Diesel heat gun of direct and indirect heating: device, principle of operation + review of manufacturers

With the onset of cold weather, the heating issue has to be solved not only in houses and apartments, but also for various industrial premises, construction sites, garages, warehouses, hangars and other non-residential facilities.

And one of the options for heating devices that attracts consumers with its affordable price and portability is a diesel heat gun. Therefore, let us consider in more detail the operating principle of this device, its scope of application and the main selection criteria.

The content of the article:

Design differences between diesel guns

The main purpose of heat guns is to quickly and economically heat large areas. They run on diesel fuel, the combustion of which releases heat, which is distributed throughout the object by a directed air flow.

According to the design principle, all diesel guns can be divided into direct and indirect heating devices.

Heat generators with direct heating

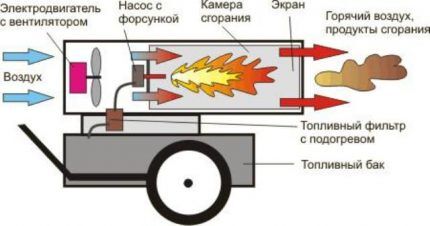

The main design elements of a diesel gun are: an electric motor with a fan, a pump with cleaning filters, a combustion chamber, a spark generator (glow plug or high-voltage system), an injector and a fuel tank.

In order for the device to work autonomously, it is equipped with a timer, flame level controller, thermostat and other electronic elements that can be built in immediately or installed for an additional fee.

The direct heating unit works like this:

- When the device is turned on, fuel is pumped from the tank to the fuel filter using a pump.

- The fuel then flows to the injector, which injects it into the combustion chamber.

- The ignition system supplies a spark that ignites the diesel.

- A protective mesh installed in the “barrel” of the gun holds the fire, preventing it from leaving the combustion chamber.

- The fan drives cold air into the chamber, where it is heated by the burning fuel and is expelled outside as a warm stream.

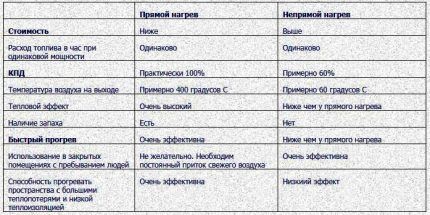

Direct heating guns have a high level of efficiency - almost 100%, the outlet air temperature can reach 400 °C.

Such heat generators can have a power from 10 to 220 kW (depending on the model), which is all used for heat.

But since an unpleasant odor, soot and other combustion products of diesel fuel penetrate into the air along with heat, the scope of application of a device without a chimney is limited to uncrowded industrial premises, open areas and various warehouses.

They are also widely used in construction, for example, for drying facades and concrete screeds during plastering or facing work.

Indirectly heated devices

The design of guns with indirect heating provides for the presence of a closed combustion chamber and a chimney, with the help of which exhaust gases containing fuel are discharged outside the heated room.

Although the maximum power of such devices reaches a maximum of 85 kW, there are also complex modular units with several “barrels” of guns that can “reach” up to 220 kW.

Although the efficiency of such units is much lower (approximately 60%), they are not only suitable for all cases where direct-flow devices can be used, but are also widely used for heating livestock farms, greenhouses, non-residential buildings, exhibition pavilions, industrial facilities and other premises with prolonged presence of people or animals.

Advantages and disadvantages of diesel equipment

Although the modern market offers a fairly wide selection of heating devices, diesel guns do not lose popularity among consumers.

Indeed, despite the fact that the cost of similar gas And electrical units are significantly lower, the operation of diesel devices is much cheaper due to the affordable price of diesel.

The advantages of a diesel heat generator include:

- High efficiency rate - even taking into account ventilation and supply ventilation The device quickly warms up the air and distributes it throughout the entire room.

- Easy to use – to start the system, just point the “barrel” of the gun at the center of the room or building element and press the power button.

- Safety – modern devices are equipped with various sensors and thermostats, thanks to which the device itself does not overheat. Accidental flame extinguishing is also excluded, and when the air is heated to a given temperature, the gun temporarily stops working.

- Low fuel cost – even devices that are demanding on the quality of diesel fuel will be much more profitable to operate than electric or gas appliances.

- Ease of transportation – the heat generator is compact and light enough (a simple device with a power of 10-22 kW weighs about 11-13 kg), so it will not be a problem to bring it to the site or move it from one room to another.

- Economical – a small amount is required to heat the room fuel, and the device can operate for a long time without refueling. For example, a 22 kW direct heating unit with a tank volume of 20 liters consumes on average about 2.5 liters per hour of operation.

- Long service life provide wear-resistant materials, standard replaceable components and simplicity of the design itself.

Of course, it was not without its drawbacks. In addition to diesel fumes that are harmful to health, the problem can be solved with the help of a chimney or a well-functioning ventilation system, the disadvantages of the device include the need to connect to the power grid, noise when the fan is running, and monitoring the fuel level.

