Replacing heating batteries with gas welding: review of work technology

When building a new house or during a major renovation of an apartment, you have to decide on the installation of new heating elements.Moreover, the problem here is not only in the choice of radiators and pipes through which the coolant will move, but also in the method of combining disparate parts of the structure into one reliably operating system.

There are several options for connecting pipes: replacing heating radiators with gas welding, electric welding or a threaded method. Although each technology has its pros and cons, most craftsmen still prefer gas welding. Why? Let's look at it in detail and with examples.

The content of the article:

Features of gas welding technology

The fastening of heating pipes by gas welding is carried out according to the following principle: the end parts of the two elements are combined, and then gradually heated in the gas-oxygen mixture to high temperatures.

For special weld strength, filler material in the form of wire or rod is used. When the hot metal cools, a monolithic joint is formed.

Advantages and disadvantages of joining pipes by welding

One of the main reasons for the popularity of the gas welding method is the specific operation of our heating systems. When circulating coolant all structural elements are constantly under pressure, deforming the joints.

Therefore, a strong weld seam reliably protects against breakthroughs and helps prevent accidents during short pressure surges and even water hammer, which often accompany the startup and shutdown of central heating.

Advantages of the gas welding method:

- Durability and reliability of the connection (it is believed that the strength of the seams after gas welding even exceeds the strength of the radiators themselves!).

- Possibility of using parts of any shape and size. The only requirement is that the elements be made of metal with a thickness of no more than 3.5 mm (if this is exceeded, it is more economical to use electric arc welding).

- Aesthetic moment - pipes and batteries welded by gas welding become a solid monolith, which easy to repaint in a color suitable for the interior.

- You can carry out work without connecting to the electrical network (especially important for a new building).

- Many metals from which pipes are made, such as copper, cast iron, brass and lead, form the strongest joints using gas welding.

The main disadvantage of this installation method is the large heating area. As a result, it is easy to damage furniture and flammable finishing materials, such as parquet, wallpaper, plastic wall panels, chipboard or MDF.

To avoid destruction, it is recommended to remove thermally unstable elements from the work area, and cover immobile elements with asbestos sheeting or other protective material.

In addition, gas welding releases substances into the air that are harmful to health; working without special protective equipment is strictly prohibited. That is why everyone who wants to master a gas welding machine in practice must study the safety rules and obtain permission to work.

Restrictions on working with a gas welding machine

Installation heating system gas welding is only allowed to be carried out by professional welders who, in addition to special education, have permission to carry out work from the fire service.

Please note that the document is issued only for a certain period, so when hiring a specialist, you should not just look at the “crust”, but also study its validity period.

Other mandatory requirements for welders: the working order of the gas apparatus and mandatory protective equipment - goggles, work gloves, a shield.

It is advisable that the master use filler wire for seams and modern equipment operating on a mixture of oxygen and acetylene. Other flammable gases, such as methane or propane, are acceptable provided that their combustion temperature is twice the melting point of the filler rod.

If you are not a professional gas welder, you can contact local heating networks or the organization that manages the house to carry out the work.To do this, the owner of the apartment draws up a statement about the need to replace the batteries and agrees on a date to shut off the flow of coolant in the common building main.

After welding and installation of radiators, the invited master must carry out crimp test and make sure the system is working properly. It is strictly prohibited to independently stop and start heating in apartment buildings.

Differences from other installation methods

An alternative for connecting pipes when replacing batteries is the threaded method. It is especially popular among home craftsmen who do not have in their arsenal such expensive equipment as a gas welding machine and the skills to work with it.

In this case, system assembly and installation selected for battery replacement carried out using threaded threads and special connecting elements - tees, fittings, nuts and other adapters.

The main (and perhaps the only) advantage of the threaded method over the gas welding method is the ability to assemble the system quietly and without fire hazards with your own hands, without resorting to the expensive services of professional craftsmen. And such a structure can be disassembled in the future if there is a need to clean or replace any element.

But the assembly process requires detailed study, precise fitting and correct selection of all connecting elements. And even if you manage to do everything correctly and start the system, over time it will still fail.

