Features of manufacturing high-pressure steel pipes - scope of application

To create communications that operate in difficult conditions, high-quality and durable materials are used.Seamless high-pressure steel pipes are in demand at most enterprises, as they can withstand any impact from the environment and working environment. During their production, GOST standards must be taken into account. Otherwise, steel pipes cannot be used when laying communications.

The content of the article:

General information about steel products

Steel is a reliable material used in the manufacture of pipes. Due to additional thermal or chemical treatment, it becomes immune to the negative effects of the environment.

Steel pipes are divided into several types:

- seamless;

- boiler rooms;

- profile;

- electric welded

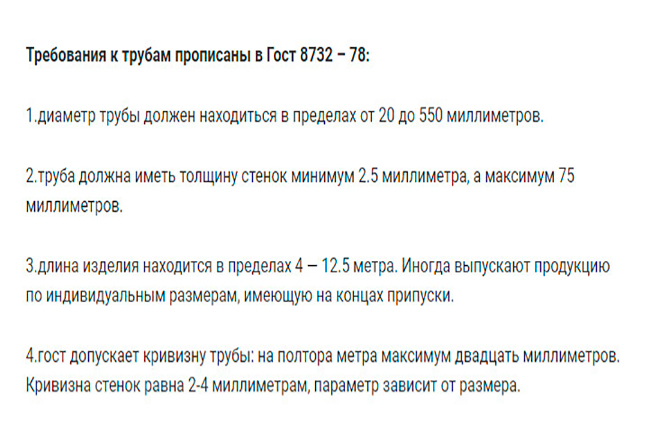

All state standards for these products are specified in GOST 10705-80, GOST 10706-80, GOST 8732-78.

The products in question are processed. To increase corrosion resistance, the surface is coated with a special composition that eliminates the appearance of traces of rust. Due to this, performance characteristics are improved. In some cases, plastic or other corrosion-resistant plastic material is applied over the metal.

High-pressure seamless steel pipes are produced using cold or hot rolling technology. Products are classified according to several criteria:

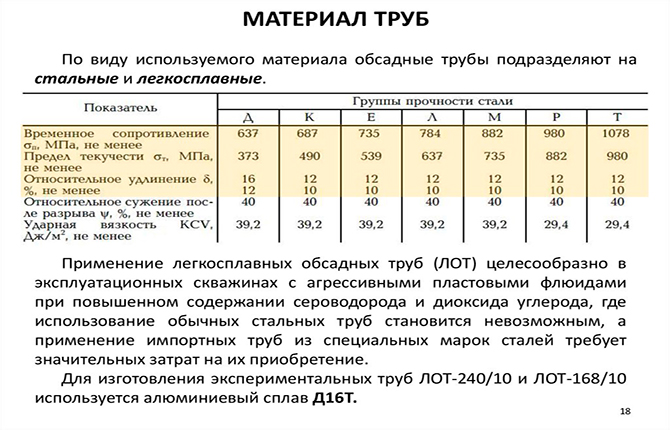

- type of material used;

- by the integrity of the material structure in cross section;

- according to the manufacturing method used;

- by internal form;

- according to technical purpose.

Manufacturers also distinguish several product classes:

- The first class is called standard or gas. It is used to supply liquid, gaseous or bulk substances. Often the first class is chosen as a protective “casing” when laying electrical cables underground.

- The second class is represented by high-pressure steel pipes. They are suitable for creating a pipeline for supplying petroleum products under pressure, as well as other fuels.

- The third class is designed to supply a working medium under pressure at high temperatures. Their use is advisable in the food or chemical industry.

- The fourth class is used in the drilling industry.

- The fifth class is considered structural, because it is used in the assembly of vehicles, the manufacture of furniture or supports.

- The sixth is suitable for use in the mechanical engineering field.

High-pressure steel pipes are found in industrial premises and are used for the installation of highways.

Features of manufacturing steel pipes using a seamless method

The diameter and thickness are specified by GOST. Carbon or stainless alloy steel is used in production. The choice largely depends on what the final cost of the pipes should be, since alloyed metals are more expensive due to the difficulties encountered in their manufacture.

There are several production technologies:

- forging;

- drawing;

- pressing;

- rental

Renting is easier to implement. It's more common. Optimal for producing large quantities. Forging is used to obtain a denser metal structure.