In addition, the cost of the gun itself and its repair will be higher than that of similar devices powered by gas or electricity.

Basics of choosing diesel heat generators

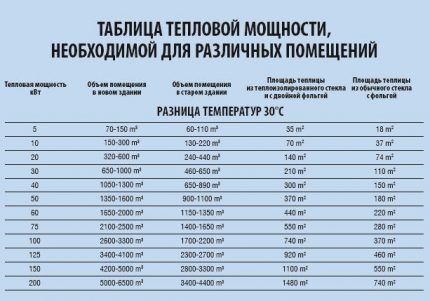

Like other heating devices, the heating rate and the size of the area that a heat gun can cover depend on its power.But in addition to this important characteristic, there are other nuances, knowledge of which will help you make the best choice when purchasing a device.

Determining the required power of the device

Not only the fuel consumption, but also the heating rate depends on the power of the heat gun. And although all technical characteristics are indicated in the accompanying documentation for the unit, before purchasing it is worth estimating the volume and presence of thermal insulation in the room that is planned to be heated using a diesel heat generator.

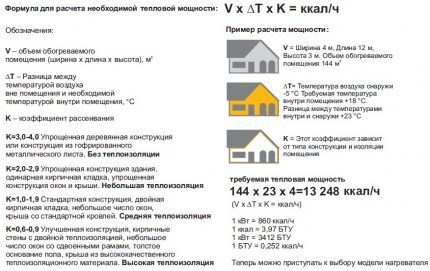

You can find out the thermal power of the device using the following algorithm:

- Calculate the volume of the room in m3 by multiplying the values of its width, length and height in meters.

- Determine the difference between the outside temperature and the required indoor temperature.

- Multiply the volume with the temperature difference and the heat loss coefficient.

- And the last stage is to convert the value from kcal/hour to the usual kW. To do this, you need to divide the resulting number by 860.

The value of the coefficient will depend on the materials from which the building is constructed and the level of its thermal insulation:

- “cold” structures made of wood or metal will have an indicator of 3 to 4;

- buildings with minimal insulation, single brick masonry and a primitive roof structure - from 2 to 2.9;

- buildings with medium thermal insulation with double masonry, standard roofing and a small glazing area - from 1 to 1.9;

- rooms with double-glazed windows, double brickwork, insulated walls and roof - 0.6-0.9.

Let's check the operation of the algorithm in practice.For example, you need to heat a metal hangar to +18 °C, with an area of 150 square meters and a height of 4 meters. The average outdoor temperature in winter is 10 degrees below zero.

Calculations:

(150 m2 * 4 m) * 28 °C * 4 = 67200 kcal/hour: 860 = 78.14 kW

That is, when choosing a heat gun model, you should focus on devices with a power of 80 kW and above.

But the fuel consumption indicator, although it seems to be an important parameter, is actually very conditional. After all, regardless of its technical capabilities, the device will require as much fuel as is needed to heat a particular building, based on the temperature you set, the volume of the room and the quality of thermal insulation.

Other important nuances

Once you have decided on the most important parameters (power and heating method), you should pay attention to other characteristics.

For example, such a nuance as the shape at first glance seems solely a “matter of taste,” especially since almost all guns have the appearance of an elongated cylinder. But among high-power devices, it is better to choose rectangular units - they have a larger area of distribution of the heated air flow.

Other technical features:

- Thermal insulation of the housing – the surface temperature of the device itself during operation should not exceed 40 degrees.

- Mobility – it is convenient when the device is equipped with a wheelbase, but lightweight guns with a power of up to 22 kW can simply be mounted on a stable base. In this case, you should pay attention to the weight of the kit, the material and strength of the pallet.

- Noisiness – the more powerful the device’s fan, the louder the “musical accompaniment” will be during its operation.

- Possibility of temperature adjustment – the device must be equipped with a handle or button with which you can independently program the thermostat parameters.

- Battery operation – if the object is not connected to the power grid, you can select a gun powered by a storage device. The device's electricity consumption is low (mainly power is required for the fan), varying between 100-500 Wh, so even a car battery is enough for uninterrupted operation for several hours in the field.

Also, when purchasing, you should inquire about the presence of a protective system against overheating (some manufacturers offer it as a separate device). For safe operation, it is desirable that the gun be equipped with automatic control of the heating level and shutdown when there is insufficient fuel.

The type and parameters of the recommended fuel is another important nuance that should be clarified with the equipment seller. For most diesel guns, it is recommended to use clarified (aviation) kerosene or “winter” automotive fuel that meets GOST 305-82.

If it is not possible to purchase a heat gun, then you can make it yourself. Read what you will need for this Further.

Start-up and safe operation rules

Typically, devices are supplied partially disassembled. That is, you will need to fix the “barrel” of the gun on a wheeled cart and install a handle (or metal arches). If we are talking about a direct heating gun, then all that remains is to fill the fuel tank, connect the device to the power supply, set the heating temperature and press the power switch.

