Calculation of a one-pipe heating system: what to consider when calculating + practical example

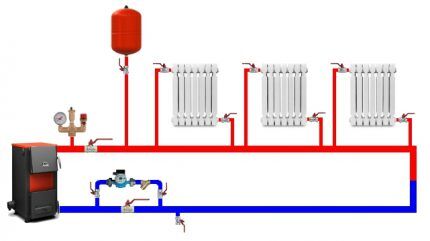

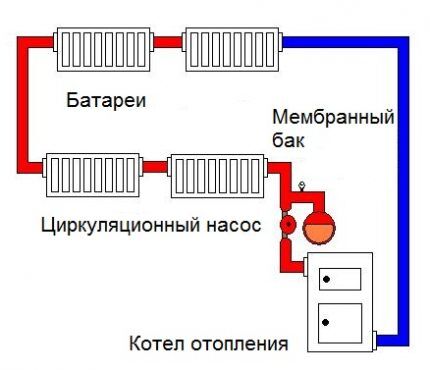

A single-pipe heating system is one of the solutions for laying pipes inside buildings with the connection of heating devices.This scheme seems to be the simplest and most effective. The construction of a heating branch using the “one pipe” option is cheaper for homeowners than other methods.

To ensure the operation of the scheme, it is necessary to perform a preliminary calculation of a single-pipe heating system - this will allow you to maintain the desired temperature in the house and prevent a loss of pressure in the network. It is quite possible to cope with this task on your own. Do you doubt your abilities?

We will tell you what the design features of a one-pipe system are, give examples of working diagrams, and explain what calculations must be performed at the planning stage of the heating circuit.

The content of the article:

Single-pipe heating circuit design

The hydraulic stability of the system is traditionally ensured by the optimal selection of the nominal diameter of pipelines (Dusl). It is quite simple to implement a stable scheme by selecting diameters, without first configuring heating systems with thermostats.

It is directly related to such heating systems single-pipe scheme with vertical/horizontal installation of radiators and in the complete absence of shut-off and control valves on the risers (branches to the devices).

By changing the diameters of pipes in a single-pipe ring heating circuit, it is possible to fairly accurately balance the existing pressure losses. The control of coolant flows inside each individual heating device is ensured by installing a thermostat.

Usually, as part of the process of designing a heating system using a single-pipe scheme, at the first stage, radiator piping units are built. At the second stage, the circulation rings are linked.

Designing a piping unit for a single device involves determining the pressure loss at the unit. The calculation is performed taking into account the uniform distribution of the coolant flow by the thermostat relative to the connection points in this circuit section.

As part of the same operation, the wicking coefficient is calculated, plus the determination of the range of flow distribution parameters in the closing section. Already relying on the calculated range of branches, they build a circulation ring.

Linking circulation rings

In order to efficiently connect the circulation rings of a single-pipe circuit, a calculation of possible pressure losses (∆Po) is first performed. In this case, the pressure loss at the control valve (∆Рк) is not taken into account.

Next, based on the coolant flow rate at the final section of the circulation ring and the value of ∆Рк (graph in the technical documentation for the device), the setting value of the control valve is determined.

The same indicator can be determined by the formula:

Kv=0.316G / √∆Рк,

Where:

- Kv – setting value;

- G – coolant flow;

- ∆Рк – pressure loss at the control valve.

Similar calculations are performed for each individual control valve in a one-pipe system.

True, the range of pressure losses at each valve is calculated using the formula:

∆Ркo=∆Ро + ∆Рк – ∆Рn,

Where:

- ∆Ro – possible pressure loss;

- ∆Рк – pressure loss on the PV;

- ∆Рn – pressure loss in the section of the n-circulation ring (without taking into account losses in the circulating air).

If, as a result of calculations, the required values for a single-pipe heating system as a whole were not obtained, it is recommended to use the version of a single-pipe system, which includes automatic flow regulators.

Devices such as automatic regulators are mounted at the end sections of the circuit (connection nodes on risers, outlet branches) at the points of connection to the return line.

