Heat guns using waste oil: analysis of types + instructions for making your own

A quick and simple method of increasing the temperature in a room are various types of large heating units, which include waste oil heat guns.

Such devices, which make it possible to heat even large spaces in a short time, are especially often used for heating workshops, garages, auto centers, and other office and industrial premises where a large amount of waste accumulates.

In this material we will consider in detail the principle of operation of heat guns and their varieties. We will also list several popular equipment manufacturers and tell you how to make a heat gun with your own hands.

The content of the article:

- General operating principle of guns

- Main characteristics of the device

- Required power indicator

- Features of heat guns during testing

- Types of used oil units

- Advantages and disadvantages of guns during testing

- Do-it-yourself gun being tested

- Manufacturers of heat guns in development

- Conclusions and useful video on the topic

General operating principle of guns

The designation “heat guns” refers to mobile heat generators capable of quickly delivering large amounts of heat.

Such devices received this name both for their specific oblong shape and for the powerful stream of heated air emerging from a specially designed hole.

The operating principle of various types of such devices is as follows:

- The main component of such devices is the heating component (heating element, burner). It is housed in a metal case. The device begins to generate heat only after it is turned on or ignited.

- A powerful built-in fan drives a stream of air through the interior, the temperature of which rises upon contact with the heating component.

- The hot air mass is forcefully pushed out through the gun nozzle, thanks to which even a large room can be heated in a few minutes.

Various fuels can be used as fuel for guns: electricity, hot water, diesel fuel, liquefied gas, waste mineral and biological oils. Depending on the fuel used, the designs of the models may differ slightly from each other.

Main characteristics of the device

High-quality heat gun models are characterized by the following characteristics:

- strength and reliability in operation;

- resistance to mechanical damage, temperature changes, and corrosion;

- water resistance, due to which such heaters can be used for heating spaces with high air humidity;

- durability - with proper operation, devices can serve for 5-10 or even more years, without requiring special maintenance or repair work;

- large model range; Manufacturers produce both small mobile heat guns used for domestic purposes and large stationary devices that are useful for heating large spaces, such as production workshops or warehouses.

It should be remembered that heat guns should be used in ventilated rooms with an air supply system or with the possibility of regular ventilation.

Required power indicator

The main indicator of a device is its power, since the effective functioning of the device depends on it.

To determine the required heat transfer of the device, it is important to simultaneously take into account a number of indicators:

- The volume of heated space, to calculate which it is enough to multiply its parameters (height, width, length).

- The difference between the temperatures inside and outside the room.

- Heat loss coefficient, the value of which depends on the thermal insulation of the room. The average value of this indicator is 1-2, while an uninsulated building has a coefficient of 3-4, and a well-insulated house has a coefficient of 0.6.

The minimum value of the required power, indicated in kilocalories per hour, can be obtained by multiplying the above values.

To convert a certain number to kilowatts, simply multiply the number by a factor of 0.001163. This value must be kept in mind when choosing a ready-made device in a store.

Features of heat guns during testing

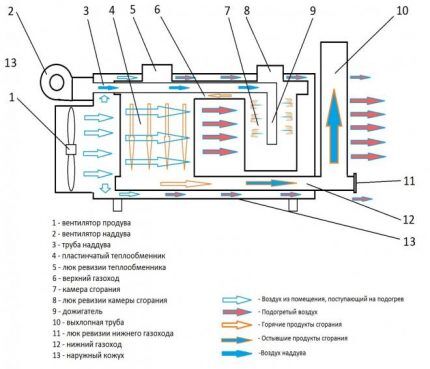

The design of units operating on waste oils is generally similar to other types of guns. Their feature is a burner with an equipped combustion bowl, to which fuel (motor or other oil) is supplied using a rotary pump.

Under the influence of heat, flammable substances burn, releasing heat and combustion products, which are discharged outside the room through a chimney specially designed for this purpose.

Different models may have their own design features. Some have two fans, one of which heats the combustion compartment, the other supplies fresh air to the chamber. Others use a remote oil pump, through which fuel enters the combustion chamber.

Oil cannons are considered safe for use by people and pets. They can be used for heating garages, warehouses, greenhouses and other premises. No permit is required for their use, but when using them, fire safety regulations must be observed.

