Heating registers: types of structures, calculation of parameters, installation features

There are a huge number of batteries of different designs and materials for heating systems for residential and non-residential premises.But heating registers stand out among them for their high heat transfer efficiency and ease of self-assembly.

Externally and structurally, these heat exchange devices resemble ordinary heated towel rail coils, but in size they are much larger than their analogues for bathrooms.

In the article we presented, we examine in detail the types of heating registers, and we will also analyze the features of installing such equipment.

The content of the article:

Types of heating registers made from pipes

The heating register is a classic water-air heat exchanger. In most cases, it is made of a smooth-walled metal pipe. The latter can be single or in the form of a series of several pipeline sections located horizontally above each other. In this case, there are individual structures with fins.

A heating device made only from a smooth-walled pipe is easier to clean during regular cleaning. There are no plate-shaped ribs or tight spots that are difficult to wipe with a rag. As a result, “colonies” of dust and dirt do not form on such a register. In this regard, it greatly outperforms the currently widespread panel-sectional radiators.

In terms of efficiency of thermal energy transfer and heating costs, the pipe register is not inferior to regular batteries, and often surpasses them. The total heat transfer surface area in both cases is approximately the same, only in the device under consideration the coolant flows through a wide channel.

The hydraulic resistance in this situation is much lower than that in a standard radiator made of several panel sections. And this directly affects the energy costs for pumping water through such a heating circuit.

Types by design shape

Externally, the heating register does not look very elegant. But it is cheap and easy to make. And if you put in a little effort, then such a heater-heat exchanger can easily fit into the interior of even a living room.

In domestic village houses, until recently, a similar version of the heating system was used almost everywhere. In Soviet times, panel-sectional radiators were not available for sale, but a wide pipe was not so difficult to get.

And then all that was required was a welding machine. The resulting pipe heater is connected to the water heat exchanger inside the wood-burning stove by welding simply and quickly. Read more about the technology of replacing batteries using the gas welding method. Further.

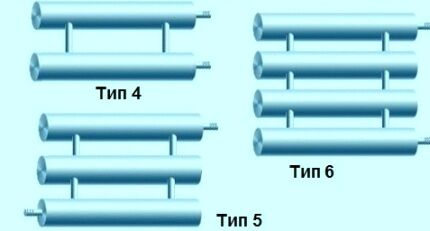

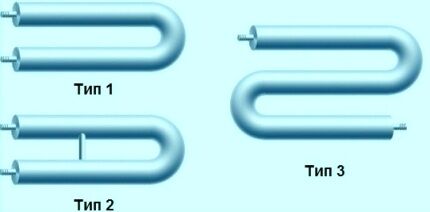

All types of heating registers are divided into two groups:

- Sectional.

- Coils (S-shaped).

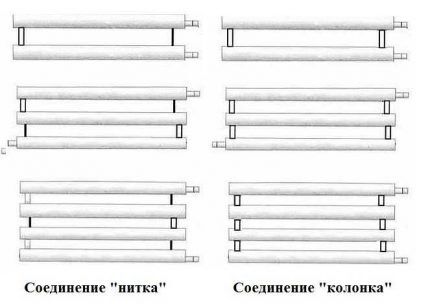

In the first case, horizontal pipes are connected to each other by transverse pipes of a smaller cross-section, and in the second - by arcs of the same diameter.

Both options involve large amounts of welding work. A coil device can also be made by bending one pipe.However, not every large-diameter steel tubular product can be bent in this way. It is much easier to take ready-made arcs and weld them to the horizontal segments of the register.

When connecting horizontal sections of a sectional register with a “column” connection, cross-bar pipes are welded at both ends. The circulation of the coolant in such a heating device occurs in a parallel circuit. As a result, certain zones in it may not receive enough heat. Hot water simply flows into the lower segment before it reaches the far end.

In the “thread”, where the coolant passes through all sections of the register, such problems do not arise. In this respect, this register is much like a serpentine. Only the water in it moves from the inlet to the outlet of the battery through pipes of different sections.

