A portion of machine oil is supplied inside through a copper tube. Fill the bowl in the bottom area of the pipe with fuel and set the contents on fire through the bottom hatch.

Close the hatch and observe through the observation window. Allow it to heat up to operating temperature, after which a constant dosed (drip) supply of waste is turned on.

By adjusting the drip dosage, the operation of the device is adjusted so as not to overheat the body. As the oven heats up, the oil entering the dosing tube will heat up. The characteristic of the fuel ignition point will change.

It is clear that in such conditions it is extremely difficult to achieve precise adjustment without automation. Therefore, if there is no automation, an oil heat gun cannot be left unattended.

Types of waste oil schemes

From the point of view of design features, there are two types of heaters operating on waste oil:

- Direct burning.

- Isolated combustion.

Similar characteristics underlie the division into subgroups diesel heat guns. Direct combustion designs are more efficient, but during operation they emit combustion products along with heat that are harmful to health.

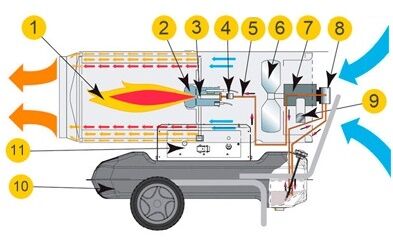

A direct combustion device is easy to make with your own hands. Moreover, there is an opportunity to implement a mobile project. Similar guns are produced at the industrial production level. You can make a device with your own hands based on an industrial design.

To work you will need:

- Container of suitable shape and size.

- Lightweight metal pipe (stainless steel).

- Axial fan.

- Miniature fuel pump.

- Burner for technical oil.

The oil container is equipped with wheels and a handle. Inside the steel pipe, in its rear half, a fan with a fuel pump, a fuel supply and injection system, and an oil burner are mounted.

The front half of the pipe (inner part) of the heater is equipped with additional protective plates. A flame limiter is installed directly at the outlet. That's the whole structure.

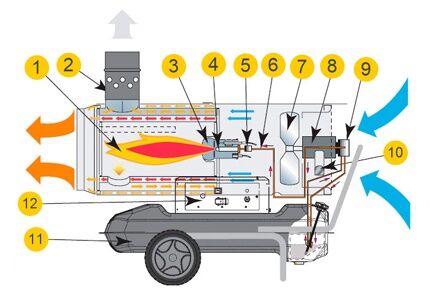

An insulated combustion heat gun is manufactured using almost the same principle. The difference with the first design is noted only in the addition of a chimney pipe to the front area and the creation of an isolated combustion chamber.

When installing a combustion chamber inside a pipe, the diameter of this part of the structure is made one third smaller than the diameter of the housing. Due to this design, inter-pipe channels are formed. The air blown through them comes out heated through the nozzle.

Features of the operation of homemade products

It is not difficult to get heat from a waste oil gun. Another question is how to use all this equipment in order to eliminate spills of used oil and the risk of fire. Therefore, during the manufacture of such structures, special attention should also be paid to waste storage facilities and the furnace supply system with this working fluid.

To store fuel, it is advisable to use sealed metal containers equipped with a metered supply system. It is permissible to place vessels with machine oil only in places far from sources of open fire, including at a distance from a homemade stove.

It is not recommended to use used oil as fuel if it contains even a small amount of water. A mixture of engine oil and water has “explosive” properties when burning.

Getting into the burner nozzle, such a composition ignites and is ejected at high speed in the form of a mass of burning oil droplets. This uncontrolled process often causes a fire.

Homemade direct combustion heaters are sources of carcinogenic substances. It is prohibited to use such installations indoors.

If an assembly with an isolated combustion chamber and exhaust of combustion products outside the room is used, measures should be taken to reduce environmental pollution. For some, all these requirements seem like a “fifty letter”, but a true designer should not ignore generally accepted rules.

In general, a heat gun is, of course, a worthwhile thing. Provided that you assemble a homemade product that is truly high-quality in all respects, the use of such devices is not prohibited. However, assembling an effective system is proportional to the cost of an industrial-style unit.

You will learn how heat guns capable of operating on various types of fuel are constructed from next article, the contents of which we highly recommend that you familiarize yourself with.

Conclusions and useful video on the topic

You can learn how to make a heating device for a garage and increase its efficiency in the following video:

If you don’t have the opportunity or desire to make a heat gun with your own hands, you can simply go to a specialized store, choose a suitable device and buy it without unnecessary fuss. The advantages are obvious: guarantees, operational safety, high efficiency with low consumption of combustible material.

Would you like to tell us about a heat gun you assembled yourself? Do you want to share technological nuances that will be useful to site visitors? Please write comments, post thematic photos, and ask questions in the block below.

Yes, now if you look at the cost of heat guns, even in the same online stores, your eyes will widen. The Chinese ones are okay - prices are more or less tolerable, but this is consumer goods. You need to buy quality, and quality is expensive. So, of course, it’s easier to do it yourself, especially since our people are savvy. The main thing is that more hands grow from that place. Otherwise, if you don’t have the skills, you can actually screw up with a heat gun, these are not toys after all.

This is the first time I’ve heard about waste oil heat guns. But potbelly stoves during mining are “famous” for their increased fire hazard. So I wouldn't risk it.