Types of heat guns + review of offers from leading manufacturers

A heat gun is an indispensable assistant for private homeowners, as well as a tool for solving many repair, construction and production problems.The unit raises the temperature in a matter of minutes and helps lower the humidity.

In order for the heat generator to cope with the tasks and not cause trouble, it is necessary to understand what types of heat guns are advisable to use in different situations. The main selection criterion is the method of heating and heat transfer.

We propose to understand how different types of heaters are structured and work, what are their strengths and weaknesses. Understanding the operating features of heat guns will help you decide on the model and not be disappointed in the purchase. To make the choice easier, we have prepared a review of the best heat generators from reliable manufacturers.

The content of the article:

Basic device and principle of operation

A heat gun is a mobile air heater for premises for various purposes. The unit is primarily used for two purposes. The first task is to organize local heating of exhibition halls, trading floors, warehouses, garages and pavilions.

The second purpose is to quickly dry individual elements during technological operations, for example, fastening French ceilings or performing interior decoration in winter.

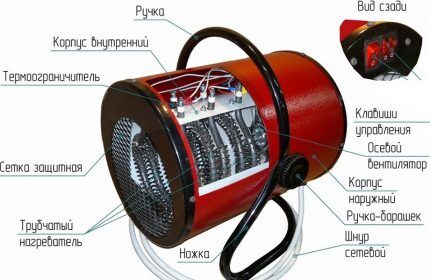

All components are assembled into a durable metal case, equipped with grilles for cold air intake and hot air exhaust. A heating element, an open spiral or a fuel tank with a heat exchanger is used as a heat-generating unit.

Operating principle of the fan heater:

- The “gun” captures air currents and passes them through the heater.

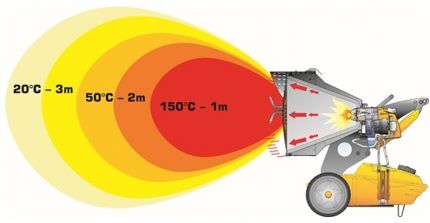

- Hot masses are pushed out through the nozzle, distributed throughout the room.

The operation of the mechanism is similar to a regular fan. The only difference is the parallel connection of heating elements supplying warm air.

Classification of units by type of energy carrier

Like any device, heat guns have a number of criteria for differentiating the range of products. According to the scope of application, household and industrial fan heaters are distinguished.

A distinctive feature is the power and limiting heating temperature of the heat-generating unit. It is clear that these parameters for industrial models exceed those of household guns.

A more extensive classification is based on the type of energy source. It is the energy carrier that largely determines the design and functional features of the unit, as well as the specifics of its application.

Electric guns – versatility of use

The electric group of heat fans is acceptable for use in residential, commercial, and office premises as an additional source of heating. Electric models often turn out to be indispensable when performing repair and finishing work to quickly reduce humidity.

Heating elements are distinguished by their efficiency and degree of safety:

- Spiral. Heats up quickly and maintains the set temperature well. Disadvantage: fire hazard.

- heating element. The tubes accumulate and burn less dust compared to an open spiral. However, the heating element is more inertial - it heats up more slowly and gives a lower outlet temperature. Significant advantages: safety and durability.

Electric “heat guns” are equipped with a thermal limiter - the element prevents overheating of the unit and helps save energy. When the user-specified temperature is reached, the thermostat turns off the heating element.

Depending on the power, the electrical appliance is connected to a two- or three-phase network. When choosing a heat generator, it is necessary to take into account the electrical wiring capabilities.

Optimal operating conditions electric models: temperature from -10°С to +35°С, humidity – up to 70%.

The main advantages of “electric guns” include:

- environmental friendliness – no harmful waste is released into the atmosphere during operation;

- compactness and mobility – the weight of a household model is about 4-8 kg, small dimensions allow the fan heater to be used in small rooms;

- continuity of operation – there is no need to refuel the unit;

- versatility applications.