Types of used oil units

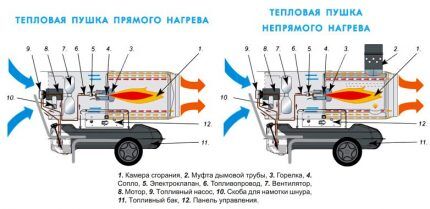

Similar to gas and diesel guns, mining devices can be of two main types: direct and indirect.

For models of the first type (direct heating) inside the cylinder body there is a round gas burner, which is blown from all sides by an air flow flowing from the fan. The heated air mass, together with combustion products, is released through a pipe located on the opposite side of the gun.

Since gaseous waste contains substances harmful to the health of people and animals, it is recommended to use cannons only in well-ventilated spaces. Direct heating devices can be used to maintain a comfortable temperature in unoccupied areas: buildings, garages, workshops.

Designs of heat guns of the second type (indirect heating) are equipped with a built-in system that allows the separation of flue gases released during oil combustion. At the same time, the heat from them is transferred to the air blown by the fan, which accumulates in a heat exchanger provided for this purpose, which avoids direct contact between the gas and air masses.

The latter, after heating, leave the heat exchange chamber through a special opening equipped in the housing, while combustion products leave the gun through the side pipe, which is connected to the chimney pipe.

Indirect heating models are environmentally friendly; when used, no harmful gases enter the room, and there are no odors, making such devices suitable for heating rooms in the presence of people.

All heat guns in testing can also be divided into the following categories:

- Stationary – high-power devices that are installed in one place and connected to the chimney.

- Mobile – compact devices that can be moved around the room. As a rule, they have direct heating and low power, since devices with large-scale heat transfer emit a lot of combustion products.

Devices operating on waste oils vary in size, shape, design, and the presence of additional functions.

Advantages and disadvantages of guns during testing

Oil heating devices have their positive and negative sides. Guns of this type have many advantages.

They universal: thermal units can operate not only on mineral oils (thermal, motor), but also on other types of fuel, for example, biological oil or a mixture of flammable substances. Only the use of transformer and other oils whose density exceeds 90 on the SAE scale is not allowed.

They cheap: waste mineral or biological oil, which is used as fuel for similar models of thermal heaters, cannot be recovered and is a production waste. It can be purchased at a minimal cost.

The devices have high efficiency. The efficiency of modern models of thermal devices can reach 100%.

When using indirect heating models, the device does not emit unpleasant odors, soot and soot, so the air in the room always remains clean.

But when fuel burns in appliances, carbon dioxide is released, the amount of which depends on the power of the appliance. Due to the high CO content2 in exhausts, guns with high heat transfer are desirable to be “tied” to chimneys through which combustion products are discharged, so high-power models are almost always stationary during testing.

Do-it-yourself gun being tested

The design of a heat gun is quite simple, so if you have certain operating skills, you can try to assemble such a unit yourself.

Homemade heater device

To make the device yourself, you can use a simplified diagram of a heat gun. At the bottom of the structure there is a fuel tank, above which there is a fan and a working chamber. The latter is supplied with fuel, while the fan pumps hot air into the room.

In addition, the device contains a pump, a filter and a connecting tube through which fuel passes, a nozzle for the release of combustion products, a pipe for heated air and a number of other elements.

Required parts and materials

Before starting work, you should stock up on materials or ready-made components of the device.

Heat gun body, for which it is necessary to use thick-walled metal. For example, a suitable sized section of pipe or other suitable product can be used as this part. You can also make the body from a thick stainless steel sheet (3-4 mm) by welding the seam.

The combustion chamber. This part is suitable for a metal cylinder, the diameter of which is half that of the body.

Fuel tank. This element is a bowl made of a material with low thermal conductivity. An ordinary metal tank, carefully covered with a heat insulator, will also work.

Fan. To ensure a simple and reliable design, it is preferable to use a reliable and economical 220 volt impeller fan, which is easy to use and durable.

There are several articles on our website in which we examined in detail how to build a heat gun with your own hands. We recommend reading them too:

Installation of the device during testing

First of all, you should take a pipe, cylinder or other outer shell of the device.