As a result, water will quickly find “weak spots”, undermine the sealing gaskets and break through. Therefore, in high-pressure lines, threaded connections quickly “give in” under the pressure of water hammer.

Another popular alternative to gas welding is electric heating. Both technologies work on a similar principle - heating to the melting point and joining metals. At the same time, electric welding is a little cheaper, and the scale of “destruction” after such work is small, since the heated area of the electric device is much smaller.

But despite these advantages, gas welding has an important feature - the ability to regulate the melting rate by changing the flame angle. Unlike almost instantaneous heating by electric welding, gas technology works gradually, without disturbing the structure and strength properties of the metal.

That is why gas welding is by far the leader when choosing a method for replacing batteries among those who like to make repairs efficiently and reliably.

Requirements for the process of replacing radiators

Modernizing home heating is impossible without preliminary calculations and selection of batteries suitable for the design. Moreover, it is not at all necessary to replace old radiators with identical ones.

It makes sense to consider models made from other materials and add/reduce the number of sections. But here it is important to follow the rule of the “golden mean” and calculate the power of the heating system in order to obtain maximum efficiency at a minimum cost.

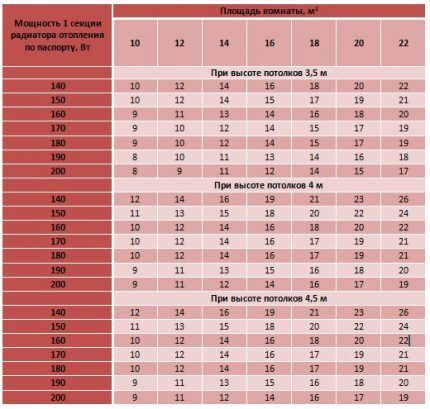

Find out the right size, working battery power and number for a room there are several ways. The simplest option is applicable for rooms with a ceiling height of 2.4-2.65 m. To calculate the sections, you should find out the area of the room and multiply by 100 W (calculated power for heating 1 m2 according to building codes).

The resulting figure must be divided by the heat transfer of 1 radiator section, which can be found from the product data sheet (standard value - 170 W) and rounded up to the nearest whole number.

For rooms with high ceilings it will be better to use volume calculations. To do this, you need to multiply the area of the room by its height, and then by the recommended thermal power indicator for your home (in a panel building it is 41 W, for a brick building - 34 W).

It remains to divide the resulting value by the same efficiency of one section, then round the figure. Of course, such calculations can only be averaged.

For more accurate indicators, a number of individual factors should be additionally taken into account:

- climate typical for your area;

- number of floors and location of the heated room;

- the number of windows and the quality of their glazing (plain glass or energy-saving packages);

- the presence of a balcony or loggia adjacent to the room;

- internal or external insulation of the apartment.

It is also important to determine whether it is planned installation of decorative screens, which many people use to cover radiators when decorating the interior.

As for the materials from which radiators are made, the most popular options today are: steel, aluminum, copper, bimetallic (an alloy of several metals) and time-tested cast iron appliances. Each of them has its own nuances and advantages, but the main thing is that they are all available for installation using gas welding.

Basic steps for replacing batteries

To dismantle radiators in an apartment with an open heating system, you must obtain permission from the local housing office and heating networks. Separately, you need to coordinate the modernization of the design, for example, if you plan to move the batteries to another location, add or remove several sections.

Welding work, as already mentioned, is allowed to be carried out only by specialists with clearance and professional education - independent initiatives can result in a hefty fine. Therefore, we will consider the main stages of the upcoming repair to avoid unpleasant surprises.

Carrying out preparatory work

To begin with, it is worth minimizing the possible consequences of the operation of the gas welding machine. Furniture close to radiators must be removed or covered from possible damage. Also protect the area of the floor and wall adjacent to the battery.

Then the water is drained from the heating system. If we are talking about a private house or other room with autonomous heating, a special tap is used, which must be provided for during the design.

In an apartment with central heating, you cannot turn off and drain the coolant from the system yourself - you should call a specialist from a service organization. Next, you need to disconnect the expired radiators. The easiest way to do this is with a grinder.