Despite the durable body and the presence of grilles, the working parts of the device are poorly protected from dirt and moisture.An additional disadvantage is the increased energy consumption when heating unheated buildings.

Gas modifications - high performance

Gas heat guns are characterized by high performance at moderate operating costs. Options for consumed fuel: liquefied bottled gas (butane/propane) or natural gas from the central line.

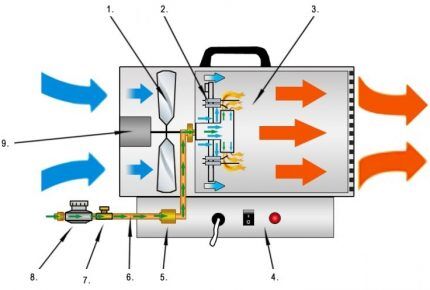

To avoid excessive gas evaporation and possible explosion, a reducer is provided between the burner and the gas cylinder. Its purpose is to ensure the conversion of liquefied fuel into a gaseous state and control the supply of gas fuel to the burner nozzle.

The operation of the heat generator requires electricity to power the fan. The power of the device determines the volume of pumped air. The indicator is 30-200 W.

The gas unit operates on a similar principle to its analogues:

- Gas is supplied through the reducer.

- Passing through the holes in the burner, gaseous fuel enters the combustion chamber - here a mechanical or automatic piezo ignition system is activated.

- When burning, the gas gives off heat to the heat exchanger.

- The air flows forced by the fan pass along the hot walls of the heat exchanger and heat up.

Gas modifications are divided into two groups: stationary and mobile. The former are connected to a common gas pipeline, the latter are powered by a cylinder.

Advantages of gas fan heaters:

- high efficiency – waste-free combustion of gas;

- economical heating spacious premises - gun productivity up to 250-300 sq.m.;

- ability to work in high humidity - the mechanism elements are protected by a case made of anti-corrosion metal;

- minor waste release during combustion - use in public places is permissible provided there is good ventilation;

- fuel availability — purchasing natural gas will be relatively inexpensive.

Despite the presence of overheating protection and a built-in flame control system, gas thermal guns belong to the category of potentially dangerous units. In addition, oxygen burns out during operation of the fan heater. The listed reasons explain the limited use of gas models in residential premises.

Gas-powered guns are popular in the agricultural sector, at construction sites and in semi-open, open-type production areas.

Diesel guns of direct and indirect heating

The scope of application of diesel heat generators is similar to the scope of gas modifications. However, diesel fuel guns are not suitable for heating residential premises. The limitations are due to excessive power and the need to arrange a chimney.

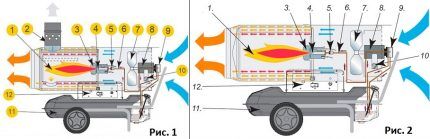

Direct heating. A simple unit with an open combustion chamber. The center of the heat generator is a pump with a nozzle that supports the combustion of the torch. Behind it is a powerful fan.

The heated air crosses the combustion chamber and is supplied to the atmosphere. Along with it, the remaining combustion products of diesel fuel enter the room. Being near such a unit is equivalent to standing at the exhaust pipe of a car. Even with active ventilation, a burning smell remains, causing dizziness and poisoning.

Indirect heating. The design includes a pipe for the emission of combustion products. The nozzle is located in a closed “combustion chamber” with a chimney.

In indirectly heated heat guns, the injected air masses do not intersect with the burning torch - the flame blows around the combustion chamber. In turn, soot and fumes are discharged outside through the chimney, bypassing the room.

Manufacturers of liquid fuel guns recommend using diesel fuel and kerosene for refueling. To avoid breakdowns and explosive situations, it is prohibited to use: gasoline, naphtha, alcohol and other flammable substances.

Strengths of diesel heat guns:

- high efficiency – efficiency up to 100%;

- efficiency — minimal energy consumption;

- compactness — small installation dimensions and ease of use;

- moderate fuel consumption – a 10 kW model burns 1 liter of diesel per hour;

- continuous operation time – about 10-12 hours;

- wide selection of units different capacities - from compact units of 10-30 kW to highly productive heat guns of 200 kW;

- speed of heating — the gun quickly warms up the room.