If there are no ready-made arcs for the S-shaped register at hand, then it is better to make a sectional device yourself. It is extremely difficult to bend a large cross-section pipe evenly without special equipment. Almost the only option is to heat the metal with gas welding and carefully bend it. But there is a risk of the pipe walls losing strength.

The sectional type also includes a register with a pair of side collectors. They are made from a pipe of the same diameter as the main sections, acting as transverse pipes. In this case, water does not move from top to bottom, but from left to right (or vice versa).

Material options

Most often, home craftsmen make heating registers with their own hands from steel pipes. The main advantages of this option are low cost, availability of material and relative ease of welding.

In factory conditions, registers are produced from:

- become;

- aluminum;

- copper;

- cast iron

Leads in heat transfer and durability copper option. But with large sizes, such a heater will cost a pretty penny. An aluminum device is inferior to it in terms of thermal conductivity, but also costs much less.

The most popular and inexpensive type of heating registers is steel. However, this is also the most inefficient option for transferring heat from water to air of all those sold in heating equipment stores.

The thermal conductivity coefficient of different steels ranges from 45–48 W/(m*K). For cast iron it is around 60, for aluminum it is 200–240, and for copper it is about 400 W/(m*K). Steel is inferior to all of them in this technical parameter.

Cast iron and aluminum are usually used only in the factory production of registers. It is too difficult to weld these metals independently in artisanal conditions. The same applies to stainless or galvanized steel, so it is better not to use pipes made from these materials. They are more difficult to cook, and their heat transfer is lower than that of their regular black counterpart.

If you have experience in welding copper surfaces, making a register from such pipes is not too problematic.Due to high heat transfer rates, they can be taken with a smaller diameter than when choosing a steel option. So the heating device will cost less.

However, copper has a serious drawback here - the need for a neutral and clean coolant. If “dirty” water with impurities circulates in the heating system, then you can forget about the long service life of such a battery.

A similar problem is also often observed due to the presence in the system of elements made of metals incompatible with copper. If a number of preventive measures are not taken, such a register will not last long due to electrochemical corrosion.

Devices with built-in heating element

The standard version of the register involves connecting it to the heating pipes of a centralized system or to a water heating boiler. But there are devices that are completely autonomous. In one of the lower pipes, a heating element is built into them, powered from a 220 V electrical network.

The power of the water heating element can vary between 1–6 kW depending on the internal volume of the heat exchanger. Such a heating device is often equipped with a circulation pump so that the coolant reaches all its areas.

Such an autonomous register is often used as an additional heat source, which is turned on only in severe frosts. When the temperatures outside are not too low, the room is heated from the general heating system. In addition to water, antifreeze can be added to the electric register.

There is an article on our website where we described in detail the features of the choice and subtleties of connecting heating elements for heating radiators. More details - go to link.

Heater design calculation

First you need to calculate the required heating power for a specific room.

According to the rules, such a thermal calculation should be done taking into account:

- area and orientation of external walls (in the southern sunny direction or not);

- cubic capacity of the heated room;

- the level of maximum possible negative temperatures in the region;

- degree of thermal insulation of walls facing the street;

- the presence of another heated room below and/or above;

- quantities, sizes and types of windows installed;

- presence/absence of doors opening directly to the street.

Building codes even recommend taking into account the prevailing wind rose in winter. On the windward side near the wall, heat loss during the winter period will obviously be higher.

If the ceilings in the room are located at a level of 3 meters or higher, then for a simplified calculation the cubic capacity of the heated space should be multiplied by 34 or 41 W. The first coefficient is taken for brick buildings, and the second for reinforced concrete buildings.

Multiplying a couple of numbers is not difficult. But we must be clearly aware that such conditional calculations can be very far from real figures, since there are many nuances here.