- At the bottom there is a heater and a fuel tank, which must be separated from the top of the device at a distance of 15 cm. To make this part of the device look neater, it can be hidden in a metal box.

- A combustion chamber is installed in the center of the free space, for which a galvanized pipe can be used. The compartment is sealed on both sides, after which holes are made in it for the nozzle and smoke exhaust. The combustion chamber is firmly fixed to the walls of the housing. It is advisable to equip the working compartment with a piezo ignition, and also connect a fan to it.

- Next, you need to install a fuel pump with a nozzle, adding a filter between these parts. It is also important to organize an outlet pipe from the tank, through which the waste will flow to the fuel filter and injector.

- It is also necessary to resolve the issue of the fan's power source. If there is an electrical outlet within reach, this item can be plugged into an outlet. If it is not available, you will have to use a battery.

Finally, you need to cover the holes located at the top with nets.

Tips for using heat guns

Experts recommend paying attention to the following points when producing heating devices:

- When operating the device, you should follow safety rules: remember that at a distance of 1 meter from the device, the temperature of the heated air stream can reach 300 °WITH.

- To warm up a room of 600 square meters, only 10 liters of fuel are enough.

- It is necessary to clean the evaporation bowl, removing slag from the waste, once after 20-50 hours of operation of the device.

- Water should not be allowed to enter the fuel cell along with used oil or other types of fuel. If a large amount of this liquid gets into the tank, the burner may go out.

You should also not forget about fire safety rules: it is better not to leave homemade heating devices unattended, and also to have a fire extinguisher or other device for extinguishing a fire within reach.

Manufacturers of heat guns in development

On sale you can find ready-made models of devices that operate using waste oil.They differ from homemade devices in their aesthetic appearance, high efficiency, energy intensity, and high technical characteristics.

Modern models are equipped with electric ignition and automation, thanks to which you can regulate the fuel supply, turn off the device urgently in emergency situations, set different thermal conditions, and adapt the unit to work on different types of fuel.

Devices operating on waste oils are produced by companies located in Europe, the USA, and Asia. Let's name just a few reputable manufacturers and their top models.

Kroll - truly German quality

The well-known company, founded more than 30 years ago, is considered one of the world leaders in the field of heating equipment (burners, dehumidifiers, heat guns, generators).

Products of this brand, which have all the necessary Russian and European quality certificates, are safe, economical, reliable in operation, and also have an attractive design.

Master is a company with half a century of experience

A well-known American manufacturer, one of the leaders in sales of thermal equipment, especially heat generators. The technical parameters of the proposed devices demonstrate record performance in the industry, at the same time, almost all options are compact and portable.

The MASTER WA line combines a series of economical devices that can operate on almost any type of spent fuel: motor and biological oils, hydraulic fluid. The power of the models included in the series varies from 19 to 59 kW, thanks to which you can easily select a device for heating a space of a certain area.

EnergyLogic - waste oil heaters

The American company, with 30 years of experience and dozens of patented innovations, places special emphasis on the production of boilers, burners, heaters and other equipment that runs on waste oil.

The products are mainly made of stainless steel, which is resistant to corrosion and has excellent ability to withstand high temperatures. In this case, standard parts widely available on the market are used, which facilitates operation, simplifies installation and maintenance.

Hiton - budget devices

Polish company founded in 2002.

The company specializes in the production of eco-fuel heating devices, including heat generators and heat guns running on waste motor oil.

Drip-type heaters of this brand HP-115, HP-125, HP-145, HP-145R can operate on waste mineral oils, diesel fuel or a mixture of these two types of fuel, as well as vegetable oils.

Conclusions and useful video on the topic

In the video below you can see detailed instructions on how to independently create a heat gun that works during mining.

A self-made or store-bought waste heat gun will allow you to significantly save money on the energy source when using an essentially waste product - used motor oil.

When operating the unit, you should remember that it can become a source of fire, so it is advisable to follow all fire safety rules and not leave the device unattended.

Can’t decide on the choice of heat gun or still have questions about building the device yourself? Please leave your comments, share your experience, and ask questions in the block below.