Like any type of heat gun, diesel heat guns are not without shortcomings.

Main disadvantages:

- energy dependence;

- noisy work;

- release of toxic substances hazardous to humans;

- spreading the smell of diesel fuel.

Diesel units are more expensive than their electric and gas counterparts.

Multi-fuel guns - waste oil recycling

Structurally, the combined units are similar to diesel guns. But multi-fuel devices are capable of operating on different fueling materials: diesel fuel, kerosene, liquefied/natural gas, waste gas (motor, hydraulic oil).

The varied “absorption” of fuel makes combined guns very popular for heating car repair shops, garage cooperatives, and technical stations. At the same time, two problems are solved: waste disposal and room heating.

Multi-fuel units come in direct and indirect action with similar technical and operational nuances as their diesel counterparts.

The thermal gun switches from one fuel to another manually - the equipment is equipped with several burners of different characteristics.

Features of operation of heat generators on the return:

- combustion of oil vapors is accompanied by heat release with the formation of slag and soot;

- the guns have significant dimensions and require a stationary floor installation;

- Operation of the gun is possible with the installation of a gas exhaust system to remove carbon dioxide.

The efficiency level reaches 98-100%, the operating period without refueling is 15-24 hours.

Features of infrared “fan heaters”

IR guns differ from their predecessors in their operating principle. The generated heat reaches surrounding objects not through directed air flows, but through radiation. To operate, the equipment is connected either to an electrical circuit or to a gas cylinder.

There is no fan in the design; heat transfer occurs thanks to the emitter – flamentin. The heating element is a spiral made of an alloy of different metals, enclosed in a quartz glass tube. When heated, tubular heating elements generate infrared radiation.

Behind the heating element there is a reflector - a mirror reflector focuses infrared rays in the desired direction and prevents heating of the internal mechanisms and gun body.

The pros and cons of the device largely depend on the type of thermal energy generator - an electric heating element or a liquid fuel burner.Each model has distinctive features of an electric or diesel gun, respectively.

Compared to “fan” models, IR heaters do not create drafts and operate very quietly. The disadvantage is the low heating rate of the entire room.

Water appliances – operational safety

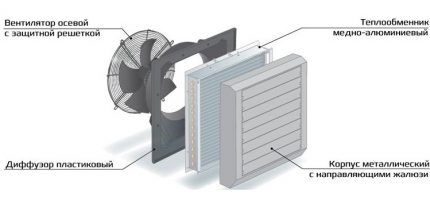

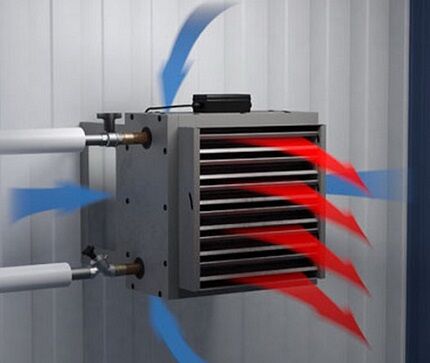

In a water fan heater, the role of the heating element is assigned to a heat exchanger with a heated liquid. The gun shell is made of stainless steel and covered with a polymer layer. This “sandwich” provides degree of protection housings – IP44.

The “hydraulic gun” is connected to heating or hot water pipes. The model resembles a traditional water heating radiator, the only difference is the presence of an electric fan.

The operating diagram of the device is quite simple:

- Cold air is drawn in through the rear grille.

- In the heat exchanger, the air masses are heated and fed back into the room through the front mesh.

To regulate the fan speed and heating intensity, three- or two-way valves are installed on the supply line. The heat transfer of the device depends on the number of fins on the external grille - the more there are, the better the heat transfer.

The main advantages of the hydro-gun: environmental friendliness, safety, economical consumption of energy resources. The disadvantage is the duration of heating the room.The water unit is mainly used as an additional means of heating in residential and office buildings, as well as greenhouses and greenhouses.