But even here you will need good skill in working with tools, because in order to connect new heating devices with a minimum of effort, it is important to make a neat and even cut.

Assembling a new structure

Next, the new radiator is packaged. If you want to save on the services of craftsmen, it is quite possible to do this work yourself.

Required materials and tools:

- Set of nuts (for radiators).

- American ball valve.

- Mayevsky crane.

- Adjustable wrench.

- Packing paste.

- Sealant (linen or fum tape).

To assemble the battery, you need to seal the nuts, treat them with paste and screw them onto the pipes at the joints. The radiator layout is completed by installing the taps.

An “American” is installed on the side of the connection with the heating system in order to be able to block the access of the coolant to a specific battery. From above, on the opposite side from the pipe entrance, a Mayevsky tap is screwed in with a wrench, with the help of which it will be possible to remove “plugs”, releasing air accumulations from the system.

Gas welding connection

The assembled radiator is suspended in place of the old battery using special fasteners, and the evenness must be checked with a building level. Before starting welding, thoroughly clean the ends of the elements to be joined from dirt, dust and degrease.

Next, the inlet and outlet pipes are welded with a adjusted slope, which helps prevent the formation of air pockets. To do this, the connecting section is heated with a burner, while simultaneously using filler wire to fill the gaps between the fragments of the system.

The type of seam and heating rate are chosen by the master, based on the wall thickness, pipe material and other professional nuances.

Seam cleaning and finishing

After the work of a gas welder, the pipes look unaesthetic: black marks and stains are unlikely to decorate the interior. But this is a fixable matter.

To process the welding site, you need to follow the following algorithm:

- Clean the pipe with 3 or 4 grit sandpaper. If the welder does not work carefully, there may be a thick bead at the joint, which some try to level with the same grinder. But you shouldn’t do this - you can damage the strength properties of the seam.

- Dust the pipe - wipe with a damp and then a dry cloth.

- Degrease with white spirit.

- Coat with anti-corrosion primer in 2 layers.

- Paint with heat-resistant enamel also in 2-3 steps (the lighter and more transparent the paint, the more layers may be needed to mask the black color).

Of course, all painting work should be carried out before connecting the system, on cold pipes.If the batteries were replaced during the heating season, you need to shut off the access to the coolant and wait until the system cools completely.

You can decorate only the pipes or the entire structure complete with the radiator. The color is usually chosen white, silver, bronze or to match the tone of the walls. But for some interior styles, you can also use a contrasting shade, for example, dark chocolate, glossy black or spectacular red.

Open the system and fill the circuit with coolant This is possible only after the paint has completely dried.

Conclusions and useful video on the topic

And finally, we suggest you study our selection of videos for a visual representation of the specifics of the upcoming work and the important nuances that you should know when replacing batteries.

Video recommendations for choosing the optimal time of year to replace heating appliances:

This video instruction will help you visually study the process of installing a bypass using gas welding using filler wire:

The video presents an example of professional installation of heating pipes and radiators using gas welding and a pipe bender:

Replacing radiators using gas welding is a reliable way to protect your home from possible leaks in the heating system and the consequences of water hammer.

But in order for the work to be done efficiently, it is important to entrust it to a specialist with good experience and modern equipment, because an incorrectly or carelessly welded seam can lead to an accident in the next heating season.

Please leave comments in the block below, post photographs related to the topic of the article, and ask questions. Tell us how you carried out gas welding work when installing new heating appliances in your apartment/office/house. Share useful information on welding technology with site visitors.

Yes, welding, of course, is the best connection option, because... really gives the most reliable result, and no connectors are visible, as is the case with the threaded version. But I noticed that in most modern apartments, most radiators are connected through threads. And the reason is simple - it’s cheaper. We can only hope that the connections are made professionally and nothing will break through anywhere.

I don’t know, on the contrary, I see welding in almost everyone. Twists often look unsightly, unlike welding. Although, again, it depends on skill. And welding can make an unsightly seam. But I'm still for her.

Andrey, I think the point is that a welding machine is not needed for threaded connections. You can change something in the system yourself with minimal skills. And welding is for installation from scratch.