Hot rolled method

To use this manufacturing method, special equipment, cast, forged or hot-rolled blanks are required. Difficulties in manufacturing relate to heating, since proper plasticity is achieved at a very high temperature. It is difficult to work with such workpieces due to the emanating heat.This also makes it more difficult to control the uniformity of wall thickness.

Production stages of high pressure steel pipes:

- The workpiece is heated in a furnace to a temperature at which crystallization occurs. It is different for each type of metal. Severe overheating of the material causes a change in its chemical composition and properties. Therefore, due attention is paid to maintaining temperature conditions in production.

- In a plastic state, the workpiece is given the desired shape and size. Pressing is carried out at high pressure. Despite the plasticity, difficulties arise with changing the geometry of the workpieces at this stage. This is due to increased viscosity, emanating heat and other properties of the molten metal.

- After the press, the pipe has an inaccurate geometry. To change it, the workpiece is driven through rollers. The high-pressure steel pipe is given a given diameter and wall thickness. In some cases, the product stretches.

- The product is cooled with water and calibrated. Temperature reduction is carried out in stages. Cooling too quickly causes the steel pipe to become brittle. Calibration is required to reduce the stress that occurs in the structure of the material at the time of crystallization. If this is not done, it loses strength and may burst even with minor impact.

- The product is cut into the required number of parts (depending on the specified length of one section) after the metal has cooled. At the finishing stage, the ends are processed.

This technology does not allow obtaining options of small diameter or with small wall thickness.

Cold-formed method

When using this method, the pipe is obtained by drawing.At the time of processing of workpieces, the temperature does not exceed 450 degrees Celsius, which is not enough to change the physical properties of the material. The technology is suitable for producing high-pressure steel pipes with small wall thickness and outer diameter.

The cold forming method is similar to hot rolling, but has several differences:

- The piercing machine constantly cools the workpiece with cold water. All other processes are carried out at low temperatures. As a result, elasticity is lost almost completely, but it is enough to give the desired shape and size to the steel pipe;

- For calibration, the workpiece is reheated and allowed to cool. This procedure is called annealing.

This type of production technology is more common. Now manufacturers are gradually switching to foreign equipment.

Classification according to various parameters

The classification of steel products is carried out according to the production methods used and the thickness of the resulting walls.

Classification depending on production technologies:

- seamless hot deformation;

- seamless thermal deformation or cold-rolled method;

- electric welding method using a spiral seam;

- electric welded with a straight seam.

The classification of steel pipes by wall thickness is taken into account when designing a structure or pipeline. The cost of the product, maximum load, weight and other technical characteristics depend on this indicator. There are several types:

- especially thick-walled;

- thick-walled;

- thin-walled;

- especially thin-walled.

The outer diameter indicator is considered the determining criterion for selection.

Some steel pipes are coated on the outside with a compound that increases the anti-corrosion properties of the product.In this case, the procedure for protecting the surface with polymers is considered optional.

Corrosion resistance is considered an important parameter. Pay attention to it when choosing a pipe for the system water- or gas supply. Adding a small amount of zinc to the metal composition protects it from the negative effects of high humidity.

High-pressure galvanized steel pipes are much more expensive, but are characterized by high reliability in use. The galvanizing process takes place in a prepared environment and involves electrochemical action.

Scope of application

The absence of seams ensures high strength of the products, therefore the likelihood of leaks is minimal. Areas of application for high pressure steel pipes:

- for installation of a hydraulic system;

- in energy. Valued due to their seamless structure and high resistance to high temperatures. Therefore, they are suitable for creating heat supply systems;

- These pipes are used to create pipelines in the oil refining industry. When various impurities are added, the metal becomes immune to chemicals;

- due to their high strength, they are practically immune to soil displacement, which puts high pressure on the product;

- in mechanical engineering. But they are less common due to their high cost.

Low weight and high strength are the main reasons for using this type of pipe. Modern manufacturing methods reduce costs.

High-pressure steel pipes are produced by Russian and foreign companies. When marking, the main parameters regarding maximum pressure, diameter, and wall thickness are indicated. This will make it easier to choose the right type for installing the highway.

Have you ever used high pressure steel pipes? Write in the comments. Share the article on social networks and save it in bookmarks so as not to lose it.

We also recommend watching selected videos on our topic.

Technology for the production of hot-deformed seamless steel pipes.

Production of seamless high pressure pipes.