Assessing the capabilities of the best heat generators

The heat gun market is stable. The leaders in the segment of electrical modifications are the products of the companies Ballu, Sturm, Quattro Elementi, Novel. Among diesel and gas guns, brands have proven themselves well Master, Elitech And Prorab.

When purchasing, special attention should be paid to the power, degree of safety, conditions of use and cost of the unit.

Electric guns from leading manufacturers

The ranking of the best electric fan heaters includes Ballu BKX5, QE-2000C from Quattro Elementi and KEV-24 from the domestic brand Novel.

Ballu BKX5. The device is equipped with a metal-ceramic heating element, an impact-resistant steel case and a dust- and moisture-proof switch for selecting the mode.

Disadvantages: short cord, annoying noise, unpleasant smell when first started. Price BKX5 – 50-60 USD

QE-2000C. Household mini-gun for servicing premises up to 20 sq.m. It can operate in 2 modes, maximum power is 2 kW.

Thanks to the QE-2000C thermostat, it automatically maintains microclimate parameters.Estimated cost – 30 USD

KEV-24. Electric gun with increased heating power and air flow intensity. Field of operation: industrial, construction sites and industrial buildings.

Gas models of various capacities

Popular gas guns: Elitech TP/30GB and Master BLP/53M.

TP/30GB from Elitech. A profitable option for heating large areas up to 200 sq.m. The unit is only suitable for use in well-ventilated buildings. Operating conditions: floor installation, supervised operation. The gun is equipped with electronic ignition and a grill on the nozzle to protect the internal mechanism.

Master BLP. Premium class device for industrial use. Housing with increased thermal insulation and anti-corrosion coating. A high degree of protection allows the gun to be used in a humid environment. If there is no fire or overheating, the electronic system will stop supplying fuel.

Diesel guns for industrial purposes

Powerful models for quickly heating large volumes of structures.The rating includes direct action guns from Prorab and Resanta.

Prorab DP50. High-performance model from a popular company. Recommended heating area – up to 500 sq.m. The gun runs on kerosene and diesel fuel.

TDP-2000 from Resant. Optimal for heating buildings – 100-150 sq.m. The multi-fuel model runs on diesel or kerosene. The gun is equipped with a large tank that ensures a long operating cycle.

If you want to save money, you can try to assemble a heat gun yourself. On our website there is a block of articles with a detailed description of the manufacturing technology of different types of heat generators.

We advise you to read:

- DIY diesel heat gun: instructions for making a homemade product

- Do-it-yourself heat gas gun: step-by-step assembly instructions

- Do-it-yourself electric heat gun: pros and cons of homemade products + assembly guide

- DIY waste oil heat gun: step-by-step manufacturing instructions

Conclusions and useful video on the topic

Detailed video instructions for choosing a heat generator. Features of the operation of different types of guns, comparison of the main technical parameters:

The primary criterion for choosing a heat gun is the type of energy carrier. The power of the device and the specifics of its application depend on the heating method.

In everyday life it is better to use safe electric models, for production purposes - diesel, gas and multi-fuel units. Water cannons can act as a secondary source of heat.

Share with readers your experience of using heat guns. Tell us what the choice of unit was based on, and whether you are satisfied with the purchase. Please leave comments on the article, ask questions and participate in discussions. The contact form is located below.

I would highly recommend this heating option only for a country house, where people visit quite rarely, but it needs to be warmed up quickly. But with constant use, such guns not only heavily load the electrical network, but also significantly dry out the air. Therefore, such an option for heating a house borders on some extreme moment when the need for a gun appears.

Sometimes, especially in winter, there is severe dampness in the house; this is due to the fact that natural ventilation cannot cope with the removal of condensate. Mold forms in downwind corners. To dry it thoroughly, I use an old gas gun. It only takes 15 minutes to completely warm up the room and eliminate dampness. I wouldn't say that too much gas is spent on this. So it's a necessary thing.