If you technically change the configuration of the automatic regulator (swap the drain valve and plug), installation of devices is also possible on the coolant supply lines.

With the help of automatic flow regulators, the circulation rings are linked. In this case, the pressure loss ∆Рс at the end sections (risers, instrument branches) is determined.

Residual pressure losses within the boundaries of the circulation ring are distributed between common sections of pipelines (∆Рмр) and a common flow regulator (∆Рр).

The value of the temporary setting of the general regulator is selected according to the graphs presented in the technical documentation, taking into account ∆Рмр of the end sections.

Calculate the pressure loss at the end sections using the formula:

∆Рс=∆Рпп – ∆Рмр – ∆Рр,

Where:

- ∆Рр – calculated value;

- ∆Рpp – specified pressure drop;

- ∆Рмр – Prab losses on pipeline sections;

- ∆Рр – losses Prab on the common RV.

The automatic regulator of the main circulation ring (provided that the pressure drop is not initially specified) is configured taking into account the setting of the minimum possible value from the setting range in the technical documentation of the device.

The quality of flow control by the automation of the general regulator is controlled by the difference in pressure loss on each individual regulator of the riser or instrument branch.

Application and business case

The absence of requirements for the temperature of the cooled coolant is the starting point for the design of single-pipe heating systems using thermostats with the installation of thermostats on the radiator supply lines. In this case, it is mandatory to equip the heating unit with automatic regulation.

Circuit solutions where there are no thermostatic devices on the radiator supply lines are also used in practice. But the use of such schemes is determined by slightly different priorities for ensuring the microclimate.

Typically, single-pipe schemes, where there is no automatic control, are used for groups of rooms designed taking into account the compensation of heat losses (50% or more) due to additional devices: supply ventilation, air conditioning, electric heating.

Also, the design of single-pipe systems is found in projects where regulations allow a coolant temperature exceeding the limit value of the operating range of the thermostat.

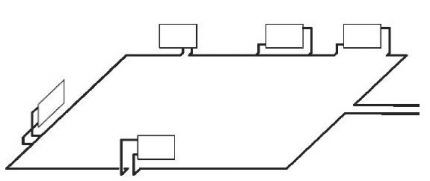

Projects of apartment buildings, where the operation of the heating system is based on the consumption of heat through meters, are usually built according to a perimeter single-pipe scheme.

The economic justification for the implementation of such a scheme is subject to the location of the main risers at different points of the structure.

The main calculation criteria are the cost of two main materials: heating pipes and fittings.

According to practical examples of the implementation of a perimeter single-pipe system, an increase in Dу of the flow area of pipelines by a factor of two is accompanied by an increase in the cost of purchasing pipes by 2-3 times. And the cost of fittings increases up to 10 times the size, depending on what material the fittings are made of.

Calculation base for installation

The installation of a single-pipe circuit, from the point of view of the arrangement of working elements, is practically no different from the installation of the same two-pipe systems. Main risers are usually located outside residential premises.

SNiP rules recommend laying risers inside special shafts or gutters. The apartment branch is traditionally built around the perimeter.

Pipelines are laid at a height of 70-100 mm from the upper border of the floor plinth. Or installation is done under a decorative plinth with a height of 100 mm or more, and a width of up to 40 mm. Modern production produces such specialized linings for the installation of plumbing or electrical communications.

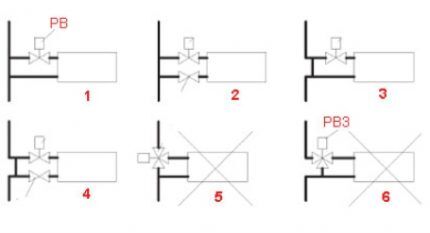

Radiator piping is carried out using a top-down scheme with pipes supplied on one side or on both sides. The location of thermostats “on a specific side” is not critical, but if heating device installation is carried out next to the balcony door, the installation of TP must be carried out on the side farthest from the door.