The best way out is to order the required calculation from a specialist who will take into account all the parameters of the room. Heat loss occurs through walls, windows, floors, ceilings and even ventilation.To obtain accurate numbers, everything must be taken into account without exception.

Next, you need to calculate the dimensions of the pipes for the heating register. To do this, use the formula:

Q= K* St*dt

letter designations:

- Q – thermal power of the register;

- K – heat transfer coefficient, depends on the pipe material;

- St – heat transfer area (equal to the number PI multiplied by the diameter and length of the pipe);

- dt – thermal pressure.

Accordingly, knowing Q and dt, all that remains is to select the diameter of the pipe and its total length. Then, depending on the design of the register, this pipeline can be divided into several sections, which will subsequently be connected by crossbars. In order not to complicate the calculations, it is better not to take into account the heat transfer from the latter.

When connecting pipes with a snake, each subsequent horizontal segment receives approximately 10% less thermal energy than the one located above. Each such section of the register pipeline should be considered as a separate battery. And as the coolant moves through them, it gradually and inevitably cools down, and the heat goes into the room.

Another parameter is the distance between the horizontal sections (main pipes), which reflects the height of the individual pipe. If this gap is made too small, then the heat flows from above and below will begin to overlap, negatively affecting each other.

This figure must be selected so that it is slightly larger than the diameter of the pipe. Then the efficiency of the register will be maximum possible.

For more detailed calculations of the power of heating batteries and their quantity, you can read Here.

Features of installation

There is nothing particularly difficult about installing a heating register. Difficulties are possible only when welding it from separate pipes. If you don’t have much experience in welding work, it’s better to practice first. When purchasing a ready-made, factory-made device, installation problems should not arise at all.

The pipe register is hung on the walls using powerful brackets (hooks). If it is placed on the floor, then iron legs will suffice. It is important to remember that the steel heater in question weighs quite a lot. Plus, the weight of the water inside is added, so the mounts and stands must be extremely reliable.

The ends of the pipe section are closed with special spherical plugs or welded using small steel rounds cut from sheet iron. Male threaded fittings for installing an air vent valve and connecting to the heating system are cut directly into the pipe walls or into the end plate.

The surface of a battery made of steel should be coated with heat-resistant paint. Thanks to it, the device will not only become more aesthetically pleasing in appearance, but will also acquire additional anti-corrosion protection.

Detailed instructions for creating heating registers with your own hands can be found in this material.

Conclusions and useful video on the topic

The video materials collected below will help you understand all the nuances of calculating the heating register and its installation in the room.

Technology for manufacturing a register from a profile rectangular pipe:

Advantages and calculation of heating register power:

If you need to heat a large room, then a register made of smooth-walled steel pipes is ideal for this.If you have the skill to perform welding work, it is not difficult to assemble such a homemade battery with your own hands. You just need to accurately calculate the parameters of this device and select the right pipe products for it.

Do you have any questions, found any shortcomings, or have valuable information that you can share with visitors to our site? Please leave your comments and ask questions in the feedback form located below the article.

That’s for sure, heating registers made from pipes are unrivaled in terms of heat transfer, according to my observations. Outwardly, of course, not everyone likes this, but for large premises, especially industrial ones, I have not yet seen anything cheaper and more effective. As for the appearance, by the way, if you have a designer flair, you can play it up very interestingly and even decorate it stylishly. This is especially true for lofts.

I installed heating registers made from pipes in my garage under the house. I can cook myself, there were large-diameter steel pipes, and I saw no point in spending money on buying new sectional batteries. The only problem was that I had to calculate the power, I called my father-in-law, he is my engineer, so in a couple of minutes he figured everything out in his head, calculated the footage, looked at my pipes and said - this is quite enough. I made it with a coil, it heats very efficiently, it’s warm in the garage in winter. Beauty!

This article about heating registers is really helpful. All important aspects, from types of structures to installation features, are discussed in detail. If you are looking for high-quality registers for your heating, I recommend visiting the site https://awstroy.ru/category/registry-otopleniya/. Good luck!