To start up the equipment, make sure that the following safety rules are observed:

- The gun is installed on a stable and level horizontal surface made of non-combustible materials, such as concrete. If the floor is wooden, you can place sheet metal under the unit.

- The distance from the nozzle from which the hot air flow will flow to the nearest object is at least 2 meters (it is advisable to maintain a distance of 80-100 cm on the right and left).

- Before the first start-up or after long-term storage, it is recommended to open the housing and manually turn the fan impeller to make sure that it rotates freely.

- The device will “signal” the need for refueling by intermittent combustion or the release of white smoke. To add fuel, be sure to disconnect the gun from the power supply.

- Always turn off the gun with the toggle switch and wait until the fan stops completely. For indirect heating devices, this process may take 2-5 minutes, but it is necessary to cool the combustion chamber. Only after this can you unplug the device from the network.

To start an indirect heating diesel gun, you must first install a chimney - a round pipe made of non-combustible material with a maximum length of 3 meters. If you need output over a long distance, it is convenient to use flexible aluminum corrugation for this purpose, but it will have to be changed several times during the heating season.

To remove it into a nearby ventilation, you can find a piece of steel pipe that will last much longer.

As for maintenance, for trouble-free operation of diesel heat generators, you will need to periodically wash the air filters and clean the combustion chamber of soot/dust. It is also important to keep the internal walls of the unit clean in the area of the injector and engine.

Review of heat gun manufacturers

The industrial heaters market offers a wide range of direct and indirect heating guns running on diesel fuel. But in order to buy a reliable heat generator and subsequently not have problems with its maintenance and replacement of worn parts, you should focus not only on the price and technical parameters, but also on time-tested brands.

For example, Master Climate Solutions is one of the recognized leaders in the climate equipment market. Thanks to a wide production and dealer network, you can find diesel heat guns of indirect and direct heating from Master in almost any city and large hardware store.

Master thermal units operate on diesel fuel, diesel fuel or purified kerosene, and are distinguished by high-quality assembly and compact dimensions.

Power varies from 10 kW for simple direct-heated guns to 220 kW for thermal installations with multiple nozzles.

Ballu diesel guns from the Italian brand Biemmedue have also proven themselves well (although in the manufacturer line you can often see traditional China). Their units are well protected from the cold and, thanks to preheating of the fuel, can be used even in temperatures down to -30 °C.

The designers paid special attention to the protection system - the device body is made of stainless steel and practically does not heat up even with the most powerful installations.

South Korean units from Tiger King and Kerona are also popular. Their diesel guns are equipped with high-quality electronic “stuffing” - thermostats that guarantee protection against overheating and economical fuel consumption, an informative display, a photoelectronic sensor that controls the operation of the ignition, and other pleasant additions.

Heating units from other foreign brands - Elitech, Firman, Kroll, Oklima, Daewoo, HYUNDAI, Patriot - have also earned good reviews from consumers.

If you prefer domestically produced products, pay attention to ProfTeplo, Interskol and Zubr diesel guns.

Conclusions and useful video on the topic

To get a clear idea of the structure of the device itself, its operational capabilities and selection rules, we suggest you watch the following videos.

The video provides a detailed overview of the Master BV 77 E indirect heating gun with technical characteristics and measurements of the air temperature at the outlet of the device:

Tips and a formula for calculating the required power of a heat gun for heating various types of premises are presented in the video:

The video explains in detail how diesel heat guns work, their varieties are presented in an accessible manner and the features of application for various rooms are indicated:

Thanks to their high power and efficiency, diesel heat guns occupy a leading position among industrial heat generators. And although the device is not cheap, its price will pay off during operation.

Therefore, if you need to organize quick and economical space heating, a diesel gun is a good choice. However, you can always consult with specialists who will advise both the heating method and the optimal heater model.

If you have any questions while reading the information or have recommendations for our readers, please leave your comments in the block below. There you can also share your experience of using diesel guns.

It's good that there are reviews here. We may need them soon. There is such a “baby” in our warehouse.Served honestly for several years. Manufacturer Daewoo. Great brand. Heated up quickly, economical. Recently the fan stopped working when turned on. Everything is fine with the thermostat. We tried to adjust it - no result. Who had this? What could it be?

Good deal. They put 2 of these in the warehouse, and in winter they normally heat the entire room, the goods do not deteriorate from humidity and cold. At the same time, we leave the windows to ventilate, we are not afraid of fire, one watchman checks every couple of hours, and everything is in order. In terms of money, it works out well, lower than if electric heaters were working, what can we say about our own generator.

Regarding the Ballu BHDP-20 gun. China dated 08.2019. The body is NOT made of stainless steel, but only painted and galvanized. Combustion chamber with rivets. There is no fuel preheating.

There is no declared and advertised function of COOLING the combustion chamber after turning the gun OFF. I disassembled the gun in detail and did not find any structural or electronic elements to implement the very useful COOLING function after shutdown.

Otherwise, this is a REGULAR gun with parts from China and made in China. I do not recommend overpaying for the BALLU brand!