Laying pipes behind the baseboard seems advantageous from a decorative point of view, but brings to mind the disadvantages when it comes to passing through areas where there are interior doorways.

The connection of heating devices (radiators) with single-pipe risers is carried out according to schemes that allow for slight linear elongation of pipes or according to schemes with compensation for pipe elongation as a result of temperature changes.

The third option for circuit solutions, which involves the use of a three-way regulator, is not recommended for reasons of economy.

If the system design involves laying risers hidden in wall grooves, it is recommended to use corner thermostats of the RTD-G type and shut-off valves similar to devices from the RLV series as connecting fittings.

The diameter of the pipe branch to the heating devices is calculated using the formula:

D>= 0.7√V,

Where:

- 0,7 - coefficient;

- V – internal volume of the radiator.

The branch is made with a certain slope (at least 5%) in the direction of the free outlet of the coolant.

Selection of the main circulation ring

If the design solution involves installing a heating system based on several circulation rings, it is necessary to select the main circulation ring. The choice theoretically (and practically) should be made according to the maximum heat transfer value of the most distant radiator.

This parameter to some extent influences the assessment of the hydraulic load as a whole falling on the circulation ring.

The heat transfer of a remote device is calculated by the formula:

Atp = Qv / Qop + ΣQop,

Where:

- Atp – calculated heat transfer of the remote device;

- Qв – required heat transfer of the remote device;

- Qop – heat transfer from radiators to the room;

- ΣQop – the sum of the required heat transfer of all devices in the system.

In this case, the parameter of the amount of required heat transfer may consist of the sum of the values of devices designed to serve the building as a whole or only a part of the building.For example, when calculating heat separately for rooms covered by one separate riser or individual areas served by an instrument branch.

In general, the calculated heat transfer of any other heating radiator installed in the system is calculated by a slightly different formula:

Atp = Qop / Qpom,

Where:

- Qop – required heat transfer for a separate radiator;

- Qpom – heat demand for a specific room where a single-pipe circuit is used.

The easiest way to understand the calculations and apply the obtained values is to use a specific example.

Practical calculation example

A residential building requires a single-pipe system controlled by a thermostat.

The nominal throughput of the device at the maximum setting limit is 0.6 m3/h/bar (k1). The maximum possible throughput characteristic for this setting value is 0.9 m3/h/bar (k2).

The maximum possible differential pressure of the TR (at a noise level of 30 dB) is no more than 27 kPa (ΔР1). Pump pressure 25 kPa (ΔР2) Operating pressure for the heating system – 20 kPa (ΔР).

It is necessary to determine the pressure loss range for the TR (ΔР1).

The internal heat transfer value is calculated as follows: Atr = 1 – k1/k2 (1 – 06/09) = 0.56. From here the required range of pressure losses at the TR is calculated: ΔР1 = ΔР * Atr (20 * 0.56...1) = 11.2...20 kPa.

If independent calculations lead to unexpected results, it is better to contact specialists or use a computer calculator to check.

Conclusions and useful video on the topic

Detailed analysis of calculations using a computer program with explanations for installation and improving the functionality of the system:

It should be noted that a full-scale calculation of even the simplest solutions is accompanied by a mass of calculated parameters. Of course, it is fair to calculate everything without exception, provided that the heating structure is organized close to the ideal structure. However, in reality, nothing is ideal.

Therefore, they often rely on calculations as such, as well as on practical examples and on the results of these examples. This approach is especially popular for private housing construction.

Do you have anything to add or have questions about calculating a single-pipe heating system? You can leave comments on the publication, participate in discussions and share your own experience in arranging a heating circuit. The contact form is located in the lower block.

Proper installation of a heating system in a house, in my opinion, is one of the most important points when building a house. At one time, when I was heating my house, I used a horizontal method of connecting radiators and laid heating pipes in the floors. I also think it is important to choose the right pump, since with a horizontal wiring diagram, the movement of the coolant must be stimulated by a circulation unit.